SKM 1200 / SKM 1500 - Forkardt

SKM 1200 / SKM 1500 - Forkardt

SKM 1200 / SKM 1500 - Forkardt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

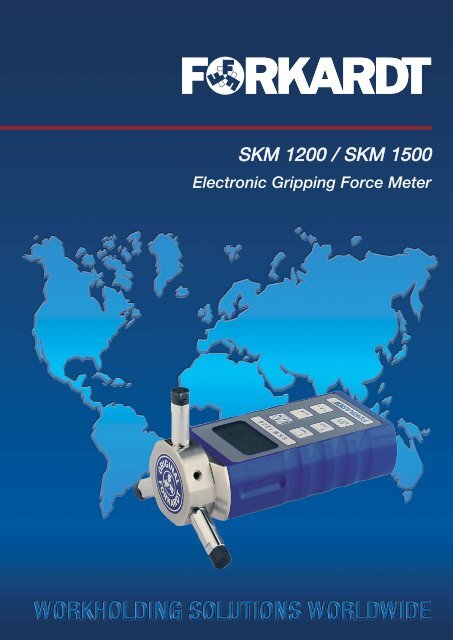

<strong>SKM</strong> <strong>1200</strong> / <strong>SKM</strong> <strong>1500</strong>Electronic Gripping Force Meter

<strong>SKM</strong> <strong>1200</strong> / <strong>SKM</strong> <strong>1500</strong> - ElectronFeaturesThe <strong>SKM</strong> gripping force meters areelectronic / mechanical units in compactdesign. This devices are ready for stationarytesting of 2 - 6 jaw chucks. They are equippedwith high precision force pick-up heads.The electronics (C-MOS technology) is housedin an ergonomically designed aluminiumcasing. A microprocessor and program routineensure the testing operation consistentlywith highest accuracy.The <strong>SKM</strong> <strong>1200</strong> and <strong>SKM</strong> <strong>1500</strong> includemany advanced features, such as:• advanced technology• lightweight, easy handling• sophisticated software• consistently high accuracy• robust design• service-free operation• applicable for mobile use• carry-casewith accessories2212Kraftaufnehmerforce transducerØ 110Ø 25Ø 58Ø 14Ø 75Dsp104Dsp55391018515514195<strong>SKM</strong> <strong>1500</strong><strong>SKM</strong> <strong>1200</strong>mm930.10.03 E 04/08

<strong>SKM</strong> <strong>1200</strong>/<strong>1500</strong>ic Gripping Force Meter930.10.03 E 04/08FunctionFORKARDT <strong>SKM</strong> devices contain a forcereceptor and processor-driven electronics withsophisticated software. The various functionsare suitable for every day measuring andchecking gripping forces of chucks.The meters' microprocessor multiplies thelevel of jaw power by the previously selectednumber of jaws to give the total jaw force ofthe chuck. The results displayed by the devicegive you the safety to decide whether theworkpiece can safely be gripped.Previous settings remain stored in the meterwhen it is switched off. Upon switching it backon measuring operations can be startedimmediately. Rechargeable power cells in themeter and a main adapter allow problem-freeand mobile use.The ergonomic casing is made fromaluminium. Its robust construction ensuresusage even under rough production conditionsin modern machining.UsageThe utilisation of modern CNC lathes and newcutting tool materials allows for ever increasingcutting speeds, thus considerably improvingmachine efficiency and productivity. High precisionand quality chucking equipment fromFORKARDT provide the gripping forces necessaryto transmit the power to the workpiece,maximising accuracy and high speeds offeredby the machine.To ensure safety when machining, theEuropean Norm EN 1550 clearly states thatthe operation of chucks should be regularlychecked by measuring the static grippingforces. Utilizing FORKARDT <strong>SKM</strong> grippingforce meters can satisfy this requirement.The <strong>SKM</strong> <strong>1200</strong> and <strong>SKM</strong> <strong>1500</strong> grippingforce meters can be used to:• check the safety of the chucking operationfor high cutting speeds and feeds• focus and optimise the use of the workholdingfixture• measure the gripping force of the chuckrelative to the number of jaws withoutmoving the jaws out of alignment• determine the chuck factor (i.e. the ratioof gripping force to axial force or adjustedpressure)• monitor lubrication of the chuck• determine lubrication intervals for safechucking• provide information regarding preventativechuck servicing• save energy, reduce stress, wear and tearon the chuck and minimise distortion of theworkpiece through focused interpretationof dynamic gripping force (Fsp0)The FORKARDT <strong>SKM</strong> meters are solely fortesting stationary gripping forces at idlechucks. Furthermore, the measured levels ofgripping forces should always be compared tothe values quoted in the relevant chuck operatorsmanual. By this, the expected loss of grippingforce can be determined, especially whenoperating chucks at highest rotational speeds.Technical DetailsThe <strong>SKM</strong> <strong>1200</strong> and <strong>SKM</strong> <strong>1500</strong> gripping forcemeters meet the EMV regulation 89/336/EWGand are marked with the CE-sign to indicateconformity with the relevant European safetystandards.The gripping force meter automatically carriesout an adjustment of the zero-point when it isswitched on. If the zero-point has been displacedby more than 20% of the maximum measuringrange value the display flashes. Thisindicates previous mechanical overloading ofthe gripping force meter and lasting distortionof the measuring bolt. In this case, the metershould be returned to FORKARDT for testingand maintenance.A second set of tension and compressionbolts is required for testing 6-jaw chucks. Thecorresponding part order numbers can befound in the ,,Accessories" section.

<strong>SKM</strong> <strong>1200</strong> <strong>SKM</strong> <strong>1500</strong>Measuring range 0 ... 200.0 kN 0 ... 500.0 kNLowest unit of measurement0.1 kNPermitted overload 100 ... 120% of max. range value, and display flashExcess overload > 120% of max. range value, flashes, display blankDisplay range0 ... 20,000 Digit´sMeasuring tolerance< +/- 0.5 % of of max. range valueMeasuring frequency1000 HzDisplay frequency4 Hz (average value from 250 readings)Maximum value recordmaximum value memoryUnit scalest, kN, k lbsNumber of jaws 2, 3, 6Batteryrechargeable with mains adapter 230 VAC / 50 HzOperating time10 hours from a full chargeRecharging time8 hours with unit switched offCasing dimensions155 x 75 x 39 mmInsulationto IP 65 standardsDimensions measuring head 55 mm Ø 104 mm ØChucking diameter (Dsp) 63 ... 293 mm Ø 114 ... 544 mm ØWeight approx 1.3 kg approx 2.9 kgDisplayNumber of jaws 2, 3, 6/ Record maximum /overloadGripping force 0-200 kN (<strong>SKM</strong> <strong>1200</strong>)0-500 kN (<strong>SKM</strong> <strong>1500</strong>)Battery needs chargingUnit scale t, kN, k lbsKey-FunctionsRecord maximum valueThe maximum value recorded is stored and displayed.Maximum value mode allows to take a reading in chuckingsituations when the display cannot be viewed.The maximum value remains displayed after unclampingthe meter. The memory can be cleared before a new maximumvalue reading is taken by pressing the CLR button. Ifthe memory isn’t cleared manually it will be cleared automaticallywhenever the next reading is taken and the newresult will be displayed. In order to avoid misinterpretedreadings, the maximum recorded value is automaticallydeleted, whenever the meter is switched off.Changing number of jawsThe number of jaws changes each time this key is pressed.The chosen number of jaws is shown in the top right cornerof the display. Possible values are 2, 3 and 6 jaws. The readingeventually displayed is the actual measurement multipliedby the number of jaws selected, and the maximumvalue is cleared.Clear maximum valueThe recorded maximum value is cleared, but the unitremains in maximum value mode.Changing the unit scaleOn pressing this button the unit scale is changed. Availableunit scales are t, kN and klbs. The value read is recalculatedand displayed when the unit scale is changed.1 kN = 1000 N, 1 t = 9807 N, 1 k lbs = 1000 lbs = 4448 N930.10.03 E 04/08Switching on / offCurrent settings remain stored when the meter is switchedoff. Upon switching it back on, measuring operations canbe started immediately.Adjusting the zero-pointThe zero-point on the meter is adjusted by pressing thisbutton. This function should only be used when the meteris not clamped or loaded.

AccessoriesExtension pieces can be mounted to the headof the FORKARDT <strong>SKM</strong> meters using combinationsof tension and compression bolts.Chucking diameters of 63 to 293 mm(<strong>SKM</strong> <strong>1200</strong>) and 114 to 544 mm (<strong>SKM</strong> <strong>1500</strong>)can be accommodated (in 10 mm intervals).One of the tension or compression bolts mustalways be screwed into the matching hole ontop of the measuring head (when viewed withdisplay side up). The measuring sensor islocated at this position in the measuring(the joint is recognisable).The remaining tension or compressionbolts should be positioned appropriatelyaccording to the number of jaws.<strong>SKM</strong> <strong>1200</strong> <strong>SKM</strong> <strong>1500</strong>System M6 Length Ident. No. System M12 Length Ident. No.3 pieces each 1 [mm] 3 pieces each 1 [mm]Tension bolt 4 D164809020 Tension bolt 5 D164814020Tension bolt 9 D164809021 Tension bolt 10 D164814021Tension bolt 14 D164809022 Tension bolt 15 D164814022Tension bolt 20 D164814023Compression bolt 15 D164809025 Compression bolt 20 D164814025Compression bolt 30 D164809026 Compression bolt 40 D164814026Compression bolt 60 D164809027 Compression bolt 80 D164814027Compression bolt 160 D1648140282 Spanners (gauge 12) 2 Spanners (gauge 22)Carry-case, mains adapterCarry-case, mains adapterTension and Compression bolts can bereordered as a set.Example of order:• <strong>SKM</strong> <strong>1200</strong> 1 set tension andcompression boltsIdent. No. D300224003• <strong>SKM</strong> <strong>1500</strong> 1 set tension andcompression boltsIdent. No. D300229003930.10.03 E 04/08