impact attenuator test results - Blogs - Dalhousie University

impact attenuator test results - Blogs - Dalhousie University

impact attenuator test results - Blogs - Dalhousie University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

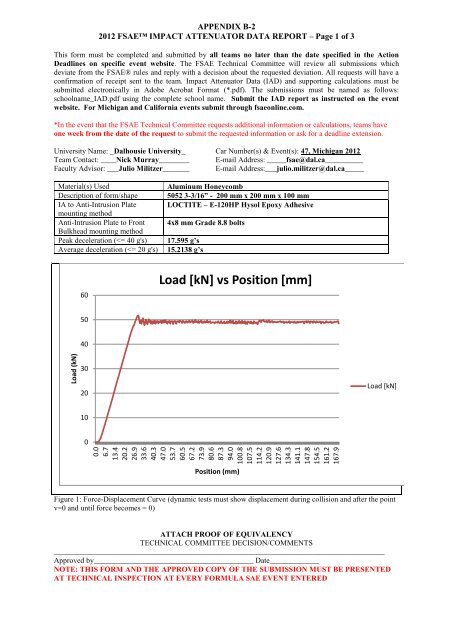

0.06.713.420.226.933.640.347.053.760.567.273.980.687.394.0100.8107.5114.2120.9127.6134.3141.1147.8154.5161.2167.9Load (kN)APPENDIX B-22012 FSAE IMPACT ATTENUATOR DATA REPORT – Page 1 of 3This form must be completed and submitted by all teams no later than the date specified in the ActionDeadlines on specific event website. The FSAE Technical Committee will review all submissions whichdeviate from the FSAE® rules and reply with a decision about the requested deviation. All requests will have aconfirmation of receipt sent to the team. Impact Attenuator Data (IAD) and supporting calculations must besubmitted electronically in Adobe Acrobat Format (*.pdf). The submissions must be named as follows:schoolname_IAD.pdf using the complete school name. Submit the IAD report as instructed on the eventwebsite. For Michigan and California events submit through fsaeonline.com.*In the event that the FSAE Technical Committee requests additional information or calculations, teams haveone week from the date of the request to submit the requested information or ask for a deadline extension.<strong>University</strong> Name: _<strong>Dalhousie</strong> <strong>University</strong>_ Car Number(s) & Event(s): 47, Michigan 2012Team Contact: ____Nick Murray________ E-mail Address: _____fsae@dal.ca__________Faculty Advisor: ___Julio Militzer_______ E-mail Address:___julio.militzer@dal.ca_____Material(s) UsedDescription of form/shapeIA to Anti-Intrusion Platemounting methodAnti-Intrusion Plate to FrontBulkhead mounting methodPeak deceleration (

Energy Absorbed (J)0.08.316.524.833.141.349.657.966.174.482.790.999.2107.5115.7124.0132.3140.5148.8157.1165.3APPENDIX B-22012 FSAE IMPACT ATTENUATOR DATA REPORT – Page 2 of 3<strong>University</strong> Name: <strong>Dalhousie</strong> <strong>University</strong> Car Number(s) & Event(s): 47, Michigan 20129000800070006000500040003000200010000Energy Absorbed [J] vs Position [mm]Energy Absorbed [J]Position (mm)Figure 2: Energy-Displacement Curve (dynamic <strong>test</strong>s must show displacement during collision and after thepoint v=0)Figure 3: Attenuator as ConstructedFigure 4: Attenuator after ImpactEnergy Absorbed (J):Must be >= 7350 JIA Crushed Displacement(mm):IA Post Crush Displacement -demonstrating any return (mm):Anti-Intrusion PlateDeformation (mm)8378.2 J Vehicle includes front wingin front of front bulkhead?170 mm crushed Wing structure included in<strong>test</strong>?30 mm returned Test Type: (e.g. barrier <strong>test</strong>,drop <strong>test</strong>, quasi-static crush)15 mm (after Test Site: (must be fromreturn)approved <strong>test</strong> site list onwebsite for dynamic <strong>test</strong>s)NoN/AQuasi-Static CrushTest<strong>Dalhousie</strong> <strong>University</strong>Engineering MaterialTesting Lab –Instrom HydraulicPress

APPENDIX B-22012 FSAE IMPACT ATTENTUATOR DATA REPORT – Page 3 of 3<strong>University</strong> Name: <strong>Dalhousie</strong> <strong>University</strong> Car Number(s) & Event(s): 47, Michigan 2012Figure 5: Design DrawingsLength (fore/aft direction): ___200__ mm (>=200mm)Width (lateral direction): ___200__ mm (>=200mm)Height (vertical direction): ___100__ mm (>=100mm)Attenuator is at least 200mm wide by 100mm high for at least 200mm: YesAttach additional information below this point and/or on additional sheetsTest schematic, photos of <strong>test</strong>, design report including reasons for selection and advantages/disadvantages, etc.Additional information shall be kept concise and relevant.

Test Photos:Impact <strong>attenuator</strong> before, during and after the crush <strong>test</strong>.Showing maximum deflection of anti-intrusion plate less than one inch.Design Selection:One of the main design goals for this year’s FSAE car was to make many of the componentslighter and more effective than the previous year’s designs. This includes the <strong>impact</strong><strong>attenuator</strong>, where the weight has been reduced by more than 20% and the space occupiedhas been reduced by more than 60%. This reduction in size also allows more flexibility in thedesign of the nose cone. In addition to being lighter and smaller, this year’s <strong>impact</strong><strong>attenuator</strong> absorbed more energy than last year’s, ultimately making the car safer whilestaying within the parameters required by FSAE rules and regulations.