Technical Manual - Plastorgomma Service

Technical Manual - Plastorgomma Service

Technical Manual - Plastorgomma Service

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

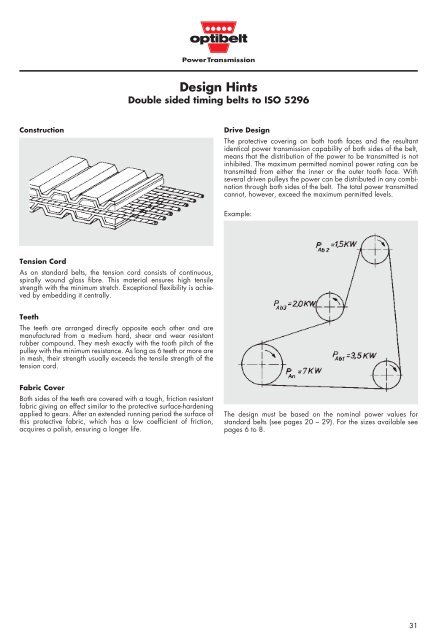

Construction<br />

Tension Cord<br />

As on standard belts, the tension cord consists of continuous,<br />

spirally wound glass fibre. This material ensures high tensile<br />

strength with the minimum stretch. Exceptional flexibility is achieved<br />

by embedding it centrally.<br />

Teeth<br />

The teeth are arranged directly opposite each other and are<br />

manufactured from a medium hard, shear and wear resistant<br />

rubber compound. They mesh exactly with the tooth pitch of the<br />

pulley with the minimum resistance. As long as 6 teeth or more are<br />

in mesh, their strength usually exceeds the tensile strength of the<br />

tension cord.<br />

Fabric Cover<br />

Both sides of the teeth are covered with a tough, friction resistant<br />

fabric giving an effect similar to the protective surface-hardening<br />

applied to gears. After an extended running period the surface of<br />

this protective fabric, which has a low coefficient of friction,<br />

acquires a polish, ensuring a longer life.<br />

Design Hints<br />

Double sided timing belts to ISO 5296<br />

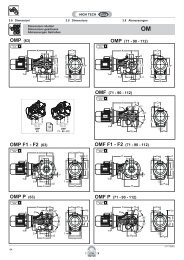

Drive Design<br />

The protective covering on both tooth faces and the resultant<br />

identical power transmission capability of both sides of the belt,<br />

means that the distribution of the power to be transmitted is not<br />

inhibited. The maximum permitted nominal power rating can be<br />

transmitted from either the inner or the outer tooth face. With<br />

several driven pulleys the power can be distributed in any combination<br />

through both sides of the belt. The total power transmitted<br />

cannot, however, exceed the maximum permitted levels.<br />

Example:<br />

The design must be based on the nominal power values for<br />

standard belts (see pages 20 – 29). For the sizes available see<br />

pages 6 to 8.<br />

31