Dry-lining versus a hemp and lime insulating render - University of ...

Dry-lining versus a hemp and lime insulating render - University of ...

Dry-lining versus a hemp and lime insulating render - University of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

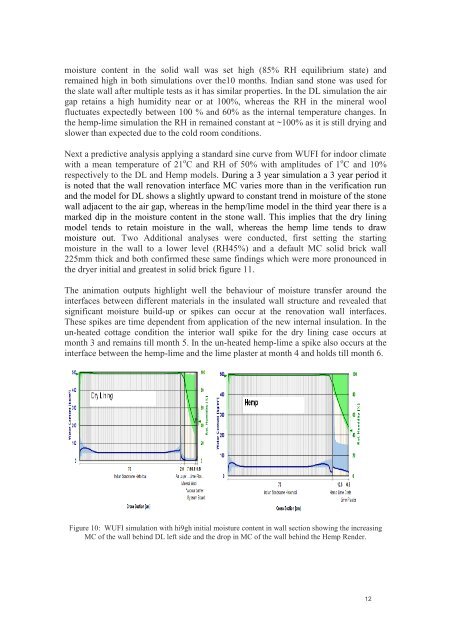

moisture content in the solid wall was set high (85% RH equilibrium state) <strong>and</strong>remained high in both simulations over the10 months. Indian s<strong>and</strong> stone was used forthe slate wall after multiple tests as it has similar properties. In the DL simulation the airgap retains a high humidity near or at 100%, whereas the RH in the mineral woolfluctuates expectedly between 100 % <strong>and</strong> 60% as the internal temperature changes. Inthe <strong>hemp</strong>-<strong>lime</strong> simulation the RH in remained constant at ~100% as it is still drying <strong>and</strong>slower than expected due to the cold room conditions.Next a predictive analysis applying a st<strong>and</strong>ard sine curve from WUFI for indoor climatewith a mean temperature <strong>of</strong> 21 o C <strong>and</strong> RH <strong>of</strong> 50% with amplitudes <strong>of</strong> 1 o C <strong>and</strong> 10%respectively to the DL <strong>and</strong> Hemp models. During a 3 year simulation a 3 year period itis noted that the wall renovation interface MC varies more than in the verification run<strong>and</strong> the model for DL shows a slightly upward to constant trend in moisture <strong>of</strong> the stonewall adjacent to the air gap, whereas in the <strong>hemp</strong>/<strong>lime</strong> model in the third year there is amarked dip in the moisture content in the stone wall. This implies that the dry <strong>lining</strong>model tends to retain moisture in the wall, whereas the <strong>hemp</strong> <strong>lime</strong> tends to drawmoisture out. Two Additional analyses were conducted, first setting the startingmoisture in the wall to a lower level (RH45%) <strong>and</strong> a default MC solid brick wall225mm thick <strong>and</strong> both confirmed these same findings which were more pronounced inthe dryer initial <strong>and</strong> greatest in solid brick figure 11.The animation outputs highlight well the behaviour <strong>of</strong> moisture transfer around theinterfaces between different materials in the insulated wall structure <strong>and</strong> revealed thatsignificant moisture build-up or spikes can occur at the renovation wall interfaces.These spikes are time dependent from application <strong>of</strong> the new internal insulation. In theun-heated cottage condition the interior wall spike for the dry <strong>lining</strong> case occurs atmonth 3 <strong>and</strong> remains till month 5. In the un-heated <strong>hemp</strong>-<strong>lime</strong> a spike also occurs at theinterface between the <strong>hemp</strong>-<strong>lime</strong> <strong>and</strong> the <strong>lime</strong> plaster at month 4 <strong>and</strong> holds till month 6.Figure 10: WUFI simulation with hi9gh initial moisture content in wall section showing the increasingMC <strong>of</strong> the wall behind DL left side <strong>and</strong> the drop in MC <strong>of</strong> the wall behind the Hemp Render.12