Automation and controls 0613.indd - Sharpe® Valves

Automation and controls 0613.indd - Sharpe® Valves

Automation and controls 0613.indd - Sharpe® Valves

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

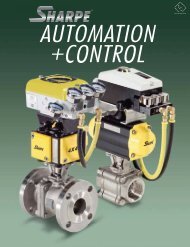

SPN II Pneumatic Actuator• Rack & pinion design• The st<strong>and</strong>ard actuator configuration has a hardanodized aluminum body <strong>and</strong> epoxy coated endcaps• Inside surface finish (Ra 0.4-0.6μm) to minimizefriction <strong>and</strong> to maximize the life of the actuator.• St<strong>and</strong>ard applications for temperature ranges from-4°F to 180°F.• Special options for extreme temperatures (upon request).• Piston bearing made of material with a low frictioncoefficient to avoid metal-on-metal contact, easilyreplaceable for maintenance.• Base drilling, for valve mounting <strong>and</strong> centering,according to ISO 5211/DIN 3337 st<strong>and</strong>ards.• The indicator is designed to remain on the actuatorfor continuous indication when limit switch is notbeing used. (Not available on SPN II 032)• Independent bidirectional travel stop adjustment±5° ensuring precise positioning in all flow <strong>controls</strong>ervices. (Not available on SPN II 032)• Direct mounted solenoid connections according toNAMUR st<strong>and</strong>ards.• Same body <strong>and</strong> end caps for double acting <strong>and</strong>spring return.• Air supply can be dry or lubricated filtercompressed air. Pressure: 40 PSI to 120 PSI• The lubrication carried out by the manufacturerqualifies for a minimum 1,000,000 operations.• Epoxy coating is a deposit of powder on cleans<strong>and</strong>blasted pieces. The chemical process iseasily kept under control <strong>and</strong> after coating, thepieces must be subjected to heat treatment. Epoxypainting of actuators is advised where environmentis strongly aggressive. With the exception ofcertain solvents, epoxy coatings resist acids <strong>and</strong>alkali, <strong>and</strong> also has a good resistance to UV rays.In order to retain its properties, the coating mustnot be scratched.• Multi-function position indicator with NAMUR slotto allow confirmation of position.• The SPN II features inserts to allow easy conversionto many square <strong>and</strong> diamond valve stems. Thereare also double D along with round bores withkeyway inserts for the same actuators for butterfl yapplications. The pinion is drilled deeper thenst<strong>and</strong>ard actuators. The SPN II series has mountingplates for the transition of the bolt circles of theactuator to be used with other industry st<strong>and</strong>ardsfor butterfly valves.• For conditions or applications that dem<strong>and</strong> themost from equipment, Sharpe offers our SPNIIwith chemical nickel plating. These actuatorsare designed to be a cost effective option incomparison to stainless steel actuators. The Nickelplating is done through chemical impregnation toprovide uniform coverage <strong>and</strong> protection. The bathis a mixture of nickel <strong>and</strong> phosphorous to provideexcellent qualities in: hardness, wear resistance,appearance <strong>and</strong> its inherent ability to withst<strong>and</strong>many wash-down applications that actuators withst<strong>and</strong>ard finishes cannot.1SHARPE ® PRODUCTS • TOLL FREE (877) 774-2773 • FAX (708) 562-9250 • www.sharpevalves.com