Delta Cutter Family - BUEHLER

Delta Cutter Family - BUEHLER

Delta Cutter Family - BUEHLER

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

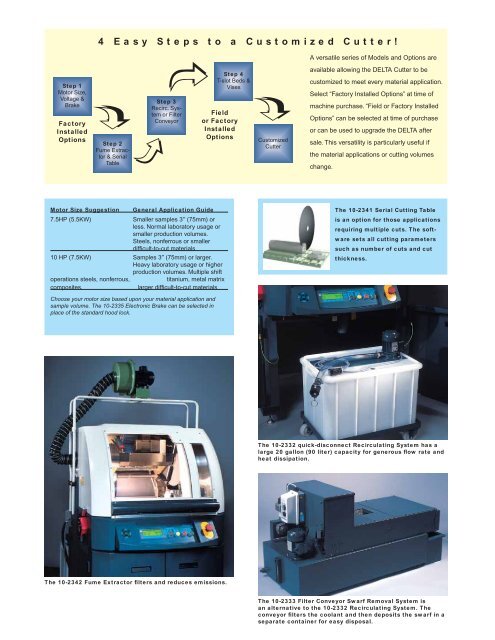

4 Easy Steps to a Customized <strong>Cutter</strong>!A versatile series of Models and Options areStep 1Motor Size,Voltage &BrakeFactoryInstalledOptionsStep 2Fume Extractor& SerialTableStep 3Recirc. Systemor FilterConveyorStep 4T-slot Beds &VisesFieldor FactoryInstalledOptionsCustomized<strong>Cutter</strong>available allowing the DELTA <strong>Cutter</strong> to becustomized to meet every material application.Select “Factory Installed Options” at time ofmachine purchase. “Field or Factory InstalledOptions” can be selected at time of purchaseor can be used to upgrade the DELTA aftersale. This versatility is particularly useful ifthe material applications or cutting volumeschange.Motor Size Suggestion7.5HP (5.5KW)General Application GuideSmaller samples 3″ (75mm) orless. Normal laboratory usage orsmaller production volumes.Steels, nonferrous or smallerdiffi cult-to-cut materials10 HP (7.5KW) Samples 3″ (75mm) or larger.Heavy laboratory usage or higherproduction volumes. Multiple shiftoperations steels, nonferrous,titanium, metal matrixcomposites,larger diffi cult-to-cut materialsThe 10-2341 Serial Cutting Tableis an option for those applicationsrequiring multiple cuts. The softwaresets all cutting parameterssuch as number of cuts and cutthickness.Choose your motor size based upon your material application andsample volume. The 10-2335 Electronic Brake can be selected inplace of the standard hood lock.The 10-2332 quick-disconnect Recirculating System has alarge 20 gallon (90 liter) capacity for generous flow rate andheat dissipation.The 10-2342 Fume Extractor filters and reduces emissions.The 10-2333 Filter Conveyor Swarf Removal System isan alternative to the 10-2332 Recirculating System. Theconveyor filters the coolant and then deposits the swarf in aseparate container for easy disposal.