Sealed FAG Spherical Roller Bearings for Continuous Casting Plants

Sealed FAG Spherical Roller Bearings for Continuous Casting Plants

Sealed FAG Spherical Roller Bearings for Continuous Casting Plants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

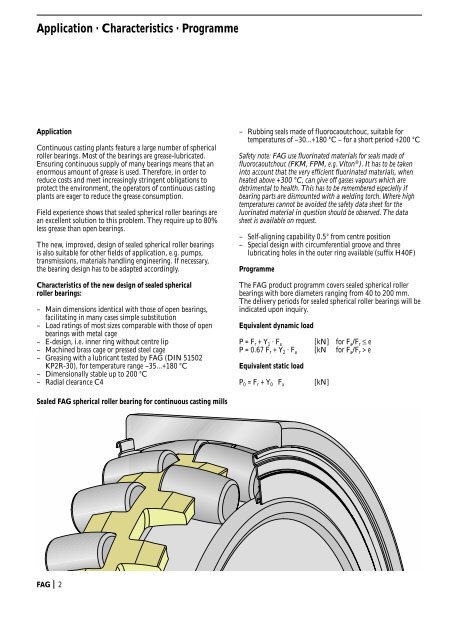

Application · Characteristics · ProgrammeApplication<strong>Continuous</strong> casting plants feature a large number of sphericalroller bearings. Most of the bearings are grease-lubricated.Ensuring continuous supply of many bearings means that anenormous amount of grease is used. There<strong>for</strong>e, in order toreduce costs and meet increasingly stringent obligations toprotect the environment, the operators of continuous castingplants are eager to reduce the grease consumption.Field experience shows that sealed spherical roller bearings arean excellent solution to this problem. They require up to 80%less grease than open bearings.The new, improved, design of sealed spherical roller bearingsis also suitable <strong>for</strong> other fields of application, e.g. pumps,transmissions, materials handling engineering. If necessary,the bearing design has to be adapted accordingly.Characteristics of the new design of sealed sphericalroller bearings:– Main dimensions identical with those of open bearings,facilitating in many cases simple substitution– Load ratings of most sizes comparable with those of openbearings with metal cage– E-design, i.e. inner ring without centre lip– Machined brass cage or pressed steel cage– Greasing with a lubricant tested by <strong>FAG</strong> (DIN 51502KP2R-30), <strong>for</strong> temperature range –35...+180 °C– Dimensionally stable up to 200 °C– Radial clearance C4– Rubbing seals made of fluorocaoutchouc, suitable <strong>for</strong>temperatures of –30...+180 °C – <strong>for</strong> a short period +200 °CSafety note: <strong>FAG</strong> use fluorinated materials <strong>for</strong> seals made offluorocaoutchouc (FKM, FPM, e.g. Viton ® ). It has to be takeninto account that the very efficient fluorinated materials, whenheated above +300 °C, can give off gasses vapours which aredetrimental to health. This has to be remembered especielly ifbearing parts are dismounted with a welding torch. Where hightemperatures cannot be avoided the safety data sheet <strong>for</strong> theluorinated material in question should be observed. The datasheet is available on request.– Self-aligning capability 0.5° from centre position– Special design with circumferential groove and threelubricating holes in the outer ring available (suffix H40F)ProgrammeThe <strong>FAG</strong> product programm covers sealed spherical rollerbearings with bore diameters ranging from 40 to 200 mm.The delivery periods <strong>for</strong> sealed spherical roller bearings will beindicated upon inquiry.Equivalent dynamic loadP = F r + Y 1 · F a [kN] <strong>for</strong> F a /F r ≤ eP = 0.67 F r + Y 2 · F a [kN <strong>for</strong> F a /F r > eEquivalent static loadP 0 = F r + Y 0 F a [kN]<strong>Sealed</strong> <strong>FAG</strong> spherical roller bearing <strong>for</strong> continuous casting mills<strong>FAG</strong> 2