NEWS & EVENTS > Berco at Bauma China for the first ... - Berco S.p.A

NEWS & EVENTS > Berco at Bauma China for the first ... - Berco S.p.A

NEWS & EVENTS > Berco at Bauma China for the first ... - Berco S.p.A

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

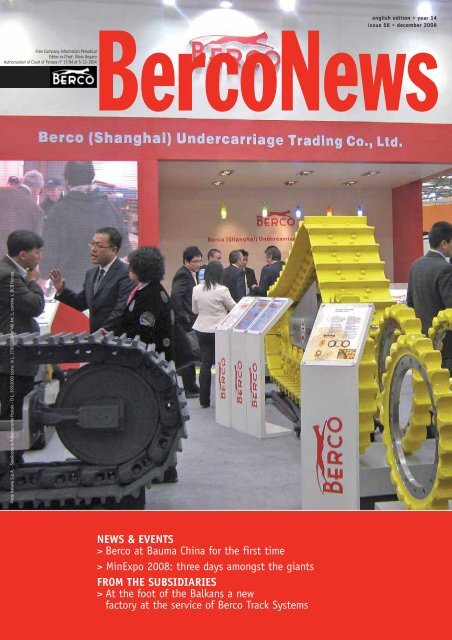

<strong>Berco</strong>Newsenglish edition > year 14issue 56 > december 2008Free Company In<strong>for</strong>m<strong>at</strong>ion PeriodicalEditor-in-Chief: Silvia UngaroAuthoris<strong>at</strong>ion of Court of Ferrara n° 17/94 of 5-12-1994Poste Italiane S.p.A. - Spedizione in Abbonamento Postale - D L. 353/2003 (conv. in L. 27/02/2004 n°46) Art. 1, comma 1, DCB Ferrara<strong>NEWS</strong> & <strong>EVENTS</strong>> <strong>Berco</strong> <strong>at</strong> <strong>Bauma</strong> <strong>China</strong> <strong>for</strong> <strong>the</strong> <strong>first</strong> time> MinExpo 2008: three days amongst <strong>the</strong> giantsFROM THE SUBSIDIARIES> At <strong>the</strong> foot of <strong>the</strong> Balkans a newfactory <strong>at</strong> <strong>the</strong> service of <strong>Berco</strong> Track Systems

EditorialDear readers,IN THIS ISSUE:2 EDITORIAL4 <strong>NEWS</strong> & <strong>EVENTS</strong>MinExpo 2008:three days amongst <strong>the</strong> giants5 FOCUS ONMINING: development prospectsin <strong>the</strong> North American coal industry6 FROM THE SUBSIDIARIESProduction starts in <strong>China</strong>7 <strong>NEWS</strong> & <strong>EVENTS</strong><strong>Berco</strong> <strong>at</strong> <strong>Bauma</strong> <strong>China</strong> <strong>for</strong> <strong>the</strong> <strong>first</strong> time8 FROM THE SUBSIDIARIESAt <strong>the</strong> foot of <strong>the</strong> Balkans a new factory<strong>at</strong> <strong>the</strong> service of <strong>Berco</strong> Track Systems9 FROM THE SUBSIDIARIES<strong>Berco</strong> UK: a very intense year10 ENVIRONMENT & SAFETYEnvironmental Management System:it’s not just <strong>the</strong> environment th<strong>at</strong>benefits11 PRODUCTS & SERVICESThe Lynx2000 grinder arrives in Brazil<strong>Berco</strong>News is a periodical published <strong>for</strong> <strong>Berco</strong> employees,customers, suppliers and friends. The articles and photos canbe copied only if expressly authorised by <strong>the</strong> Editor.Cover: <strong>Bauma</strong> <strong>China</strong> 2008Published by: BERCO S.p.A. - Communic<strong>at</strong>ions DepartmentVia 1° Maggio, 237 - 44034 Copparo (FE) ItalyTel. +39 0532 864116 - fax +39 0532 864462,e-mail: berconews@berco.comEditor-in-Chief: Silvia UngaroTel. +39 0532 864116 - fax +39 0532 864462,e-mail: s.ungaro@berco.comEditorial Committee: E. Bacilieri, S. Bottacin, L. Guzzin<strong>at</strong>i,S. Mastellari, G. Neodo, A. Bavarone, R. Robbiano, S. Sal<strong>at</strong>ini,S. SalviEditorial Secretary: D.RoversiTel. +39 0532 864 270 - e-mail: d.roversi@berco.comGraphics and pagin<strong>at</strong>ion: Communic<strong>at</strong>ions DepartmentPrinted: Chinchio Industria Grafica S.p.A. (PD)Circul<strong>at</strong>ion: Italian 4.200, English 5.300as you all know, our2007/2008 financial yearended on <strong>the</strong> 30th ofSeptember.A year in which, insteadof <strong>the</strong> long-awaited signsof recovery in ourmarkets, <strong>the</strong>re was adifficult process ofconsolid<strong>at</strong>ion andtransition, culmin<strong>at</strong>ing ina financial and economic crisis generally defined as “<strong>the</strong>worst of <strong>the</strong> last seventy years”.I feel nei<strong>the</strong>r compelled nor entitled to add to <strong>the</strong> vastamount of in<strong>for</strong>m<strong>at</strong>ion and expert analysis th<strong>at</strong> we hearand read every day about <strong>the</strong> causes and consequencesof <strong>the</strong> current general economic crisis.There<strong>for</strong>e I shall limit myself to a few simpleconsider<strong>at</strong>ions, with regards to our company, givinghighlights of <strong>the</strong> past financial year summed up asfollows.The <strong>first</strong> is undoubtedly <strong>the</strong> persistence of <strong>the</strong> big dropin demand in North American markets th<strong>at</strong> began in2007, linked to <strong>the</strong> financial crisis and <strong>the</strong> standstill inconstruction.The second is rel<strong>at</strong>ed to <strong>the</strong> very big rise in raw m<strong>at</strong>erialand energy costs th<strong>at</strong> lasted right to <strong>the</strong> end of July,caused more by specul<strong>at</strong>ive factors than actual marketconditions.And <strong>the</strong> third is <strong>the</strong> result of a collapse in demand onEuropean markets as well, starting in August, followedby collapses on <strong>the</strong> Russian, Indian and Asian markets.Despite all this, our production volume reached 243,000tons, just slightly below <strong>the</strong> target of 250,000 tonsachieved in <strong>the</strong> previous year, a reduction of less than3%.This result would be highly s<strong>at</strong>isfactory, if it were not <strong>for</strong><strong>the</strong> fact th<strong>at</strong> in <strong>the</strong> meantime, over <strong>the</strong> last few months,<strong>the</strong> economy plummeted even fur<strong>the</strong>r, cre<strong>at</strong>ing moredifficulties and challenges ahead thus <strong>for</strong>cing us toreschedule production <strong>for</strong> <strong>the</strong> October-December trimesterand probably <strong>for</strong> <strong>the</strong> January-March trimester as well.There are no simple solutions or easy short cuts <strong>for</strong>getting through times like <strong>the</strong>se. Of one thing, though,we are absolutely certain: <strong>the</strong> human factor can andmust make <strong>the</strong> difference.Our “team”, with its directors, managers, office staffand workers <strong>at</strong> all levels, has all <strong>the</strong> required ingredientssuch as professionalism, sense of responsibility andmotiv<strong>at</strong>ion to face up to and manage this difficultperiod of transition leading to <strong>the</strong> recovery, which,despite <strong>the</strong>re being, as yet, no visible signs of it, willsurely come. The "seniors" among us, whose 30 years ormore of loyalty to <strong>the</strong> company and are soon to be

acknowledged in a prize giving ceremony on <strong>the</strong> 20thof December, have already lived through similar crisissitu<strong>at</strong>ions in <strong>the</strong> past, from which <strong>the</strong> company hasalways emerged, somewh<strong>at</strong> leaner perhaps, butdefinitely streng<strong>the</strong>ned in all respects. Theirexperience and learnings can and must provide <strong>the</strong>younger gener<strong>at</strong>ion with <strong>the</strong> support, trust andguidance necessary to cope not only competently, butalso bravely and determinedly, with <strong>the</strong> challenge of<strong>the</strong> <strong>for</strong>thcoming months as we await <strong>the</strong> return tonormality. As far as I and those with whom I workmost directly are concerned, I assure you th<strong>at</strong> noef<strong>for</strong>t will be spared to increase our productivity, withregard both to investment and <strong>the</strong> implement<strong>at</strong>ion ofaction plans aimed <strong>at</strong> optimising our costs andwinning new markets.Our primary objective, toge<strong>the</strong>r with <strong>at</strong>tainingpositive results <strong>for</strong> <strong>the</strong> company, has always been toguarantee <strong>the</strong> maximum level of employment allowed by<strong>the</strong> market situ<strong>at</strong>ion, not only <strong>for</strong> <strong>the</strong> sake of <strong>the</strong> futureemployment of our work<strong>for</strong>ce, both in <strong>the</strong> Italianfactories and <strong>for</strong>eign branches, but also <strong>for</strong> <strong>the</strong> localsupply chain and economy.As <strong>the</strong> festive season approaches, and in times ofwidespread crisis such as <strong>the</strong>se, <strong>the</strong> desire and need toexchange <strong>the</strong> customary greetings becomes moreheartfelt than ever.There<strong>for</strong>e, may I wish yourselves and your families all<strong>the</strong> very best <strong>for</strong> a peaceful Christmas and, above all, ahappy and better New Year!Tonnell<strong>at</strong>e (x 1.000)300250200150100500180‘00AM - AfterMarketOEM - 1st equipment181 180 180‘01‘02‘03200,3‘04230‘05243 250 243‘06‘07‘08Production trend over <strong>the</strong> last 9 yearsBruno S<strong>at</strong>urniManaging DirectorThe winning drawing in <strong>the</strong>“Christmas on Tracks 2008”competition, open to allemployees’ children, by AndreaBurini, aged 7.BN56 > december 20083

News & EventsMINEXPO 2008Three daysamongst <strong>the</strong> giantsGoing against <strong>the</strong> trend of <strong>the</strong> world economic crisis, <strong>the</strong>mining industry appears to be undergoing steady growth,thanks above all to demand in developing countries and <strong>the</strong>trend in <strong>the</strong> energy market, which seems as though itseriously intends to free itself from <strong>the</strong> dominance of oil.4MINEXPO 2008 EDITIONMINExpo is <strong>the</strong> only mining fair inNorth America and <strong>the</strong> mostprestigious in <strong>the</strong> world. Every fouryears, in Las Vegas, this event bringstoge<strong>the</strong>r all <strong>the</strong> major represent<strong>at</strong>ivesof <strong>the</strong> world mining industry and <strong>the</strong>whole universe th<strong>at</strong> surrounds it. Thisyear saw <strong>the</strong> previous edition’s<strong>at</strong>tendance record broken (44% up onMINExpo 2004), with 38,500 visitorsfrom all over <strong>the</strong> world and almost1,300 exhibitors. It occupied a surfacearea of about 180,000 square metres(30% more than <strong>the</strong> 2004 edition) of<strong>the</strong> Las Vegas Convention Centre.A MARKETGOING AGAINST THE TRENDDespite <strong>the</strong> difficult world economicsitu<strong>at</strong>ion, most visitors bore witness to<strong>the</strong> fact th<strong>at</strong> <strong>the</strong> mining industry isundergoing steady growth. With manysectors of industry struggling <strong>for</strong>survival, in <strong>the</strong> mining industry <strong>the</strong>reis actually gre<strong>at</strong> demand <strong>for</strong> equipmentand skilled personnel. The growth isparticularly evident in developingcountries, where <strong>the</strong>re is increasingdemand <strong>for</strong> mining products andmachinery. The popularity of <strong>the</strong> coalextraction industry is blooming, due to<strong>the</strong> worldwide interest in developingenvironmentally friendly coal-basedtechnology, capable both of meetinggrowing energy demands and of beingan altern<strong>at</strong>ive solution to oil. Marketanalysts expect exports of UnitedSt<strong>at</strong>es coal, comprising no less than27% of world reserves, to growexponentially over <strong>the</strong> next threeBN56 > december 2008years, with <strong>the</strong> consequent positiveeffect on mining equipment sales in<strong>the</strong> years to come. This conviction isconfirmed by <strong>the</strong> fact th<strong>at</strong> most of <strong>the</strong>machines on show were already soldand, <strong>for</strong> some, <strong>the</strong>re were waiting listsof almost two years.THE BERCO STAND<strong>Berco</strong> took part in <strong>the</strong> fair with a standin two sections, one dedic<strong>at</strong>ed todozers and <strong>the</strong> o<strong>the</strong>r to excav<strong>at</strong>ors.On show in <strong>the</strong> <strong>for</strong>mer section was alarge-size triangular undercarriage <strong>for</strong>dozers, part of <strong>the</strong> <strong>Berco</strong> range <strong>for</strong>track chain pitches of up to 350 mm.This was accompanied by a sprocket<strong>for</strong> <strong>the</strong> same machine, displayed in anunfinished st<strong>at</strong>e to highlight one of<strong>the</strong> main techniques underlying <strong>the</strong>characteristic <strong>the</strong> quality of <strong>the</strong> <strong>Berco</strong>brand, hot <strong>for</strong>ging. <strong>Berco</strong> has beeninvesting in <strong>the</strong> technology <strong>for</strong> <strong>the</strong>development of this production process<strong>for</strong> over twenty years.In <strong>the</strong> excav<strong>at</strong>ors section of <strong>the</strong> stand,a section of a track chain <strong>for</strong> a 120-ton excav<strong>at</strong>or was displayed, toge<strong>the</strong>rwith a section of a track chain <strong>for</strong> anR994 excav<strong>at</strong>or. Trade fairs are alwaysgre<strong>at</strong> occasions <strong>for</strong> exchange andcomparison, presenting opportunitiesto renew rel<strong>at</strong>ionships with existingcustomers and make new contacts <strong>for</strong><strong>the</strong> future. For us, <strong>the</strong> outcome of thisedition of MINExpo was definitelypositive and we expect <strong>the</strong> meetingsth<strong>at</strong> took place during <strong>the</strong> fair todevelop into growth opportunities <strong>for</strong>both ourselves and our customers, oldand new. The success of ourparticip<strong>at</strong>ion in this important eventcan definitely be partly <strong>at</strong>tributed to<strong>the</strong> synergic rel<strong>at</strong>ionship th<strong>at</strong> has beenestablished between <strong>the</strong> Americanbranch and <strong>the</strong> Copparo headquarters,a working rel<strong>at</strong>ionship which yet againdemonstr<strong>at</strong>ed how coordin<strong>at</strong>ing ef<strong>for</strong>tsin <strong>the</strong> <strong>at</strong>tainment of specific companygoals always brings <strong>the</strong> best results.We would like to take this occasion toexpress our special thanks to all thosewho visited <strong>the</strong> <strong>Berco</strong> stand, especiallyour customers and dealers, andwe hope to see you all again <strong>at</strong>MINExpo 2012!Antonio Pelà<strong>Berco</strong> of America

Focus onMINING: developmentprospects in <strong>the</strong> NorthAmerican coal industryTHE ROLE OF COAL IN THEFUTURE OF NORTH AMERICAOn <strong>the</strong> 16th of January 2008, Kraig R.Naasz, President and CEO of <strong>the</strong>N<strong>at</strong>ional Mining Associ<strong>at</strong>ion, <strong>the</strong>official voice of <strong>the</strong> North Americanmining industry, opened <strong>the</strong> four<strong>the</strong>dition of <strong>the</strong> “Annual St<strong>at</strong>e of <strong>the</strong>Energy Industry” with a longintroduction on <strong>the</strong> role of coal in <strong>the</strong>energy industry and <strong>the</strong> deb<strong>at</strong>e onclim<strong>at</strong>e change, referring in particularto <strong>the</strong> United St<strong>at</strong>es, given its gre<strong>at</strong>wealth of coal deposits: no less than27% of all world reserves, <strong>the</strong> highestconcentr<strong>at</strong>ion in any single n<strong>at</strong>ion.Currently, coal gener<strong>at</strong>es 50% ofavailable energy in <strong>the</strong> United St<strong>at</strong>es,a figure which is expected to reach57% by 2030. Wh<strong>at</strong> should be takeninto account, though, is th<strong>at</strong> in <strong>the</strong>same period, a popul<strong>at</strong>ion growth of300 million units is <strong>for</strong>ecast, with a40% increase in energy demand.The accessibility of this mineral, <strong>the</strong>need to become independent of <strong>the</strong>countries th<strong>at</strong> control <strong>the</strong> productionof oil and, last but not least, <strong>the</strong>environmental awareness developed inEurope resulting from <strong>the</strong> industrialapplic<strong>at</strong>ion of <strong>the</strong> Kyoto Protocol, haveall contributed strongly to <strong>the</strong> desireto develop <strong>the</strong> coal extraction industry.Since 2003 this desire has been fur<strong>the</strong>rmotiv<strong>at</strong>ed by <strong>the</strong> “FutureGen” projectand <strong>the</strong> development of <strong>the</strong> <strong>first</strong> evercoal-based simultaneous electricityand hydrogen production plant, a plantdesigned to reduce noxious emissionsto zero and elimin<strong>at</strong>e carbon dioxideemissions by sequestr<strong>at</strong>ion andunderground storage. The plant, whichis to be in M<strong>at</strong>toon, Illinois, will havea power of 275 MW and will beoper<strong>at</strong>ional by 2012.The investment was 1.75 billiondollars, 1.5 billion of this having beenprovided by <strong>the</strong> project sponsor, USGovernment Department of Energy(http://www.futuregenalliance.org/).This ambitious project, th<strong>at</strong>, if thisprototype will be successful, willinvolve <strong>the</strong> construction of more plantsof this kind, is based on <strong>the</strong>assumption th<strong>at</strong> <strong>the</strong>re will be fur<strong>the</strong>rdevelopments in <strong>the</strong> coal industry andall its correl<strong>at</strong>ed market.THE FUTURE OF “MINING”This prospect <strong>for</strong> development in <strong>the</strong>North American coal industry opens upfur<strong>the</strong>r growth scenarios <strong>for</strong> <strong>Berco</strong> inmining, an area in which <strong>the</strong> companyhas been making large-scaleinvestments both in process, with <strong>the</strong>cre<strong>at</strong>ion of new production systemsand lines specifically <strong>for</strong> <strong>the</strong>manufacture of large-size components,and in logistics, with <strong>the</strong> expansion ofits organis<strong>at</strong>ion in order to provide <strong>the</strong>customer with a more complete,effective and efficient service.NOT JUST “GIGANTIC” MACHINESDon’t <strong>for</strong>get th<strong>at</strong> mining doesn’t justmean huge machines, but also all <strong>the</strong>service machinery and equipmentneeded <strong>for</strong> working in a mine. Thesemedium-size machines could also beinvolved in <strong>the</strong> expected growth over<strong>the</strong> next few years. In this area, <strong>Berco</strong>has a wide range of products th<strong>at</strong> addto <strong>the</strong> quality of <strong>the</strong> offer, a qualitywhich, it should be noted, guaranteesbetter per<strong>for</strong>mance and maximum lifeeven in <strong>the</strong> harshest conditions and, inaddition, <strong>the</strong> best value <strong>for</strong> money inrel<strong>at</strong>ion to <strong>the</strong> number of hoursworked. And so, <strong>for</strong> <strong>the</strong> years to come,<strong>Berco</strong> confirms its growth target inthis sector, as <strong>the</strong> current world crisisseems to be avoiding those marketareas involved in <strong>the</strong> manufacture ofproducts in some way linked tosafeguarding <strong>the</strong> environment.Silvia UngaroCommunic<strong>at</strong>ions Department ManagerBN56 > december 20085

From <strong>the</strong> SubsidiariesPRODUCTION starts in <strong>China</strong>“Safeguarding <strong>Berco</strong> brand quality” – this is <strong>the</strong> guiding philosophy of <strong>the</strong> oper<strong>at</strong>ionalstaff <strong>at</strong> <strong>the</strong> new Chinese branch, which began its roller and track chain assembly work on <strong>the</strong>13th of September, using components produced in <strong>the</strong> Italian factories.6The 13th of September 2008, <strong>the</strong> day on which <strong>Berco</strong>Shanghai Undercarriage produced its <strong>first</strong> b<strong>at</strong>ches ofrollers and track chains, will be remembered as animportant d<strong>at</strong>e in <strong>the</strong> history of <strong>the</strong> Chinese branch.Achieving this goal wasn’t easy: from a simple 12 m 2office manned by three people to a 5,200 m 2industrial building with a staff of 25 office andfactory personnel, in just 18 months. The facilitiesinstalled include a warehouse with capacity <strong>for</strong> about1,000 containers, a 200 m 2 incoming goods testinglabor<strong>at</strong>ory, a small test sample prepar<strong>at</strong>ion workshopof about 100 m 2 , a roller assembly line and a trackchain assembly line, and in <strong>the</strong> meantime asignificant order portfolio has been built up.Fur<strong>the</strong>rmore, a turnover of 13 million euros is<strong>for</strong>ecast <strong>for</strong> 2009 with <strong>the</strong> startup of machining andhe<strong>at</strong> tre<strong>at</strong>ment lines <strong>for</strong> locally procured castings.There has been no lack of difficulties: customsinspections and continuous surveillance bygovernment agencies have delayed machine startupsBN56 > december 2008considerably, but <strong>the</strong> tenacity of our Chinesecolleagues and <strong>the</strong> technical support from our Italiancolleagues, to whom we extend our special thanks,have made it possible to get <strong>the</strong> lines up andrunning well ahead of schedule.Currently, roller production is <strong>at</strong> about 150 items pershift and is expected to go above 180 per shift by<strong>the</strong> end of <strong>the</strong> year.Assembly of chains complete with track shoes beganwith <strong>the</strong> FL4 model. The current production r<strong>at</strong>e isabout 6 chains per shift and, again by <strong>the</strong> end of <strong>the</strong>year, is expected to exceed 8 per shift.In this startup period we have paid special heed to<strong>the</strong> input given by our management: “safeguard<strong>Berco</strong> quality“. For this reason, <strong>Berco</strong> ShanghaiUndercarriage, as well as training engineeringpersonnel, has also concentr<strong>at</strong>ed on incentiv<strong>at</strong>ingquality.The <strong>first</strong> shipment was disp<strong>at</strong>ched <strong>at</strong> <strong>the</strong> end ofSeptember, well within <strong>the</strong> times requested bycustomers.Our <strong>first</strong> customers were Kobelco and BobC<strong>at</strong>, butnew contacts have already been established withimportant manufacturers, both local andintern<strong>at</strong>ional.In <strong>the</strong>se uncertain times in <strong>the</strong> world economy, <strong>the</strong>driving <strong>for</strong>ce provided by <strong>the</strong> Chinese market is ofprime importance, not only <strong>for</strong> <strong>the</strong> development of<strong>Berco</strong> Shanghai Undercarriage but also <strong>for</strong> <strong>the</strong> <strong>Berco</strong>factories in Italia, given th<strong>at</strong> <strong>the</strong> roller shells, tracklinks, pins and bushings are manufactured exclusivelyin Italy.Flavio Forner<strong>Berco</strong> Shanghai UndercarriageTechnical Supervisor

News & Events<strong>Berco</strong> <strong>at</strong><strong>Bauma</strong> CHINA<strong>for</strong> <strong>the</strong> <strong>first</strong> timeThe 2008 edition of <strong>Bauma</strong> <strong>China</strong> was heldfrom <strong>the</strong> 25th to <strong>the</strong> 28th of November. Thefair, one of <strong>the</strong> most important intern<strong>at</strong>ionalevents in <strong>the</strong> construction industry, obviously<strong>at</strong>tracted a large number of major companies.This becomes evident when we look <strong>at</strong> someof <strong>the</strong> main figures:- total exhibiting area: 210,000 m 2- more than 1,500 exhibitors from 30countries- more than 100,000 visitors- <strong>Bauma</strong> <strong>China</strong> 2008 was significantly bigger(+ 40%) than <strong>the</strong> 2006 edition, in terms ofboth exhibiting area and number of visitors.<strong>Berco</strong> particip<strong>at</strong>ed directly in <strong>the</strong> fair <strong>for</strong> <strong>the</strong><strong>first</strong> time with its own stand of 110 m 2 , set upby <strong>the</strong> Chinese branch, exhibiting products <strong>for</strong>excav<strong>at</strong>ors, mini excav<strong>at</strong>ors, dozers andundercarriage maintenance machines.<strong>Berco</strong>’s particip<strong>at</strong>ion in <strong>the</strong> fair was importantbecause it was a way of announcing itspresence in <strong>China</strong> with a new branch andproduction plant.There were many visitors to our stand in <strong>the</strong> 4days of <strong>the</strong> fair, and important contacts weremade, both OEM and aftermarket.Our staff were involved in detailed technicalbusinessmeetings with a number ofintern<strong>at</strong>ional OEMs, such as Volvo, JCB, Terex,SANY, John Deere and Wirtgen.In addition, in<strong>for</strong>m<strong>at</strong>ion was exchanged andexisting joint work schemes were consolid<strong>at</strong>edwith o<strong>the</strong>r leading OEMs.It was also noted during <strong>the</strong> fair th<strong>at</strong> demand<strong>for</strong> heavy machinery undercarriage is high,thus giving <strong>Berco</strong> a growing number ofopportunities to gain a foothold in <strong>the</strong> FarEastern aftermarket.Despite <strong>the</strong> world economic crisis, <strong>the</strong>construction industry in <strong>China</strong> hasreconfirmed its growth trend, as demonstr<strong>at</strong>edby <strong>the</strong> 400 billion euro infrastructureincentive scheme recently funded by <strong>the</strong>Chinese government.<strong>Berco</strong> has no intention of letting thisopportunity to enter <strong>the</strong> Chinese market passby, and has <strong>for</strong>mul<strong>at</strong>ed a specially tailoredstr<strong>at</strong>egy to streng<strong>the</strong>n its position as aleading manufacturer of undercarriagecomponents, not only in <strong>the</strong> NAFTA area or on<strong>the</strong> European market, but alsoin <strong>the</strong> vast expanses of <strong>China</strong>and South East Asia.Yi Zeng<strong>Berco</strong> Shanghai UndercarriageGeneral ManagerBN56 > december 20087

From <strong>the</strong> SubsidiariesAt <strong>the</strong> foot of <strong>the</strong>BALKANS a new factory<strong>at</strong> <strong>the</strong> service of BERCO TRACK SYSTEMSComplete “turnkey” undercarriage systems:an all-European challenge.The complete systems are actually designedand assembled <strong>at</strong> <strong>the</strong> factories in Copparo,Imola and <strong>the</strong> new Apriltsi branch in Bulgaria.<strong>Berco</strong> Bulgaria was <strong>for</strong>med on <strong>the</strong> 25th of July andwas fully ready <strong>for</strong> oper<strong>at</strong>ion on <strong>the</strong> 1st of October2008, extending <strong>the</strong> <strong>Berco</strong> project on <strong>the</strong> supply ofcomplete systems, which began in October 2007 with<strong>the</strong> purchase of Forteq.The loc<strong>at</strong>ion of <strong>the</strong> newly <strong>for</strong>med branch is Apriltsi,surrounded by <strong>the</strong> Central Balkan mountain chain,just two hours from Sofia with easy access viamotorway and rail.The industrial plant covers a surface area of about30,000 m2, with a main production building of about3,000 m2 and smaller buildings fitted out aswarehouses.The main activity being <strong>the</strong>manufacture of frames,with components from<strong>the</strong> Imola factoriesbeing welded here in<strong>the</strong> Bulgarian branch.Production capacity isabout 500 frames a month.Currently, <strong>the</strong> branch has 35 employees workingunder Managing Director Plamen Peevski.The newly acquired facility has been thoroughlymodernised and restructured in <strong>the</strong>se months,involving, on <strong>the</strong> one hand, <strong>the</strong> buildings, resultingin <strong>the</strong> standardis<strong>at</strong>ion not only of <strong>the</strong> plant, but also<strong>the</strong> administr<strong>at</strong>ive, IT and management processes.The new factory will make <strong>the</strong> newly cre<strong>at</strong>ed <strong>Berco</strong>Track System division more competitive, fur<strong>the</strong>rincreasing production capacity in response to <strong>the</strong>ever more pressing need to respond to <strong>the</strong> demandnot only <strong>for</strong> complete systems <strong>for</strong> excav<strong>at</strong>ors,compact track loaders, asphalt pavers,road planers and rockboring machines,but also <strong>for</strong>w e l d e dstructuressuch asexcav<strong>at</strong>or arms, rotary boxes, loader arms, lowerframes and o<strong>the</strong>r accessory structures <strong>for</strong> earthmoving machines. At a time when manymanufacturers and sub-suppliers have turned toSouth East Asian countries <strong>for</strong> <strong>the</strong>ir main ofsupply of complete steel structures, <strong>Berco</strong> hasdecided to keep its productionbase in Europe, in orderto be able to exercisemore direct controlover <strong>the</strong> entireprocess and face up to<strong>the</strong> challenge fromemerging countries in amore cost-competitive way.With a str<strong>at</strong>egy based on keepingdesign and production closely integr<strong>at</strong>ed, <strong>Berco</strong> isable to guarantee its customers high standards ofreliability in deliveries and manufacturing quality.At just over a year from <strong>the</strong> purchase of Forteq,we can safely say th<strong>at</strong> we’re s<strong>at</strong>isfied: <strong>the</strong> TrackSystems division is fully active, new projects havebeen launched with many o<strong>the</strong>rs in <strong>the</strong> prototypestage and <strong>Berco</strong> engineering is currently workingon a number of new requests.All this is fur<strong>the</strong>r evidence of <strong>the</strong> considerabledevelopment possibilities <strong>for</strong> <strong>Berco</strong> Track Systems.M<strong>at</strong>teo FrabettiAdministr<strong>at</strong>ion DepartmentLuca Bar<strong>at</strong>toniTrack System Division8BN56 > december 2008

From <strong>the</strong> Subsidiaries<strong>Berco</strong> UK: a very intense yearThe British branch has just ended its third financial year, withlots of things achieved and many more plans <strong>for</strong> <strong>the</strong> future.The Christmas period, perhaps morethan any o<strong>the</strong>r, is a time when youlook back and make an assessment of<strong>the</strong> year just ending.Looking back <strong>at</strong> <strong>the</strong> last twelvemonths, we can say th<strong>at</strong> <strong>the</strong>y werereally intensive, highly eventful andlived in two completely differenteconomic contexts: <strong>the</strong> <strong>for</strong>mer full oftrust in a very healthy market (withturnover growing by 30%), <strong>the</strong> l<strong>at</strong>ter -evident as from May - in rapid declineand characterised by an almost verticaldrop in demand.Never<strong>the</strong>less, despite this suddenslowdown, by <strong>the</strong> end of <strong>the</strong> year<strong>Berco</strong> UK had achieved a turnover of51 million euros, in line with 2007,with a growth in profit over <strong>the</strong>previous year. The organis<strong>at</strong>ionalstructure grew as well, rising to 25units, and work was done onoptimising internal structures andimproving assembly line productivity(getting up to <strong>the</strong> r<strong>at</strong>e of 12 trackchains a shift).Gre<strong>at</strong> ef<strong>for</strong>ts were also put intomaintaining <strong>the</strong> excellent standards ofservice to <strong>the</strong> two main customers,with <strong>the</strong> <strong>at</strong>tainment of <strong>the</strong> Kom<strong>at</strong>suUK’s prestigious “Supplier of <strong>the</strong> Year”award.NEW PREMISESThe most important project of <strong>the</strong> yearwas undoubtedly <strong>the</strong> move to newpremises in Spennymoor, near Durham.With <strong>the</strong> rental contract on <strong>the</strong>Middlesbrough building about toexpire, <strong>the</strong> search began <strong>for</strong> biggerpremises (about 14,000 m2), bigenough above all to housenew track chain assemblyand complete frame subassemblylines, because<strong>the</strong>se are <strong>the</strong> activities th<strong>at</strong><strong>Berco</strong> UK is banking on toincrease its business in <strong>the</strong>years to come.After completing <strong>the</strong>bureaucr<strong>at</strong>ic necessities(contract, permits, etc.),work began <strong>at</strong> <strong>the</strong> end of’07 on fitting out <strong>the</strong>building, with jobs such <strong>the</strong>install<strong>at</strong>ion of two bridgecranes and a paint boothand <strong>the</strong> electricity, gas andcompressed air circuits, etc.This work went on <strong>for</strong> fivemonths.The office move was done <strong>at</strong><strong>the</strong> beginning of May, and<strong>the</strong> goods and stock movebegan in May and lasted 4-5weeks, with no interruptionin <strong>the</strong> flow of deliveries tocustomers.On <strong>the</strong> 18th of July we werefinally able to celebr<strong>at</strong>e <strong>the</strong>reloc<strong>at</strong>ion to <strong>the</strong> newpremises with a <strong>Berco</strong> UKOpen Day.This began in <strong>the</strong> morningwith a press conference,followed by an inaugur<strong>at</strong>ionceremony and an officialpresent<strong>at</strong>ion. Guests were<strong>the</strong>n shown round <strong>the</strong>factory, followed by <strong>the</strong>customary toast.Numerous customers,suppliers, friends and local authoritiestook part in <strong>the</strong> event, including localMP Helen Goodman, <strong>the</strong> guest ofhonour.In <strong>the</strong> afternoon, after <strong>the</strong> guests hadleft, it was <strong>the</strong> turn of <strong>the</strong> employeesand <strong>the</strong>ir families, <strong>the</strong>y too having <strong>the</strong>chance to have a look round <strong>Berco</strong> UK.FUTURE PROJECTSAlthough <strong>the</strong> difficult economicsitu<strong>at</strong>ion and continuous talk of <strong>the</strong>recession hitting Europe and Americaleave little room <strong>for</strong> optimism,never<strong>the</strong>less, <strong>at</strong> <strong>the</strong> same time,difficult periods are a unique occasionto look <strong>for</strong> new stimuli, discoveruntapped resources and develop newideas and projects to lay <strong>the</strong> basis <strong>for</strong>strong future growth.Despite <strong>the</strong> drop in sales, <strong>Berco</strong> UK hasredoubled its ef<strong>for</strong>ts and is working onnumerous projects, both internal (suchas <strong>the</strong> ISO 9001, ISO 14001, OHSAS18001 and Investor in People qualitycertific<strong>at</strong>ion schemes), and external(such as, in particular, <strong>the</strong>development of <strong>the</strong> aftermarket and<strong>the</strong> supply of complete frames <strong>for</strong>mobile crushers and screens).The challenges are ambitious, but <strong>the</strong>enthusiasm and dedic<strong>at</strong>ion of <strong>the</strong><strong>Berco</strong> UK team are bound to achieves<strong>at</strong>isfactory results in <strong>the</strong> near future.Giovanni MichelettoGeneral Manager, <strong>Berco</strong> UKBN56 > december 20089

Environment & SafetyENVIRONMENTAL MANAGEMENT SYSTEM:it’s not just <strong>the</strong> environment th<strong>at</strong> benefitsThe sizeable investment required <strong>for</strong> <strong>the</strong> introduction and maintenance of an EnvironmentalManagement System is justified by <strong>the</strong> considerable benefits th<strong>at</strong> derive from it, both m<strong>at</strong>erially and interms of company image. <strong>Berco</strong> is fully aware of this fact and works constantly to ensure th<strong>at</strong> itsEnvironmental Management System (EMS) is ever more integr<strong>at</strong>ed and effective.The aim of EnvironmentalManagement Systems isto identify <strong>the</strong> mainenvironmental factors of acompany, keep <strong>the</strong>m undercontrol and coordin<strong>at</strong>eall <strong>the</strong> activities th<strong>at</strong> impact<strong>the</strong> environment, with<strong>the</strong> assignment ofspecific responsibilities.Environmental problemsthus become an integralpart of companymanagement, with <strong>the</strong>setting of voluntary goals,<strong>the</strong> <strong>at</strong>tainment of which ismonitored by <strong>the</strong> companyitself. <strong>Berco</strong> has been ISO14001 certified since 2000and had its third inspection<strong>for</strong> renewal in October 2008.The inspection <strong>for</strong>con<strong>for</strong>mity to <strong>the</strong>ISO14001:04 Standard wasparticularly thorough and<strong>the</strong> three inspectorsg<strong>at</strong>hered objective evidenceof con<strong>for</strong>mity (ornoncon<strong>for</strong>mity) to <strong>the</strong> Standardrequirements by means of checkingdocuments, surveys in departments,observ<strong>at</strong>ion of activities and staffinterviews. On completing <strong>the</strong>ir visit,<strong>the</strong> inspectors concluded th<strong>at</strong> <strong>the</strong>rewas a growth in <strong>the</strong> professionalexpertise of <strong>the</strong> Environment andSafety group and in <strong>the</strong> m<strong>at</strong>urity of <strong>the</strong>EMS, but th<strong>at</strong> this now had to bedissemin<strong>at</strong>ed to all areas/departments.For this, <strong>the</strong>y suggested nomin<strong>at</strong>ingorganis<strong>at</strong>ional reference persons <strong>for</strong>environmental questions in <strong>the</strong> variousdepartments-areas. They also pointedout <strong>the</strong> need to redefine roles andresponsibilities with <strong>the</strong> drafting of anew company organis<strong>at</strong>ion chart. Inoverall terms, <strong>the</strong> assessment of <strong>the</strong>company was positive, and <strong>the</strong>progress made in reducing energy, oiland solvent consumption and in <strong>the</strong>management of <strong>at</strong>mospheric emissionswas acknowledged. But we mustn’t reston our laurels: <strong>the</strong> certifying agencyspecified an exacting course of actionto follow if we are to improve ourenvironmental per<strong>for</strong>mance <strong>at</strong> <strong>Berco</strong>.Having an Environmental Management System, infact, means taking on important commitments interms of time, energy and capital, not only in <strong>the</strong>implement<strong>at</strong>ion stage, but also and above all in<strong>the</strong> maintenance stage. Given th<strong>at</strong> developing anEnvironmental Management System and oper<strong>at</strong>ingaccording to its principles is a voluntary choice of<strong>the</strong> company, you may ask why an organis<strong>at</strong>iondecides to bear <strong>the</strong>se considerable costs. As wellas being aware of environmental problems, acompany th<strong>at</strong> makes this kind of choice knowsth<strong>at</strong> it will get a range of different benefits. Theimmedi<strong>at</strong>e advantages are "environmental ", suchas reducing impact, lessening accident risk andbeing more sure of compliance wi<strong>the</strong>nvironmental standards, thus reducing <strong>the</strong> riskof legal action.The medium and short term benefits th<strong>at</strong> standout are <strong>the</strong> lower supply and waste disposalcosts, derived from savings in raw m<strong>at</strong>erials andenergy and lower waste production. Finally, <strong>the</strong>reare <strong>the</strong> benefits of a more "str<strong>at</strong>egic" type, be<strong>the</strong>y external, with <strong>the</strong> cre<strong>at</strong>ion of a better imagewith <strong>the</strong> public, institutions and customers, orinternal, with <strong>the</strong> improved employee efficiency,motiv<strong>at</strong>ion and particip<strong>at</strong>ion.Saverio SalviEnvironment and Safety ManagerMAIN BENEFITS DERIVING FROM COMPLIANCE WITH ISO 14001:04 SYSTEMLegal safeguard: Observance and document<strong>at</strong>ion of all n<strong>at</strong>ional, regional and local requirements, elimin<strong>at</strong>ing <strong>the</strong> risk of incurringcriminal or civil penalties.Reduced accident risk: Identific<strong>at</strong>ion of inefficiencies in production processes thanks to better in<strong>for</strong>m<strong>at</strong>ion on potentialhazards and correct management of plant, work procedures and emergencies.Cost saving: Thanks in particular to <strong>the</strong> optimis<strong>at</strong>ion of processes, <strong>the</strong>se being: energy, raw m<strong>at</strong>erials, w<strong>at</strong>er supply, wasteproducts and <strong>the</strong> rel<strong>at</strong>ed optimis<strong>at</strong>ion of <strong>the</strong> raw m<strong>at</strong>erials used in <strong>the</strong> processes, energy consumption and pollutant<strong>at</strong>mospheric emissions.Competitive advantages: The gaining or maintaining of market shares, especially in countries with a strong environmentalculture, where <strong>the</strong> selection of products or suppliers is decided by <strong>the</strong> final customer.Improved company image: Better credibility with o<strong>the</strong>r economic actors, thanks to <strong>the</strong> use of <strong>the</strong> ISO 14001:04 logo.Improved rel<strong>at</strong>ions with <strong>the</strong> authorities: When granting authoris<strong>at</strong>ions or making inspections, controlling authorities areable to take into account <strong>the</strong> ef<strong>for</strong>ts made by <strong>the</strong> company and <strong>the</strong> responsible <strong>at</strong>titude to <strong>the</strong> law, as evidenced by <strong>the</strong> certific<strong>at</strong>ion.Staff motiv<strong>at</strong>ion: Gre<strong>at</strong>er sense of responsibility and involvement of personnel in <strong>the</strong> <strong>at</strong>tainment of eco-comp<strong>at</strong>ibleefficiency, thanks to <strong>the</strong> in<strong>for</strong>m<strong>at</strong>ion provided and awareness shown by company management.10BN56 > december 2008

Products & ServicesThe LYNX2000GRINDERarrives in BRAZILIt gives us gre<strong>at</strong> s<strong>at</strong>isfaction to see a companylike ThyssenKrupp Metalúrgica Campo Limpoamongst <strong>the</strong> customers th<strong>at</strong> have chosen tointroduce a machine tool like <strong>the</strong> Lynx2000 intoits production processes.ThyssenKrupp Metalúrgica Campo Limpo is aThyssenKrupp Technologies company, part of <strong>the</strong>Mechanical Components division, like <strong>Berco</strong>.TKMCL, toge<strong>the</strong>r with <strong>the</strong> ThyssenKruppCrankshasft Co. and ThyssenKrupp Gerlach, is amember of <strong>the</strong> ThyssenKrupp Forging Groupwhich, with its factories in Europe, North andSouth America and Asia, is one of <strong>the</strong> leadingproducers of shafts and engine componentsin <strong>the</strong> world.TKMCL recently installed a double motorised headversion of <strong>the</strong> Lynx2000 grinder in its CampoLimpo factory, <strong>for</strong> final crank pin grinding on amachining line <strong>for</strong> 4 and 6 cylinder heavytransport engine crankshafts.Be<strong>for</strong>e shipment, <strong>the</strong> grinder had to go through apre-acceptance stage in <strong>the</strong> <strong>Berco</strong> factories,which involved <strong>the</strong> grinding of a hundred or socrankshafts with capability testing.Capability testing is a st<strong>at</strong>istical technique <strong>for</strong>analysing <strong>the</strong> capability of a production processto comply with requested design/drawingspecific<strong>at</strong>ions. During <strong>the</strong> subsequent machiningof <strong>the</strong> acceptance b<strong>at</strong>ch shafts, dimensional and<strong>for</strong>m checking was done in our labor<strong>at</strong>ory, withparticular reference to <strong>the</strong> roundness, linearity,cylindricity and angular and radial position of<strong>the</strong> crank pins.This type of analysis is particularly stringent as itrequires high precision machining with stabilityover time.The machine passed <strong>the</strong> test and was shipped. InOctober our engineers, working toge<strong>the</strong>r withTKMCL engineers, completed <strong>the</strong> install<strong>at</strong>ionand started production with <strong>the</strong> grinder.The machine installed, a Lynx2000DW-Crank, is<strong>the</strong> double motorised head version withautom<strong>at</strong>ic workpiece clamping by means offlo<strong>at</strong>ing jaws and is particularly suitable <strong>for</strong>grinding medium ad large size crankshafts.Workpiece drive, in fact, is on both <strong>the</strong> workhead and tailstock side, thus guaranteeinghigh precision control of <strong>the</strong> shaft positionduring machining.The special fe<strong>at</strong>ures of this machine mean th<strong>at</strong><strong>the</strong> workpiece rot<strong>at</strong>ion and <strong>the</strong> position ofwheel in its orbital movement make it possibleto obtain extremely high precision in <strong>the</strong> crankpin roundness.With <strong>the</strong> conviction th<strong>at</strong> this <strong>first</strong> order will be<strong>the</strong> basis <strong>for</strong> fur<strong>the</strong>r collabor<strong>at</strong>ion between <strong>the</strong>two companies in <strong>the</strong> development ofsubsequent production-line crankshaft grindersdesigned to customer specific<strong>at</strong>ions, we wishto thank TKMCL as of now <strong>for</strong> <strong>the</strong> opportunity<strong>the</strong>y have given us.We would also like to take this opportunity tothank Scuderia Ferrari, who installed aLynx2000 in 2004 <strong>for</strong> machining F1 singlese<strong>at</strong>ercrankshafts. The continuousdevelopment of <strong>the</strong> machining process, in fact,allows us to extend our knowledge and fur<strong>the</strong>rrefine grinding technology in a market whereabsolute quality has no limits.Orazio Cappell<strong>at</strong>oDesign Service DivisionBN56 > december 200811

WHATEVER'S ON TOP...WE'LL TAKE CARE OF THE BOTTOMBERCO S.p.A.A Company of ThyssenKrupp TechnologiesVia 1° Maggio, 237Copparo (FE) 44034 - ItalyTel. +39 0532 864111Fax +39 0532 864259www.berco.commarketing@berco.com