A Publication of John Deere Power Systems - John Deere Industrial ...

A Publication of John Deere Power Systems - John Deere Industrial ...

A Publication of John Deere Power Systems - John Deere Industrial ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

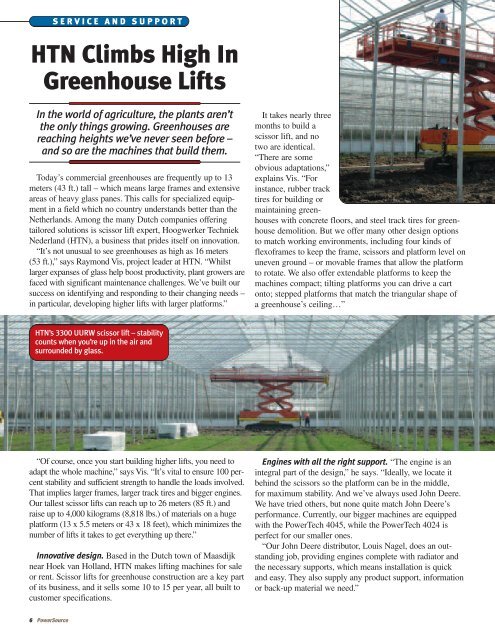

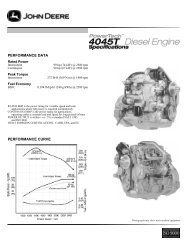

SERVICE AND SUPPORTHTN Climbs High InGreenhouse LiftsIn the world <strong>of</strong> agriculture, the plants aren’tthe only things growing. Greenhouses arereaching heights we’ve never seen before –and so are the machines that build them.Today’s commercial greenhouses are frequently up to 13meters (43 ft.) tall – which means large frames and extensiveareas <strong>of</strong> heavy glass panes. This calls for specialized equipmentin a field which no country understands better than theNetherlands. Among the many Dutch companies <strong>of</strong>feringtailored solutions is scissor lift expert, Hoogwerker TechniekNederland (HTN), a business that prides itself on innovation.“It’s not unusual to see greenhouses as high as 16 meters(53 ft.),” says Raymond Vis, project leader at HTN. “Whilstlarger expanses <strong>of</strong> glass help boost productivity, plant growers arefaced with significant maintenance challenges. We’ve built oursuccess on identifying and responding to their changing needs –in particular, developing higher lifts with larger platforms.”It takes nearly threemonths to build ascissor lift, and notwo are identical.“There are someobvious adaptations,”explains Vis. “Forinstance, rubber tracktires for building ormaintaining greenhouseswith concrete floors, and steel track tires for greenhousedemolition. But we <strong>of</strong>fer many other design optionsto match working environments, including four kinds <strong>of</strong>flex<strong>of</strong>rames to keep the frame, scissors and platform level onuneven ground – or movable frames that allow the platformto rotate. We also <strong>of</strong>fer extendable platforms to keep themachines compact; tilting platforms you can drive a cartonto; stepped platforms that match the triangular shape <strong>of</strong>a greenhouse’s ceiling…”HTN’s 3300 UURW scissor lift – stabilitycounts when you’re up in the air andsurrounded by glass.“Of course, once you start building higher lifts, you need toadapt the whole machine,” says Vis. “It’s vital to ensure 100 percentstability and sufficient strength to handle the loads involved.That implies larger frames, larger track tires and bigger engines.Our tallest scissor lifts can reach up to 26 meters (85 ft.) andraise up to 4,000 kilograms (8,818 lbs.) <strong>of</strong> materials on a hugeplatform (13 x 5.5 meters or 43 x 18 feet), which minimizes thenumber <strong>of</strong> lifts it takes to get everything up there.”Innovative design. Based in the Dutch town <strong>of</strong> Maasdijknear Hoek van Holland, HTN makes lifting machines for saleor rent. Scissor lifts for greenhouse construction are a key part<strong>of</strong> its business, and it sells some 10 to 15 per year, all built tocustomer specifications.Engines with all the right support. “The engine is anintegral part <strong>of</strong> the design,” he says. “Ideally, we locate itbehind the scissors so the platform can be in the middle,for maximum stability. And we’ve always used <strong>John</strong> <strong>Deere</strong>.We have tried others, but none quite match <strong>John</strong> <strong>Deere</strong>’sperformance. Currently, our bigger machines are equippedwith the <strong>Power</strong>Tech 4045, while the <strong>Power</strong>Tech 4024 isperfect for our smaller ones.“Our <strong>John</strong> <strong>Deere</strong> distributor, Louis Nagel, does an outstandingjob, providing engines complete with radiator andthe necessary supports, which means installation is quickand easy. They also supply any product support, informationor back-up material we need.”6 <strong>Power</strong>Source