GS Clamps

GS Clamps

GS Clamps

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

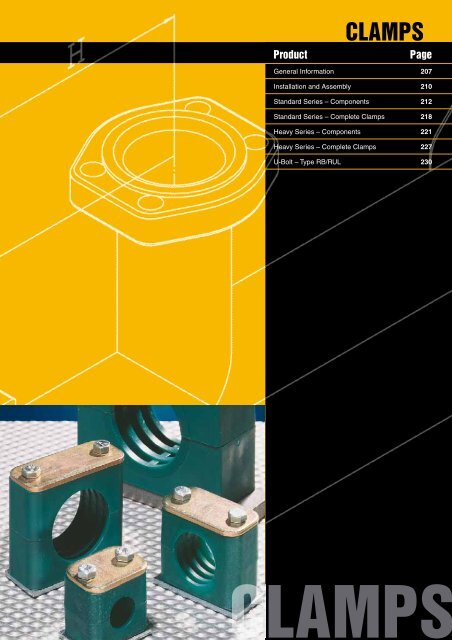

GENERALINFORMATIONProductCLAMPSPageHYDRAULIC PIPES 10-40 BAR SAE 50 BAR SAE 3000 PSI DIN 350-400 BAR SCHEDULE SERIESAE 3000 PSIGeneral Information 207Installation and Assembly 210Standard Series – Components 212Standard Series – Complete <strong>Clamps</strong> 218Heavy Series – Components 221Heavy Series – Complete <strong>Clamps</strong> 227U-Bolt – Type RB/RUL 230SCHEDULE SERIESAE 6000 PSISCHEDULE SERIEDIN 350-400 BARLAMPS

CLAMPSGeneral Information<strong>GS</strong>-FLANGESYSTEM<strong>GS</strong>-Hydro’s tube clamps conform to DIN 3015 and are designed to support all pipes,tubes and hoses up to 12” NB (324 mm OD). The clamps consist of two polypropylene,polyamide, aluminum or rubber clamp halves, held to a steel welding plate ormounting rail by one or more bolts through a cover plate.207TUBES & PIPESCLAMPSThe <strong>GS</strong>-multipipe clamp allows several tubes or pipes of the same group to be stacked on top of each other.The <strong>GS</strong>-tube clamp range includes the light (A), twin (B) and heavy (C) series.VALVESBITE TYPEFITTIN<strong>GS</strong>Size Range<strong>GS</strong> Tube <strong>Clamps</strong> Series A (Light)Clamp Group O.D. mm Tube N.B. Inch O.D.0 6– 12 1/8 1/4– 3/81 6– 12 1/8 1/4– 3/82 12.7– 18 1/4– 3/8 1/2– 5/83 19– 25 1/2 3/4– 14 26.9– 30 3/45 32– 42 1– 1 1/4 1 1/4– 1 1/2SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong><strong>GS</strong> Tube <strong>Clamps</strong> Series B (Twin)Clamp Group O.D. mm Tube N.B. Inch O.D.1 6– 12 1/8 1/4– 3/82 12.7– 18 1/4– 3/8 1/2– 5/83 19– 25 1/2 3/4– 14 26.9– 30 3/45 32– 42 1– 1 1/4 1 1/4– 1 1/2<strong>GS</strong> Tube <strong>Clamps</strong> Series C (Heavy)Clamp Group O.D. mm Tube N.B. Inch O.D.1 6– 18 1/8– 3/8 5/16– 5/82 19– 30 1/2– 3/4 3/4– 13 30– 42 1– 1 1/4 1 1/4– 1 1/24 38– 70 1 1/4– 2 1 1/2– 2 1/25 70– 90 2 1/2– 3 3– 3 1/26 90– 127 3 1/2– 4 4 – 57 127– 168.3 5– 6 5– 6 5/88 168.3– 220 8 6 5/8– 8 5/89 250– 324 10– 12 9 7/8– 12 3/4ADAPTORSSPECIALSOLUTIONSMACHINESTECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSGeneral InformationTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORS SPECIALSOLUTIONSMACHINES TECHNICALINFORMATION208Clamp Body MaterialMetal PartsClamp BodyMaterial PropertiesCopolymericPolypropylene PPColour: greenPolyamide PAColour: blackMechanical PropertiesFlexural Deflection DIN 53452* 36 N/mm² 130—200 N/mm²Impact Resistance DIN 53453* no failure 60 KJ/m²Aluminium Al Si 12Santoprene SAColour: blackCompressive Strength DIN 53454* 90 N/mm² 120 N/mm² 60—80 HB 5/250Hardness73—87 Shore AModulus of Elastisity DIN 53452* 1150 N/mm² 3000 N/mm² 7000 N/mm² 3.5—6.9 N/mm²Tensile Stress DIN 53455* 28 N/mm² 140 N/mm² 220—300 N/mm² 8.5—15.9 N/mm²Thermal PropertiesMax. Temperature Resistance –30 — +90°C –40 — +120°C up to 300°C –40 — +120°CChemical PropertiesWeak acids, solvents cond. consistent cond. consistent cond. consistent consistentBenzine, mineral oils cond. consistent consistent consistent cond. consistentAlcohol, seawater consistent consistent consistent consistent* = DIN specifications refer to plastics onlyOther thermoplastics and materials for clamp bodies on request.Surface Finishing• Steel cover plates• BoltsMaterials• Carbon steel• Stainless steelThreadsAll threads are available with UNC-threads upon request.Thread ChartStandard-SeriesGroup Metric Thread UNC Thread012345678M61/4–20 UNCzinc/nickelelectric zinc chromatedSt371.4301/1.4305 (AISI 304)1.4401/1.4571 (AISI 316/316Ti)Heavy-SeriesGroup Metric Thread UNC Thread3S4S5S6SM10M123/8–16UNC7/16–14UNC7S M16 5/8–11UNC8S M20 3/4–10UNC9S M24 7/8–9UNC10S M30 1 1/8–7UNC11S M30 1 1/4–7UNC12STwin-SeriesGroup Metric Thread UNC Thread1D M6 1/4–20UNC2D3D4D5DM8 5/16–18UNCMaterial Properties Anti Corrosion ClampMaterial Property Test Method Unit ValueDensity ISO 1133 g/cm 3 0.908Flexural Modulus ISO 178 MPa 1170Tensile E. Modulus ISO 527-2 MPa 1170Yield Strength ISO 527-2 MPa 26Yield Strain ISO 527-2 % 7.9Tensile Stregth at Break ISO 527-2 MPa 14.1Izod-Imact notched 23°C ISO 180/1A KJ/m 2 6.1Izod-Imact notched 0°C ISO 180/1A KJ/m 2 4.5Izod-Imact notched -20°C ISO 180/1A KJ/m 2 3.6Ball Intendation Hardness ISO 2039 MPa 57Softening Temperature Vicat 10 N ISO 306A °C 149Heat Sistortion Temp. HDT 0.45 MPa ISO 75B °C 72.5

CLAMPSGeneral Information<strong>GS</strong>-FLANGESYSTEMDesign of Clamp BodiesStandard-SeriesHeavy-SeriesTwin-SeriesTUBES & PIPES209CLAMPSStandard design– profiled inside –VALVESStandard design– profiled inside –TECHNICALINFORMATIONMACHINESADAPTORSBITE TYPEFITTIN<strong>GS</strong>H-design– smooth inside –(recommended for hoses)RI-designfor rubber insertsH-design– smooth inside –(recommended for hoses)Standard design– profiled inside –SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>Oval designRI-designfor rubber insertsH-design– smooth inside –(recommended for hoses)SPECIALSOLUTIONSRectangular-designWAG-designfor ball inserts

<strong>GS</strong>-FLANGESYSTEMCLAMPSInstallation and AssemblyTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>210The following provides the installation principles for clamps. For detailed installation instructions kindly refer to <strong>GS</strong>-Hydro’s installation manuals.Installation InformationInstallation on Weld Plates<strong>GS</strong>-Hydro weld plates are available for the followingSeries:• Standard-Series• Heavy-Series• Twin-Series• Special <strong>Clamps</strong>For best alignment of <strong>GS</strong>-Hydro clamps it isrecommended to mark their location first. Weldplates, push on bottom half of clamp, installpipe, mount top half of clamp and cover plateand bolt unit together.In order to avoid damage to the clamp bodiesit is recommended to mount the plastic clampbodies after having welded the weld plates.Installation on Mounting Rails<strong>GS</strong>-Hydro mounting rails can be used with thefollowing Series:• Standard-Series• Heavy-Series (Group 3S – 6S)• Twin-Series• Special <strong>Clamps</strong><strong>GS</strong>-Hydro mounting rails are available in fourdifferent height sizes.The rails are either welded or bolted to thesupporting construction.For Standard- and Twin-Series insert hexagonrail nut and turn to lock.For Heavy-Series slide in rail nut.Push on bottom half of clamp, install pipe,mount top half of clamp and cover plate andbolt unit together.Clamp units can be adjusted before beingfirmly bolted.Multi-Level Assembly<strong>GS</strong>-Hydro multi-level pipe clamps permiteasy stacking of several tubes or pipes of thegroup.(Twin-<strong>Clamps</strong> group 2 – 5 allow stacking of differentgroup sizes.)The clamps are connected by stacking bolts(AF).Safety plates (SIG/SIP/SI) inserted betweenthe clamps prevent stacking bolts from turning.<strong>GS</strong>-Hydro stacking assembly can be fitted toweld plates or to rails.SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORS SPECIALSOLUTIONSMACHINES TECHNICALINFORMATION

CLAMPSInstallation and Assembly<strong>GS</strong>-FLANGESYSTEMTightening Torques and Maximum Loads in Pipe DirectionTUBES & PIPESAll tightening torques and max. loads in pipe directionrefer to clamps with cover plates and hexagon headbolts acc. to DIN 931/933.211CLAMPSSliding starts when the shown values (F) are reached.TECHNICALINFORMATIONVALVESClamp GroupHexagonHead Bolt DIN931/933TighteningTorque(Nm)Standard-Series (acc. to DIN 3015, part 1)Polypropylene Polyamide AluminumMax. load inpipe directionF (kN)TighteningTorque(Nm)Max. load inpipe directionF (kN)TighteningTorque(Nm)Max. load inpipe directionF (kN)08 0.6 10 0.6 12 3.51 8 1.1 10 0.7 12 4.22 8 1.3 10 0.8 12 4.33M68 1.4 10 1.6 12 4.94 8 1.5 10 1.7 12 5.05 8 1.9 10 2.0 12 7.36 8 2.0 10 2.5 12 8.9Clamp GroupHexagonHead Bolt DIN931/933TighteningTorque(Nm)Heavy-Series (acc. to DIN 3015, part 2)Polypropylene Polyamide AluminumMax. load inpipe directionF (kN)TighteningTorque(Nm)Max. load inpipe directionF (kN)TighteningTorque(Nm)Max. load inpipe directionF (kN)3S12 1.6 20 4.2 30 12.14S M1012 2.9 20 4.5 30 15.15S 15 3.3 25 5.1 35 15.56S M12 30 8.2 40 9.3 55 29.47S M16 45 11.0 55 25.8 120 34.98S M20 80 14.0 150 21.0 220 70.69S M24 110 28.0 200 32.0 250 50.010S180 40.0 350 48.0 500 84.511S M30200 119.0 370 125.0 500 181.512S 270 168.0 450 180.0 600 244.5Clamp GroupHexagonHead Bolt DIN931/933Tightening Torque(Nm)Twin-Series (acc. to DIN 3015, part 3)PolypropyleneMax. load in pipe directionF (kN)Tightening Torque(Nm)PolyamideMax. load in pipe directionF (kN)1D M6 5 0.9 5 0.92D12 2.1 12 2.23D 12 1.9 12 2.0M84D 12 2.7 12 2.95D 8 1.7 8 2.5BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORSSPECIALSOLUTIONSMACHINES

<strong>GS</strong>-FLANGESYSTEMCLAMPSStandard-Series – ComponentsTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORS SPECIALSOLUTIONSMACHINES TECHNICALINFORMATION212Material CodeMaterials and designs of clamps bodiesPolypropylene, profiled inside, with tension clearancePolypropylene, smooth inside, without tension clearancePolyamide, profiled inside, with tension clearancePolyamide, smooth inside, without tension clearanceSantoprene, profiled inside, with tension clearanceSantoprene, smooth inside, without tension clearanceAluminum, profiled inside, with tension clearance(AL group 1 A – 6 only)Other thermoplastics and O.D. on request.<strong>GS</strong>HGroupSurface finishing (see technical appendix) – DIN 50942 Fe/Znph r 10 DIN 50942 Fe/Znph r 10DINGroup1 01A 12 23 34 45 56 67 78 8Outside O.D.Tube or HosemminchXXX-PP-PPH-PA-PAH-SA-SAH-ALNominalBore PipeinchGroup 1Clamp Body(2 halves)(xxx -see material code)6 106 xxx6.4 1/4 106.4 xxx8 5/16 108 xxx9.5 3/8 109.5 xxx10 1/8 110 xxx12 112 xxx6 106 Axxx6.4 1/4 106.4Axxx8 5/16 108 Axxx9.5 3/8 109.5Axxx10 1/8 110 Axxx12 112 Axxx12.7 1/2 212.7 xxx13.5 1/4 213.5 xxx14 214 xxx15 215 xxx16 5/8 216 xxx17.2 3/8 217.2 xxx18 218 xxx19 3/4 319 xxx20 320 xxx21.3 1/2 321.3 xxx22 7/8 322 xxx25 1 325 xxx26.9 3/4 426.9 xxx28 428 xxx30 430 xxx32 1 1/4 532 xxx33.7 1 533.7 xxx35 535 xxx38 1 1/2 538 xxx40 540 xxx42 1 1/4 542 xxx44.5 1 3/4 644.5 xxx48.3 1 1/2 648.3 xxx50.8 2 650.8 xxx57.2 2 1/4 757.2 xxx60.3 2 760.3 xxx63.5 2 1/2 763.5 xxx70 2 3/4 770 xxx73 2 7/8 2 1/2* 773 xxx76.1 3 2 1/2** 776.1 xxx88.9 3 888.9 xxx102 4 8102 Lxxx* = (except DIN 2448)** = (DIN 2448 only)Group 1 Group 1Group 1 A – 8 Group 1 A – 8 Group 1 A – 8SingleWeld PlateSPElongatedWeld PlateSPVSP 1 SPV 1SP 1 ASPV 1 ASP 2 SPV 2SP 3 SPV 3SP 4 SPV 4SP 5 SPV 5SP 6 SPV 6SP 7 SPV 7SP 8 SPV 8

CLAMPSStandard-Series – ComponentsTECHNICALINFORMATION<strong>GS</strong>-FLANGESYSTEMMACHINESSAE J514 JICFLARE FITTIN<strong>GS</strong>BITE TYPEFITTIN<strong>GS</strong>TUBES & PIPESGroup 1Group 1Group 1TS213CLAMPSGroup 1 A – 6DIN 50942 Fe/Znph r 10 – – – – (TSL z.p.) –TwinWeld PlateDSPGroup 1 A – 6GroupWeld PlateRAPGroup 1 A – 6 Group 1 A – 6 TSLGroup 1 – 8Weld Plate,angledWSPBridgeWeld PlateBSPMounting RailTS/TSLHexagon RailNutSMVALVESDSP !/40 RAP 1/30/10 WSP 1DSP 1 A/37 RAP 1 A/37/10 WSP 1 A BSP 1 ADSP 2/44 RAP 2/44/10 WSP 2 BSP 2DSP 3/52 RAP 3/52/10 WSP 3 BSP 3TS 11TS 14TS 30SMHOSES &HOSE COUPLIN<strong>GS</strong>TSL 11DSP 4/60 RAP 4/60/5 WSP 4 BSP 4(available in 1 and2 m lengths)ADAPTORSDSP 5/75 RAP 5/75/5 WSP 5 BSP 5DSP 6/90 RAP 6/90/5 WSP 6 BSP 6SPECIALSOLUTIONS

<strong>GS</strong>-FLANGESYSTEMCLAMPSStandard-Series – ComponentsTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>214Group 1Group 1 A – 8Cover PlateDPDP 1Hexagon HeadBoltASDIN 931/933AS 1/1 A(M6x30)Socket Cap ScrewISDIN 912IS 1/1 A(M6x20)DIN 50942 Fe/Znph r 10Slotted HeadScrewLIDIN 84LI 1/1 A(M6x20)Stacking BoltAFAF 1/1 AGroup 1Group 1 A – 8Safety LockingPlateSI<strong>GS</strong>IG 1Only for hexagonhead boltsas DIN 931/933Group 1 – 8Safety WasherSIDIN 93DP 1 ASIG 1 ASAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>DP 2 AS 2(M6x35)DP 3 AS 3(M6x40)IS 2(M6x25)IS 3(M6x30)LI 2(M6x25)LI 3(M6x30)AF 2 SIG 2AF 3 SIG 3SI 6.4ADAPTORS SPECIALSOLUTIONSDP 4AS 4(M6x45)DP 5 AS 5(M6x60)DP 6AS 6(M6x70)IS 4(M6x35)IS 5(M6x50)IS 6(M6x60)LI 4(M6x35) AF 4 SIG 4LI 5(M6x50)AF 5 SIG 5LI 6(M6x60) AF 6 SIG 6MACHINES TECHNICALINFORMATIONDP 7AS 7(M6x100)DP 8 AS 8(M6x125)IS 7(M6x90) AF 7 SIG 7IS 8(M6x110)AF 8 SIG 8

CLAMPSStandard-Series – Components<strong>GS</strong>-FLANGESYSTEMMaterial CodeMaterials and designsof clamps bodiesXXXPolypropylene,profiled inside,with tension clearance-PPPolypropylene,smooth inside,without tension clearance -PPHPolyamide, profiled inside,with tension clearance-PAPolyamide, smooth inside,without tensionclearance- PAHSantoprene, profiled inside,with tension clearance-SASantoprene, smooth inside,without tension clearance -SAHAluminum, profiled inside,with tension clearance-AL(AL group 1 A – 6 only)Group 1Group 1Group 1215TUBES & PIPESCLAMPSVALVESOther thermoplastics and O.D. onrequest.Surface finishing (see also techn. appendix) – DIN 50942 Fe/Znph r 10 DIN 50942 Fe/Znph r 10<strong>GS</strong>HGroupDINGroup1 01A 12 23 34 45 56 67 78 8Pipe-O.D.Ø D1[mm]66,489,5101266,489,5101212,713,514151617,218192021,3222526,928303233,73538404244,548,350,857,260,363,5707376,188,9102L1L228 9,5 2737 20 2742 26 3350 33 3659 40 4271 52 5886 66 66121 94 93147 120 118Group 1A - 8 Group 1A - 8 Group 1A - 8Clamp Body(2 halves)SingleWeld PlateSPElongatedWeld PlateSPVInside surfaceprofiled smooth WidthH S H L1 L2 B S H øD L1 L2 L3 B S H øD1 øD20,4min.0,4min.0,6min.0,6min.0,6min.0,8min.0,8min.26 30 31,5 10 30 3 6,5 12 58 24,5 44 30 3 6,5 12 6,526 30 36 20 30 3 6,5 12 64 20 50 30 3 6,5 12 6,532 30 42 26 30 3 6,5 12 70 26 56 30 3 6,5 12 6,535,5 30 50 33 30 3 6,5 12 78 33 64 30 3 6,5 12 6,541,5 30 60 40 30 3 6,5 12 87 40 73 30 3 6,5 12 6,556,5 30 71 52 30 3 6,5 12 100 52 86 30 3 6,5 12 6,564,5 30 88 66 30 3 6,5 12 115 66 100 30 3 6,5 12 6,50,8min. 92 30 122 94 30 5 6,5 12 150 94 136 30 5 6,5 12 6,508,min.116 30 148 120 30 5 6,5 12 178 120 162 30 5 6,5 12 6,5BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORSSPECIALSOLUTIONSMACHINESTECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSStandard-Series – ComponentsTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>216Group 1Group 1A - 6DIN 50942 Fe/Znph r 10 – – –TwinWeld PlateDSPGroup 1Group 1A - 6GroupWeld PlateRAPGroup 1Weld Plate,angledWSPBridgeWeld PlateBSPL1 L2 L3 B S H øD L1 L2 L3 B S H øD L1 L2 B1 B2 S H øD1 øD2 L1 L2 B S H1 H2 øD87 40 40 30 3 6,5 12 314 31 31 30 4 6,5 12 30 14 30 30 3 6,5 12 6,5Group 1A - 6 Group 1A - 6HOSES &HOSE COUPLIN<strong>GS</strong>77 20 37 30 3 6,5 12 373 20 37 30 4 6,5 12 36 20 30 30 3 6,5 12 6,5 48 20 30 3 13 6,5 1286 26 44 30 3 6,5 12 442 26 44 30 4 6,5 12 42 26 30 30 3 6,5 12 6,5 54 26 30 3 13 6,5 12ADAPTORS SPECIALSOLUTIONS102 33 52 30 3 6,5 12 521 33 52 30 4 6,5 12 50 33 30 30 3 6,5 12 6,5 62 33 30 3 13 6,5 12120 40 60 30 3 6,5 12 300 40 60 30 4 6,5 12 60 40 30 30 3 6,5 12 6,5 71 40 30 3 13 6,5 12145 52 75 30 3 6,5 12 378 52 75 30 4 6,5 12 70 52 30 30 3 6,5 12 6,5 85 52 30 3 13 6,5 12MACHINES TECHNICALINFORMATION178 66 90 30 3 6,5 12 450 66 90 30 4 6,5 12 88 66 30 30 3 6,5 12 6,5 98 66 30 3 13 6,5 12

CLAMPSStandard-Series – Components<strong>GS</strong>-FLANGESYSTEMTS 11TUBES & PIPESTS 14Group 1Group 1217CLAMPSTS 30VALVESTSL 11(z.p.)– – DIN 50961 Fe/Zn 8 CMounting RailTS/TSLGroup 1 - 8 Group 1A - 8 Group 1A - 8 Group 1 - 8Hexagon RailNutSMCover PlateDPHexagonHead BoltASDIN 931/933SocketCap ScrewISDIN 912SlottedHead ScrewLIDIN 84StackingBoltAFSafetyLocking PlateSIGB1 B2 S L B H1 H2 øD L1 L2 B S øD G x L G x L D S G x L D S G L1 L2 L3 SW L B1 B2 S øDSafetyWasherSIDIN 9328 9,5 30 3 7 M6x30 M6x20 11 0,8 M6x20 11 0,8 M6 34 20 12 11 17 32 11,1 1 6,4min.BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>34 20 30 3 7 M6x30 M6x20 11 0,8 M6x20 11 0,8 M6 34 20 12 11 34 28 11,1 1 6,4min.HOSES &HOSE COUPLIN<strong>GS</strong>40,5 26 30 3 7 M6x35 M6x25 11 0,8 M6x25 11 0,8 M6 40 25 12 11 40 28 11,1 1 6,4min.28 11 2 25,4 10,4 13 5 1248 33 30 3 7 M6x40 M6x30 11 0,8 M6x30 11 0,8 M6 44 30 12 11 47 28 11,1 1 6,4min.ADAPTORS57 40 30 3 7 M6x45 M6x35 11 0,8 M6x35 11 0,8 M6 48 35 12 11 56 28 11,1 1 6,4min.70 52 30 3 7 M6x60 M6x50 11 0,8 M6x50 11 0,8 M6 64 50 12 11 69 28 11,1 1 6,4min.SPECIALSOLUTIONS86 66 30 3 7 M6x70 M6x60 11 0,8 M6x60 11 0,8 M6 73 60 12 11 85 28 11,1 1 6,4min.118 94 30 5 7 M6x100 M6x90 11 0,8 M6 99 85 12 11 117 28 11,1 1 6,4min.MACHINES144 120 30 5 7 M6x125 M6x110 11 0,8 M6 124 110 12 11 143 28 11,1 1 6,4min.TECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSStandard-Series – Complete <strong>Clamps</strong>TUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>218<strong>GS</strong>HGroup11A2Pipe-O.D.[mm]Order Code6 106 xxx6,4 106,4 xxx8 108 xxx9,5 109,5 xxx10 110 xxx12 112 xxx6 106 A xxx6,4 106,4 A xxx8 108 A xxx9,5 109,5 A xxx10 110 A xxx12 112 A xxx12,7 212,7 xxx13,5 213,5 xxx14 214 xxx15 215 xxx16 216 xxx17,2 217,2 xxx18 218 xxxMaterial CodeMaterials and designsof clamps bodies XXXPolypropylene,profiled inside, with tension clearancePolypropylene,smooth inside,without tension clearancePolyamide,profiled inside, with tension clearancePolyamide,smooth inside, without tension clearanceSantoprene,profiled inside, with tension clearanceSantoprene,smooth inside, without tension clearanceAluminum,profiled inside, with tension clearance(AL group 1 A – 6 only)Other thermoplastics and O.D. on request.- PAH- SAH- PP- PPH- PA- SA- AL19 319 xxxSAE J514 JICFLARE FITTIN<strong>GS</strong>3420 320 xxx21,3 321,3 xxx22 322 xxx25 325 xxx26,9 426,9 xxx28 428 xxxHOSES &HOSE COUPLIN<strong>GS</strong>530 430 xxx32 532 xxx33,7 533,7 xxx35 535 xxx38 538 xxx40 540 xxx42 542 xxxADAPTORS SPECIALSOLUTIONS6744,5 644,5 xxx48,3 648,3 xxx50,8 650,8 xxx57,2 757,2 xxx60,3 760,3 xxx63,5 763,5 xxx70 770 xxx73 773 xxx76,1 776,1 xxx888,9 888,9 xxx102 8102 L xxxDesign of clamp bodies see technical appendix, page 209.MACHINES TECHNICALINFORMATION

CLAMPSStandard-Series – Complete <strong>Clamps</strong><strong>GS</strong>-FLANGESYSTEMOrder Code Order Code Order CodeSP * ** , *xxx DP-ASSP * ** , *xxx ISSP * ** , *xxx LITUBES & PIPESMaterial anddesign ofclamp bodyPipe-O.D.Material anddesign ofclamp bodyPipe-O.D.Material anddesign ofclamp bodyPipe-O.D.219CLAMPS<strong>GS</strong>HGroup<strong>GS</strong>HGroup<strong>GS</strong>HGroupClamp consisting of:1 x Single Weld Plate1 x Clamp Body(2 halves)1 x Cover Plate2 x Hexagon Head BoltDIN 931/933Clamp consisting of:1 x Single Weld Plate1 x Clamp Body(2 halves)2 x Socket Cap ScrewDIN 912with washerClamp consisting of:1 x Single Weld Plate1 x Clamp Body(2 halves)2 x Slotted Head ScrewDIN 84with washerVALVESOrder Code Order Code Order CodeBITE TYPEFITTIN<strong>GS</strong>SPV * ** , *xxx DP-ASSPV * ** , *xxx ISSPV * ** , *xxx LIMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupSAE J514 JICFLARE FITTIN<strong>GS</strong>Clamp consisting of:1 x Elongated Weld Plate1 x Clamp Body(2 halves)1 x Cover Plate2 x Hexagon Head BoltDIN 931/933Clamp consisting of:1 x Elongated Weld Plate1 x Clamp Body(2 halves)2 x Socket Cap ScrewDIN 912with washerClamp consisting of:1 x Elongated Weld Plate1 x Clamp Body(2 halves)2 x Slotted Head ScrewDIN 84with washerHOSES &HOSE COUPLIN<strong>GS</strong>Order Code Order Code Order CodeADAPTORSSM * ** , *xxx DP-ASSM * ** , *xxx ISSM * ** , *xxx LIMaterial anddesign ofclamp bodyPipe-O.D.Material anddesign ofclamp bodyPipe-O.D.Material anddesign ofclamp bodyPipe-O.D.SPECIALSOLUTIONS<strong>GS</strong>HGroup<strong>GS</strong>HGroup<strong>GS</strong>HGroupClamp consisting of:1 x Hexagon Rail Nut1 x Clamp Body(2 halves)1 x Cover Plate2 x Hexagon Head BoltDIN 931/933Clamp consisting of:1 x Hexagon Rail Nut1 x Clamp Body(2 halves)2 x Socket Cap ScrewDIN 912with washerClamp consisting of:1 x Hexagon Rail Nut1 x Clamp Body(2 halves)2 x Slotted Head ScrewDIN 84with washerMACHINESTECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSStandard-Series – Complete <strong>Clamps</strong>TUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>220Order Code Order Code Order Code* ** , *xxx DP-ASMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupClamp consisting of:1 x Clamp Body(2 halves)1 x Cover Plate2 x Hexagon Head BoltDIN 931/933* ** , *xxx ISMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupClamp consisting of:1 x Clamp Body(2 halves)2 x Socket Cap ScrewDIN 912with washer* ** , *xxx LIMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupClamp consisting of:1 x Clamp Body(2 halves)2 x Slotted Head ScrewDIN 84with washerOrder Code Order Code Order Code* ** , *xxx SIG-AFSP1 * ** , *xxx DP-AS1 * ** , *xxx SI-AFSAE J514 JICFLARE FITTIN<strong>GS</strong>Material anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupHOSES &HOSE COUPLIN<strong>GS</strong>Clamp consisting of:1 x Clamp Body(2 halves)1 x Safety Locking Plate2 x Stacking BoltClamp consisting of:1 x Elongated Weld Plate1 x Clamp Body(2 halves)2 x Socket Cap ScrewDIN 912with washerClamp consisting of:1 x Elongated Weld Plate1 x Clamp Body(2 halves)2 x Slotted Head ScrewDIN 84with washerADAPTORS SPECIALSOLUTIONSInformationIn order to protect hexagon head bolts against unscrew causedby vibrations safety washers acc. to DIN 93 are recommended.Items are supplied non-assembled.MACHINES TECHNICALINFORMATION

CLAMPSHeavy-Series – Components<strong>GS</strong>-FLANGESYSTEMMaterial CodeMaterials and designs of clamps bodiesXXXPolypropylene, profiled inside, with tension clearance - PPPolypropylene, smooth inside, without tension clearance - PPH (up to Gr. 6S)Polyamide, profiled inside, with tension clearance - PAPolyamide, smooth inside, without tension clearance - PAH (up to Gr. 6S)Santoprene, profiled inside, with tension clearance - SA (up to Gr. 6S)Santoprene, smooth inside, without tension clearance - SAH (up to Gr. 6S)Aluminum, profiled inside, with tension clearance - ALOther thermoplastics and O.D. on request.221TUBES & PIPESCLAMPSSurface finishing (see also technical appendix) –<strong>GS</strong>HGroupDINGroup3S 14S 25S 36S 47S 58S 69S 710S 811S 912S 10Outside diameterTube or HoseNominalbore PipeinchClamp Body(2 halves)(xxx - see material code)mminch6 3006 xxx6,4 1/4 3006,4 xxx8 3008 xxx9,5 3/8 3008 xxx10 1/8 3009,5 xxx12 3012 xxx12,7 1/2 3012,7 xxx13,5 1/4 3013,5 xxx14 3014 xxx15 3015 xxx16 5/8 3016 xxx17,2 3/8 3017,2 xxx18 3018 xxx19 3/4 4019 xxx20 4020 xxx21,3 1/2 4012,3 xxx22 7/8 4022 xxx25 4025 xxx26,9 3/4 4026,9 xxx28 4028 xxx30 4030 xxx30 5030 xxx32 1 1/4 5032 xxx33,7 1 5033,7 xxx35 5035 xxx38 1 1/2 5038 xxx40 5040 xxx42 1 1/4 5042 xxx38 1 1/2 6038 xxx42 1 1/4 6042 xxx44,5 1 3/4 6044,5 xxx48,3 1 1/2 6048,3 xxx50,8 2 6050,8 xxx55 6055 xxx57 2 1/4 6057 xxx60,3 2 6060,3 xxx63,5 2 1/2 6063,5 xxx65 6065 xxx70 6070 xxx65 7065 xxx70 7070 xxx73 2 7/8 2 1/2 7073 xxx75 7075 xxx76,1 3 2 1/2 7076,1 xxx80 7080 xxx82,5 3 1/4 7082,5 xxx88,9 3 7088,9 xxx88,9 3 8088,9 xxx100 8100 xxx102 3 1/2 8102 xxx108 4 1/4 8108 xxx114 4 8114 xxx127 5 8127 xxx133 5 1/4 8133 xxx133 5 1/4 9133 xxx140 5 9140 xxx152 6 9152 xxx159 6 1/4 9159 xxx165 6 1/2 9165 xxx168 6 9168 xxx168 6 10168 xxx177,8 7 10177,8 xxx193,7 7 5/8 10193,7 xxx216 8 1/2 10216 xxx219 8 10219 xxx219 8 11219 xxx273 10 11273 xxx324 12 11324 xxx356 14 12356 xxx406 16 12406 xxxGroup 3 S - 7 S:DIN 50942 Fe/Znph r 10Weld Platefor Single <strong>Clamps</strong>SPALSPAL 3 SSPAL 4 SSPAL 5 SSPAL 6 SSPAL 7 SSPAL 8 SSPAL 9 SSPAL 10 SSPAL 11 SSPAL 12 SGroup 3 S - 7 S:DIN 50942 Fe/Znph r 10Weld Platefor Double <strong>Clamps</strong>SPASSPAS 3 SSPAS 4 SSPAS 5 SSPAS 6 SSPAS 7 SSPAS 8 SSPAS 9 SSPAS 10 SSPAS 11 SSPAS 12 SVALVESBITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORSSPECIALSOLUTIONSMACHINESTECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSHeavy-Series – ComponentsTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>222Group 3 S - 7 S:DIN 50942 Fe/Znph r 10ElongatedWeld Platefor Single <strong>Clamps</strong>SPAL/DUBSPAL/DUB 3 SGroup 3S - 9S Group 10S - 12S up to Group 6 S only up to Group 6 S onlyGroup 3 S - 7 S:DIN 50942 Fe/Znph r 10ElongatedWeld Platefor Double <strong>Clamps</strong>SPAS/DUBSPAS/DUB 3 S– – –ElongatedWeld Platefor Double <strong>Clamps</strong>SPAS/DÜBMounting RailSTSVMounting RailNutGMVGMV 10Group 3 S - 7 S:DIN 50942 Fe/Znph r 10Cover Platefor Single <strong>Clamps</strong>DPALDPAL 3 SSAE J514 JICFLARE FITTIN<strong>GS</strong>SPAL/DUB 4 S SPAS/DUB 4 S STSVDPAL 4 S(availablein 1 and 2 mlengths)SPAL/DUB 5 S SPAS/DUB 5 S DPAL 5 SHOSES &HOSE COUPLIN<strong>GS</strong>SPAL/DUB 6 S SPAS/DUB 6 S GMV 12 DPAL 6 SADAPTORS SPECIALSOLUTIONSSPAL/DUB 7 S SPAS/DUB 7 S DPAL 7 SSPAL/DUB 8 S SPAS/DUB 8 S DPAL 8 SSPAL/DUB 9 S SPAS/DUB 9 S DPAL 9 SMACHINES TECHNICALINFORMATIONSPAL/DUB 10 S SPAS/DUB 10 S DPAL 10 SSPAL/DUB 11 S SPAS/DUB 11 S DPAL 11 SSPAL/DUB 12 S SPAS/DUB 12 S DPAL 12 S

CLAMPSHeavy-Series – Components<strong>GS</strong>-FLANGESYSTEMOnly forHexagonHead BoltsAS DIN 931/933TUBES & PIPESGroup 3S - 6S Group 3S - 10S Group 3S - 10S223CLAMPSGroup 3 S - 7 S:DIN 50942 Fe/Znph r 10– – –Group 3 S - 7 S:DIN 50942 Fe/Znph r 10DIN 50961 Fe/Znph 8 CCover Platefor Double <strong>Clamps</strong>DPASHexagon Head BoltASDIN 931/933Socket Cap ScrewISDIN 912Stacking BoltAFSafety Locking PlateSIPSafety WasherSIDIN 93VALVESDPAS 3 SAS 3 S(M10 x 45)IS 3 S(M10 x 30)AF 3 SSIP 3 SSI 10,5BITE TYPEFITTIN<strong>GS</strong>DPAS 4 SDPAS 5 SAS 4 S(M10 x 60)AS 5 S(M10 x 70)IS 4 S(M10 x 40)IS 5 S(M10 x 50)AF 4 SAF 5 SSIP 4 SSIP 5 SSAE J514 JICFLARE FITTIN<strong>GS</strong>DPAS 6 SAS 6 S(M12 x 100)IS 6 S(M12 x 80)AF 6 S SIP 6 S SI 13HOSES &HOSE COUPLIN<strong>GS</strong>DPAS 7 SAS 7 S(M16 x 130)AF 7 S SIP 7 S SI 17ADAPTORSDPAS 8 SAS 8 S(M20 x 190)AF 8 S SIP 8 S SI 21SPECIALSOLUTIONSDPAS 9 SAS 9 S(M24 x 220)AF 9 S SIP 9 S SI 25DPAS 10 SDPAS 11 SAS 10 S(M30 x 300)AS 11 S(M30 x 450)AF 10 SSIP 10 SSI 31MACHINESDPAS 12 SAS 12 S(M30 x 560)TECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSHeavy-Series – ComponentsTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORS SPECIALSOLUTIONSMACHINES TECHNICALINFORMATION224Material CodeMaterials and designs of clamps bodiesXXXPolypropylene, profiled inside, with tension clearance - PPPolypropylene, smooth inside, without tension clearance - PPH (up to Gr. 6S)Polyamide, profiled inside, with tension clearance - PAPolyamide, smooth inside, without tension clearance - PAH (up to Gr. 6S)Santoprene, profiled inside, with tension clearance - SA (up to Gr. 6S)Santoprene, smooth inside, without tension clearance - SAH (up to Gr. 6S)Aluminum, profiled inside, with tension clearance - ALOther thermoplastics and O.D. on request.Surface finishing (see also techincal appendix) –Group 3 S - 7 S:DIN 50942 Fe/Znph r 10Pipe-O.D.Clamp Body (2 halves)Weld Plate<strong>GS</strong>HDINøD1Inside surfacefor Single <strong>Clamps</strong>GroupGroupL1SPAL[mm]L2 profiled smoothPP/PA AL H S HWidthL1 L2 B S H G D166,489,5103 S 11212,755 56 33 32 0,6min.13,530,5 30,5 74 33 30 8 8 M10 1814151617,2184 S 25 S 36 S 47 S 58 S 69 S 710 S 811 S 912 S 10192021,3222526,92830303233,735384042384244,548,350,8555760,363,5657065707576,18082,588,988,9100102108114127133133140152159165168168177,8193,721621921927332435640670 70 45 48 0,6 46,5 30,5 86 45 30 8 8 M10 18min.85 85 60 60 0,6min.58 30,5 100 60 30 8 8 M10 18115 120 90 89 2min.87 45 140 90 45 10 8 M12 20152 150 122 120 2min.60 180 122 60 10 12 M16 24206 208 168 167 2min.80 226 168 80 15 18 M20 30251 255 205 200 3min.91 270 205 90 15 21 M24 35336 326 265 270 3min.120 340 265 120 25 21 M30 50470 470 395 410 8min.630 630 534 530 20min.162 520 395 160 30 38 M30 50182 680 534 180 30 38 M30 50

CLAMPSHeavy-Series – ComponentsBITE TYPEFITTIN<strong>GS</strong>TUBES & PIPES<strong>GS</strong>-FLANGESYSTEMGroup 3S - 9SGroup 3 S - 7 S:Group 3 S - 7 S:Group 3 S - 7 S:DIN 50942 Fe/Znph r 10 DIN 50942 Fe/Znph r 10 DIN 50942 Fe/Znph r 10–Weld Platefor Double <strong>Clamps</strong>SPASElongated Weld Platefor Single <strong>Clamps</strong>SPAL/DUBElongated Weld Platefor Double <strong>Clamps</strong>SPAS/DUBElongated Weld Platefor Double <strong>Clamps</strong>SPAS/DUBL1 L2 B1 B2 S H G øD1 L1 L2 L3 B S H G øD1 øD2 L1 L2 L3 B1 B2 S H G øD1 øD2 L1 L2 L3 B1 B2 S H G øD1 øD2225CLAMPSVALVES74 33 60 30,5 8 8 M10 18 113 33 85 30 8 8 M10 18 13 113 33 85 60 30,5 8 8 M10 18 1386 45 60 30,5 8 8 M10 18 125 45 97 30 8 8 M10 18 13 125 45 97 60 30,5 8 8 M10 18 13100 60 60 30,5 8 8 M10 18 140 60 112 30 8 8 M10 18 13 140 60 112 60 30,5 8 8 M10 18 13SAE J514 JICFLARE FITTIN<strong>GS</strong>140 90 90 46 10 8 M12 20 187 90 155 45 10 8 M12 20 16 187 90 155 90 46 10 8 M12 20 16HOSES &HOSE COUPLIN<strong>GS</strong>180 122 120 61 10 12 M16 24 238 122 198 60 12 12 M16 24 21 238 122 198 120 61 10 12 M16 24 21ADAPTORS226 168 160 81 15 18 M20 30 309 168 259 80 15 18 M20 30 26 309 168 259 160 81 15 18 M20 30 26SPECIALSOLUTIONS270 205 180 91 15 21 M24 35 370 205 310 90 15 21 M24 35 31 370 205 310 180 91 15 21 M24 35 31340 265 240 121 25 21 M30 45 440 265 380 120 25 21 M30 45 31 440 265 380 240 121 25 21 M30 45 31MACHINES520 395 324 166 30 38 M30 50 590 395 530 160 30 38 M30 50 31 590 395 530 324 166 30 38 M30 50 31680 534 364 186 30 38 M30 50 750 534 690 180 30 38 M30 50 31 750 534 690 394 186 30 38 M30 50 31TECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSHeavy-Series – ComponentsTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>226up to Group6S only– –Mounting RailSTSVup to Group6S onlyMounting RailNutGMVGroup 3 S - 7S:DIN 50942 Fe/Znph r 10Cover Plate forSingle <strong>Clamps</strong>DPALGroup 3 S - 7S:DIN 50942 Fe/Znph r 10Cover Plate forDouble <strong>Clamps</strong>DPASGroup3S -6S Group 3S-10S Group 3S-10SGroup 3 S - 7S:DIN 50942 Fe/Znph r 10Socket CapSafety LockingStacking BoltScrewPlateIS DIN 912AFSIP– – –HexagonHead BoltAS DIN 912B1 B2 H S L B H1 H2 H3 G øD L1 L2 B s øD L1 L2 B1 B2 S øD G x L G x L G L1 L2 L3 SW L1 L2 B1 B2 S øD26 23 19 6 6 M 10 18 55 33 30 8 11 56 33 60 30 8 11 M10 X 45 M10 X 30 M 10DIN 50961Fe/Zn 8 CSafetyWasherSI DIN 9349 25 15 15 56 13 30 15 8 10,5min.SAE J514 JICFLARE FITTIN<strong>GS</strong>40 14 22 570 45 30 8 11 70 45 60 30 8 11 M10 x 60 M10 X 40 M 1085 60 30 8 11 84 60 60 30 8 11 M10 X 70 M10 X 50 M 1065 40 15 15 70 26 30 15 8 10,5min.77 51 15 15 85 40 30 15 8 10,5min.HOSES &HOSE COUPLIN<strong>GS</strong>26 23 22 7,5 6 M 12 20 115 90 45 10 14 116 90 90 46 10 14 M12 X 100 M12 X 80 M 12110 82 18 17 116 69 45 17 10 13min.ADAPTORS SPECIALSOLUTIONS152 122 60 10 19 153 122 120 61 10 19 M16 X 130206 168 80 15 22 206 168 160 81 15 22 M20 X 190M144 110 24 21 153 97 60 22 10 1716 min.M200 150 30 27 206 130 80 28 15 2120 min.251 205 90 15 26 251 205 180 91 15 26 M24 X 220M240 180 50 30 251 166 90 31 15 2524 min.MACHINES TECHNICALINFORMATION320 265 120 25 35 320 265 240 120 25 35 M30 X 300M331 256 62 46 317 205 120 49 25 3130 min.470 395 160 30 35 470 395 321 166 30 35 31630 534 180 30 35 630 534 361 186 30 35 M30 X 560 31

CLAMPSHeavy-Series – Complete <strong>Clamps</strong><strong>GS</strong>-FLANGESYSTEMMaterial CodeMaterials and designsof clamps bodies XXXPolypropylene,profiled inside, with tension clearancePolypropylene,smooth inside,without tension clearancePolyamide,profiled inside, with tension clearancePolyamide,smooth inside, without tension clearanceSantoprene,profiled inside, with tension clearanceSantoprene,smooth inside, without tension clearanceAluminum,profiled inside, with tension clearance(AL group 1 A – 6 only)Other thermoplastics and O.D. on request.- PP- PPH(up to Gr. 6S)- PA- PAH(up to Gr. 6S)- SA- SAH(up to Gr. 6S)- ALDesign of clamp bodies see technical appendix, page 209.<strong>GS</strong>HGroup3 S4 S5 S6 S7 S8 S9 S10 S11 S12 SPipe-O.D.[mm]Order Code6 3006 xxx6,4 3006,4 xxx8 3008 xxx9,5 3009,5 xxx10 3010 xxx12 3012 xxx12,7 3012,7 xxx13,5 3013,5 xxx14 3014 xxx15 3015 xxx16 3016 xxx17,2 3017,2 xxx18 3018 xxx19 4019 xxx20 4020 xxx21,3 4021,3 xxx22 4022 xxx25 4025 xxx26,9 4026,9 xxx28 4028 xxx30 4030 xxx30 5030 xxx32 5032 xxx33,7 5033,7 xxx35 5035 xxx38 5038 xxx40 5040 xxx42 5042 xxx38 6038 xxx42 6042 xxx44,5 6044,5 xxx48,3 6048,3 xxx50,8 6050,8 xxx55 6055 xxx57 6057 xxx60,3 6060,3 xxx63,5 6063,5 xxx65 6065 xxx70 6070 xxx65 7065 xxx70 7070 xxx75 7075 xxx76,1 7076,1 xxx80 7080 xxx82,5 7082,5 xxx88,9 7088,9 xxx88,9 8088,9 xxx100 8100 xxx102 8102 xxx108 8108 xxx114 8114 xxx127 8127 xxx133 8133 xxx133 9133 xxx140 9140 xxx152 9152 xxx159 9159 xxx165 9165 xxx168 9168 xxx168 10168 xxx177,8 10177,8 xxx193,7 10193,7 xxx216 10216 xxx219 10219 xxx219 11219 xxx273 11273 xxx324 11324 xxx356 12356 xxx406 12406 xxx227TUBES & PIPESCLAMPSVALVESBITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORSSPECIALSOLUTIONSMACHINESTECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSHeavy-Series – Complete <strong>Clamps</strong>TUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>228Order CodeSPAL** *** , *xxx DPAL-ASMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupClamp consisting of:1 x Weld Plate for Single Clamp1 x Clamp Body(2 halves)1 x Cover Plate for Single Clamp2 x Hexagon Head BoltDIN 931/933Order CodeSPAS** *** , *xxx DPAS-ASMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupClamp consisting of:1 x Weld Plate for Douple Clamp1 x Clamp Body(2 halves)2 x Cover Plate for Double Clamp4 x Hexagon Head BoltDIN 931/933HOSES &HOSE COUPLIN<strong>GS</strong>Order CodeOrder CodeADAPTORS SPECIALSOLUTIONSSPAL/DUB** *** , *xxx DPAL-ASMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupSPAS/DUB** *** , *xxx DPAS-ASMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupMACHINES TECHNICALINFORMATIONClamp consisting of:1 x Elongated Weld Platefor Single Clamp1 x Clamp Body(2 halves)1 x Cover Plate for Single Clamp2 x Hexagon Head BoltDIN 931/933Group 3S-9SGroup 10S-12SClamp consisting of:1 x Elongated Weld Platefor Douple Clamp2 x Clamp Body(2 halves)1 x Cover Plate for Double Clamp4 x Hexagon Head BoltDIN 931/933

CLAMPSHeavy-Series – Complete <strong>Clamps</strong><strong>GS</strong>-FLANGESYSTEMOrder CodeOrder CodeTUBES & PIPES** *** , *xxx SIP-AFGMV ** *** , *xxx DPAL-AS229CLAMPSMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupMaterial anddesign ofclamp bodyPipe-O.D.<strong>GS</strong>HGroupVALVESClamp consisting of:1 x Clamp Body(2 halves)1 x Safety Locking Plate2 x Stacking BoltClamp consisting of:2 x Mounting Rail Nut1 x Clamp Body(2 halves)1 x Cover Plate for Single Clamp2 x Hexagon Head BoltDIN 931/933BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>InformationOrder CodeIn order to protect hexagon head bolts againstunscrew caused by vibrations safety washers acc.to DIN 93 are recommended.Items are supplied non-assembled.HOSES &HOSE COUPLIN<strong>GS</strong>SPAL** *** , *xxx ISMaterial anddesign ofclamp bodyADAPTORSPipe-O.D.<strong>GS</strong>HGroupSPECIALSOLUTIONSClamp consisting of:1 x Weld Plate for Single Clamp1 x Clamp Body(2 halves)2 x Socket Cap ScrewDIN 912MACHINESTECHNICALINFORMATION

<strong>GS</strong>-FLANGESYSTEMCLAMPSU-Bolt – Type RB/RULTUBES & PIPES CLAMPSVALVES BITE TYPEFITTIN<strong>GS</strong>SAE J514 JICFLARE FITTIN<strong>GS</strong>HOSES &HOSE COUPLIN<strong>GS</strong>ADAPTORS SPECIALSOLUTIONSMACHINES TECHNICALINFORMATION230DN20253240Pipe-O.D. øD1 Round Steel U-Bolt RB Plastic Pipe Saddle RULmm Nominal Bore A L1 H1 H2 H3 H4 G L2 L3 B H5 H6 øD42517,530 40 73,5 4626,9 3/4 18,5302038 48 813033,7 1 2250382446 56 8942,4 1 1/4 26,244,527,252 62 100 55 3548,3 1 1/2 29M1075 4080 4890 5695 625733,55064 76 118 63110 7660,3 2 35,239M1265 76,1 2 1/2 82 94 135 77 43 135 9480 88,9 3 94 106 152 82 54,5 145 10610012510864120 136 190114,3 4 6713376,5148 164 217139,7 5 105 47 80M16190 136220 16415991,5150176 192 247250 192168,3 6 96175 193,7 202 218 273 109 270 218200250300350400500Order CodeRB + RUL completeRB xxxx RUL/ xx*** , *216120228 248 311219,1 8 121,5267145,5282 302 364 125 55273 10 148,5318174332 352 418323,9 12 177355,6 14193378 402 475368 199406,4 16218419 428 452 526 145 63 224,5457 236,5508 20269530 554 627521 276Pipe-O.D. ø D1 (mm)PP - PolypropylenePA - PolyamideMaterial:St 37 no surface finishing - no further information requiredSt 37 Fe/Zn 8 C - zinc platedSt 37 plastic coated - plastic coatedStainless steel 1.4571 - 1.4571Clamp consisting of:1 x Round Steel U-Bolt, 4 x Nuts DIN 934,1 x Plastic Pipe Saddle RUL/xxRound Steel U-BoltRB xxxx A*** , * completeM20M24315 248370 302420 352480 402540 452640 554Material:St 37 no surface finishing - no further informationSt 37 Fe/Zn 8 CrequiredSt 37 plastic coated - zinc platedStainless steel 1.4571 - plastic coated- 1.4571Clamp consisting of:1 x Round Steel U-Bolt4 x Nuts DIN 934Dimension Aup to DN 50without counternut3051235 1540 10 2050 12 2560 15 30Plastic Pipe SaddleRUL*** , * xx1114182226PP - PolypropelenePA - PolyamidePipe-O.D. øD1(mm)Information:Items are supplied non-assembled.Other materials and surface finishingson request.