Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

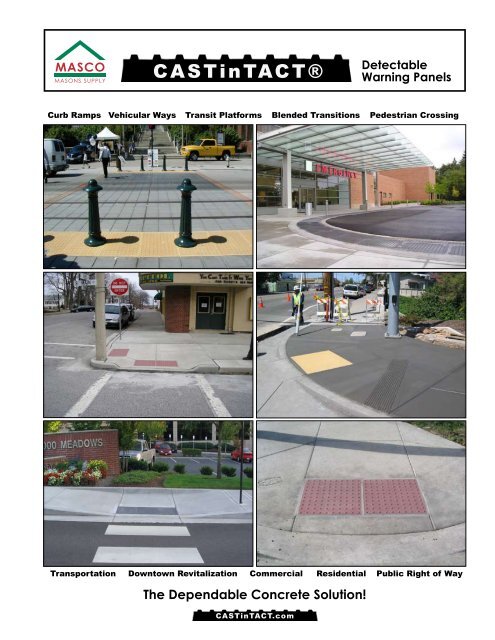

C A S T i n TAC T ®DetectableWarning <strong>Panel</strong>sCurb Ramps Vehicular Ways Transit Platforms Blended Transitions Pedestrian CrossingTransportation Downtown Revitalization Commercial Residential Public Right of WayThe Dependable Concrete Solution!<strong>CASTinTACT</strong>.com

<strong>CASTinTACT</strong>® Standard ColorsCustom colors available on requestColors are approximate, samples available on request.Black YellowSalem Red White<strong>Panel</strong> Specification<strong>Panel</strong> Thickness 1"ReinforcementMonofilament self fibrillating polypropylene /polyethylene structural fiber.Compressive Strength ASTM C 140 9,000 psi averageFlexural Strength ASTM C 140 750 lbs averageWater Absorption ASTM C 140 < 5% averageFreeze ThawResistanceASTM C 1262 (75 cycles)3% NaCIUS Patent No. 6,711,866< 1%Abrasion Resistance ASTM C 799 (1 hour) < .02"Slip Resistance ASTM D 2047 Modified > .8 wet or dry<strong>Panel</strong> Dimensions (Top Face)2.35" Dome Spacing Actual Sizes2' x 2' <strong>Panel</strong> 23.5" width x 24" depth2.5' x 2' <strong>Panel</strong>30.55" width x 24" depth3' X 2' <strong>Panel</strong> 23.5" width x 36" depthDimension Tolerances: +/- 1/8" (width, length, height)<strong>CASTinTACT</strong>® has been successfully used bymany states and cities in the United States.Call for a list of projects in your area.<strong>CASTinTACT</strong>® Advantage:Unique fast "early entry - fresh set" install method.High strength, durable, and crack resistant cementitiousconcrete panels for new construction and retrofit.Versatile, easy to cut and core, use on radiuses, around vault boxes and bollards.Compatible with substrate, same thermal co-efficient of expansion as concrete.Same weight as concrete, preventing floating, voids and tripping hazards.<strong>Panel</strong>s become a structural and integral part of the walking surface.Aesthetic natural slip resistant concrete finish.Easy to clean, maintain and repair.<strong>CASTinTACT</strong>® is offered with a five year limited warrantyand will certify panels to meet or exceed internal standardsas well as previously stated ASTM performance standards.<strong>CASTinTACT</strong>.comJUN 08

<strong>CASTinTACT</strong>®Early Entry - Fresh Set InstallUS Patent No 7,000,361 & 7,121,048& other patents pending12Pour concrete and finish to proper grade.Set INSTALaTACT ® into fresh concrete 8" from curb face.Removal of concrete is fast & easy with a square point shovel.34Remove the INSTALaTACT ® tool and levelconcrete base with wood float.Pre-dampen and parge the back of the panel with<strong>CASTinTACT</strong> ® Premix or fresh concrete.56Set <strong>CASTinTACT</strong> ® with rubber mallet, check slope with level.Finish surrounding concrete flush with panel.Install joints and finish to specifications.78Clean up is fast and easy with stainless steel brushand hydra sponge.<strong>CASTinTACT</strong> ® - THE DEPENDABLE CONCRETE SOLUTION!

C A S T i n TAC T ®DetectableWarning <strong>Panel</strong>sEarly Entry - Fresh Set3.3 CAST IN PLACE INSTALLATION PROCEDURESA. Temperature affects the setting time and rate of strength ofconcrete, standard ACI procedures for storing, mixing, and placingconcrete in hot or cold weather are recommended. See ACI 305“Standards on Hot Weather Concreting," or ACI 306 “Standard onCold Weather Concreting.”B. Provide expansion and control joint width indicated in drawings.All joint materials used follow manufacturer’s directions andinstructions.1. Expansion joints must be carried through all layers of installationmaterials including warning panels, concrete substrate and steelreinforcing. Joints should be spaced typically 8’ to 12’ in bothdirections. All perimeter edges of ramps or blended transitionsshould have expansion joints. (Refer to ACI 360R guidelines fordetails on placement, size and specifications of material)C. Position forms for proper grade, slopes and uniform slab thickness.Consult contract documents for details on reinforcement and jointplacement to prevent random cracking.D. The concrete specified shall conform to contract documentswith a maximum slump of 4”. Concrete shall be poured andfinished to the proper grade and slope prior to warning panelplacement. Concrete thickness shall be increased 1” in depthbeneath area receiving warning panels.E. Consult contract documents for more information on locationsto receive detectable warning panels.1. Monolithic poured curb and sidewalk - place panels 6” to 8”from curb face.2. Existing curbs - place panels 8” from curb face to allow 2” ofnew concrete in front of panels.3. Install across the full width of ramp or blended transition aminimum 24” in depth.F. Recessed panels below finish grade with INSTALaTACT®installation template tool before initial concrete set and level basewith wood float to leave an open surface.G. Pre-dampen back of <strong>CASTinTACT</strong>® panels with potable water.Apply 1/8” thickness of <strong>CASTinTACT</strong>® Wet Set PreMix (3:1 ratio ofpowder to potable water) or (2:1:1 ratio of Portland cement, cleanmasons sand and potable water). Work into textured surfaceon back of panel with rubber float for 100% surface coverage.Alternatively a scrub coat of fresh concrete removed from theINSTALaTACT® tool can be used as a parge coat.surface contact with square edges of panel joints butted together.Base of truncated dome should be flush with adjacent surfaces topermit proper drainage and eliminate tripping hazard betweensurfaces. Tolerance between tactile panels and surroundingsurfaces is 1/16” maximum. Immediately after placement recheckslope and elevation for proper grade.ALTERNATE (EXTREME CLIMATES) Leave a 3/16” gap betweensquare cut panels joints and seal with a compatible elastomericsealant conforming to ASTM C920. Follow sealant’s manufacturer’srecommendations for joint preparation and installation procedures.Protect from traffic until sealant cured.I. Finish surrounding concrete flush with tactile panels. Edgearound panels with 1/8” radius edger, install control joints andfinish in accordance with project specifications.J. Finish joints per specifications. Follow all manufacturer’srecommendations for joint preparation and installationprocedures.K. Clean fresh dried concrete residue off panels with a stainlesssteel wire brush and rinse with clean water and hydra sponge toensure a clean appearance.L. Fresh concrete surrounding tactile panels should be cured inaccordance with ACI 308. Use a curing compound meeting ASTMC 309. PROTECT PANELS WITH PROTECTaTACT OR SIMILAR WHILESPRAYING CURING COMPOUND.3.4 CLEANINGA. Remove all unused material, tools, and equipment. Disposeof properly.B. If the detectable / tactile surface requires, clean the panels inaccordance with <strong>CASTinTACT</strong>® Cleaning and Maintenance Guide.3.5 PROTECTIONProtect the <strong>CASTinTACT</strong>® Warning <strong>Panel</strong> surface from traffic untildesired strength is achieved. If necessary, protect panels withplywood and a underlayment layer of non-staining, non-woven curingblanket until acceptance of work. Secure plywood if needed.Distributed by:H. Install Tactile <strong>Panel</strong>s immediately in fresh concrete and lightlytap panels to grade using a rubber mallet to insure bond and 100%additional information available JUN 08<strong>CASTinTACT</strong>.com

Versatility of <strong>CASTinTACT</strong>® - New Construction and RetrofitINSTALaTACT(US Patent No 7,000,361 & 7,121,048)Unique fast early entry - fresh set installOne man job - 10 minute installCAST in PLACERecess concrete with INSTALaTACT, lock in <strong>CASTinTACT</strong>®panels , install control joints and finish.US Patent No 7,000,361 & 7,121,048 & other patents pending.Thin - Set PaversBlended TransitionEasy to cut and core drill. Use on radiuses,around vaults, bollards, and light standards.Total <strong>CASTinTACT</strong>® Solution - Installation, Durability, and Maintenance.REPAIRaTACT Dome Repair System Replace & Grout<strong>CASTinTACT</strong>.comJUN 08