Fasteners - hdgasa

Fasteners - hdgasa

Fasteners - hdgasa

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

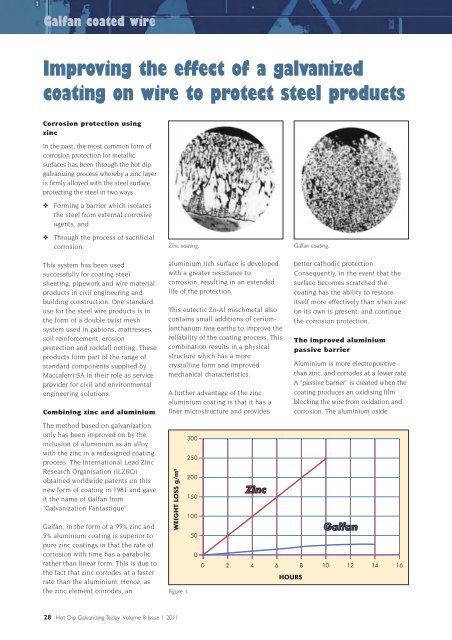

Galfan coated wireImproving the effect of a galvanizedcoating on wire to protect steel productsCorrosion protection usingzincIn the past, the most common form ofcorrosion protection for metallicsurfaces has been through the hot dipgalvanizing process whereby a zinc layeris firmly alloyed with the steel surface,protecting the steel in two ways:❖Forming a barrier which isolatesthe steel from external corrosiveagents, and❖Through the process of sacrificialcorrosion.Zinc coating.Galfan coating.This system has been usedsuccessfully for coating steelsheeting, pipework and wire materialproducts in civil engineering andbuilding construction. One standarduse for the steel wire products is inthe form of a double twist meshsystem used in gabions, mattresses,soil reinforcement, erosionprotection and rockfall netting. Theseproducts form part of the range ofstandard components supplied byMaccaferri SA in their role as serviceprovider for civil and environmentalengineering solutions.Combining zinc and aluminiumaluminium rich surface is developedwith a greater resistance tocorrosion, resulting in an extendedlife of the protection.This eutectic Zn-Al mischmetal alsocontains small additions of ceriumlanthanumrare earths to improve thereliability of the coating process. Thiscombination results in a physicalstructure which has a morecrystalline form and improvedmechanical characteristics.A further advantage of the zincaluminium coating is that it has afiner microstructure and providesbetter cathodic protection.Consequently, in the event that thesurface becomes scratched thecoating has the ability to restoreitself more effectively than when zincon its own is present, and continuethe corrosion protection.The improved aluminiumpassive barrierAluminium is more electropositivethan zinc, and corrodes at a lower rate.A “passive barrier” is created when thecoating produces an oxidising filmblocking the wire from oxidation andcorrosion. The aluminium oxideThe method based on galvanizationonly has been improved on by theinclusion of aluminium as an alloywith the zinc in a redesigned coatingprocess. The International Lead ZincResearch Organisation (ILZRO)obtained worldwide patents on thisnew form of coating in 1981 and gaveit the name of Galfan from“Galvanization Fantastique”.Galfan, in the form of a 95% zinc and5% aluminium coating is superior topure zinc coatings in that the rate ofcorrosion with time has a parabolicrather than linear form. This is due tothe fact that zinc corrodes at a fasterrate than the aluminium. Hence, asthe zinc element corrodes, anWEIGHT LOSS g/m 2Figure 1.3002502001501005000 2 4 6 8 10 12 14 16HOURS28 Hot Dip Galvanizing Today Volume 8 Issue 1 2011