Advanced In-Wheel Electric Propulsion Technology - Protean Electric

Advanced In-Wheel Electric Propulsion Technology - Protean Electric

Advanced In-Wheel Electric Propulsion Technology - Protean Electric

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

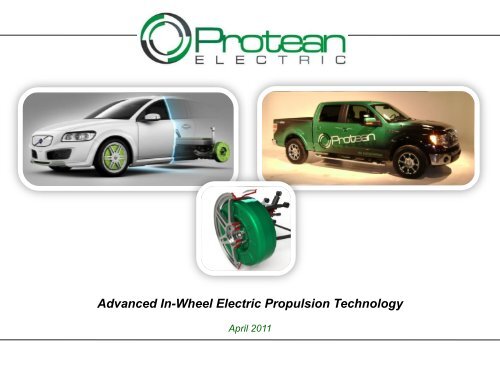

<strong>Advanced</strong> <strong>In</strong>-<strong>Wheel</strong> <strong>Electric</strong> <strong>Propulsion</strong> <strong>Technology</strong>April 2011www.proteanelectric.com

<strong>In</strong>troductionwww.proteanelectric.com 2

<strong>Protean</strong> <strong>Electric</strong>: Company Overview<strong>Protean</strong> <strong>Electric</strong>:• Clean technology company• Leading global supplier of in-wheel electricmotor technologyProduct Offering:• <strong>In</strong>-wheel electric motor designed for highvolumemanufacturing as simple, low costsolution, featuring built-in inverter andcontrol electronicsPerformance and Design Opportunities:• Suitable for 2 and 4-wheel drive,commercial vehicles, pickups, SUVs andfamily passenger cars – vehicles customersprefer and OEMs profit from<strong>Protean</strong> Drive direct drive inwheelmotor with integratedpower electronics/ inverterwww.proteanelectric.com 3

Company Overview<strong>Protean</strong><strong>Electric</strong> Ltd(UK)<strong>Protean</strong> Holdings Corp(US)<strong>Protean</strong><strong>Electric</strong><strong>In</strong>c (US)<strong>Protean</strong><strong>Electric</strong> GmbH(Germany)CorporateStructureEmployeesProductsTestVehiclesFunding toDateU.S. holding company, operatingsubsidiaries in UK, US andGermany83 (73 engineers)<strong>Protean</strong> Drive<strong>In</strong>-<strong>Wheel</strong> Motors with <strong>In</strong>tegrated<strong>In</strong>verter.System ECU (SECU)<strong>In</strong>dependent Motor ControlSoftwareVolvo ReCharge Plug-in SHEVFord F150 EVVauxhall Vivaro PHEVGAC Trumpchi EVOak <strong>In</strong>vestment Partnerswww.proteanelectric.com 4

<strong>Wheel</strong> Assembly – Exploded View<strong>Wheel</strong> BearingRotorVehicle SuspensionConventional <strong>Wheel</strong> RimStatorCoils and Power Electronics/Micro <strong>In</strong>vertersPermanent Magnetswww.proteanelectric.com 5

Sub-Motor ArchitectureUnique Distributed Drive ArchitectureSub-Motors = Multiple autonomous motors each with its own micro-inverter and sharing acommon rotor - Patent grantedwww.proteanelectric.com 7

System Control ArchitectureAccelerator,brake, gearselect, vehiclespeed, batterystatus etc.)Vehicle ECU (SECU)TorqueDemand<strong>Protean</strong> High-<strong>In</strong>tegrity SystemControl Software.ISO26262 Processfor SafetyCertificationMotor 1Motor 2Motor 3Motor 4www.proteanelectric.com 8

Conventional IC Engine Vehicle Layoutwww.proteanelectric.com9

PowerElectronics/<strong>In</strong>verter<strong>Electric</strong>MotorConventional <strong>Electric</strong> Vehicle LayoutBatteryPackwww.proteanelectric.com10

<strong>Protean</strong> Drive Vehicle Layout<strong>Protean</strong> Drive<strong>Protean</strong> DriveBatteryPack<strong>Protean</strong> Drive<strong>Protean</strong> Drivewww.proteanelectric.com11

CompetitiveAdvantageswww.proteanelectric.com 12

Key AdvantagesPower and Torque• Unique patented distributed drive architecture• High torque direct-drive (no gearing)• Scalable to support wide range of vehiclesSafety• System redundancy through distributed architecture• Order of magnitude benefits compared to alternativesolutionsPackaging <strong>In</strong>tegration• No need for additional power electronics (inverterintegrated in motor)• No need for additional mechanical components (e.g.gears, differential, drive-shafts)www.proteanelectric.com 13

Key AdvantagesCost• Reduced part count for total vehicle• Less complex, reduced assembly costs• Total system equal to conventional drive train cost• Enables new design paradigms for future EVs, furtherreducing costsCompatibility, Validation and Time to Market• <strong>In</strong>tegrates easily into existing vehicle platforms, limited chassismodifications• Through-the-road hybrid (TTRH) configurations for light commercialand performance vehicle applications• Selectable driving modes (conventional ICE, blended and EV)addresses market concerns over reliability, performance and rangewww.proteanelectric.com 14

Attributes <strong>Protean</strong> CompetitorsTorqueDensity<strong>In</strong>-wheelDirect DriveSafety<strong>In</strong>tegratedelectronicsEase of UsePatentProtected- 26Nm/kg & 53Nm/l for motor + inverter- Highest torque density EV motor available- Designed for in-wheel deployment- No gearing required- Reduced part count- Improved safety and reliability- ISO26262 functional safety- Multiple levels of redundancy- No single failure can cause unsafe condition(enabled by sub-motor architecture)- Enables sub-motor modularity- Compatibility with volume production processes- Can be fitted to existing vehicle platforms- Broad patent portfolioKey AdvantagesUQM 6Nm/kg; 13Nm/lACP 5Nm/kg; 5.5Nm/lNot suitable for in-wheeldeploymentGearing required to increasetorqueNo known competitor offersISO26262 safety compliance formulti-motor applications and noclear way for standard 3-phasemotors to achieve this.Separate inverter with no submotormodularity; large powercomponents not compatible withautomated productionMajor vehicle tear-up required forretrofitLittle innovation in core motortechnologywww.proteanelectric.com 15

Packaging: Fully-<strong>In</strong>tegrated SolutionConventional Solution<strong>Protean</strong> <strong>Electric</strong>2WD Drive-train Volume (litres)92.08 (in chassis)2WD Drive-train Volume (litres)30.48 (in wheel)2WD Drive-train Weight110kg2WD Drive-train Weight62kgSeparate power electronics7.3” x 12.3” x 30”<strong>In</strong>tegrated power electronics8 units, 3” x 2.5” x 0.5”each<strong>In</strong>-board motor12" diameter x 15" deep<strong>In</strong>-wheel motor16.5” diameter x 4.5” deepwww.proteanelectric.com 16

Packaging: It Fits with Room To SpareConventional Solution<strong>Protean</strong> <strong>Electric</strong><strong>Protean</strong> Drivemotor with<strong>In</strong>tegrated<strong>In</strong>verter andcontrolelectronicsMotor Gearbox & Differential DriveshaftAC <strong>Propulsion</strong> power electronics(AC <strong>Propulsion</strong> test vehicle)<strong>Protean</strong> <strong>Electric</strong> in-wheel motors(Volvo ReCharge)www.proteanelectric.com17

DevelopmentHistorywww.proteanelectric.com 18

New <strong>Technology</strong>?1898 Ferdinand Porsche designs thefirst hub motor driven carFleet of 300 electric delivery vehicles,all using in-wheel motors1901 Lohmer-Porsche race car – 4Wdelectric using in-wheel motorsHybrid car with electric motors in thewheels, and Porsche’s 1901 race car ofsimilar designwww.proteanelectric.com 19

Company History1963198920012003200420062007CompanyEstablished,pioneeredprintedarmaturemotorsDevelopedpoweredwheelchairmotorsandcontrollersFocus onhighperformancemotors anddrivesDevelopmentfocuses onwheelmotortechnologyFirst PMLmulti-wheelwheelmotordrivenvehicleFirst publicdebut of theHi-PaDrivetechnologyFirst Hi-PaDriveequippedOEM vehicleshown to thepublicwww.proteanelectric.com20

Company History (cont’d)20082009200920102011.....<strong>Wheel</strong>motordevelopmentcontinuesPMLFlightlinksplitsNew UK <strong>Protean</strong><strong>Electric</strong>developmentcentreNew CEO,Expansioninto US &Germanywww.proteanelectric.com21

Example VehicleApplicationswww.proteanelectric.com22

Example Vehicle ApplicationsYou don’t have to be small to be green!Complete range of family sized vehicles sedans, SUVs, light commercial and pick-uptrucks, all profitable for OEMsSupports plug-in SHEVs, PHEVs, BEVs, Through-the-Road HybridsGAC TrumpchiVolvo ReChargeFord F150Vauxhall Vivaro• 2WD EV• 2 <strong>Protean</strong> <strong>In</strong>-<strong>Wheel</strong>motors• Gross vehicleweight: 1,495kg(3,300 lb)• Plug in SHEV• 4 <strong>Protean</strong> <strong>In</strong>-<strong>Wheel</strong>motors• Gross vehicleweight: 1,640kg(3,616 lb)• BEV• 4 <strong>Protean</strong> <strong>In</strong>-<strong>Wheel</strong>motors• Gross vehicleweight: 2,472kg(5,450 lb)• Through -The-RoadHybrid• 2 <strong>Protean</strong> <strong>In</strong>-<strong>Wheel</strong>motors• Gross vehicle weight:2,700kg (5,953 lb)www.proteanelectric.com23

GAC E-Trumpchi2WD full electric drive vehicle version of the new GAC TrumpchiUses 2 <strong>Protean</strong> Drive PD18 in-wheel motorsDebuted at the 2010 Guangzhou Auto ShowGross vehicle weight:1,495kg (3,300 lb)220hp rear wheel driveall electric vehiclewww.proteanelectric.com24

Volvo ReCharge4WD full electric drive vehicle conversion of a Volvo C30Uses 4 <strong>Protean</strong> Drive PD18 in-wheel motorsDebuted on Volvo’s stand at the2007 Frankfurt Motor ShowGross vehicle weight:1,640kg (3616 lb).0-60 mph in 5 seconds,over 130 mph top speedwww.proteanelectric.com25

Example Vehicle Application - Volvo ReChargewww.proteanelectric.com26

Ford F150 Pickup TruckFull electric vehicle conversion of 4 wheel drive F150 pickup truckUses 4 <strong>Protean</strong> Drive PD18 in-wheel motorsDebuted on Ford’s stand at the 2008 SEMA showGross vehicle weight:2,472kg (5,450 lb)100mph top speed,over 100 mile rangewww.proteanelectric.com27

Example Vehicle Application - Ford F150www.proteanelectric.com28

Vauxhall Vivaro TTRHJoint project between <strong>Protean</strong> <strong>Electric</strong> and Millbrook Proving Ground (GM’s UKvehicle testing and evaluation centre)2 <strong>Protean</strong> Drive PD18’s mounted to the rear rear in a Through-The-Road-Hybrid(TTRH) layout - enabling a hybrid mode to be added to any existing vehicle55 miles pure electric range, over a 3x increase in fuel economy (114mpg in hybridmode)Debuted at the 2010 Low CarbonVehicle ShowThree driver-selectable operatingmodes.• IC engine only (front wheel drive).• EV only (rear wheel drive).• IC engine + <strong>Electric</strong> motors(four wheel drive).www.proteanelectric.com29

Example Vehicle Application - Vauxhall Vivaro TTRHwww.proteanelectric.com30

Challengeswww.proteanelectric.com31

Challenges<strong>Technology</strong>DevelopmentTorque densityMotor controlPackagingSoftware integrationEnvironmental protectionBrake integrationVibration resistanceABS, TC, stability controlTorque/ speed profileDesign for manufactureCustomerAcceptanceUnfamiliar technologyNot invented here<strong>In</strong>grained prejudicesConservative industryExtremely large companiesEstablished relationshipsEconomic climateTime to MarketCompanyDevelopmentFundingStaff costsTime to marketRapid growthPersonality conflictsCompany culturePartner companiesEconomic climatewww.proteanelectric.com 32

Solutions<strong>Technology</strong>DevelopmentExperienceMany iterationsTestingCertificationSpecialistsImproved designTimePartner CompaniesCustomerAcceptanceProve technologyDemonstration vehiclesMarket reaction<strong>In</strong>ternal championsSupport at many levelsRegulatory pressuresLack of choiceTimeCompanyDevelopmentCulture shiftWilling to accept changePragmatismCommitmentThe right peopleEnthusiasmwww.proteanelectric.com 33

ThePotentialwww.proteanelectric.com 34

Concept CarsVirtually every concept car being designed by today’s automotive designers andautomotive design students use in-wheel motors...www.proteanelectric.com 35

www.proteanelectric.comandrew.vallance@proteanelectric.comwww.proteanelectric.com