Standard Engine Exhaust Silencers and Accessories - Universal ...

Standard Engine Exhaust Silencers and Accessories - Universal ...

Standard Engine Exhaust Silencers and Accessories - Universal ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

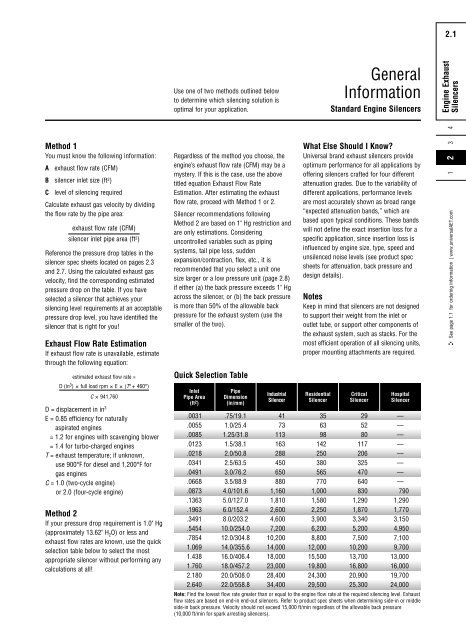

2.1 2.1Use one of two methods outlined belowto determine which silencing solution isoptimal for your application.GeneralInformation<strong>St<strong>and</strong>ard</strong> <strong>Engine</strong> <strong>Silencers</strong><strong>Engine</strong> <strong>Exhaust</strong>Rotary <strong>Silencers</strong> PositiveBlower <strong>Silencers</strong>Method 1You must know the following information:A exhaust flow rate (CFM)B silencer inlet size (ft 2 )C level of silencing requiredCalculate exhaust gas velocity by dividingthe flow rate by the pipe area:exhaust flow rate (CFM)silencer inlet pipe area (ft 2 )Reference the pressure drop tables in thesilencer spec sheets located on pages 2.3<strong>and</strong> 2.7. Using the calculated exhaust gasvelocity, find the corresponding estimatedpressure drop on the table. If you haveselected a silencer that achieves yoursilencing level requirements at an acceptablepressure drop level, you have identified thesilencer that is right for you!<strong>Exhaust</strong> Flow Rate EstimationIf exhaust flow rate is unavailable, estimatethrough the following equation:Regardless of the method you choose, theengine’s exhaust flow rate (CFM) may be amystery. If this is the case, use the abovetitled equation <strong>Exhaust</strong> Flow RateEstimation. After estimating the exhaustflow rate, proceed with Method 1 or 2.Silencer recommendations followingMethod 2 are based on 1" Hg restriction <strong>and</strong>are only estimations. Consideringuncontrolled variables such as pipingsystems, tail pipe loss, suddenexpansion/contraction, flex, etc., it isrecommended that you select a unit onesize larger or a low pressure unit (page 2.8)if either (a) the back pressure exceeds 1" Hgacross the silencer, or (b) the back pressureis more than 50% of the allowable backpressure for the exhaust system (use thesmaller of the two).What Else Should I Know?<strong>Universal</strong> br<strong>and</strong> exhaust silencers provideoptimum performance for all applications byoffering silencers crafted for four differentattenuation grades. Due to the variability ofdifferent applications, performance levelsare most accurately shown as broad range“expected attenuation b<strong>and</strong>s,” which arebased upon typical conditions. These b<strong>and</strong>swill not define the exact insertion loss for aspecific application, since insertion loss isinfluenced by engine size, type, speed <strong>and</strong>unsilenced noise levels (see product specsheets for attenuation, back pressure <strong>and</strong>design details).NotesKeep in mind that silencers are not designedto support their weight from the inlet oroutlet tube, or support other components ofthe exhaust system, such as stacks. For themost efficient operation of all silencing units,proper mounting attachments are required.See page 1.1 for ordering information | www.universalAET.com 1 2 3 4estimated exhaust flow rate =Quick Selection TableD (in 3 ) full load rpm E (T° 460°)C 941,760D = displacement in in 3E = 0.85 efficiency for naturallyaspirated engines= 1.2 for engines with scavenging blower= 1.4 for turbo-charged enginesT = exhaust temperature; if unknown,use 900°F for diesel <strong>and</strong> 1,200°F forgas enginesC = 1.0 (two-cycle engine)or 2.0 (four-cycle engine)Method 2If your pressure drop requirement is 1.0" Hg(approximately 13.62" H 2 O) or less <strong>and</strong>exhaust flow rates are known, use the quickselection table below to select the mostappropriate silencer without performing anycalculations at all!InletPipe Area(ft 2 ).0031.0055.0085.0123.0218.0341.0491.0668.0873.1363.1963.3491.5454.78541.0691.4381.7602.1802.640PipeDimension(in/mm).75/19.11.0/25.41.25/31.81.5/38.12.0/50.82.5/63.53.0/76.23.5/88.94.0/101.65.0/127.06.0/152.48.0/203.210.0/254.012.0/304.814.0/355.616.0/406.418.0/457.220.0/508.022.0/558.8IndustrialSilencer41731131632884506508801,1601,8102,6004,6007,20010,20014,00018,00023,00028,40034,400ResidentialSilencer3563981422503805657701,0001,5802,2503,9006,2008,80012,00015,50019,80024,30029,500CriticalSilencer2952801172063254706408301,2901,8703,3405,2007,50010,20013,70016,80020,90025,300HospitalSilencer————————7901,2901,7703,1504,9507,1009,70013,00016,00019,70024,000Note: Find the lowest flow rate greater than or equal to the engine flow rate at the required silencing level. <strong>Exhaust</strong>flow rates are based on end-in end-out silencers. Refer to product spec sheets when determining side-in or middleside-in back pressure. Velocity should not exceed 15,000 ft/min regardless of the allowable back pressure(10,000 ft/min for spark arresting silencers).