Vertical Pump Tests - ANSI/HI 2.6: 2000 - the Hydraulic Institute

Vertical Pump Tests - ANSI/HI 2.6: 2000 - the Hydraulic Institute

Vertical Pump Tests - ANSI/HI 2.6: 2000 - the Hydraulic Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

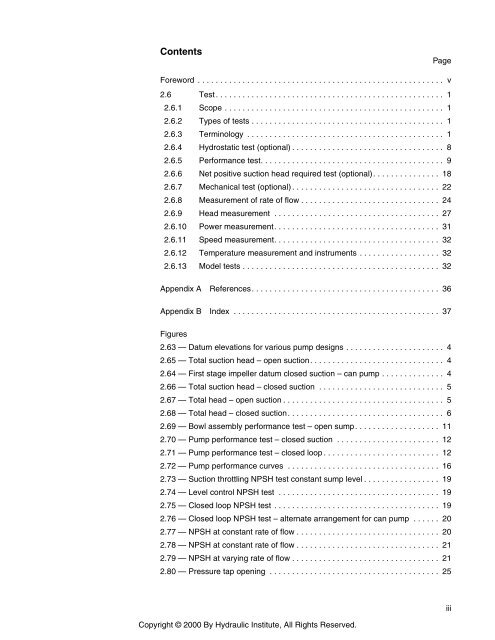

ContentsPageForeword ....................................................... v<strong>2.6</strong> Test................................................... 1<strong>2.6</strong>.1 Scope................................................. 1<strong>2.6</strong>.2 Typesoftests........................................... 1<strong>2.6</strong>.3 Terminology ............................................ 1<strong>2.6</strong>.4 Hydrostatictest(optional).................................. 8<strong>2.6</strong>.5 Performancetest......................................... 9<strong>2.6</strong>.6 Netpositivesuctionheadrequiredtest(optional)............... 18<strong>2.6</strong>.7 Mechanicaltest(optional)................................. 22<strong>2.6</strong>.8 Measurementofrateofflow............................... 24<strong>2.6</strong>.9 Headmeasurement ..................................... 27<strong>2.6</strong>.10 Powermeasurement..................................... 31<strong>2.6</strong>.11 Speedmeasurement..................................... 32<strong>2.6</strong>.12 Temperaturemeasurementandinstruments.................. 32<strong>2.6</strong>.13 Modeltests............................................ 32AppendixA References.......................................... 36AppendixB Index .............................................. 37Figures<strong>2.6</strong>3—Datumelevationsforvariouspumpdesigns...................... 4<strong>2.6</strong>5—Totalsuctionhead–opensuction.............................. 4<strong>2.6</strong>4—Firststageimpellerdatumclosedsuction–canpump.............. 4<strong>2.6</strong>6—Totalsuctionhead–closedsuction ............................ 5<strong>2.6</strong>7—Totalhead–opensuction.................................... 5<strong>2.6</strong>8—Totalhead–closedsuction................................... 6<strong>2.6</strong>9—Bowlassemblyperformancetest–opensump................... 112.70—<strong>Pump</strong>performancetest–closedsuction ....................... 122.71—<strong>Pump</strong>performancetest–closedloop.......................... 122.72—<strong>Pump</strong>performancecurves .................................. 162.73—SuctionthrottlingNPSHtestconstantsumplevel................. 192.74—LevelcontrolNPSHtest .................................... 192.75—ClosedloopNPSHtest..................................... 192.76—ClosedloopNPSHtest–alternatearrangementforcanpump ...... 202.77—NPSHatconstantrateofflow................................ 202.78—NPSHatconstantrateofflow................................ 212.79—NPSHatvaryingrateofflow................................. 212.80—Pressuretapopening ...................................... 25Copyright © <strong>2000</strong> By <strong>Hydraulic</strong> <strong>Institute</strong>, All Rights Reserved.iii

2.81 — Welded-onpressuretapopening ............................. 252.82 — Singletapconnection ...................................... 282.83 — Loopmanifoldconnectingpressuretabs........................ 282.84 — Gauge/valve arrangement. .................................. 282.85 — Bowlassemblyheadmeasurement ........................... 292.86 — Total head measurement – canpump.......................... 292.87 — Total head measurement – wetpit ............................ 302.88 — Gaugebelowatmosphericpressure........................... 302.89 — Fluid gauge with air leg below atmospheric pressure . . . . . . . . . ..... 30Tables2.11 — Symbols.................................................. 22.12 — Subscripts................................................ 32.13 — Recommendedinstrumentcalibrationinterval ................... 102.14 — Straight pipe required following any fitting before venturi meter indiametersofpipe................................................ 262.15 — Straight pipe required following any fitting before nozzle or orificeplatemeterindiametersofpipe..................................... 262.16 — Straight pipe required following downstream pressure tap of anozzleororificeplatemeterbeforeanyfittingindiametersofpipe.......... 27ivCopyright © <strong>2000</strong> By <strong>Hydraulic</strong> <strong>Institute</strong>, All Rights Reserved.