Biomek® Cell Workstation - Beckman Coulter

Biomek® Cell Workstation - Beckman Coulter

Biomek® Cell Workstation - Beckman Coulter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

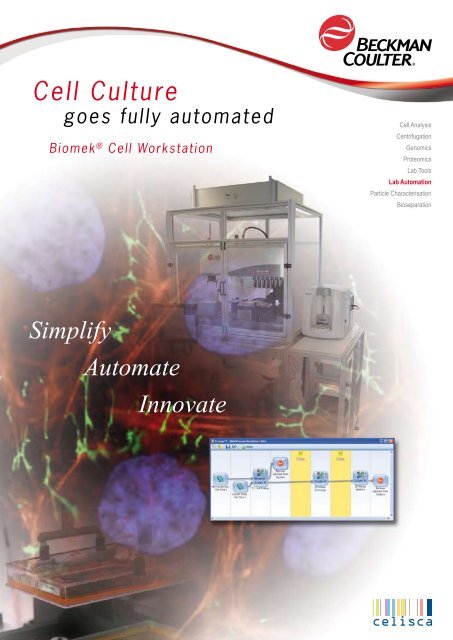

<strong>Cell</strong> Culturegoes fully automatedBiomek ® <strong>Cell</strong> <strong>Workstation</strong><strong>Cell</strong> AnalysisCentrifugationGenomicsProteomicsLab ToolsLab AutomationParticle CharacterisationBioseparationSimplifyAutomateInnovate

Biomek ®<strong>Cell</strong> <strong>Workstation</strong>Seeding<strong>Cell</strong>MaintenanceFeedingAn essential prerequisite in high throughputand high content screening , stem cell research,cell therapy, tissue engineering and productionof biopharmaceuticals is the permanent culturingand production of cells.<strong>Cell</strong>-based assays require cells of consistent qualityto reduce inter-assay variability.Production cell lines must be optimized andcontinuously monitored for consistent quality oftheir products.Passaging<strong>Cell</strong>ExpansionHarvestingCountingCountingPlating<strong>Cell</strong>ProductionPoolingMaintaining living cells in continuous cultureand managing multiple cell lines with differentrequirements in parallel is not an easy task.<strong>Cell</strong> culture is a complex process consisting ofmultiple tasks including cell seeding, growing, harvesting,counting and passaging. Processes mayrun for weeks or months and thus are demandingspecifically in terms of maintaining sterilityand tracking all relevant information.Integrated Biomek ® <strong>Workstation</strong>s for research andproduction have been developed to specificallyaddress automation of cell culture media optimization,hybridoma selection, production cell line optimizationand fully automated monoclonal antibody production.Biomek ® <strong>Cell</strong> <strong>Workstation</strong> is the latest additionto this range of cellular systems and was developedin cooperation between Celisca and <strong>Beckman</strong> <strong>Coulter</strong>.

Process toSolutionSoftware• SAMI ® Process Managementsoftware to organize paralleland interleaved processes.Includes a calendar view tosimplify laboratory resourcemanagement.Biomek ® <strong>Cell</strong> <strong>Workstation</strong> enables fully automated cell seeding,growth rate monitoring and quality control, cell harvesting andplating into microtiter plates.Different cell lines can be cultured in parallel without user interventionover days, weeks or even months. Advanced softwarecontrol allows true 24/7 operation.Monolayer <strong>Cell</strong> Culture Processcell culture flask,confluentmonolayer of cell10 ml PBS toremove cell culturemedium/serum1 ml trypsin/EDTA oncell monolayer todetach cells• SAMI ® Process Definition Editorenables users to graphically definecomplex processes consistingof multiple tasks.• Intuitive graphic editor to defineand schedule individual tasks indetail. Integrated data trackingprovides on-the-fly feasibilitychecking of these tasks.incubation (3-5 days)medium10mlbuffer10 ml buffer1 ml trypsinEDTA9 ml cell culturemedium (37°C)10 ml cellsuspensionIncubation(3-10 min, 37°C)• Pipetting actions can be optimizedfor any cell type, liquidclass and and labware type.max. 20 new cellculture flasks5 (5x10 cells)3 microplates,96 wells,30.000 cells/wellBiomek ® <strong>Cell</strong> <strong>Workstation</strong> is based on the Biomek ® liquid handlerand includes new hard- and software components to automatecell culture applications.The system can be used with both adherent and suspensioncell cultures and can be easily optimized for different growthcharacteristics. Advanced planning and scheduling tools allowmultiple tasks such as cell line expansion and media exchangeto occur simultaneously.15 ml cell culturemedium per flask0,5 ml cell suspensionin new flasks150 l mediumper well33 l cell suspensionper well0,5 ml cellsuspension9,5 ml cellsuspension (ca.10 7 cells)cell counting,viability test• Unique integrated data management,i.e. tracking, logging andreporting. Any information aboutany sample, well, or plate isregistered in a database andavailable for later use. Labwarereports provide information aboutevery single plate in the systemat any point of time.• Data management systemincludes SQL viewer for easyLIMS connectivity.

Process toSolutionThe software components of Biomek ® <strong>Workstation</strong>enable users to run and monitor complex processes over weeksand months. Biomek ® <strong>Workstation</strong> utilizes the Biomek ® liquid handler’s integrated SQL databaseto ensure integrity of all process steps. <strong>Beckman</strong> <strong>Coulter</strong>’s data acquisition and reporting tool is an integralpart of any Biomek ® <strong>Workstation</strong> system. Data acquisition and reporting insures data integrity between tasksand utilizes the integrated SQL database. These data management toolsallow tracking of locations for every single plate in the system at anypoint of time. SAMI ® Process Management Software includes a viewof future, current and completed tasks within the system. Thisinterface provides easy access to more detailed reports, includingdetailed labware reports.Easy to use...At the same time, the software system provides flexibility for the userto optimize each single step within a process and configure entirelynew processes.Planning and Process Definitionand OptimizationSAMI ® Process Definition Editor is an intuitivegraphical user interface to map taskswithin a complete process.Any SAMI ® EX task is available as a buildingblock for new processes or process variations.... to flexibleTask Definition and OptimizationBiomek ® <strong>Cell</strong> <strong>Workstation</strong> includes <strong>Beckman</strong> <strong>Coulter</strong>’sSAMI ® EX optimizing scheduler to define and runindividual tasks in any cell cultivation process.New tasks can be developed on a simulation systemwithout interfering with running processes.Pipetting OptimizationAny pipetting action, e.g speed andtip motion path can be optimizedfor any type of labware and cell line.More OptionsThe Biomek ® <strong>Cell</strong> <strong>Workstation</strong> is a modular systemthat can be tailored to your specific needs. Systems can rangefrom small footprint workstations for simple cell seeding and feeding tomultiple workstation configurations for complex processes such as fully automated monoclonalantibody production.• Integration of large capacity CO 2Incubators with optional customization for specific environmentalcontrol needs• Expanded liquid handling capability including multichannel pipetting for 96- or 384 well plates• Integration of devices for a variety of cell growth characteristics• Integration of high performance plate readers such as <strong>Beckman</strong> <strong>Coulter</strong>’s Paradigm Detection Platform• Integration of <strong>Beckman</strong> <strong>Coulter</strong>‘s Flow Cytometry instruments for high content cell analysis• Integration of analyzers for quality control of biopharmaceutical proteins• Fully automated system for cell fusion in monoclonal antibody production• Options for controlled rate cell freezing and media collection in cell line optimization systems

Biomek ® <strong>Cell</strong><strong>Workstation</strong>Biomek ® <strong>Cell</strong> <strong>Workstation</strong> is based upon <strong>Beckman</strong> <strong>Coulter</strong>’sBiomek ® Liquid Handler and provides modular integration ofcomponents for fully automated cell culture in microplatesand automation friendly tissue culture flasks.www.beckmancoulter.com/labautomat3D TiltALP for culture flask handlingTiltALP for multiwell plates189 slot CO 2incubator for cell growthdual slot shaking incubator• Biomek ® NX P for liquid handling and labware transport onworkstation deck provides small volume handling with highaccuracy and precision• Sterile enclosure with HEPA filtration and laminar flow• Integrated CO 2incubator• Barcode scanning for labware registration and confirmatory readsBarcodes and other labware properties are tracked through theentire process• Integrated Vi-CELL ® <strong>Cell</strong> Viability Analyzer generates cell countand viability data to normalize cell densities in assay plates• Proprietary devices such as the 3D tilting-clamping-tapping ALP• On-deck shaking incubator for trypsinization / cell dissociationprocedures• Refrigerated multiple media storage with in-line warming• Integrated high volume rapid bulk media dispense• Self refilling disposable reservoirs for on-deck media supply• Media quality control and quality managementplate lift

<strong>Cell</strong> Culture goesfully automatedPart No.CWS 0011DescriptionBiomek ® <strong>Cell</strong> <strong>Workstation</strong>Biomek ® <strong>Cell</strong> <strong>Workstation</strong> SpecificationsHeight2.615 cmWidth1.800 cmDepth1.260 cmPower Requirements 50/60 Hz, 100-240 VACSufficient to support 181.4 kg (400 lb)ion®B I O M E K P I P E T T I N G P E R F O R M A N C E S P E C I F I C AT I O N SS PA N-8 S Y S T E M STransfer Span-8 Tip Accuracy PrecisionVolume Syringe Volume Types ± % < %0.5 µL 250 µL P20, Fixed 60 mm 5 101 µL 250, 500, 1000 µL P20, P50, Fixed 60 mm 3 75 µL 250, 500, 1000 µL P20, Fixed 60 mm 3 510 µL 500 µL P50, P250 3 550 µL 500 µL P250 3 5100 µL 500 µL P250, P1000 3 5250 µL 500 µL P1000 2 2950 µL 1000 µL P1000 1 1M U LT I C H A N N E L S Y S T E M STransfer Multichannel Tip Accuracy PrecisionVolume Configuration Types ± % < %0.5 µL 384 P30 3 71 µL 96 & 384 P20, P50, P30 3 55 µL 96 & 384 P20 & P30 3 5<strong>Beckman</strong> <strong>Coulter</strong> and Celisca are able to provide further customizationof Biomek ® <strong>Cell</strong> <strong>Workstation</strong> specific to your needs.Please contact your <strong>Beckman</strong> <strong>Coulter</strong> representative to learn more aboutautomated cell culture systems, cellular analysis, quality control inproduction of biopharmaceuticals or genetic analysis tools.Our Solutions for your Automation!Biomek ® 30001- or 8-Channel PipettorBiomek ® NX pSpan-8 or (96) 384-channelpipetting <strong>Workstation</strong>Biomek ® FX p2 independent pod-systems forSpan-8 or multichannel (96/384)Czech Republic, Prague (420) 267 00 85 13Eastern Europe, Middle East, North Africa, South West Asia: Switzerland, Nyon (41) 22 365 3707France, Villepinte (33) 1 49 90 90 00 Germany, Krefeld (49) 2151 33 35India, Mumbai (91) 22 3080 5101 Italy, Cassina de’ Pecchi, Milan (39) 02 953921Netherlands, Mijdrecht (31) 297 230630 South Africa/Sub-Saharan Africa, Johannesburg (27) 11 805 2014/5Spain, Madrid (34) 91 3836080 Sweden, Bromma (46) 8 564 85 900 Switzerland, Nyon (41) 0800 850 810Turkey, Istanbul (90) 216 309 1900 UK, High Wycombe (44) 01494 441181BR-4501BREU