Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

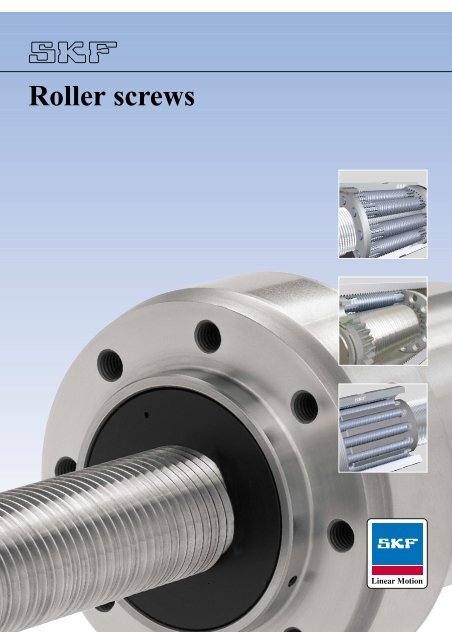

<strong>Roller</strong> screws

General<strong>SKF</strong> GroupThe <strong>SKF</strong> Group is an internationalindustrial corporation owned by <strong>SKF</strong>Sweden AB. Founded in 1907, thecompany has some 39 000 employees,80 manufacturing sites and a salesnetwork via its own sales companies,distributors and dealers, covering 150countries around the world.<strong>SKF</strong> is the world leader in the rollingbearing business.<strong>SKF</strong> Linear Motion<strong>SKF</strong> Linear Motion belongs to the <strong>SKF</strong>Group and is specialised in themanufacturing and sales of a widerange of high precision components,units and systems for linearmovements, providing solutions forguiding, driving, actuation andpositioning tasks.In addition, <strong>SKF</strong> Linear Motion alsooffers an extensive assortment ofindustrial products which are in totalsynergy to our linear motion productsand therefore complete our solutionsto customers.<strong>SKF</strong> Linear Motion comprises 4 productlines with 10 specialised salescompanies in Europe and NorthAmerica; additionally, productavailability and product applicationsupport is provided world-wide by theinternational sales network of the <strong>SKF</strong>Group.A complete range from a single source for alllinear motion functions.GuidingDrivingActuationPositioning2

Comparing roller screws to ball screws 6The principle of planetary roller screws 8The principle of recirculating roller screws 9Design hints 10Service range 19Standard range 27Ultra power range 60Electro-mechanical cylinders 62<strong>SKF</strong> worldwide 63Calculation formulas 64Symbols 66Ordering code 67

SRCSRFWith axial playSVCWith axial playPlanetary roller screwTRU/PRURecirculating roller screwPVUTRK/PRKPVKPreloadedPreloaded4

Service rangePageQuick delivery of custom-built assemblies :Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Range details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22Flanged thrust bearings, FLRBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25Standard rangePresentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Planetary roller screws : technical data and dimensionsCylindrical nuts with axial play, SRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30Flanged nuts with axial play, SRF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34Preloaded cylindrical nuts, TRU/PRU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38Preloaded flanged nuts, TRK/PRK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42Flanged thrust bearing unit, FLRBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46Recirculating roller screws : technical data and dimensionsCylindrical nuts with axial play, SVC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Preloaded cylindrical nuts, PVU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54Preloaded flanged nuts, PVK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Flanged thrust bearing unit, FLRBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58Ultra Power rangePresentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Technical data and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 615

Comparing roller screws to ball screwsThe load carrying capacity of a rolling screw depends practically on the surfaces at the points of contact :■ their diameter■ the number of contactsBall screws■ their hardness■ their surface finish■ the precision of the contacts to assureload sharing between them.<strong>Roller</strong> screwsF45°In ball screws, the load is transmittedfrom the nut to the shaftthrough the balls engaged in thegroove.In a single start ball screw, the balldiameter is limited to approximately70 % of the lead : there is only asingle helix of balls in a nut ofgiven length so the number ofcontacts is small.In roller screws, the load is transmitted from the nut to the shaft throughthe barrelled surfaces of all the engaged rollers.The diameter of the contact surface is substantially increased as is thenumber of points of contact.2 types of roller screwsPlanetary roller screwThreaded rollers are the basis of« SR / BR / TR / PR » planetary roller screws.Recirculating roller screwGrooved rollers are the basis of« SV /BV / PV » recirculating roller screws.======Contact surfacesDiameterNumberHardnessSurface finishPrecisionLoad rating===ExtendedlifeHIGHLOADRATINGSMinimummaintenancecostsMore reliableoperation6

The principle of planetary roller screwsThreaded rollers are the basis ofSR/BR/TR/PR planetary roller screws.The specific qualities of <strong>SKF</strong> planetary roller screwsMany strong contact surfaces High load carrying capacity Long lifeNo recirculation and no contact No weak points in the nut Less fatiguebetween rolling elements. High rotation speed Robust & shock resistantGuided rollers No loss in preload torque Smooth runningwhen changing directionTiming mechanism Exceptional reliability Ability to work with ice, dirt orpoor lubricationAdaptable tooling Non standard and left hand Tailor-madeleads availableAll parts made "in house", special steels possibleTypical applicationsThe capacity to carry heavy loads for thousands ofhours in the most arduous conditions makesSR/BR/TR/PR planetary roller screws suitable for themost demanding applications. The robust nut canwithstand shock loads and the timing mechanismensures reliability even in harsh environments and athigh accelerations ; the long lead and the symmetricaldesign of the nut permit high linear speeds.Examples :• Plastic molding.• Broaching machines.• Valves.• Presses• Machine tools.• The steel industry.• The tyre industry.• Automatic handling.• Military aircraft, tanks, rocket launchers, radar, shipsand submarines.• The nuclear industry.8

The principle of recirculating roller screwsGrooved rollers are the basis ofSV/BV/PV recirculating roller screws.The specific qualities of <strong>SKF</strong> recirculating roller screwsVery small leads (1mm) Fine resolution Minimum drive torque High mechanical advantageNo miniature parts Simple Robust ReliableMany strong contact Heavy load High rigidity Long lifepointscarrying capacityAll parts made "in house", special steels possibleTypical applicationsUltimate positioning accuracy can be obtained usingthe fine lead of SV/BV/PV recirculating roller screws.Their great mechanical advantage minimizes inputtorque and increases resolution. They can simplify acomplete transmission and improve its rigidity. Theyare often used in applications of advancing technologywhere reliable optimum performance is vital.Examples :• Grinding machines• Laboratory equipment.• Hospital equipment.• Paper making• The printing industry• Telescopes• Satellites9

Recommendations for selectionOnly basic selection parameters are included. To make the very best selection of a roller screw, the designershould specify such critical parameters as the load spectrum, the linear or rotational speed, the rates of accelerationand deceleration, the cycle rate, the environment, the required life, the lead accuracy, the stiffness, and anyspecial requirement. If in doubt, please consult an <strong>SKF</strong> specialist before placing an order.Basic dynamic loadrating (C a )The dynamic rating is used to computethe fatigue life of roller screws.It is the axial load constant in magnitudeand direction, and acting centrallyunder which the nominal life(as defined by ISO) reaches one millionrevolutions.Nominal fatigue life L 10The nominal life of a roller screw isthe number of revolutions (or thenumber of operating hours at agiven constant speed) which the rollerscrew is capable of enduringbefore the first sign of fatigue (flaking,spalling) occurs on one of therolling surfaces (screw, nut or rollerthread or groove).It is however evident from both laboratorytests and practical experiencethat seemingly identical roller screwsoperating under identical conditionshave different lives, hence the notionof nominal life. It is, in accordancewith ISO definition, the life achievedor exceeded by 90% of a sufficientlylarge group of apparently identicalroller screws, working in identicalconditions (alignment, axial and centrallyapplied load, speed, acceleration,lubrication, temperature andcleanliness).In cases where more than 90 % probability of ascrew attaining or exceeding its life is required.10% reliability Adjusted life90 % 1 x L 1095 % 0,62 x L 1096 % 0,53 x L 1097 % 0,44 x L 1098 % 0,33 x L 1099 % 0,21 x L 10Service lifeIt is the actual life achieved by aspecific roller screw before it fails.Failure is not only by fatigue (flakingor spalling) ; but also by inadequatelubrication and wear ; wear of therecirculation system, corrosion,contamination, and, more generally,by loss of the functional characteristicsrequired by the application.Experience acquired with similarapplications will help to select theproper screw to obtain the requiredservice life. Also, one must take intoaccount structural requirementssuch as the strength of screw endsand nut attachments, due to theloads applied on the elements in service.To attain L10 life performance amean working load of up to 80 % ofC a is permitted.Equivalent dynamic loadsThe loads acting on the screw canbe calculated according to the lawsof mechanics if the external forces(e.g. power transmission, work,rotary and linear inertia forces) areknown or can be calculated. It isnecessary to calculate the equivalentdynamic load : this load isdefined as that hypothetical load,constant in magnitude and direction,acting axially and centrally on thescrew which, if applied, would havethe same influence on the screw lifeas the actual loads to which thescrew is subjected.Radial and moment loads must betaken by linear bearing systems. It isextremely important to resolve theseproblems at the earliest conceptualstage. These forces are detrimentalto the life and the expectedperformance of the screw.(1) <strong>SKF</strong> can help you to define this value in relation with the actual conditions of service.Fluctuating loadWhen the load fluctuates during theworking cycle, it is necessary to calculatethe equivalent dynamic load :this load is defined as that hypotheticalload, constant in magnitude anddirection, acting axially and centrallyon the screw which, if applied, wouldhave the same influence on thescrew life as the actual loads towhich the screw is subjected.Additional loads due, for example tomisalignment, uneven loading,shocks, and so on, must be taken inaccount. Their influence on thenominal life of the screw is generallytaken care of, consult <strong>SKF</strong> for advice.Static load carryingcapacity (C oa )<strong>Roller</strong> screws should be selected onthe basis of the basic static loadrating C oa instead of on life whenthey are submitted to continuous orintermittent shock loads, whilestationary or rotating at very lowspeed for short duration. Thepermissible load is determined bythe permanent deformation causedby the load acting at the contactpoints. It is defined by ISO standardsas the purely axially and centrallyapplied static load which willcreate, by calculation, a total (rollingelement + thread surface) permanentdeformation equal to .0001 ofthe diameter of curvature of therolling element.The roller screw must be selected byits basic static load rating which mustbe, at least, equal to the product ofthe maximum axial static loadapplied and a safety factor “s o ”. Thesafety factor is selected in relationwith past experience of similar applicationsand requirements of runningsmoothness and noise level (1).

Critical rotating speed forscrew shaftsThe shaft is equated to a cylinderthe diameter of which is the root diameterof the thread. The formulasuse a parameter the value of whichis dictated by the mounting of thescrew shaft (whether it is simplysupported or fixed). As a rule the nutis not considered as a support of thescrew shaft. Because of the potentialinaccuracies in the mounting ofthe screw assembly, a safety factorof .80 is applied to the calculated criticalspeeds.Calculations which consider the nutas a support of the shaft, or reducethe safety factor, require practicaltests and possibly an optimization ofthe design (1).Permissible speed limitThe permissible speed limit is thatspeed which a screw cannot reliablyexceed at any time. It is generallythe limiting speed of the recirculationsystem in the nut. It is expressed asthe product of the rpm and thediameter of the screw shaft (in mm).The speed limits quoted in this catalogue(see page 64) are the maximumspeed that may be applied throughvery short periods and in optimizedrunning conditions of alignment, lightexternal load and preload with monitoredlubrication. Running a screwcontinuously at the permissible speedlimit may lead to a reduction of thecalculated life of the nut mechanism.!High speed associated with high loadrequires a large input torque andyields a relatively short nominal life (1).In the case of high acceleration anddeceleration, it is recommended toeither work under a nominal externalload or to apply a light preload to thenut to avoid internal sliding duringreversal. The value of the preload ofscrews submitted to high accelerationis that preload which ensuresthe rolling elements do not slide (1).Too high a preload will create unacceptableincreases of the internaltemperature.The lubrication of screws rotatingat high speed must be properlyconsidered in quantity and quality.The volume, spread and frequencyof the application of the lubricant (oilor grease) must be properly selectedand monitored. At high speed thelubricant spread on the surface ofthe screw shaft may be thrown off bycentrifugal forces. It is important tomonitor this phenomenon during thefirst run at high speed and possiblyadapt the frequency of re-lubricationor the flow of lubricant, or select alubricant with a higher viscosity.Monitoring the steady temperaturereached by the nut permits thefrequency of re-lubrication or the oilflow rate to be optimized.Oil lubricationA centralised recirculating oil systemis ideal because it continuouslychanges the oil in the nut withcooled filtered oil from the reservoir.This system is prescribed when thetemperature is likely to affect thepositioning accuracy. The flow of oilcan be regulated to optimise filmthickness and removal of heat.Selection of oilMineral oil normally used to lubricateother rotating parts such as bearingsand gears may be used for the screw.The viscosity of the oil is defined bythe speed, running temperature andload. The oil should have a viscosityof 100 ISO at the running temperature.An increase in viscosity or speedwill increase the running temperature.At low speed (< 10 rpm) theviscosity should be 200 ISO at therunning temperature. Under heavyload an EP additive to improve thefilm strength is recommended.Corrosion resistant and stabilizingadditives may also be used toadvantage.Grease lubricationWhere oil lubrication is not practicable,the grease recommended forthe support bearings of the screwmay also be used for the screw.After a few full strokes the greasewill be spread evenly over the usefulthreaded length of the screw shaft,which will also help to protect thescrew against corrosion. Howeverthe grease is open to the air.To prevent dirt which may fall on itfrom entering the nut, wipers shouldbe mounted in each end of the nut.Also the grease on the screw shaftwill age more quickly than that inthe screw support bearings so morefrequent regreasing is needed,especially in a dirty environment.If the screw cannot be dismountedand cleaned before regreasing it isnecessary to thoroughly clean theold grease from the screw shaft.This can be done with a spatula andthen with a clean fluff proof cloth.To clean even more a cloth wettedwith a solvent such as white spiritmay be used. We do not adviseusing brushes to remove old orspread new grease (risk of bristlescoming out). Apply also the newgrease through the nut to push outthe old from inside the nut.The grease type is defined above allby the operating temperature, environmentand load on the screw.Speed, starting torque and chemicalcompatibility may also be taken intoconsideration.Normally bearing greases of NLGIconsistency 2 are used. A greasewhich is too hard at low temperaturemay restrict rotation or one which istoo soft at high temperature may runoff.Selection of greaseLithium base greases are generallysuitable for use from -30°C to +110°C.A few can be used to +150°C.Lithium base greases are virtuallyinsoluble in water and very workstable. However they absorb largequantities of water when worked toextremes. Other soaps are advisedin the presence of much water.At low speed or heavy load lithiumbase greases with EP additive arerecommended as they adhere wellto the rolling surfaces and are insolublein water. As a rule EP greasesare recommended for medium andlarge sized screws.(1) <strong>SKF</strong> can help you to define this value in relation with the actual conditions of service.11

Lubrication intervalThe lubrication interval depends onthe working cycle of the screw andwhether the lubricant is pollutedduring use. General advice is difficultbut the following will help you todefine the interval. On start upcheck the grease quality regularly,for instance every month.If the viscosity of the grease samplehas increased, it needs replacing.If the grease sample is darker thannew it may indicate oxidation or thepresence of metallic particles.If it is discoloured, it is probablymixed with water.It is helpful to take samples not onlyfrom the part of the screw whererunning has occured but also fromunused parts of the screw where thegrease acts as corrosion preventer.Quantity of lubricant• OilWe advise a quantity of 5 ➝ 25 cm 3 /hin shots of 0,1 cm 3 as an order ofmagnitude depending on the size ofthe screw and its running conditions.• GreaseThe total volume of grease neededfor a new roller screw is the sum ofthe quantities needed for the screwshaft and the nut.The volume of grease necessary forthe screw shaft Z s can be estimatedfrom this formulaZ s = 4,4 x 10 -4 d o l 1This quantity of grease should bespread over the whole threadedlength of the shaft. The volume ofgrease for the nut Z n is one third ofthe free volume in the nut.The quantity Z n is given in thedimension tables : it should be injectedthrough the lubrication hole whileturning the shaft.Before applying load the nut shouldbe run twice along the completestroke to ensure grease is evenlyspread.Relubrication, see also ‘Greaselubrication’In the case of the existing greasebeing polluted, remove as much of itas possible and apply the samequantity as when first lubricated.If the existing grease is clean add avolume Z n into the nut.Efficiency and back-drivingThe performance of a screw is mainlydependant on the geometry of thecontact surfaces and their finish aswell as the helix angle of the thread.It is, also, dependant on the workingconditions of the screw (load, speed,lubrication, preload, alignment, etc…).The «direct efficiency» is used todefine the input torque required totransform the rotation of one memberinto the translation of the other.Conversely, the «indirect efficiency»is used to define the axial load requiredto transform the translation ofone member into the rotation of theother one. It is used, also, to definethe braking torque required toprevent that rotation.It is safe to consider that thesescrews are reversible or backdriveableunder almost all circumstances.It is therefore necessaryto design a brake mechanism ifbackdriving is to be avoided (gearreducers or brake).Preload torque : Internally preloadedscrews exhibit a torque due tothis preload. This persists evenwhen they are not externally loaded.Preload torque is measured at50 rpm when assembly is lubricatedwith ISO grade 64 oil.Starting torque :This is defined as the torque neededto overcome the following to startrotation :a) the total inertia of all moving partsaccelerated by the energy source(including rotation and linear movement).b) the internal friction of thescrew/nut assembly, bearing andassociated guiding devices.In general, torque to overcome inertia(a) is greater than friction torque(b).The coefficient of friction of the highefficiency screw when starting µ s isestimated at up to double the dynamiccoefficient µ, under normalconditions of use.Axial play and preloadPreloaded nuts are subject to muchless elastic deformation than nonpreloadednuts. Therefore theyshould be used whenever the accuracyof positioning under load isimportant.Backlash elimination can be achievedby fitting oversize rollers in one-piecenut (BRC-BVC).Preload for backlash elimination(TRU/TRK) or optimum rigidity(PRU/PRK - PVU/PVK) can be attainedwith two half-nuts, pressedtogether or pushed apart.The preload is defined by the valueof the preload torque. The torquedepends on the type of nut and onthe mode of preload (elastic or rigid).Static axial stiffness of acomplete assemblyIt is the ratio of the external axialload applied on the system and theaxial displacement of the face of thenut in relation with the fixed (anchored)end of the screw shaft. Theinverse of the rigidity of the totalsystem is equal to the sum of all theinverses of the rigidity of each of thecomponents (screw shaft, nut asmounted on the shaft, supportingbearing, supporting housings, etc…).1 1 1––– = ––– + –––R t R s R nBecause of this, the rigidity of the totalsystem is always less than the smallestindividual rigidity.12

Nut rigidity : R nWhen a preload is applied to a splitnut, firstly, the internal play is eliminated,then, the Hertzian elasticdeformation increases as the preloadapplied so that the overall rigidityincreases.The theoretical deformation does nottake into account machining inaccuracies,actual sharing of the loadbetween the different contact surfaces,the elasticity of the nut and ofthe screw shaft. The practical stiffnessvalues given in the catalogueare lower than the theoretical valuesfor this reason. They are determinedby <strong>SKF</strong> based on the value of theselected basic preload and an externalload equal to twice this preload.Shaft rigidity : R sThe elastic deformation of screwshaft is proportional to its length andinversely proportional to the squareof the root diameter.According to the relative importanceof the screw deformation (see rigidityof the total system), too large anincrease in the preload of the nutand supporting bearings yields alimited increase of rigidity and notablyincreases the preload torque andtherefore the running temperature.Consequently, the preload stated inthe catalogue for each dimension isoptimum and should not be increased.d 22R s = 165 ––– (N/µm)1for standard steel1165 d 22 lR s = –––––––––l2 (l - l2)for standard steel2Screw shaft bucklingThe column loading of the screwshaft must be checked when it issubmitted to compression loading(whether dynamically or statically).The maximum permissible compressiveload is calculated using theEuler formulas. It is then multipliedby a safety factor of 3 to 5, dependingon the application.The type of end mounting of theshaft is critical to select the propercoefficients to be used in the Eulerformulas.When the screw shaft comprises asingle diameter, the root diameter isused for the calculation. When thescrew comprises different sectionswith various diameters, calculationsbecome more complex (1).Materials and heattreatmentsStandard screw shafts are machinedfrom 42 CrMo4 steel which is surfacehardened by induction.Standard nuts are machined in100Cr6 steel which is throughhardened.Hardness of the contact surfaces is56-60 HRc.Most assemblies made of stainlessmaterial have a surface hardness inthe range 42 to 58 HRc : the loadrating of the catalogue thereforemust be derated (1).Working environmentOur products have not been developedfor use in an explosive atmosphere,consequently we cannot takeany responsibility for their use in thisfield.NOTE : 42 CrMo4, an AFNOR referenceis similar to AISI 4140; 100Cr6is similar to AISI 52100.Shaft DesignIt is possible to deliver roller screwswith one end larger than the outsidediameter, d 1 of the shaft. To grind thethread efficiently an undercut at rootdiameter d 2 and length l 2 is needed.When d 3 ≤ 1,3 d 1SR/BR/TR/PRP h ≤ 8 mm,P h > 8 mm,l 2 ≥ 10 mml 2 ≥ 1,4 P hSV/BV/PVP h = 1+ 40 x 2, 50 x 2, 63 x 2 l 2 ≥ 9 mmAll othersl 2 ≥ 14 mmWhen d 3 ≥ 1,3 d 1contact <strong>SKF</strong>(1) <strong>SKF</strong> can help you to define this value in relation with the actual conditions of service.13

Strength of machined endsThe end machining of a rollerscrew is designed by the customer.Due to the high static anddynamic load ratings of rollerscrews it is important to check thestrength of the machined ends.This checking must be yourresponsibility unless you specificallyask <strong>SKF</strong>.This simple approach takes intoaccount the different diameters ofthe end where stress concentrationfactors must be used : it takesinto consideration only axial andtorsional stresses.Zone A. Torsion onlyThe nominal shear stress τ causedby the drive torque T is given by :16 Tτ = ––––π d 53This is increased by a stressconcentration factor f 4 to give thereal shear stress, τ pτ p = f 4 τAccording to Von Mises the totalstress, σ tσ t = 1,73 τ pZone B. Axial + torsionalstressesThe nominal axial stress caused bythe axial load F is given by4Fσ = –––πd 42This is increased by a stressconcentration factor f 5 to give thereal principal stress σ pσ p =f 5 σas aboveτ p = f 4 τAccording to Von Mises the totalstress σ tManufacturing precisionGenerally speaking, the precisionindication given in the designationdefines the lead precision :see page 15.Lead precision according to ISO(ex. G1 - G5…).Parameters other than lead precisioncorrespond to our internal standards(generally based on ISO 3408-3class 5).If you require special tolerances(for example class 1 or 3) pleasespecify when requesting a quotationor ordering.For safety σ t should be less than67 % of the 0,2 % proof stress of thesteel.If the end diameter d 5 includes akeyway of depth e calculate with(d 5 - e).The angle of twist of the screw shaftis given by0,0648 Tlθ = ––––––d o4The linear positioning error, δ,caused by this twistP h θδ = ––––360σ t = (σ p2 + 3 τp 2 ) 1/2For safety σ t should be less than67 % of the 0,2 % proof stress of thesteel.14

Lead precision according to ISOLead precision is measured at 20°C on the useful stroke l u , which is the threaded length decreased, at each end, bythe length l e equal to the screw shaft diameter.G1 G3 G5V 300p, µm 6 12 23l u e p v up e p v up e p v upmm µm0 - 315 6 6 12 12 23 23(315) - 400 7 6 13 12 25 25(400) - 500 8 7 15 13 27 26(500) - 630 9 7 16 14 32 29(630) - 800 10 8 18 16 36 31(800) - 1000 11 9 21 17 40 34(1000) - 1250 13 10 24 19 47 39(1250) - 1600 15 11 29 22 55 44(1600) - 2000 35 25 65 51(2000) - 2500 41 29 78 59(2500) - 3150 96 69(3150) - 4000 115 82l eMean travel :the line which fitsthe curve best bymethod of leastsquares.v300aThreaded length300 mml uµm+l emml 0v up+ v ua-l mv 300pl u =l e =l o =l s =c =e p =useful travelexcess travel (no lead precision required)nominal travelspecified traveltravel compensation (difference between l s andl o to be defined by the customer, for instanceto compensate an expansion)tolerance over the specified travelV = travel variation (or permissible band width)V 300p = maximum permitted travel variation over 300 mmV up = maximum permitted travel variation over theuseful travel l uV 300a = measured travel variation over 300 mmV ua = measured travel variation over the useful travelCase with value of c specified by thecustomer.Case with c = 0 = standard version whenno value given by the customer.leThreaded lengthl uµm+l eThreaded lengthµm+mml 0l el ul ee p v upe pcl mv upe pl 0mme p-l s-15

Recommended assembly procedure<strong>Roller</strong> screws are precision components and should be handled with care to avoid shocks. When stored out of the shippingcrate they must lie on wooden or plastic vee blocks and should not be allowed to sag.Screw assemblies are shipped, wrapped in a heavy gauge plastic tube which protects them from foreign materialand possible pollution. They should stay wrapped until they are used.Radial and moment loadsAny radial or moment load on thenut will overload some of the contactsurfaces, thus significantly reducingits life.YES!Axial loadsAlignmentNO!Radial loads<strong>SKF</strong> linear guidance componentsshould be used to ensure correct alignmentand avoid non-axial loading.The parallelism of the screw shaftwith the guiding devices must bechecked. If external linear guidanceprove impractical, we suggest mountingthe nut on trunnions or gimbalsand the screw shaft in self-aligningbearings.Mounting the screw in tension helpsalign it properly and eliminatesbucking.Depending on the selected lubricant,it may be necessary to remove thisfilm before applying the lubricant(there may be a risk of non-compatibility).If this operation is performed in apotentially polluted atmosphere it ishighly recommended to proceedwith a thorough cleaning of theassembly.Designing the screw shaft endsGenerally speaking, when the endsof the screw shaft are specified bythe customer’s engineering personnel,it is their responsability to checkthe strength of these ends. <strong>Roller</strong>screws can be supplied with oneend bigger than the diameter of thethreaded portion. The core strengthof such an end may be affected bylarge reductions of diameter. Whenthis concept of a large end is used, aminimum length at root diameter isneeded between the end of thethread and the face of the larger diameter.This minimum length is 5 mmfor recirculating roller screws (SV),and 1.5 times the lead of thread forthe planetary design (SR).Operating temperature<strong>Screws</strong> made from standard steel(see page 13) and operating undernormal loads can sustain temperaturesin the range minus 20°- plus110° Celsius.Between 110° Celsius and 130°Celsius, <strong>SKF</strong> must be notified sothat it adapts the annealing procedureand checks that the applicationcan be successful with a hardnessbelow the standard minimum valueAbove 130° Celsius, steels adaptedto the temperature of the applicationshould be selected.Consult <strong>SKF</strong> for advice.NOTE :Operating at high temperature willlower the hardness of the steel, alterthe accuracy of the thread and mayincrease the oxidability of the materials.Starting-up the screwLubricationGood lubrication is essential for theproper functioning of the screw andfor its long term reliability (1).Before shipping, the screw is coatedwith a protective fluid that dries to afilm. This protective film is not alubricant.16After the assembly has been cleaned,mounted and lubricated, it isrecommended that the nut is allowedto make several full strokes atlow speed ; to check the properpositioning of the limit switches orreversing mechanism beforeapplying the full load and the fullspeed.(1) <strong>SKF</strong> can help you to define this value in relation with the actual conditions of service.

Preload adjustmentCylindrical nutsIn the case of cylindrical nuts (types TRU and PRU for planetary roller screws -type PVU for recirculating roller screws), the threaded housing stoppers must betightened to the values shown into tables 1 and 2 below. These torques canalso be used with one-piece nuts (SRC - BRC - SVC - BVC).SRC/BRCSRC / BRC / TRU / PRUd oHousing Tightening Squeezestopperthreadtorqueloadmm mN N81215212530394448606475809912015030 x 1.035 x 1.040 x 1.050 x 1.060 x 1.070 x 1.590 x 1.588 x 1.5110 x 1.5130 x 2.0125 x 2.0158 x 2.0148 x 2.0215 x 2.5230 x 2.5340 x 2.520354565801001401601802302503103404405507302700410046005500550059006400760068007400830082009600850099508950Table 1TRU/PRUSSVC/BVCThe standard nut is through hardened to 56 60 HRc : under some load conditions it isnecessary to use hardened & ground spacers (S) to avoid bedding of the nut into the housing &stopper resulting in loss of preload and rigidity.SVC / BVC / PVUHousing Tightening Squeezestopperd torqueload1 threadmm mN N81012162025324050638010012525 x 127 x 130 x 135 x 140 x 147 x 160 x 175 x 1.587 x 1.5108 x 2146 x 2185 x 2.5230 x 2.520273548628211014519025033544058032504000480056006400720076008000900096009500990010000Table 2PVUS17

Preload adjustmentFlanged nutsFor flanged nuts (types TRK and PRK for planetary roller screws - type PVK for recirculating roller screws), fixingbolts must be tightened according to table 3.TRK / PRK / PVKd o810121516202125 (T/PRK)25 (PVK)30323639404448505660636480100125Numberofscrews66666666666666666666681212<strong>Screws</strong>izeM4M4M4M5M4M5M5M6M5M8M6M8M10M8M10M12M10M12M16M12M16M16M16M18TighteningtorquemN333636610625102550255080508020080200200200270Table 3Preload torque tolerancesFor each roller screw, preloaded for optimum rigidity, a range of value of preload torque , T pr is given in the technical data.The customer is free to choose any value in this range : if no value is specified on the order the mean value will be taken.A. Tolerance of preload torque forscrews with ø < 11°B. Tolerance of preload torque forscrews with ø ≥ 11°l 1 /d 0 < 40 l 1 /d 0 < 60and l 1 < 4000 and l 1 < 4000Tpr G1 G3 G5 G1 G3 G5Nm ±%< 0,2 35 40 50 40 50 60(0,2) - 0,6 25 30 35 30 35 40(0,6) - 1,0 20 25 30 25 30 35(1,0) - 2,5 15 20 25 20 25 30(2,5) - 6,3 10 15 20 15 20 25(6,3) -10,0 10 10 15 15 15 20l 1 < 2000 2000 < l 1 < 4000Tpr G3 G5 G3 G5Nm ±%0 - 10,0 70 80 80 90Planetary roller screws preloaded for optimum rigidity with ø ≥ 11° are not available in G1 lead precision.18

Service RangePagePLANETARY ROLLER SCREWS• Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20• BRC range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22• Standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24• Thrust bearings FLRBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25RECIRCULATING ROLLER SCREWS• Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21• BVC range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23• Standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24• Thrust bearings FLRBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2519

Service RangePlanetary roller screws with bearing units1 weekwithout end machining2 weekswith machined endsNuts preloadedWith oversize rollers, BRC range4 weekswith machined endsto customer drawingStandard nutsWith axial play : SRC-SRFWith backlash elimination : TRU-PRUPreloaded : TRK-PRKLead515 21 30 39Nominal diameterLead1086515 21 25 30Nominal diameter39 48Details page 22CapabilitiesDetails : see page 24CapabilitiesMachined ends :• premachined shafts for machining bythe customer• to customer drawing (see general rules)• suitable for FLRBU unitsScrew dimensions : see page 22Machined ends to customer drawing(see general rules)Screw dimensions :• up to 1500 mm maxi length• up to 900 mm threaded length.GENERAL RULES FOR THE WHOLE SERVICE RANGE• up to 3 pieces.• lead precision : G5 to ISO standard.• standard nuts, standard steel (no special documents such as conformity report).• lubrication : screw assemblies delivered with machined ends are greased with <strong>SKF</strong> LGEP2 (temperaturerange : -20°C/+120°C) ; without end machining, they are only protected with Quakers rust inhibitor.20

Service RangeRecirculating roller screws with bearing units1 weekwithout end machining2 weekswith machined endsNuts preloadedWith oversize rollers, BVC range4 weekswith machined endsto customer drawingStandard nutsWith axial axial play : SVCPreloaded : PVU-PVKLead120 25 32Nominal diameterLead2116 20 25 32Nominal diameter40Details page 23CapabilitiesDetails : see page 24CapabilitiesMachined ends :• premachined shafts for machining bythe customer• to customer drawing (see general rules)• suitable for FLRBU unitsScrew dimensions : see page 23Machined ends to customer drawing(see general rules)Screw dimensions :• up to 1500 mm maxi length• up to 900 mm threaded length.RULES (continuation)• standard machining : no spline, no hollow shaft, no radius in grinding operations. If such anyrequirements, order cannot be accepted by the Service Channel. Unless specified, tolerances will beaccording to class 5, ISO 3408-3 (see page 15). FLRBU thrust bearing units can be delivered for all sizes.• screws for nuclear, military or medical applications are excluded.21

Service RangePlanetary roller screws “BRC”DesignationC aBasic axialload ratingMaximumpreloadtorque *MinimumnutstiffnessC oaT prR nrd 1d 8Screw dimensionsd 10B 5B 6RDANut dimensionsw a bHQkNkNNmN/µmBRC 15x5-R521.236.30.1015015.414.4251154001.235500.541636.55BRC 21x5-R541.368.30.3020021.420.4301585501.245640.5520475BRC 30x5-R575.2148.60.6030030.429.450213800264850.563266.55BRC 39x5-R5105.6224.11.1040039.438.45021310002801001840837“BRC” roller screw + thrust bearing assemblyScrewdesignationThrust bearingdesignationB 7B 8End which can be machined tocustomer requirementsBRC 15x5-R5BRC 21x5-R5FLRBU2FLRBU3285392398548Maximum threaded length : canbe cut & machined to customerrequirementsBRC 30x5-R5BRC 39x5-R5FLRBU5FLRBU5587787798998N.B. : Nut and thrust bearing unit cannot bemodified. Wipers without thread.* Preload torque measured at 50rpm22

Service RangeRecirculating roller screws “BVC”Basic axialload ratingMaximumpreloadtorque *MinimumnutstiffnessScrew dimensionsNut dimensionsDesignationC aC oaT prR nrd 1d 8d 10B 5B 6RDAwabHQkNkNNmN/µmBVC 20x1-R118.536.60.202002019.1281164001.234370.531635.25BVC 25x1-R132.968.40.302502524.1331595001.242440.542043.55BVC 32x1-R164.3159.20.403003231.1401795001.25457142555.55“BVC” roller screw + thrust bearing assemblyScrewdesignationThrust bearingdesignationB 7B 8End which can be machined tocustomer requirementsBVC 20x1-R1BVC 25x1-R1FLRBU2FLRBU3284341397497Maximum threaded length : canbe cut & machined to customerrequirementsBVC 32x1-R1FLRBU4321497N.B. : Nut and thrust bearing unit cannot bemodified. Nut without wipers.* Preload torque measured at 50rpm23

Service RangeStandard nuts - Planetary roller screwsSRCSRF TRU/PRU TRK/PRKd 0 P h NC a C oa DimensionsSRC/SRF TRU/PRU - TRK/PRK SRC/SRF TRU/PRU - TRK/PRK155521,211,736,318,2215541,322,868,334,2216541,622,964,732,3218544,524,565,032,52125251051055548,451,759,426,728,532,769,290,287,834,645,143,9Seepages30 to 45305575,241,4148,674,33010586,947,9145,372,63955105,658,2224,1112,139105124,868,7225,8112,94855161,989,2401,3200,648105189,3104,3395,9198,0Standard nuts - Recirculating roller screwsSVC PVU PVKd 0 P h NC a C oa DimensionsSVC PVU - PVK SVC PVU - PVK161111,56,616,88,4162211,56,616,88,4201118,510,636,618,320252521221218,532,932,910,618,918,936,668,468,418,334,234,2Seepages52 to 57321164,336,9159,279,6322264,336,9159,279,6401179,145,4231,6115,8402149,928,7117,258,624

Service RangeFlanged thrust bearing unitsIn standard version, the"FLRBU" thrust bearing unitis assembled according todrawing page 22 or 23.If you require a differentassembly, please indicate itwhen ordering40° angular contact ball bearing Lock nutFlanged bearingunit designationFLRBU1Basic axialload ratingC aC oaNumber ofbearingsBearingsdesignationDesignationHigh precision KMT nutHookspannerTighteningtorquekN kNNm N/µm Nm/mradNm13,314,727201 BEGBPMaximumpreloadtorque *0,1Axialrigidity150Tiltrigidity40KMT 1HN 310Grub screwsSize Maxtighteningtorque, NmM54,5FLRBU227.931.927303 BEGBP0.2519051KMT 3HN 415M68FLRBU340.163.847204 BEGBP0.25400140KMT 4HN 518M68FLRBU474.2119.247305 BEGBP1.1450160KMT 5HN 525M68FLRBU5109.4188.447307 BEGBP1.1600715KMT 7HN 742M68FLRBU6208.8392.347310 BEGBP1.57501000KMT 10HN 1070M68FLRBU7305,3615,447313 BEGBP212501600KMT 13HN 14100M818Flanged bearingunit designationL 2L 3L 4D 1D 2D 3h7D 4D 5S 1H13FixingscrewsEL 16.6FLRBU1421025147650476330M6 x 2527FLRBU24610321890626076376.6M6 x 2532FLRBU37713601890596074409M8 x 2532FLRBU48916682012080801004411M10 x 3044FLRBU5110208222140991001205413M12 x 4054FLRBU61402598.5251711301301527513M12 x 4067FLRBU718030133.5282251701701989517.5M16 x 5587* Preload torque measured at 50rpm25

Thrust bearingunitsFLRBU1d 4 d 5 d 9 B 1 B 2 B 4 B 3 GG 1 c b a d 7 R a R b a bh6 h7js12 js12 6g h11 N9 + 0.100012 10 17 58 20 78 5 M12 x 1 17 0.5 1.5 10.5 0.4 0.4 3 1.8b 1+ 0.5016b 21.5FLRBU21715236630965M17 x 1220.51.515.50.60.653252FLRBU320172797401377M20 x 1220.51.518.50.60.653352FLRBU4252034112451577M25 x 1.5250.52.322.80.60.663.5402.5FLRBU53530451345518910M35 x 1.52612.332.80.60.684452.5FLRBU65040681686523312M50 x 1.53112.347.80.60.6125554FLRBU765608321010031018M65 x 2321362.20.81187902.5UndercutUndercut l 2 is defined p13.26

Standard RangePagePlanetary roller screws : technical data and dimensionsCylindrical nuts with axial play, SRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30Flanged nuts with axial play, SRF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34Cylindrical nuts preloaded, TRU/PRU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38Flanged nuts preloaded, TRK/PRK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42Flanged thrust bearing units, FLRBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46Recirculating roller screws : technical data and dimensionsCylindrical nuts with axial play, SVC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Cylindrical nuts preloaded, PVU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54Flanged nuts preloaded, PVK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Flanged thrust bearing unit, FLRBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5827

Standard RangeThe full range of “SR” planetary roller screwsNominal diameter, do812 15 20 21 24 25 30 36 39 44 48 56 60 64 75 80 99 100 120 120 150 150 180 210Lead, P h42403635302524201816151210986544 5 5 6 5 6 5 5 6 5 6 5 6 5 6 5 6 5 6 6 5 6 5 5 5Number of startsStandard programRight hand leadManufacturingpossibilitieson request28

<strong>SKF</strong> planetary roller screwsThe robust screw for long life in tough conditionshas these advantagesSRC/BRC★★★★★★★★★★★★★Very high load carrying capacityVery long lifeHigh rotational speed and long lead permit linearspeed up to 60 metres/minutePlanetary timing mechanism permits highacceleration (> 7000 rad/sec 2 )Robust design to withstand shock loadsChoice of 3 classes of lead precisionPlanetary timing mechanism ensures correct functioningeven in adverse environments such as ice,dirt or poor lubricationSpecial and left hand leads easily availableSpecial steels availableSpecial surface treatments and lubrication availableNut removal without losing rolling elementsCylindrical and flanged nuts, with play orpreloadedBuilt in wipers available in all cases.SRFTRU/PRUBacklash elimination with oversizerollers :as an option under following conditions :➤total lengthd 0≤ 30➤threaded lengthd 0≤ 15TRK/PRK29

Technical data and dimensionsPlanetary roller screwsCylindrical nuts with axial play, SRCBacklash elimination with oversize rollersd 0 8 ➙ 44 mmas an optiondo P h N l Ø C C s m m tpoa apIa n s s I I Z nn ns nBezeichnungDesignation2 2mm mm – mm ° kN kN mm kg kg/m kgmm/m kgmmkgmm 2cm38121515202121212124242525253030303036363636363939393939444444444445586568106125101556102069121824510152025812182430455565555665555555666665555566666500750975975130014001400140014001600160016501650165020002000200020002400240024002400240026502650265026502650300030003000300030009,047,556,069,715,454,335,206,958,624,559,043,647,2610,813,043,636,0611,983,044,556,069,0411,982,344,676,989,2711,533,304,967,429,8512,249,1914,521,222,421,941,341,644,548,434,639,051,759,464,775,277,686,9100,874,079,787,293,3101,1105,6124,8137,1141,3142,9109,2117,5129,0137,2135,616,322,336,333,937,468,364,765,069,254,352,090,287,888,7148,6146,1145,3147,7149,5145,0150,9147,1153,7224,1225,8227,4217,4207,5226,3219,1220,8222,5205,40,020,020,020,020,020,020,020,020,040,020,040,020,040,070,020,020,040,070,020,020,040,070,070,020,040,070,070,070,040,040,070,070,070,10,20,20,20,30,40,40,40,40,50,50,70,70,71,21,21,21,21,21,21,21,21,22,12,12,12,12,11,71,71,71,71,70,40,91,41,42,32,72,72,72,73,63,63,93,93,95,65,65,65,68,08,08,08,08,09,49,49,49,49,411,911,911,911,911,93,216,039,039,0123,3149,9149,9149,9149,9255,7255,7301,0301,0301,0624,2624,2624,2624,2129E1129E1129E1192E1129E1178E1178E1178E1178E1178E1289E1289E1289E1289E1289E111,422,945,245,271,8141,2141,2141,2141,2173,2173,2321,9321,9321,9762,4762,4762,4761,9922,8922,8873,1873,1873,1203E1203E1203E1203E1203E1173E1173E1173E1173E1173E10,10,41,21,22,56,56,56,56,56,36,314,314,314,336,236,236,235,945,745,745,745,745,7124,4124,4123,6123,6123,6119,2119,2118,3118,3118,30,911,432,292,292,475,035,035,035,034,244,2410,210,210,213,713,713,713,713,413,413,413,413,427,927,927,927,927,922,822,822,822,822,8SRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRC8x412x515x515x820x621x521x621x821x1024x624x1225x525x1025x1530x530x630x1030x2036x636x936x1236x1836x2439x539x1039x1539x2039x2544x844x1244x1844x2444x30Designation : page 67 - Symbols : page 6630

31SRC8,412,415,415,520,421,421,421,521,824,424,825,425,826,230,430,430,831,536,436,536,837,237,539,439,840,240,540,944,444,845,245,545,97,311,314,31419,320,320,32019,723,322,724,323,723,129,329,328,727,535,335,134,734,133,538,337,737,136,535,943,242,742,141,540,9253035354045454545484853535364646464686868686880808080808080808080444450505064646464585878787885858585808080808010010010010010090909090900,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,5111110,50,50,50,50,544444555555666666655555888886666612121616162020202020202525253232323225252525254040404040323232323226,531,536,536,541,547474747505055,555,555,566,566,566,566,57070707070838383838382,582,582,582,582,5555555555555555555555557777777777333344444666667777888888888888888212530303540,540,540,540,54242474747585858586262626262737373737374747474748x412x515x515x820x621x521x621x821x1024x624x1225x525x1025x1530x530x630x1030x2036x636x936x1236x1836x2439x539x1039x1539x2039x2544x844x1244x1844x2444x30SRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCD 3D 2BQHbawADd 2d 1h9h12g6/H7131720202526262626313132323238383838454545454550505050505656565656d 0 81215152021212121242425252530303030363636363639393939394444444444Bezeichnungmm mm mm mm mm mm mm mm mm mm mm mm mmDesignationWiper recessWiper on request

Technical data and dimensionsPlanetary roller screwsCylindrical nuts with axial play, SRCBacklash elimination with oversize rollersd 0 48 ➙ 210 mmas an optiondo P h N l Ø C C s m m tpoa apIa n s s I I Z nn ns nBezeichnungDesignation2 2mm mm – mm ° kN kN mm kg kg/m kgmm/m kgmmkgmm 2cm3484848484848565656606060646464646475757580808080809910012012015015018021058101520251224361015201218243036101520121824364220242425362530305555556665556666655566666566565553300330033003300330033004000400040004250425042504600460046004600460055005500550060006000600060006000750080008000800080008000800080001,903,033,795,687,559,413,907,7711,563,044,556,063,425,126,818,4910,152,433,644,852,734,105,458,159,493,684,373,643,794,373,043,042,60161,9178,6189,3210,7217,2236,1173,5198,0215,4276,8305,0326,2242,3258,9268,9262,8262,1412,7458,9485,2335,4372,8401,2375,5360,9784,2556,1775,8955,9980,9135416641946401,3392,2395,9405,3385,2409,2360,9349,3353,5649,7652,2654,7636,1604,6574,7516,5491,2123912431247969,3973,0976,7832,6777,5257515222523336534235680755894790,020,040,040,070,070,070,040,070,070,040,070,070,040,070,070,070,070,040,070,070,040,070,070,070,070,070,070,070,070,070,070,070,074,24,24,24,24,24,23,23,23,27,37,37,35,45,25,24,94,914,614,614,68,98,98,98,98,936,219,638,055,579,8155,7397,8542,714,214,214,214,214,214,219,319,319,322,222,222,225,325,325,325,325,334,734,734,739,539,539,539,539,560,461,788,888,8138,7138,7199,8271,9409E1409E1409E1409E1409E1409E1758E1758E1758E1999E1999E1999E1129E2129E2129E2129E2129E2244E2244E2244E2316E2316E2316E2316E2316E2740E2771E2160E3160E3390E3390E3809E3150E4652E1652E1652E1652E1652E1652E1500E1500E1500E1165E2165E2164E2106E2105E2105E2103E2103E2469E2469E2469E2260E2260E2260E2252E2252E2207E3962E2278E3453E3959E3232E4105E5188E5370,8370,8370,8370,8370,8369,6385,3383,1383,1110E1110E1110E1984,3914,0911,2771,0771,0415E1415E1415E1272E1272E1271E1229E1229E1175E2836E1224E2409E2676E2146E3392E3757E354,054,054,054,054,054,046,246,246,210310310346,254,054,069,469,4143143143103103103132132342200363545719122725733771SRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRC48x548x848x1048x1548x2048x2556x1256x2456x3660x1060x1560x2064x1264x1864x2464x3064x3675x1075x1575x2080x1280x1880x2480x3680x4299x20100x24120x24120x25150x36150x25180x30210x30Designation : page 67 - Symbols : page 6632

3348,448,648,849,249,549,956,857,558,360,861,261,564,865,265,565,966,375,876,276,580,881,281,582,382,7100,5101,5121,5121,9152,3151,9182,3212,347,347,146,746,145,544,954,753,552,358,758,157,562,762,161,560,960,373,773,172,578,778,177,576,375,796,597,5117,5116,9146,3146,9176,3206,310010010010010010010010010012212212211511511511511515015015014014014014014020018022024028032042048012712712712712712711211211215215215212912912912912919119119115615615615615626019524028030540051555011111111111111111111111111,51,521,523338888888881010108888810101010101010101610161616323240454545454545404040454545454545454563636363636363631006310010010016016020010310310310310310310310310312512512511811811811811815315315314314314314314320418322424428432742748977777777710,510,510,57777710,510,510,510,510,510,510,510,51510,5151515152020989999999999111111111110101012121212121212121213131320909090909090939393110110110106106106106106136136136132132132132132180162196220250280340385D 3D 2BQHbawADd 2d 1h9h12g6/H760606060606066666671717175757575758787879292929292112116136180200230250280d 0 4848484848485656566060606464646464757575808080808099100120120150150180210Beteckningmm mm mm mm mm mm mm mm mm mm mm mm mm48x548x848x1048x1548x2048x2556x1256x2456x3660x1060x1560x2064x1264x1864x2464x3064x3675x1075x1575x2080x1280x1880x2480x3680x4299x20100x24120x24120x25150x36150x25180x30210x30SRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCSRCDesignationSRCWiper recessWiper on request

34Technical data and dimensionsPlanetary roller screwsFlanged nuts with axial play, SRFd 0 8 ➙ 44 mmd Ø C s IBeteckningo P h N sl tpapoaC a m n m s I nn I ns Z n81215152021212121242425252530303030363636363639393939394444444444mm – mm ° kN mm kg kg/m kgmm/m kgmm2 2kgmm 2cm50075097597513001400140014001400160016001650165016502000200020002000240024002400240024002650265026502650265030003000300030003000455865681061251015561020691218245101520258121824304555655556655555556666655555666669,047,556,069,715,454,335,206,958,624,559,043,647,2610,813,043,636,0611,983,044,556,069,0411,982,344,676,989,2711,533,304,967,429,8512,249,1914,521,222,421,941,341,644,548,434,639,051,759,464,775,277,686,9100,874,079,787,293,3101,1105,6124,8137,1141,3142,9109,2117,5129,0137,2135,616,322,336,333,937,468,364,765,069,254,352,090,287,888,7148,6146,1145,3147,7149,5145,0150,9147,1153,7224,1225,8227,4217,4207,5226,3219,1220,8222,5205,40,020,020,020,020,020,020,020,020,040,020,040,020,040,070,020,020,040,070,020,020,040,070,070,020,040,070,070,070,020,040,070,070,070,30,30,50,50,50,70,70,70,70,80,81,41,41,42,12,12,12,12,22,22,12,12,14,04,04,04,04,03,63,63,63,63,60,40,91,41,42,32,72,72,72,73,63,63,93,93,95,65,65,65,68,08,08,08,08,09,49,49,49,49,411,911,911,911,911,93,216,039,039,0123,3149,9149,9149,9149,9255,7255,7301,0301,0301,0624,2624,2624,2624,2129E1129E1129E1192E1129E1178E1178E1178E1178E1178E1289E1289E1289E1289E1289E166,4106,0201,6201,6289,5436,6436,6436,6436,6524,2524,2120E1120E1120E1268E1268E1268E1268E1317E1317E1312E1312E1312E1836E1836E1836E1836E1836E1803E1803E1803E1803E1803E10,10,41,21,22,56,56,56,56,56,36,314,314,314,336,236,236,235,945,745,745,745,745,7124,4124,4123,6123,6123,6119,2119,2118,3118,3118,30,911,432,292,292,475,035,035,035,034,244,2410,210,210,213,713,713,713,713,413,413,413,413,427,927,927,927,927,922,822,822,822,822,88x412x515x515x820x621x521x621x821x1024x624x1225x525x1025x1530x530x630x1030x2036x636x936x1236x1836x2439x539x1039x1539x2039x2544X844x1244x1844x2444x30SRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFmmkN3DesignationDesignation : page 67 - Symbols : page 66

35Wiper on requestWiper recessEquidistant8,412,415,415,520,421,421,421,521,824,424,825,425,826,230,430,430,831,536,436,536,837,237,539,439,840,240,540,944,444,845,245,545,97,311,314,31419,320,320,320,019,723,322,724,323,723,129,329,328,727,535,335,134,734,133,538,337,737,136,535,943,242,742,141,540,9253035354045454545484856565664646464686868686882828282828282828282444450505064646464585878787885858585808080808010010010010010090909090906xM46xM46xM56xM56xM56xM56xM56xM56xM56xM56xM56xM66xM66xM66xM86xM66xM86xM86xM86xM86xM86xM86xM86xM106xM106xM106xM106xM106xM106xM106xM106xM106xM100,40,40,40,40,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,81,21,21,21,21,21,21,21,21,21,2M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6303030303030303030303030303030303030303030303030303030303030303030333344444666667777888888888888888212530303540,540,540,540,5424247474758585858626262626273737373737474747474D 3D 2BADd 2d 1 +0,4h12131720202526262626313132323238383838454545454550505050505656565656d 0 81215152021212121242425252530303030363636363639393939394444444444Bezeichnungmm mm mm mm mm mm mm mm ° mm mm mm14141616162323232320202929292929292926,526,526,526,526,533,533,533,533,533,528,528,528,528,528,5A 2mm161618181818181818181820202027272727272727272733333333333333333333mm465158586368686868717184848497979797102102102102102124124124124124124124124124124mm3641464651565656565959707070818181818585858585102102102102102102102102102102js12mmA 1 D 1 uQrGJ8x412x515x515x820x621x521x621x821x1024x624x1225x525x1025x1530x530x630x1030x2036x636x936x1236x1836x2439x539x1039x1539x2039x2544x844x1244x1844x2444x30SRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSFRSRFSRFSRFSRFDesignation

36Designation : page 67 - Symbols : page 66484848484848565656606060646464646475757580808080809910012012015015018021033003300330033003300330040004000400042504250425046004600460046004600550055005500600060006000600060007500800080008000800080008000800058101520251224361015201218243036101520121824364220242425362530305555556665556666655566666566565551,903,033,795,687,559,413,907,7711,563,044,556,063,425,126,818,4910,152,433,644,852,734,105,458,159,493,684,373,643,794,373,043,042,60161,9178,6189,3210,7217,2236,1173,5198,0215,4276,8305,0326,2242,3258,9268,9262,8262,1412,7458,9485,2335,4372,8401,2375,5360,9784,2556,1775,8955,9980,9135416641946401,3392,2395,9405,3385,2409,2360,9349,3353,5649,7652,2654,7636,1604,6574,7516,5491,2123912431247969,3973,0976,7832,6777,5257515222523336534235680755894790,020,040,040,070,070,070,040,070,070,040,070,070,040,070,070,070,070,040,070,070,040,070,070,070,070,070,070,070,070,070,070,070,077,74,27,77,77,76,96,56,56,512,112,112,111,311,211,210,910,920,620,620,617,717,717,717,717,748,329,751,189,0103,3182,2436,6597,514,214,214,214,214,214,219,319,319,322,222,222,225,325,325,325,325,334,734,734,739,539,539,539,539,560,461,788,888,8138,7138,7199,8271,9409E1409E1409E1409E1409E1409E1758E1758E1758E1999E1999E1999E1129E2129E2129E2129E2129E2244E2244E2244E2316E2316E2316E2316E2316E2740E2771E2160E3160E3390E3390E3809E3150E4230E2230E2230E2230E2230E2191E2213E2213E2213E2528E2528E2528E2502E2501E2501E2499E2499E2114E3114E3114E3108E3108E3108E3108E3108E3449E3259E3598E3129E4190E4388E4145E5266E5370,8370,8370,8370,8370,8369,6385,3383,1383,1110E1110E1110E1984,3914,0911,2771,0771,0415E1415E1415E1272E1272E1271E1229E1229E1175E2836E1224E2409E2676E2146E3392E3757E354,054,054,054,054,054,046,246,246,210310310346,254,054,069,469,414314314310310310313213234220036354571912272573377148x548x848x1048x1548x2048x2556x1256x2456x3660x1060x1560x2064x1264x1864x2464x3064x3675x1075x1575x2080x1280x1880x2480x3680x4299x20100x24120x24120x25150x36150x25180x30210x30d Ø C s IBeteckningo P h N sl tpapoaC a m n m s I nn I ns Z nmm – mm ° kN mm kg kg/m kgmm/m kgmm2 2kgmm 2cmSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFmmkN3Technical data and dimensionsPlanetary roller screwsFlanged nuts with axial play, SRFd 0 48 ➙ 210 mmDesignation

3748,448,648,849,249,549,956,857,558,360,861,261,564,865,265,565,966,375,876,276,580,881,281,582,382,7100,5101,5121,5121,9152,3151,9182,3212,347,347,146,746,145,544,954,753,552,358,758,157,562,762,161,560,960,373,773,172,578,778,177,576,375,796,597,5117,5116,9146,3146,9176,3206,31051051051051051051051051051221221221201201201201201501501501501501501501502001802202602803204204801271271271271271271121121121521521521291291291291291911911911561561561561562601952402803054005155506xM126xM126xM126xM126xM126xM126xM126xM126xM126xM166xM166xM166xM166xM166xM166xM166xM168xM168xM168xM168xM168xM168xM168xM168xM1612xM1612xM1612xM1612xM161,21,21,21,21,21,21,21,21,21,61,61,61,61,61,61,61,61,61,61,61,61,61,61,61,62,42,42,42,4M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M12303030303030303030303030303030303022°3022°3022°3022°3022°3022°3022°3022°3015151515999999999999111111111110101012121212121212121213131320909090909090939393110110110106106106106106136136136132132132132132180162196220250280340385D 3D 2BuQrGADd 2d 1 +0,4h1260606060606066666671717175757575758787879292929292112116136180200230250280d 04848484848485656566060606464646464757575808080808099100120120150150180210Beteckningmm mm mm mm mm mm mm mm ° mm mm mm45454545454537,537,537,553,553,553,5424242424273737355,555,555,555,555,5102,572,592,5112,5A 2mm3737373737373737374545454545454545454545454545454555505555mm150150150150150150150150150180180180180180180180180210210210210210210210210275255295340mm127127127127127127127127127150150150150150150150150180180180180180180180180245220260305Jjs12mmA 1 D 148x548x848x1048x1548x2048x2556x1256x2456x3660x1060x1560x2064x1264x1864x2464x3064x3675x1075x1575x2080x1280x1880x2480x3680x4299x20100x24120x24120x25150x36150x25180x30210x30SRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFSRFConsult <strong>SKF</strong>DesignationWiper on requestWiper recessEquidistant

Technical data and dimensionsPlanetary roller screwsPreloaded cylindrical nuts, TRU for backlash eliminationPRU for optimum rigidityd 0 8 ➙ 36 mmTRUPRUdo P h N l Ø C tpC oa T pe R m m Ia n s s I I Z ng R nr T pr F prnn ns n2 2mm mm – mm ° kN kN Nm N/µm N/µm Nm N kg kg/m kgmm/m kgmmkgmm 2cm3812151520212121212424252525303030303636363636455865681061251015561020691218244555655556655555556666640060075075010501100110011001100125012501300130013001600160016001600190019001900190019009,047,556,069,715,454,335,206,958,624,559,043,647,2610,813,043,636,0611,983,044,556,069,0411,985,067,9811,712,412,122,822,924,526,719,021,528,532,735,641,442,847,955,540,743,948,051,555,78,1611,118,216,918,734,232,332,534,627,226,045,143,944,374,373,072,673,974,772,575,573,576,80,070,130,190,190,300,330,330,330,330,410,410,440,440,440,590,590,590,590,800,800,800,800,8011018029024229040035931120037015046029018062056142019077053051026024015024038031538052046740426049020060038023081072955026010006896603303100,06 - 0,130,12 - 0,250,18 - 0,360,18 - 0,360,26 - 0,580,31 - 0,630,31 - 0,630,31 - 0,630,31 - 0,630,39 - 0,780,39 - 0,780,42 - 0,840,42 - 0,840,42 - 0,840,57 - 1,130,57 - 1,130,57 - 1,130,85 - 1,410,77 - 1,530,77 - 1,530,77 - 1,530,77 - 1,531,15 - 1,9123657093295413051341139413545571597541157710084261844178014725552334196018207076490,10,20,20,20,30,40,40,40,40,50,50,70,70,71,21,21,21,21,21,21,21,21,20,40,91,41,42,32,72,72,72,73,63,63,93,93,95,65,65,65,68,08,08,08,08,03,216,039,039,0123,3149,9149,9149,9149,9255,7255,7301,0301,0301,0624,2624,2624,2624,2129E1129E1129E1192E1129E111,422,945,245,271,8141,2141,2141,2141,2173,2173,2321,9321,9321,9762,4762,4762,4761,922,8922,8873,1873,1873,10,10,41,21,22,56,56,56,56,56,36,314,314,314,336,236,236,235,945,745,745,745,745,70,911,432,292,292,475,035,035,035,034,244,2410,210,210,213,713,713,713,713,413,413,413,413,4Designation : page 67 - Symbols : page 6638

39RUTPWiper on requestWiper recess8,412,415,415,520,421,421,421,521,824,424,825,425,826,230,430,430,831,536,436,536,837,237,57,311,314,31419,320,320,32019,723,322,724,323,723,129,329,328,727,535,335,134,734,133,5253035354045454545484853535364646464686868686844445050506464646458587878788585858580808080800,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,50,544444555555666666655555121216161620202020202025252532323232252525252526,531,536,536,541,547474747505055,555,555,566,566,566,566,570707070705555555555555555555555533334444466666777788888212530303540,540,540,540,542424747475858585862626262628x412x515x515x820x621x521x621x821x1024x624x1225x525x1025x1530x530x630x1030x2036x636x936x1236x1836x24D 3D 2BQHbawADd 2d 1h9h12g6/H71317202025262626263131323232383838384545454545d 0 812151520212121212424252525303030303636363636Bezeichnungmm mm mm mm mm mm mm mm mm mm mm mm mmRURURURURURURURURURURURURURURURURURURURURURURUTTTTTTTTTTTTTTTTTTTTTTTPPPPPPPPPPPPPPPPPPPPPPPDesignation

Technical data and dimensionsPlanetary roller screwsPreloaded cylindrical nuts, TRU for backlash eliminationPRU for optimum rigidityd 0 39 ➙ 64 mmTRUPRUdo P h N l Ø C tpC oa T pe R m m Ia n s s I I Z ng R nr T pr F prnn ns n2 2mm mm – mm ° kN kN Nm N/µm N/µm Nm N kg kg/m kgmm/m kgmmkgmm 23cm393939393944444444444848484848485656566060606464646464510152025812182430581015202512243610152012182430365555566666555555666555666662100210021002100210024002400240024002400260026002600260026002600310031003100340034003400365036503650365036502,344,676,989,2711,533,304,967,429,8512,241,903,033,795,687,559,413,907,7711,563,044,556,063,425,126,818,4910,1558,268,775,577,878,760,264,771,075,674,789,298,4104,3116,1119,7130,095,6109,1118,7152,5168,0179,8135,4144,6150,3146,8146,4112,1112,9113,7108,7103,8113,2109,5110,4111,2102,7200,6196,0198,0202,7192,7204,6180,5174,7176,8324,9326,2327,4318,0302,4287,4258,3245,60,920,920,920,920,921,121,121,121,121,121,301,301,301,301,301,301,681,681,681,881,881,882,092,092,092,092,097505003902202106886104302901901080889760600460320810410290103083070093079064044035098065051029028089580055038025014101156980780600480106053037013401080910120010308405704500,88 - 1,750,88 - 1,750,88 - 1,750,88 - 1,751,31 - 2,191,07 - 2,141,07 - 2,141,07 - 2,141,07 - 2,141,60 - 2,681,24 - 2,471,24 - 2,471,24 - 2,471,24 - 2,471,24 - 2,471,24 - 2,471,60 - 3,191,60 - 3,192,39 - 3,991,79 - 3,581,79 - 3,581,79 - 3,581,99 - 3,981,99 - 3,981,99 - 3,981,99 - 3,981,99 - 3,98228819651465694697243222971497725727269825832405207214237822952157991029132635232633282900231812928922,12,12,12,12,11,71,71,71,71,74,24,24,24,24,24,23,23,23,27,37,37,35,45,25,24,94,99,49,49,49,49,411,911,911,911,911,914,214,214,214,214,214,219,319,319,322,222,222,225,325,325,325,325,3178E1178E1178E1178E1178E1289E1289E1289E1289E1289E1409E1409E1409E1409E1409E1409E1758E1758E1758E1999E1999E1999E1129E2129E2129E2129E2129E2203E1203E1203E1203E1203E1173E1173E1173E1173E1173E1652E1652E1652E1652E1652E1652E1500E1500E1500E1165E2165E2164E2106E2105E2105E2103E2103E2124,4124,4123,6123,6123,6119,2119,2118,3118,3118,3370,8370,8370,8370,8370,8369,6385,3383,1383,1110E1110E1110E1984,3914,0911,2771,0771,027,927,927,927,927,922,822,822,822,822,854,054,054,054,054,054,046,246,246,210310310346,254,054,069,469,4Designation : page 67 - Symbols : page 6640

4139,439,840,240,540,944,444,845,245,545,948,448,648,849,249,549,956,857,558,360,861,261,564,865,265,565,966,338,337,737,136,535,943,242,742,141,540,947,347,146,746,145,544,954,753,552,358,758,157,562,762,161,560,960,3808080808080808080801001001001001001001001001001221221221151151151151151001001001001009090909090127127127127127127112112112152152152129129129129129111110,50,50,50,50,511111111111111111888886666688888888810101088888404040404032323232324545454545454040404545454545454545838383838382,582,582,582,582,5103103103103103103103103103125125125118118118118118777777777777777777710,510,510,577777888888888899999999999911111111117337737373747474747490909090909093939311011011010610610610610639x 539x1039x1539x2039x2544x844x1244x1844x2444x3048x548x848x1048x1548x2048x2556x1256x2456x3660x1060x1560x2064x1264x1864x2464x3064x36D 3D 2BQHbawADd 2d 1h9h12g6/H7505050505056565656566060606060606666667171717575757575d 0 393939393944444444444848484848485656566060606464646464Beteckningmm mm mm mm mm mm mm mm mm mm mm mm mmRURURURURURURURURURURURURURURURURURURURURURURURURURURUTTTTTTTTTTTTTTTTTTTTTTTTTTTPPPPPPPPPPPPPPPPPPPPPPPPPPPDesignationRUTPWiper on requestWiper recess

Technical data and dimensionsPlanetary roller screwsPreloaded flanged nuts,d 0 8 ➙ 39 mmTRK for backlash eliminationPRK for optimum rigidityTRKPRKdo P h N l Ø C tpC oa T pe R m m Ia n s s I I Z ng R nr T pr F prnn ns n2 2mm mm – mm ° kN kN Nm N/µm N/µm Nm N kg kg/m kgmm/m kgmmkgmm 23cm81215152021212121242425252530303030363636363639393939394558656810612510155610206912182451015202545556555566555555565666555554006007507501050110011001100110012501250130013001300160016001600160019001900190019001900210021002100210021009,047,556,069,715,454,335,206,958,624,559,043,647,2610,813,043,636,0611,983,044,556,069,0411,982,344,676,989,2711,535,067,9811,712,412,122,822,924,526,719,021,528,532,735,641,442,847,955,540,743,948,051,555,758,268,775,577,878,78,1611,118,216,918,734,232,332,534,627,226,045,143,944,374,37372,673,974,772,575,673,576,8112,1112,9113,7108,7103,80,070,130,190,190,300,330,330,330,330,410,410,440,440,440,590,590,590,590,800,800,800,800,800,920,920,920,920,9211018029024229040035931120037015046029018062056142019077053051026024075050039022021015024038031538052046740426049020060038023081072955026010006896603303109806505102902800,06 - 0,130,12 - 0,250,18 - 0,360,18 - 0,360,26 - 0,580,31 - 0,630,31 - 0,630,31 - 0,630,31 - 0,630,39 - 0,780,39 - 0,780,42 - 0,840,42 - 0,840,42 - 0,840,57 - 1,130,57 - 1,130,57 - 1,130,85 - 1,410,77 - 1,530,77 - 1,530,77 - 1,530,77 - 1,531,15 - 1,910,88 - 1,750,88 - 1,750,88 - 1,750,88 - 1,751,31 - 2,1923657093295413051341139413545571597541157710084261844178014725552334196018207076492288196514656946970,30,30,50,50,50,70,70,70,70,80,81,41,41,42,12,12,12,12,12,12,12,12,14,04,04,04,04,00,40,91,41,42,32,72,72,72,73,63,63,93,93,95,65,65,65,68,08,08,08,08,09,49,49,49,49,43,216,039,039,0123,3149,9149,9149,9149,9255,7255,7301,0301,0301,0624,2624,2624,2624,2129E1129E1129E1192E1129E1178E1178E1178E1178E1178E166,4106,0201,6201,6289,5436,6436,6436,6436,6524,2524,2120E1120E1120E1268E1268E1268E1268E1317E1317E1312E1312E1312E1836E1836E1836E1836E1836E10,10,41,21,22,56,56,56,56,56,36,314,314,314,336,236,236,235,945,745,745,745,745,7124,4124,4123,6123,6123,60,911,432,292,292,475,035,035,035,034,244,2410,210,210,213,713,713,713,713,413,413,413,413,427,927,927,927,927,9Designation : page 67 - Symbols : page 6642

43Wiper on requestWiper recessEquidistant8,412,415,415,520,421,4212121,824,424,825,425,826,230,430,831,831,536,436,536,837,237,539,439,840,240,540,97,311,314,31419,320,320,320,019,723,322,724,323,723,129,329,328,727,535,335,134,734,133,538,337,737,136,535,92530353540454545454848565656646464646868686868828282828244445050506464646458587878788585858580808080801001001001001006xM46xM46xM56xM56xM56xM56xM56xM56xM56xM56xM56xM66xM66xM66xM86xM86xM86xM86xM86xM86xM86xM86xM86xM106xM106xM106xM106xM100,40,40,40,40,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,81,21,21,21,21,2M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6M6303030303030303030303030303030303030303030303030303030303333444446666677778888888888212530303540,540,540,540,54242474747585858586262626262737373737313172020252626262631313232323838383845454545455050505050812151520212121212424252525303030303636363636393939393914141616162323232320202929292929292926,526,526,526,526,533,533,533,533,533,51616181818181818181818202020272727272727272727333333333346515858636868686871718484849898989810210210210210212412412412412436414646515656565659597070708181818185858585851021021021021028x412x515x515x820x621x521x621x821x1024x624x1225x525x1025x1530x530x630x1030x2036x636x936x1236x1836x2439x539x1039x1539x2039x25D 3D 2BuQrGADd 2d 1 +0,4h12d 0Bezeichnungmm mm mm mm mm mm mm mm mm° mm mmA 2mm mm mmJjs12mmA 1 D 1RKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKTTTTTTTTTTTTTTTTTTTTTTTTTTTTPPPPPPPPPPPPPPPPPPPPPPPPPPPPDesignationDowel pinsto holdpreload3 Boltsfortransport

Technical data and dimensionsPlanetary roller screwsPreloaded flanged nuts,d 0 44 ➙ 64 mmTRK for backlash eliminationPRK for optimum rigidityTRKPRKdo P h N l Ø C tpC oa T pe R m m Ia n s s I I Z ng R nr T pr F prnn ns n2 2mm mm – mm ° kN kN Nm N/µm N/µm Nm N kg kg/m kgmm/m kgmmkgmm 23cm4444444444484848484848565656606060646464646481218243058101520251224361015201218243036666665555556665556666624002400240024002400260026002600260026002600310031003100340034003400365036503650365036503,304,967,429,8512,241,903,033,795,687,559,413,907,7711,563,044,556,063,425,126,818,4910,1560,264,771,075,674,789,298,4104,3116,1119,7130,095,6109,1118,7152,5168,0179,8135,4144,6150,3146,8146,4113,2109,5110,4111,2102,7200,6196,0198,0202,7192,7204,6180,5174,7176,8324,9326,2327,4318,0302,4287,4258,3245,61,121,121,121,121,121,301,301,301,301,301,301,681,681,681,881,881,882,092,092,092,092,097616104302901901080889760600460320810410290103083070093079064044035098980055038025014101156980780600420106053037013401080910120010308405704501,07 - 2,141,07 - 2,141,07 - 2,141,07 - 2,141,60 - 2,681,24 - 2,471,24 - 2,471,24 - 2,471,24 - 2,471,24 - 2,471,24 - 2,471,60 - 3,191,60 - 3,192,39 - 3,991,79 - 3,581,79 - 3,581,79 - 3,581,99 - 3,981,99 - 3,981,99 - 3,981,99 - 3,981,99 - 3,98344522971497725724269825832405207214237822952157991029132635232633282900231812928923,63,63,63,63,67,77,77,77,77,77,76,56,56,512,112,112,111,311,311,311,311,311,911,911,911,911,914,214,214,214,214,214,219,319,319,322,222,222,225,325,325,325,325,3289E1289E1289E1289E1289E1409E1409E1409E1409E1409E1409E1758E1758E1758E1999E1999E1999E1129E2129E2129E2129E2129E2802E1802E1802E1802E1802E1230E2230E2230E2230E2230E2230E2213E2213E2213E2528E2528E2528E2502E2502E2502E2502E2502E2119,2119,2118,3118,3118,3370,8370,8370,8370,8370,8369,6385,3383,1383,1110E1110E1110E1984,3914,0911,2771,0771,022,8122,8122,8122,8122,8153,9553,9553,9553,9553,9553,9546,1846,1846,18102,6102,6102,646,2446,2446,2446,2446,24Designation : page 67 - Symbols : page 6644

4544,444,845,245,545,948,448,648,849,249,549,956,857,558,360,861,261,564,865,265,565,966,343,242,742,141,540,947,347,146,746,145,544,954,753,552,358,758,157,562,762,161,560,960,3828282828210510510510510510510510510512212212212012012012012090909090901271271271271271271121121121521521521291291291291296xM106xM106xM106xM106xM106xM126xM126xM126xM126xM126xM126xM126xM126xM126xM166xM166xM166xM166xM166xM166xM166xM161,21,21,21,21,21,21,21,21,21,21,21,21,21,21,61,61,61,61,61,61,61,6M6M6M6M6M6M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1M8x1303030303030303030303030303030303030303030308888899999999999911111111117474747474909090909090939393110110110106106106106106565656565660606060606066666671717175757575754444444444484848484848565656606060646464646428,528,528,528,528,545454545454537,537,537,553,553,553,5424242424233333333333737373737373737374545454545454545124124124124124150150150150150150150150150180180180180180180180180102102102102102127127127127127127127127127150150150150150150150150D 3D 2BuQrGADd 2d 1 +0,4h12d 0Beteckningmm mm mm mm mm mm mm mm mm° mm mmA 2mm mm mmJjs12mmA 1 D 144x844x1244x1844x2444x3048x548x848x1048x1548x2048x2556x1256x2456x3660x1060x1560x2064x1264x1864x2464x3064x36RKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKRKTTTTTTTTTTTTTTTTTTTTTTPPPPPPPPPPPPPPPPPPPPPPDesignationWiper on requestWiper recessEquidistantDowel pinsto holdpreload3 Boltsfortransport

Flanged thrust bearing unitsIn standard version, the"FLRBU" thrust bearing unitis assembled according todrawing page 22 or 23.If you require a differentassembly, please indicate itwhen ordering40° angular contact ball bearing Lock nutFlanged bearingunit designationFLRBU1Basic axialload ratingC aC oaNumber ofbearingsBearingsdesignationDesignationHigh precision KMT nutHookspannerTighteningtorquekN kNNm N/µm Nm/mradNm13,314,727201 BEGBPMaximumpreloadtorque *0,1Axialrigidity150Tiltrigidity40KMT 1HN 310Grub screwsSize Maxtighteningtorque, NmM54,5FLRBU227.931.927303 BEGBP0.2519051KMT 3HN 415M68FLRBU340.163.847204 BEGBP0.25400140KMT 4HN 518M68FLRBU474.2119.247305 BEGBP1.1450160KMT 5HN 525M68FLRBU5109.4188.447307 BEGBP1.1600715KMT 7HN 742M68FLRBU6208.8392.347310 BEGBP1.57501000KMT 10HN 1070M68FLRBU7305,3615,447313 BEGBP212501600KMT 13HN 14100M818Flanged bearingunit designationL 2L 3L 4D 1D 2D 3h7D 4D 5S 1H13FixingscrewsEL 16.6FLRBU1421025147650476330M6 x 2527FLRBU24610321890626076376.6M6 x 2532FLRBU37713601890596074409M8 x 2532FLRBU48916682012080801004411M10 x 3044FLRBU5110208222140991001205413M12 x 4054FLRBU61402598.5251711301301527513M12 x 4067FLRBU718030133.5282251701701989517.5M16 x 5587* Preload torque measured at 50rpm46

Thrust bearingunitsFLRBU1d 4 d 5 d 9 B 1 B 2 B 4 B 3 GG 1 c b a d 7 R a R b a bh6 h7js12 js12 6g h11 N9 + 0.100012 10 17 58 20 78 5 M12 x 1 17 0.5 1.5 10.5 0.4 0.4 3 1.8b 1+ 0.5016b 21.5FLRBU21715236630965M17 x 1220.51.515.50.60.653252FLRBU320172797401377M20 x 1220.51.518.50.60.653352FLRBU4252034112451577M25 x 1.5250.52.322.80.60.663.5402.5FLRBU53530451345518910M35 x 1.52612.332.80.60.684452.5FLRBU65040681686523312M50 x 1.53112.347.80.60.6125554FLRBU765608321010031018M65 x 2321362.20.81187902.5UndercutUndercut l 2 is defined p13.47

Flanged thrust bearing units<strong>SKF</strong> “FLRBU” flanged thrust bearing units can be fitted on the screw shafts in the table below :Flanged thrustbearing Suitable for SRC & SRF Suitable for PRU & PRKFLRBU1FLRBU2FLRBU3FLRBU4SR 8 x 4 - R4SR 12 x 5 - R5SR 15 x 5 - R5SR 15 x 8 - R5SR 20 x 6 - R6SR 21 x 5 - R5 – SR 21 x 6 - R5 – SR 21 x 8 - R5SR 21 x 10 - R5SR 24 x 6 - R6 – SR 24 x 12 - R6SR 25 x 5 - R5PR 8 x 4 - R4 – PR 15 x 5 - R5PR 12 x 5 - R5 – PR 15 x 8 - R5PR 20 x 6 - R6PR 21 x 5 - R5 – PR 21 x 6 - R5 – PR 21 x 8 - R5PR 21 x 10 - R5PR 24 x 6 - R6 – PR 24 x 12 - R6PR 25 x 5 - R5 – PR 25 x 10 - R5 – PR 25 x 15 - R5PR 30 x 5 - R5 – PR 30 x 6 - R5PR 36 x 6 - R6PR 30 x 10 - R5 – PR 30 x 20 - R5SR 25 x 10 - R5SR 25 x 15 - R5PR 36 x 9 - R6PR 36 x 24 - R6PR 39 x 5 - R5– PR 36 x 12 - R6 – PR 36 x 18 - R6– PR 39 x 10 - R5 – PR 39 x 15 - R5PR 44 x 12 - R6 – PR 44 x 18 - R6 – PR 44 x 24 - R6PR 44 x 30 - R6FLRBU5SR 30 x 5 - R5– SR 30 x 6 - R5 – SR 30 x 10 - R5PR 39 x 20 - R5 – PR 39 x 25 - R5SR 30 x 20 - R5PR 48 x 5 - R5– PR 48 x 8 - R5 – PR 48 x 10 - R5SR 36 x 6 - R6– SR 36 x 9 - R6 – SR 36 x 12 - R6PR 56 x 12 - R6 – PR 56 x 24 - R6FLRBU6FLRBU7SR 36 x 18 - R6 – SR 36 x 24 - R6SR 39 x 5 - R5SR 44 x 8 - R6SR 39 x 10 - R5 – SR 39 x 15 - R5SR 39 x 20 - R5 – SR 39 x 25 - R5SR 44 x 12 - R6 – SR 44 x 18 - R6SR 44 x 24 - R6 – SR 44 x 30 - R6SR 48 x 5 - R5 – SR 48 x 10 - R5SR 48 x 15 - R5SR 56 x 12 - R6 – SR 56 x 18 - R6SR 56 x 24 - R6 – SR 56 x 30 - R6SR 60 x 10 - R5 – SR 60 x 15 - R5SR 64 x 12 - R6 – SR 64 x 18 - R6SR 64 x 24 - R6 – SR 64 x 30 - R6PR 60 x 10 - R5 – PR 60 x 15 - R5PR 60 x 20 - R5 – PR 60 x 25 - R5PR 60 x 30 - R5PR 64 x 12 - R6 – PR 64 x 18 - R6PR 64 x 24 - R6 – PR 64 x 30 - R6PR 64 x 36 - R6PR 80 x 12 - R6PR 80 x 18 - R649

Standard RangeThe full range of “SV” recirculating roller screws5External diameter, d 18 10 12 16 20 25 32 40 50 63 80 100 1254Lead, P h321Standard programRight hand leadManufacturing possibilitieson request50