- Page 1 and 2:

European Co-operation in the Field

- Page 3 and 4:

Table of ContentsTable of ContentsE

- Page 5 and 6:

Chapter 4Chapter 4 : Pavement Wear

- Page 7 and 8:

Chapter 44.2 SCOPE OF THE WORKHisto

- Page 9 and 10:

Chapter 44.3 DEFINITION OF THE PROB

- Page 11 and 12:

Chapter 4It is observed 50 that the

- Page 13 and 14:

Chapter 4RimTyresFigure 4.4 - Tyre

- Page 15 and 16:

Chapter 4• Trucks may travel incr

- Page 17 and 18:

Chapter 4Table 4.2 - Length of Prim

- Page 19 and 20:

Chapter 4be noted that not all coun

- Page 21 and 22:

Chapter 4lesser effect than the loa

- Page 23 and 24:

Chapter 4(side view)1. load scaleor

- Page 25 and 26:

Chapter 44.3.4.4 The contact area s

- Page 27 and 28:

Chapter 4Figure 4.10 shows a simpli

- Page 29 and 30:

Chapter 4others). These different g

- Page 31 and 32:

Chapter 44.3.5.2 Pavement distress

- Page 33 and 34:

Chapter 44.3.6 Load effects4.3.6.1

- Page 35 and 36:

Chapter 4arrives within that period

- Page 37 and 38:

Chapter 4inflationdifferencepressur

- Page 39 and 40:

Chapter 4Mechanistic-empirical perf

- Page 41 and 42:

Chapter 4distressN2N1D1D2load cycle

- Page 43 and 44: Chapter 4pressure, diameter, contac

- Page 45 and 46: Chapter 4Table 4.10 - Summary of re

- Page 47 and 48: Chapter 4Table 4.11 - Properties of

- Page 49 and 50: Chapter 4difference in tyre pressur

- Page 51 and 52: Chapter 4Table 4.14 - Footprint wid

- Page 53 and 54: Chapter 4• Drive axle, twin tyres

- Page 55 and 56: Chapter 4for a given rim diameter,

- Page 57 and 58: Chapter 4Figure 4.21- Setup for whe

- Page 59 and 60: Chapter 4Table 4.17 - Unequal load

- Page 61 and 62: Chapter 44.4.9.3 Tekscan Measuremen

- Page 63 and 64: Chapter 4Figure 4.30 - 295/60R22.5

- Page 65 and 66: Chapter 4The following conclusions

- Page 67 and 68: Chapter 4An extensive identificatio

- Page 69 and 70: Chapter 4different diameter tyres.

- Page 71 and 72: Chapter 4pavement surface, for the

- Page 73 and 74: Chapter 4Table 4.21 - Maximum subgr

- Page 75 and 76: Chapter 44.50Initial readings amend

- Page 77 and 78: Chapter 42.0m 3.5m 2.0m 2.0m 3.5m2.

- Page 79 and 80: Chapter 4• the maximum rut depth

- Page 81 and 82: Chapter 4measurements but needs fur

- Page 83 and 84: Chapter 4Figure 4.47 - Manège de F

- Page 85 and 86: Chapter 4(0.48 m depth) and near th

- Page 87 and 88: Chapter 4this question was to compa

- Page 89 and 90: Chapter 4The conclusion of the anal

- Page 91 and 92: Chapter 46050Stress [kPa]403020100B

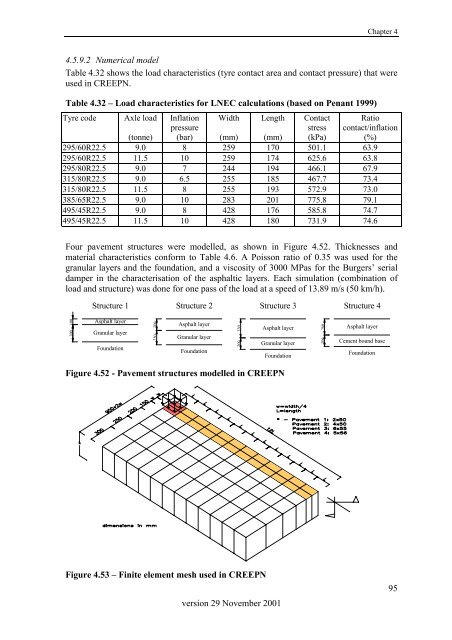

- Page 93: Chapter 4Length contact areaDirecti

- Page 97 and 98: Chapter 4Table 4.33 - Practical per

- Page 99 and 100: Chapter 4Practical permanent deform

- Page 101 and 102: Chapter 4• “Pressure ratio” i

- Page 103 and 104: Chapter 4also may be that the param

- Page 105 and 106: Chapter 41.21.0Ln Distress ratio pr

- Page 107 and 108: Chapter 44.5.10.7 Regression result

- Page 109 and 110: Chapter 44.5.10.8 Summary and concl

- Page 111 and 112: Chapter 44.6 EFFECTS OF UNEQUAL LOA

- Page 113 and 114: Chapter 4• Molzer used worst-case

- Page 115 and 116: Chapter 4Table 4.43 - Vertical subg

- Page 117 and 118: Chapter 4Table 4.47 - Practical per

- Page 119 and 120: Chapter 42544 km (divided over 1998

- Page 121 and 122: Chapter 44.7 EFFECTS OF DYNAMICS4.7

- Page 123 and 124: Chapter 43. Measurements of dynamic

- Page 125 and 126: Chapter 4Figure 4.65 - Truck tyre o

- Page 127 and 128: Chapter 4road. The results of the D

- Page 129 and 130: Chapter 4Table 4.55 - Calculated st

- Page 131 and 132: Chapter 4The wide base single tyre

- Page 133 and 134: Chapter 4In the two tables below th

- Page 135 and 136: Chapter 44.8.3 Evaluation and sensi

- Page 137 and 138: Chapter 4fatigue• The total conta

- Page 139 and 140: Chapter 4Like for the towed axles,

- Page 141 and 142: Chapter 4Table 4.66 - Overview of a

- Page 143 and 144: Chapter 44.8.6 Specification of roa

- Page 145 and 146:

Chapter 4Table 4.67 Values of Axle

- Page 147 and 148:

Chapter 4Table 4.70 Proposed TCF li

- Page 149 and 150:

Chapter 44.9 SUMMARY, CONCLUSIONS A

- Page 151 and 152:

Chapter 4values were calculated as

- Page 153 and 154:

Chapter 4334 established good techn

- Page 155 and 156:

Chapter 4The development of the Tyr

- Page 157 and 158:

Chapter 4• From the same viewpoin

- Page 159 and 160:

Chapter 4DBMdistressDLCdouble axled

- Page 161 and 162:

Chapter 4pavementPCCperformanceperm

- Page 163 and 164:

Chapter 4tandem axleTCFtfthermal cr

- Page 165 and 166:

Chapter 44.11 REFERENCESAddis RR (1

- Page 167 and 168:

Chapter 4rutting from new single ty

- Page 169 and 170:

Chapter 4Molzer C (1998) Revision o