• transversal unevenness of the pavement,• centre distance of the tyres in the dual assembly.For the theoretical case with equally distributed loads but different contact stresses,Molzer found that the maximum distress factor (at the bottom of the asphaltic layers)occurs close to the centre of the most highly inflated tyre. This maximum distress factorwas found to be dependent mainly on the pressure of this most highly inflated tyre (at acertain wheel load), and almost independent of the inflation pressure of the other tyre.For the theoretical case with unequal loads but equal contact stresses, Molzer found thatthe thinner pavement was less sensitive to load imbalance than the thicker pavements. Healso found that the sensity to load imbalance for all pavements increases with increasingcontact stress. Finally, he found that the thinner pavements are much more sensitive to themagnitude of the contact stress.The first two factors above were investigated only as theoretical cases to differentiate theeffects of load and pressure. Molzer notes that unequal inflation pressures in a dual tyreassembly not only give rise to higher contact stresses under the most highly inflated tyre,but also to increased stiffness of that tyre and higher loads on that tyre. He citesZahnmesser (1981) who determined the load difference for (then) common radial tyreassemblies (10R20 to 13R22.5) as a function of inflation pressure difference. Zahnmesserfound that 50.5% < R 1 /Q < 51% for 1 bar pressure difference, and 51.2% < R 1 /Q < 52.5%for 2 bar pressure difference, so a substantial difference in pressure only gives smalldifferences in load. Molzer used worst case R 1 /Q values of 55% and 57.5 in hiscalculations, corresponding to pressure differences of more than 3 to 4 bar, orincorporating load differences due to other factors, such as differing tyre wear.Transverse unevenness (rutting) of the pavement may cause unequal load sharing becauseit may cause one tyre (outside or up the slope of the rut) to be compressed more than theother (at the bottom or down the slope of the rut), see Figure 4.15. Molzer determined themaximum difference in tyre compression ∆y in mm for a dual tyre assembly with 0.34centre distance between the tyres, on about 30 measured rut profiles. Linear regression onthis data yielded ∆y = 0.67*RD, where RD is the rut depth in mm. The worst-case relationon the data was ∆y = 0.92*RD. He then again cited Zahnmesser (1981), who found that60% < R 1 /Q < 63% for ∆y = 20 mm (R 1 /Q ≈ 0.6* ∆y). However, Molzer takes anotherworst case approach and uses R 1 /Q = 0.7*∆y or R 1 /Q = 0.75*∆y. He then combines thesedata with a rut depth development according to RD = A + B ∗ t , and calculates the timeaveragedvalue of R 1 /Q until a maximum allowable rut depth of 20 or 30 mm. For amaximum rut depth of 20 mm, he finds R 1 /Q ≈ 56.8%, using the minimum values of hisparameters above. (For 30 mm maximum rut depth, he finds R 1 /Q ≈ 65%, using themaximum parameter values.)Combining the load imbalance due to pressure differences and due to transverseunevenness, Molzer finds R 1 /Q ≈ 62% for 20 mm maximum rut depth and R 1 /Q ≈ 72.5%for 30 mm maximum rut depth. He then proceeds his calculations with a value of R 1 /Q ≈75% (meaning that one tyre carries three times as much load as the other).However, this value is unrealistically high, because of the following reasons:• because of aquaplaning dangers, the maximum allowable rut depth in Europe isgenerally around 20 mm, and not 30 mm,112version 29 November 2001

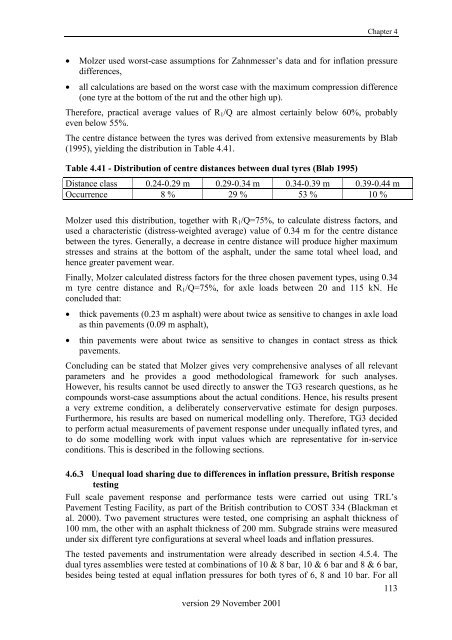

Chapter 4• Molzer used worst-case assumptions for Zahnmesser’s data and for inflation pressuredifferences,• all calculations are based on the worst case with the maximum compression difference(one tyre at the bottom of the rut and the other high up).Therefore, practical average values of R 1 /Q are almost certainly below 60%, probablyeven below 55%.The centre distance between the tyres was derived from extensive measurements by Blab(1995), yielding the distribution in Table 4.41.Table 4.41 - Distribution of centre distances between dual tyres (Blab 1995)Distance class 0.24-0.29 m 0.29-0.34 m 0.34-0.39 m 0.39-0.44 mOccurrence 8 % 29 % 53 % 10 %Molzer used this distribution, together with R 1 /Q=75%, to calculate distress factors, andused a characteristic (distress-weighted average) value of 0.34 m for the centre distancebetween the tyres. Generally, a decrease in centre distance will produce higher maximumstresses and strains at the bottom of the asphalt, under the same total wheel load, andhence greater pavement wear.Finally, Molzer calculated distress factors for the three chosen pavement types, using 0.34m tyre centre distance and R 1 /Q=75%, for axle loads between 20 and 115 kN. Heconcluded that:• thick pavements (0.23 m asphalt) were about twice as sensitive to changes in axle loadas thin pavements (0.09 m asphalt),• thin pavements were about twice as sensitive to changes in contact stress as thickpavements.Concluding can be stated that Molzer gives very comprehensive analyses of all relevantparameters and he provides a good methodological framework for such analyses.However, his results cannot be used directly to answer the TG3 research questions, as hecompounds worst-case assumptions about the actual conditions. Hence, his results presenta very extreme condition, a deliberately conservervative estimate for design purposes.Furthermore, his results are based on numerical modelling only. Therefore, TG3 decidedto perform actual measurements of pavement response under unequally inflated tyres, andto do some modelling work with input values which are representative for in-serviceconditions. This is described in the following sections.4.6.3 Unequal load sharing due to differences in inflation pressure, British responsetestingFull scale pavement response and performance tests were carried out using TRL’sPavement Testing Facility, as part of the British contribution to <strong>COST</strong> <strong>334</strong> (Blackman etal. 2000). Two pavement structures were tested, one comprising an asphalt thickness of100 mm, the other with an asphalt thickness of 200 mm. Subgrade strains were measuredunder six different tyre configurations at several wheel loads and inflation pressures.The tested pavements and instrumentation were already described in section 4.5.4. Thedual tyres assemblies were tested at combinations of 10 & 8 bar, 10 & 6 bar and 8 & 6 bar,besides being tested at equal inflation pressures for both tyres of 6, 8 and 10 bar. For allversion 29 November 2001113