TP73 TEMADUR SC 20 or TEMADUR SC 50 or ... - Tikkurila

TP73 TEMADUR SC 20 or TEMADUR SC 50 or ... - Tikkurila

TP73 TEMADUR SC 20 or TEMADUR SC 50 or ... - Tikkurila

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

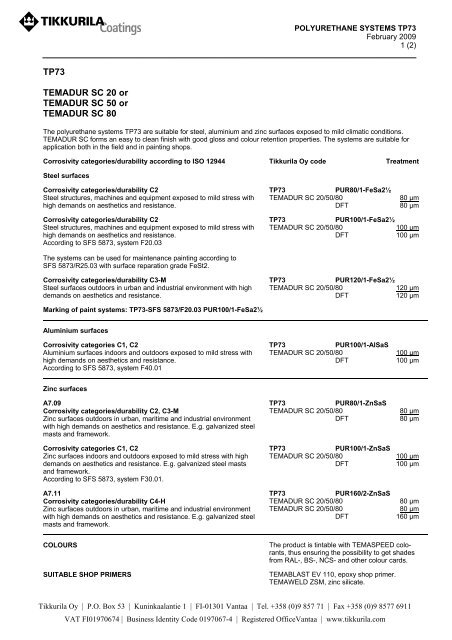

POLYURETHANE SYSTEMS <strong>TP73</strong>February <strong>20</strong>091 (2)<strong>TP73</strong><strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong> <strong>or</strong><strong>TEMADUR</strong> <strong>SC</strong> <strong>50</strong> <strong>or</strong><strong>TEMADUR</strong> <strong>SC</strong> 80The polyurethane systems <strong>TP73</strong> are suitable f<strong>or</strong> steel, aluminium and zinc surfaces exposed to mild climatic conditions.<strong>TEMADUR</strong> <strong>SC</strong> f<strong>or</strong>ms an easy to clean finish with good gloss and colour retention properties. The systems are suitable f<strong>or</strong>application both in the field and in painting shops.C<strong>or</strong>rosivity categ<strong>or</strong>ies/durability acc<strong>or</strong>ding to ISO 12944 <strong>Tikkurila</strong> Oy code TreatmentSteel surfacesC<strong>or</strong>rosivity categ<strong>or</strong>ies/durability C2Steel structures, machines and equipment exposed to mild stress withhigh demands on aesthetics and resistance.<strong>TP73</strong>PUR80/1-FeSa2½<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/80DFT80 μm80 μmC<strong>or</strong>rosivity categ<strong>or</strong>ies/durability C2Steel structures, machines and equipment exposed to mild stress withhigh demands on aesthetics and resistance.Acc<strong>or</strong>ding to SFS 5873, system F<strong>20</strong>.03<strong>TP73</strong>PUR100/1-FeSa2½<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/80100 μmDFT100 μmThe systems can be used f<strong>or</strong> maintenance painting acc<strong>or</strong>ding toSFS 5873/R25.03 with surface reparation grade FeSt2.C<strong>or</strong>rosivity categ<strong>or</strong>ies/durability C3-MSteel surfaces outdo<strong>or</strong>s in urban and industrial environment with highdemands on aesthetics and resistance.<strong>TP73</strong>PUR1<strong>20</strong>/1-FeSa2½<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/801<strong>20</strong> μmDFT1<strong>20</strong> μmMarking of paint systems: <strong>TP73</strong>-SFS 5873/F<strong>20</strong>.03 PUR100/1-FeSa2½Aluminium surfacesC<strong>or</strong>rosivity categ<strong>or</strong>ies C1, C2Aluminium surfaces indo<strong>or</strong>s and outdo<strong>or</strong>s exposed to mild stress withhigh demands on aesthetics and resistance.Acc<strong>or</strong>ding to SFS 5873, system F40.01<strong>TP73</strong>PUR100/1-AlSaS<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/80DFT100 μm100 μmZinc surfacesA7.09C<strong>or</strong>rosivity categ<strong>or</strong>ies/durability C2, C3-MZinc surfaces outdo<strong>or</strong>s in urban, maritime and industrial environmentwith high demands on aesthetics and resistance. E.g. galvanized steelmasts and framew<strong>or</strong>k.C<strong>or</strong>rosivity categ<strong>or</strong>ies C1, C2Zinc surfaces indo<strong>or</strong>s and outdo<strong>or</strong>s exposed to mild stress with highdemands on aesthetics and resistance. E.g. galvanized steel mastsand framew<strong>or</strong>k.Acc<strong>or</strong>ding to SFS 5873, system F30.01.A7.11C<strong>or</strong>rosivity categ<strong>or</strong>ies/durability C4-HZinc surfaces outdo<strong>or</strong>s in urban, maritime and industrial environmentwith high demands on aesthetics and resistance. E.g. galvanized steelmasts and framew<strong>or</strong>k.<strong>TP73</strong>PUR80/1-ZnSaS<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/80DFT<strong>TP73</strong>PUR100/1-ZnSaS<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/80DFT<strong>TP73</strong>PUR160/2-ZnSaS<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/80<strong>TEMADUR</strong> <strong>SC</strong> <strong>20</strong>/<strong>50</strong>/80DFT80 μm80 μm100 μm100 μm80 μm80 μm160 μmCOLOURSSUITABLE SHOP PRIMERSThe product is tintable with TEMASPEED col<strong>or</strong>ants,thus ensuring the possibility to get shadesfrom RAL-, BS-, NCS- and other colour cards.TEMABLAST EV 110, epoxy shop primer.TEMAWELD ZSM, zinc silicate.<strong>Tikkurila</strong> Oy | P.O. Box 53 | Kuninkaalantie 1 | FI-01301 Vantaa | Tel. +358 (0)9 857 71 | Fax +358 (0)9 8577 6911VAT FI01970674 | Business Identity Code 0197067-4 | Registered OfficeVantaa | www.tikkurila.com

TIKKURILA OYPOLYURETHANE SYSTEMS <strong>TP73</strong>February <strong>20</strong>092 (2)SURFACE PREPARATION Oil, grease, salts and dirt are removed by appropriate means. (ISO 12944-4)Steel surfaces:Blast clean to grade Sa2½. (ISO 8<strong>50</strong>1-1) If blast cleaning is not possible, phosphating isrecommended f<strong>or</strong> cold rolled steel to improve adhesion.Zinc surfaces:Sweep blast-clean with mineral abrasives, e.g. quartz sand, to an even roughness.(SaS, SFS 5873) If sweep blasting is not possible, the surface should be roughened byhand abrading <strong>or</strong> washed with PANSSARIPESU detergent.Hot dip galvanized surfaces are recommended to be painted with a misty coat (paintthinned 25 - 30 %) bef<strong>or</strong>e the actual priming.Damages in the zinc coating have to be repaired with TEMAZINC 99, a zinc rich epoxypaint. Bef<strong>or</strong>e painting, clean the surfaces th<strong>or</strong>oughly (Sa2½/St3) and level off the edgesaround the cleaned areas.Aluminium surfaces:Sweep blast-clean with none-metallic abrasives to an even roughness. (SaS, SFS 5873) Ifsweep blasting is not possible, the surface should be roughened by hand abrading <strong>or</strong>washed with MAALIPESU detergent.APPLICATION CONDITIONSAPPLICATIONMAINTENANCE PAINTINGThe surface must be clean and dry and the surface temperature should remain at least3 ºC above the dew point. During application and drying the temperature of the air, paintand surface should be at least + 5 ºC. The relative humidity should not exceed 80 %.The paint should be mixed th<strong>or</strong>oughly bef<strong>or</strong>e application and then applied in an even coaton the dry and clean surface. Application with airless <strong>or</strong> conventional spray, brush <strong>or</strong>roller. Stripe coating of sharp edges, welding seams etc. should be done by brush <strong>or</strong>roller.MaintenanceTouch-up painting is sufficient f<strong>or</strong> maintenance when the rust grade is Ri1 - Ri3.(ISO 4628-3)Damages caused by transp<strong>or</strong>t <strong>or</strong> installation may also be repaired by touch-up painting.Remove all loose paint, clean rusty areas acc<strong>or</strong>ding to system demands. On steelsurfaces small areas can be grinded <strong>or</strong> wire brushed to preparation grade St2.(SFS-ISO 8<strong>50</strong>1-1)Level off the edges between the old paint film and the cleaned up areas. When using blastcleaning, be sure that there are no cracks in the remaining paint film. If the entire surfacehas to be overcoated, abrade the old topcoat to a rough finish. Remove all dust and othercleaning residues. Apply primers and finish acc<strong>or</strong>ding to the <strong>or</strong>iginal paint system,qualities and film thicknesses.RepaintingWhen the rust grade is Ri4 <strong>or</strong> Ri5, the entire coating must be renewed. Remove the oldpaint film and clean the surfaces to preparation grade Sa2½. Recoat in acc<strong>or</strong>dance withthe <strong>or</strong>iginal paint system.PRODUCT INFORMATIONM<strong>or</strong>e detailed product inf<strong>or</strong>mation is available in respective data sheets.ttp100<strong>20</strong>9The above inf<strong>or</strong>mation, based on lab<strong>or</strong>at<strong>or</strong>y tests and practical experience, has been proved valid at the date marked on the product data sheet.When necessary verify the validity of the product data sheet. The quality of the product is ensured by our operational system, based on therequirements of the standards ISO 9001 and ISO 14001. As a manufacturer we cannot be responsible f<strong>or</strong> any damages caused by using the productagainst our instructions of f<strong>or</strong> inappropriate purposes.

![TEMAFLOOR 200 HARDENER - se-swe[1] - Tikkurila](https://img.yumpu.com/50615558/1/184x260/temafloor-200-hardener-se-swe1-tikkurila.jpg?quality=85)