PURCHASE SPECIFICATIONS FOR NUAIRE ... - NuAire, Inc.

PURCHASE SPECIFICATIONS FOR NUAIRE ... - NuAire, Inc.

PURCHASE SPECIFICATIONS FOR NUAIRE ... - NuAire, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

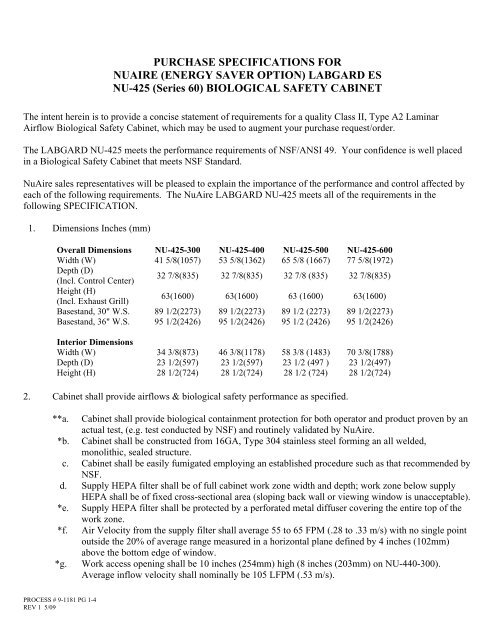

<strong>PURCHASE</strong> <strong>SPECIFICATIONS</strong> <strong>FOR</strong><strong>NUAIRE</strong> (ENERGY SAVER OPTION) LABGARD ESNU-425 (Series 60) BIOLOGICAL SAFETY CABINETThe intent herein is to provide a concise statement of requirements for a quality Class II, Type A2 LaminarAirflow Biological Safety Cabinet, which may be used to augment your purchase request/order.The LABGARD NU-425 meets the performance requirements of NSF/ANSI 49. Your confidence is well placedin a Biological Safety Cabinet that meets NSF Standard.<strong>NuAire</strong> sales representatives will be pleased to explain the importance of the performance and control affected byeach of the following requirements. The <strong>NuAire</strong> LABGARD NU-425 meets all of the requirements in thefollowing SPECIFICATION.1. Dimensions <strong>Inc</strong>hes (mm)Overall Dimensions NU-425-300 NU-425-400 NU-425-500 NU-425-600Width (W) 41 5/8(1057) 53 5/8(1362) 65 5/8 (1667) 77 5/8(1972)Depth (D)(<strong>Inc</strong>l. Control Center)32 7/8(835) 32 7/8(835) 32 7/8 (835) 32 7/8(835)Height (H)(<strong>Inc</strong>l. Exhaust Grill)63(1600) 63(1600) 63 (1600) 63(1600)Basestand, 30" W.S. 89 1/2(2273) 89 1/2(2273) 89 1/2 (2273) 89 1/2(2273)Basestand, 36" W.S. 95 1/2(2426) 95 1/2(2426) 95 1/2 (2426) 95 1/2(2426)Interior DimensionsWidth (W) 34 3/8(873) 46 3/8(1178) 58 3/8 (1483) 70 3/8(1788)Depth (D) 23 1/2(597) 23 1/2(597) 23 1/2 (497 ) 23 1/2(497)Height (H) 28 1/2(724) 28 1/2(724) 28 1/2 (724) 28 1/2(724)2. Cabinet shall provide airflows & biological safety performance as specified.**a. Cabinet shall provide biological containment protection for both operator and product proven by anactual test, (e.g. test conducted by NSF) and routinely validated by <strong>NuAire</strong>.*b. Cabinet shall be constructed from 16GA, Type 304 stainless steel forming an all welded,monolithic, sealed structure.c. Cabinet shall be easily fumigated employing an established procedure such as that recommended byNSF.d. Supply HEPA filter shall be of full cabinet work zone width and depth; work zone below supplyHEPA shall be of fixed cross-sectional area (sloping back wall or viewing window is unacceptable).*e. Supply HEPA filter shall be protected by a perforated metal diffuser covering the entire top of thework zone.*f. Air Velocity from the supply filter shall average 55 to 65 FPM (.28 to .33 m/s) with no single pointoutside the 20% of average range measured in a horizontal plane defined by 4 inches (102mm)above the bottom edge of window.*g. Work access opening shall be 10 inches (254mm) high (8 inches (203mm) on NU-440-300).Average inflow velocity shall nominally be 105 LFPM (.53 m/s).PROCESS # 9-1181 PG 1-4REV 1 5/09

*3. The cabinet shall be ergonomically designed for maximum user comfort and adjustability to meet therequirements of the American Disabilities Act (ADA.)• Standard non-metallic armrest/airfoil incorporating large 1-1/2 inch (38mm) forearm support area with1/2 inch (12mm) recessed front grill designed for armrest comfort while maintaining containmentperformance.• Maximum visibility into cabinet workzone shall be at least 22-1/4 inches (565mm) from front accessairfoil to exterior light housing.• Cabinet shall have a centrally located instrument panel within the control center that is easily servicedwith quick disconnects.• Cabinet shall have the capability of incorporating a user adjustable base stand or base storage cabinet asan option.• The cabinet shall have a smooth operating sliding window from full closure to full opening at19-1/2 inches (495mm).• Cabinet shall have a large worktray (17.250 inch (438mm) depth) removable with coved corners for easycleaning.*4. The cabinet shall have all positive pressure plenums surrounded by a vacuum relative to the room (theLABGARD employs the HEPEX Zero Leak Airflow System).5. Electrical power shall be supplied with a 12 foot (2.5m), 3-wire cord with molded plug. Electrical supplyshould be 115 VAC, 60 Hz (current rating varies per cabinet size, reference Electrical Requirements Page4) protected with thermal circuit breaker from distribution panel.*6. The cabinet shall use a DC ECM Motor with an optimally determined forward-curved fan for each modelsize/width to maximize both energy efficiency and filter loading capacity.7. The cabinet shall have two internal electrical circuits; one for blower/lights and one for the duplex outlets.Each circuit shall be protected with a circuit breaker located in the Control Center.8. The cabinet shall be listed by Underwriters Laboratories to meet the requirements of both the U.S. andCanada for electrical/mechanical integrity.*9. Total cabinet airflow shall be controlled via a solid-state DC Motor Controller that provides automaticcompensation (constant volume control) for both filter loading and line voltage variances.10. Balancing of cabinet workzone downflow (recycling flow) to exhaust flow shall be accomplished with aninternal exhaust flow damper, externally adjustable with screwdriver and sealed with liquid tight fastener.11. The cabinet shall be easily transportable through a standard 36 inch (914mm) wide door withoutdisassembly.12. Sound level shall be no more than 60 dbA measured 15 inches (381mm) above the work tray and 12 inches(305mm) in front of viewing window.*13. Fluorescent lighting shall be externally mounted and provide greater than 100 (1076) foot-candles (LUX)on work surface. Fluorescent lamps shall be T8 for energy efficiency, low replacement cost and wideavailability. The ballast is to be electronic containing thermal protection with automatic reset.*14. Cabinet shall have a minihelic gauge to display pressure drop over the supply HEPA filter.PROCESS # 9-1181REV 1 5/09 2

*15. Cabinets shall come standard with two outlets with drip proof covers on back wall (one outlet forNU-425-300); one gas valve/service coupling on right side wall; one service coupling on right side wall.16. Cabinet shall be easily converted to a freestanding console model with the addition of the optional BaseSupport Stand.*17. Cabinet work zone shall be all 16 GA. stainless steel and reinforced with stainless steel U channels tominimize vibration.18. A 3/8 inch (10 mm) ball valve shall be provided in the drain trough beneath the work tray.*19. Cabinet shall have the capability of incorporating a permanent positive pressure plenum with quick releasesupply filter removal as an option.*20. Motor/blower shall be positioned so as to create an even filter loading, thereby prolonging the life of HEPAfilters, automatically handling a 250% minimum increase in filter loading without reducing total airdelivery by more than 10%.*21. Cabinet shall be capable of front filter removal without disassembly of the control panel and slidingwindow tracks/hardware. HEPA filters shall be 99.99% efficient on 0.3 micron size particles by PAO test.22. The following optional equipment shall be available to support installation and user requirements:Energy Saver ECM Motor option included as stated above.8 <strong>Inc</strong>h (203mm) Access OpeningUltraviolet LightGround Fault Interrupter for Electrical SystemAdditional Service Valves for Gas, Air, VacuumRemote Service ValvesAdditional OutletIV Bar with 6 Stainless Steel HooksAlarm SystemsExhaust InterlocksBase Support Stand (available in standard working surface heights of 30 or 36 inches)(762 or 914mm) With or Without Storage ShelvesAdjustable Control for Support Stand or Storage CabinetHinged Viewing WindowMicroscope Viewing WindowSinks with Hot/Cold or DI Water FaucetsStorage Pull-Out TraysLay in Sorbent Exhaust FilterDecorative Side Panels (hides plumbing fixture connections)Permanent Plenum w/Quick Release Supply FilterMetal Framed HEPA FiltersHEPA Filters 99.999% @ 0.3 MicronStainless Steel ArmrestExhaust Transitions*Having all of these features is unique ONLY to <strong>NuAire</strong> cabinets.**NU-425-300 containment tests performed by <strong>NuAire</strong>, <strong>Inc</strong>.PROCESS # 9-1181REV 1 5/09 3

Catalog NumberPerformance Specifications1. Personal Protection2. Product ProtectionLabgard ES Energy Saver Class II, Type A2Laminar Flow Biological Safety CabinetModels NU-425-300/400/500/600NU-425-300Nominal 3 foot (0.9m)Catalog NumberNU-425-400Nominal 4 foot (1.2m)*15A Configuration does not include accessory outlet.**Remote controlled valve handles project through front faring. Decorative side panels are available to cover plumbing.***Crated shipping weight does not include weight for accessories or options+ Based on cabinet with new filters running at 115VAC.PROCESS # 9-1181REV 1 5/09 4NU-425-500Nominal 5 foot (1.5m)NU-425-600Nominal 6 foot (1.8m)NSF/ANSI 49 NSF/ANSI 49 NSF/ANSI 49 NSF/ANSI 49NSF Std. No. 49 Class Class II, Type A2 Class II, Type A2 Class II, Type A2 Class II, Type A2Style of CabinetBench top/console w/basestand/storage cabinetBench top/console w/basestand/storage cabinetBench top/console w/basestand/storage cabinetBench top/console w/basestand/storage cabinetCabinet ConstructionAll welded stainless steel16GA, Type 304pressure tight designAll welded stainless steel16GA, Type 304 pressuretight designAll welded stainless steel16GA, Type 304 pressuretight designAll welded stainless steel16GA, Type 304 pressuretight designDiffuser for Air Supply (Metal) Non-flammable Non-flammable Non-flammable Non-flammableHEPA Filter Seal Type:Supply Filter-99.99% Eff. on 0.3micronsExhaust Filter-99.99% Eff. on 0.3HEPEX SealNeoprene, SpringloadedHEPEX SealNeoprene, SpringloadedHEPEX SealNeoprene, SpringloadedHEPEX SealNeoprene, SpringloadedmicronsFumigation per NIH/NSF Procedure Yes Yes Yes YesStandard Services:Service Coupling (3/8 inch NPT)Gas Valve/Service Coupling (3/8" NPT)Duplex OutletOptional Services:Gas Cocks 3/8" NPTRemote Controlled Valves**Ultraviolet LightStandard/Cup SinksCabinet Size <strong>Inc</strong>hes (mm):Height (Fully Assembled)Height (Minimum for Transport)WidthDepth (with Control Center)Work Access Opening <strong>Inc</strong>hes (mm):Standard Opening Height/OptionalStandard Inflow VelocityWork Zone <strong>Inc</strong>hes (mm):HeightWidthDepthViewing Window <strong>Inc</strong>hes (mm):Standard is tempered sliding glassHinged Tempered Glass (optional)Required Exhaust CFM/CMHStandard/Optional:Thimble (NU-918/917)Thimble (NU-916)One, Right SidewallOne, Right SidewallOne, Backwall CenterUp to 3 ea. SidewallUp to 3 ea. SidewallOne, BackwallLeft or Right Work Surf.63 (1600)60 (1524)41 5/8 (1057)32 7/8 (835)8 (203)105 FPM (.53 m/s)28 1/2 (724)34 3/8 (873)23 1/2 (597)Fully closed to19 1/2 (495) open8 (203) opening8 (203) openingOne, Right SidewallOne, Right SidewallTwo, BackwallUp to 3 ea. SidewallUp to 3 ea. SidewallOne, BackwallLeft or Right Work Surf.63 (1600)60 (1524)53 5/8 (1362)32 7/8 (835)10 (254)/8 (203)105 FPM (.53 m/s)28 1/2 (724)46 3/8 (1178)23 1/2 (597)Fully closed to19 1/2 (495) open8 (203) &10 (254) openings10(254) / 8(203) openingOne, Right SidewallOne, Right SidewallTwo, BackwallUp to 3 ea. SidewallUp to 3 ea. SidewallOne, BackwallLeft or Right Work Surf.63 (1600)60 (1524)65 5/8 (1667)32 7/8 (835)10 (254)/8 (203)105 FPM (.53 m/s)28 1/2 (728)58 3/8 (1483)23 1/2 (597)Fully closed to19 1/2 (495) open8 (203) &10 (254) openings10(254) / 8(203) openingOne, Right SidewallOne, Right SidewallTwo, BackwallUp to 3 ea. SidewallUp to 3 ea. SidewallOne, BackwallLeft or Right Work Surf.63 (1600)60 (1524)77 5/8 (1972)32 7/8 (835)10 (254)/8 (203)105 FPM (.53 m/s)28 1/2 (724)70 3/8 (1788)23 1/2 (597)Fully closed to19 1/2 (495) open8 (203) &10 (254) openings10(254) / 8(203) opening282 (479)306 (519)438 (739) / 370 (624)462 (783) / 394 (667)542 (921) / 456 (775)566 (962) / 480 (813)647 (1100) / 545 (925)669 (1139) / 567 (964)Plant Duct Static Pressure Eng/Metric 0.05-0.1"/1.27-2.54mm 0.05-0.1"/1.27-2.54mm 0.05-0.1"/1.27-2.54mm 0.05-0.1"/1.27-2.54mmHeat Rejected, BTU, Per Hour8 (203) opening10(254) / 8(203) opening 10(254) / 8(203) opening 10(254) / 8(203) opening(non-vented)8261140/10201768/16111884/1768(vented)120157198198Electrical:Volts, AC 60 Hz+Amps: Blower/Lights (10/8 openings)Amps: DuplexRated Amps:12 ft. Power Cord (one)Crated Shipping Weight: ***Net WeightU.L./U.L.-C Listed1152.131014 GA - 3 Wire, 15A475 lbs. / 215 kg.425 lbs. / 193 kg.U.L./U.L.-C Listed1152.9/2.631214 GA - 3 Wire, 15A550 lbs. / 249 kg.500 lbs. / 227 kg.U.L./U.L.-C Listed1154.5/4.1314/*12*12/14 GA-3 Wire,20A Std., 15A Optional650 lbs. / 295 kg.600 lbs. / 273 kg.U.L./U.L.-C Listed1154.8/4.5314/*12*12/14 GA-3 Wire,20A Std., 15A Optional730 lbs. / 331 kg.680 lbs. / 308 kg.