THE GUIDE TO FILES AND FILING - Evenfall Studios

THE GUIDE TO FILES AND FILING - Evenfall Studios

THE GUIDE TO FILES AND FILING - Evenfall Studios

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

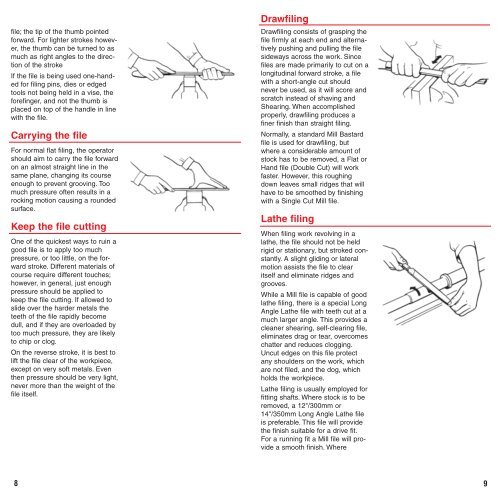

file; the tip of the thumb pointedforward. For lighter strokes however,the thumb can be turned to asmuch as right angles to the directionof the strokeIf the file is being used one-handedfor filing pins, dies or edgedtools not being held in a vise, theforefinger, and not the thumb isplaced on top of the handle in linewith the file.Carrying the fileFor normal flat filing, the operatorshould aim to carry the file forwardon an almost straight line in thesame plane, changing its courseenough to prevent grooving. Toomuch pressure often results in arocking motion causing a roundedsurface.Keep the file cuttingOne of the quickest ways to ruin agood file is to apply too muchpressure, or too little, on the forwardstroke. Different materials ofcourse require different touches;however, in general, just enoughpressure should be applied tokeep the file cutting. If allowed toslide over the harder metals theteeth of the file rapidly becomedull, and if they are overloaded bytoo much pressure, they are likelyto chip or clog.On the reverse stroke, it is best tolift the file clear of the workpiece,except on very soft metals. Eventhen pressure should be very light,never more than the weight of thefile itself.DrawfilingDrawfiling consists of grasping thefile firmly at each end and alternativelypushing and pulling the filesideways across the work. Sincefiles are made primarily to cut on alongitudinal forward stroke, a filewith a short-angle cut shouldnever be used, as it will score andscratch instead of shaving andShearing. When accomplishedproperly, drawfiling produces afiner finish than straight filing.Normally, a standard Mill Bastardfile is used for drawfiling, butwhere a considerable amount ofstock has to be removed, a Flat orHand file (Double Cut) will workfaster. However, this roughingdown leaves small ridges that willhave to be smoothed by finishingwith a Single Cut Mill file.Lathe filingWhen filing work revolving in alathe, the file should not be heldrigid or stationary, but stroked constantly.A slight gliding or lateralmotion assists the file to clearitself and eliminate ridges andgrooves.While a Mill file is capable of goodlathe filing, there is a special LongAngle Lathe file with teeth cut at amuch larger angle. This provides acleaner shearing, self-clearing file,eliminates drag or tear, overcomeschatter and reduces clogging.Uncut edges on this file protectany shoulders on the work, whichare not filed, and the dog, whichholds the workpiece.Lathe filing is usually employed forfitting shafts. Where stock is to beremoved, a 12"/300mm or14"/350mm Long Angle Lathe fileis preferable. This file will providethe finish suitable for a drive fit.For a running fit a Mill file will providea smooth finish. Where8 9