Premier AFO Order Form General Information - Townsend Design

Premier AFO Order Form General Information - Townsend Design

Premier AFO Order Form General Information - Townsend Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

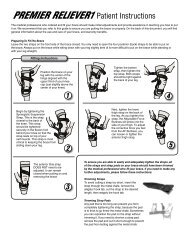

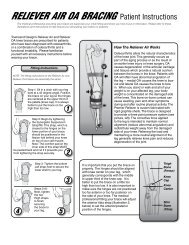

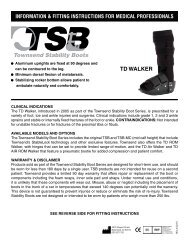

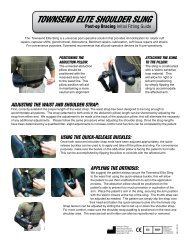

<strong>Premier</strong> <strong>AFO</strong>Specialty Bracing Solutions<strong>Townsend</strong>’s <strong>AFO</strong>s are a low profilemore cosmetically-appealingalternative to traditional plasticbraces. The rigid graphite shellprovides enhanced stabilization andsupport. A wide range of orderingoptions allow for patient-specificconfiguration of the brace.<strong>Order</strong>ing OptionsThe <strong>Premier</strong> <strong>AFO</strong> is available in four shell designs. The shell height can befrom 6-13 inches (measured from center of the ankle joint to the top band).1 2 3 4Routinely Prescribed For...Patients with global ankle instabilities,weakness or absent musculature ofthe foot who require a lower leg braceto ambulate and participate in routineactivities of daily living.This Product Can Be <strong>Order</strong>ed...• Custom from a cast moldOffered With These Standard Features...• Custom Molded Solid Core CarbonGraphite Shells• Custom Shell Pad• Non-Elastic Straps• Polypro Foot PlateAvailable Options Include...• Shell Configuration And Height• A Variety Of Ankle Joints• Dorsi Assist Bands Added To Joints• Graphite Foot Plate• Foot Plate Trim Lines & Padding1) Anterior Pre-Tibial Proximal Band2) Posterior Proximal Band3) Anterior Proximal Band andSecondary Posterior Distal Band4) Posterior Proximal and Distal BandsModels #3 and #4 with a secondary distal band are recommended when orderinganterior stop ankle joints.<strong>AFO</strong>s can be fabricated with a variety of ankle joints, including joints fromother manufacturers (i.e. Becker).<strong>AFO</strong>s can be fabricated with a variety of foot plates.www.townsenddesign.comToll Free: 800.432.3466 Ph: 661.837.1795 Fax: 661.837.0613

<strong>General</strong> <strong>Information</strong>Patient’s Last Name: _________________________________Patient’s First Name: ________________________________Male Female Age ____ Height _____ Weight ________Leg: Left RightPatient’s Clinical Diagnosis:_____________________________Surgeries (type/date): _________________________________Has this patient previously worn a <strong>AFO</strong>? ___ Yes ___ NoIf yes, please describe the brace (shell structure, hinges, etc.)__________________________________________________Work/Activities: Activities of Daily Living OtherPlease describe the patients desired mobility/function:____________________________________________________________________________________________________If there is a question about this order, who should we contact?Name:______________________ Phone:__________________Email: ______________________________________________BILLING: P.O. Number ________________________________<strong>Townsend</strong> Account Number: __________________________Bill To: ______________________________________________Address: ____________________________________________City: ________________________________________________State: _______ Zip Code: ___________ Country: _____________Phone: _____________________ Fax: ____________________<strong>Premier</strong> <strong>AFO</strong> <strong>Order</strong> <strong>Form</strong>What ankle control do you need this <strong>AFO</strong> to provide?Please check all that applyDorsiflexion Plantarflexion Inversion EversionANKLE/FOOT EVALUATION (WEIGHT BEARING)Weight bearing ankle position is:Neutral Inverted___degrees Everted___degreesAnkle movement: Flexible RigidDorsiflexion & Plantarflexion range of motion:Full ROM Limited ROM FusedDorsiflexion____degrees Plantarflexion____degreesForefoot position: Pronated SupinatedBEND KNEE TO 90 DEGREES & CHECK TOE OUTToe Out is _____ degrees (use medial border of foot)Heel Height of Shoe (use casting block) _____”CAST MOLD CORRECTIONSCasted Weight Bearing; Semi WB; Non WBANKLECasted in corrected positionPlease correct: Please correct:Forefoot Supination Hindfoot InversionForefoot Pronation Hindfoot EversionPOSTING FOR INVERTED/EVERTED CORRECTIONWhen casting, use external posts for inverted/everted correction.Indicate what posting was done during casting.Ship To: ____________________________________________Address: ____________________________________________Lateral Heel Post_____mmLat. Forefoot Post_____mmMedial Heel Post_____mmMed. Forefoot Post_____mmCity: _______________________________________________State: _______ Zip Code: _____________ Country: __________Phone: ______________________ Attention: ______________Fit Date: If known, please indicate the date you arescheduled to fit the patient:__________________(Routine Fabrication Schedule: 4-5 business days)Shipping Preference:Ground 2-Day P.M. 2-Day A.M.Next Day P.M. Next Day A.M.TOWNSEND’S SHIPPING DEPARTMENT USE ONLYNEW BRACE SERVICE -- Original Brace Returned? Yes NoNew Cast Sent? Yes No Plaster SyntheticRECEIVED _____________SHIPPED VIA ______________PROVIDE HEIGHT MEASUREMENTS______ inches 1. Measurement from floor to1fibular head2. Measurement from floor to2 ______ incheslateral apex of the ankleANKLE JOINTS (SELECT ONE)Free AnkleDorsi AssistSingle Adj. With Anterior Stop*Single Adj. With Posterior StopSingle Adj. With Ant. Stop & Assist*Double Adjustable*Double Adjustable With Assist*Solid Lamination (Fused Ankles)**

SELECT SHELL CONFIGURATION (Check one box)1 2 3 4Options 3 and 4 strongly recommended when ordering anterior stopankle joints for floor reaction control. A strap is positioned opposite theproximal band. If you would like a band or strap added, please clearlymark additions on the model you have marked and write in the measurementfrom ankle joint to the desired height in the space, below.Add Strap: ______ inches from AJAdd Band: ______ inches from AJAdd Foot StrapCHOOSE HEIGHT OF PROXIMAL BAND8 inches9 inches10 inches11 inches12 inches13 inchesOther _____FOOT PLATE SELECTIONS (Material, Sides, Length, Heel, Pad)Graphite Lamination (rigid, max control, less adjustable)Polypropylene (stiff, heat adjustable)Co-Polymer (softer, more flexible, heat adjustable)High Sides(UCB Type)Measure from thelateral apex ofthe ankle (anklejoint position) towhere you wantthe top edge of theproximal band.Low Side(Sole Plate)*Heel Cup (proximal to the base of the 5th metatarsal)Trim Proximal to the Metatarsal HeadsTrim to Toe SulcusTrim to Toes -- Outline of full foot required!!!Fabricate entire foot plate with no paddingLine entire foot plate with 1/8 inch paddingLine entire foot plate with 1/4 inch paddingLine sides with 1/8 inch; sole with 1/4 inchLine sole with 1/8 inch; no padding on sides* DO NOT uselow side foot platewith anterior stopankle joints.BRACE COLOR (SELECT ONE)Powdercoat Finish (Lightest, Most Durable Finish)Black Antique Pewter (Silver)Royal Blue BurgundyView colorson ourweb site.High Gloss Paint FinishBlack Royal Blue Burgundy BeigeEmerald Green White Burnt OrangeDark Violet Steel Blue Indy Yellow QuicksilverCustom High Gloss Paint Finish (Additional Charge)Provide Custom Paint # _______Casting Protocol1. Apply stockinette from the knee to the foot. The cast length must exceedthe length of the <strong>AFO</strong> you are ordering. If we need to extend the length of thecast, the fit of the brace may be compromised.2. Place a piece of latex tubing under the stockinette. Insert a cuttingtube beneath the stockinette. This should follow a line down the anterolateralaspect of the leg, beginning at the top of the stockinette and extending ontothe dorsum of the foot. Be certain the tube does not go directly over the tibialcrest or the fibular head.3. Outline bony landmarks. On the stockinette, use an indelible blue pencilto outline any applicable bony prominences. These may include the tibialcrest, fibular head, ankle, met heads, navicular, etc.4. Take a weight bearing cast and apply posting. The foot and anklecomplex, at least, must be casted under weight bearing conditions so thatthe foot spreads adequately, and the subtalar joint assumes its proper weightbearing attitude. If a heel or forefoot post is desired, the leg must be castedwith the appropriate post attached to the cast. This procedure will ensure thatthe orthosis is made with the correct subtalar angulation and proper foot width.5. Use SYNTHETIC CASTING MATERIAL ONLY. The cast should bewrapped at least three layers thick. One to two rolls of five inch wide syntheticcasting tape is sufficient for most legs.6. Mark the cast for removal. Mark along the length of the surgical tube, andmake hash marks at two inch intervals along the tube. This will enable us tomatch the cut edges when sealing the cast.7. Cut the cast along the tube. Using a cast cutter, cut the cast along thecutting tube. Using bandage scissors, cut the stockinette along this same line.8. Remove the cast. Spread the cast and remove it from the patient’s limb.Try not to distort the cast too much. Remove the stockinette from inside thecast, and tape or staple the cast closed.9. Write the patient’s name and your office phone number on thecast. Be certain to include this basic information on the cast itself. This way, ifthe order form gets separated from the cast, or lost entirely, we will be able tocontact you for fabrication instructions.Open Heel(graphite footplate, only)Full Heel (Closed)Half Heel (graphite(graphite footplate, only)10. Complete this <strong>AFO</strong> order form. In addition to providing all measurementsand information requested on the order form, please note any observationsyou have about abnormal characteristics of the patient’s leg and/or lowerbody alignment. This information will help our staff orthotists customize thefabrication process to ensure the brace fits and functions properly.EXTRA SHELL LINERS1 Extra Set of Liners 2 Extra Sets of Liners<strong>Townsend</strong> <strong>Design</strong>4615 Shepard St., Bakersfield, CA, 93313Phone: 800.432.3466 or 661.837.1795; Fax: 800.798.2722

<strong>Premier</strong> <strong>AFO</strong>Ankle Joint Options<strong>Townsend</strong> manufactures a variety of high strength ankle joints that are incorporated into our custom <strong>AFO</strong> and K<strong>AFO</strong> products.Customers can also contact <strong>Townsend</strong> regarding the submission and use of another manufacture’s ankle joints.Free Ankle(Standard And High Strength)These joints allow free plantarflexionand dorsiflexion, while helping to restrictinversion and eversion of the ankle joint.Double AdjustableThese ankle joints prevent or restrictankle inversion and eversion, andprovide maximum control andadjustment. Double Adjustable Jointsfeature both anterior and posteriorstops. These joints can be adjustedinto a locked position in plantarflexion,neutral, or dorsiflexion.Dorsi AssistThese joints prevent or restrict ankleinversion and eversion. The dorsi assistfeature provides an external assistmechanism that will dorsiflex the foot.Double AdjustableWith Dorsi AssistThese ankle joints have the samedesign, features and benefits ofDouble Adjustable Joints with theaddition of a dorsi assist mechanism.Single Adjustable(Anterior or Posterior Stop)Anterior stop joints prevent or restrictankle inversion and eversion, while alsopreventing or restricting dorsiflexionof the ankle. These joints provide noplantarflexion control. Posterior stopjoints prevent or restrict ankle inversionand eversion, while also preventing orrestricting plantarflexion of the ankle.Single Adjustable,Anterior Stop and Dorsi AssistThese ankle joints are the same as thesingle adjustable anterior stop joints witha dorsi assist mechanism.