Energy deep thinker - DNV

Energy deep thinker - DNV

Energy deep thinker - DNV

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

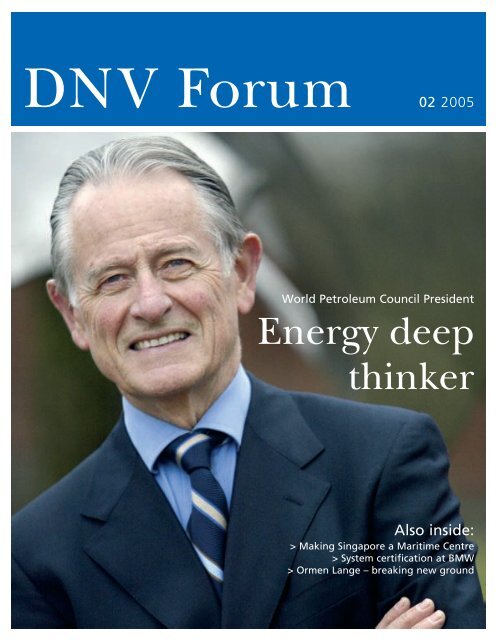

<strong>DNV</strong> Forum02 2005World Petroleum Council President<strong>Energy</strong> <strong>deep</strong><strong>thinker</strong>Also inside:> Making Singapore a Maritime Centre> System certification at BMW> Ormen Lange – breaking new ground

content06 10 24 2801 Editorial02 <strong>Energy</strong> <strong>deep</strong> <strong>thinker</strong>06 Building a stronger Singapore10 Nothing more than intelligent staff management14 Breaking new ground18 Right the first time20 Considering environment equal to safety24 Perfect timing for concrete sandwich26 Providing risk status28 Bottling the flavour of Argentina32 News36 Last word

A role to playThe oil and gas industry is facing increasing expectations from a multitude ofstakeholders. In the public domain, zero tolerance of failure is a reality. Consistent,transparent and predictable operation is expected from this industry.Two areas of growing concern and complexity add tothe challenges: future field developments in Arcticareas and aging installations. In both of these areas<strong>DNV</strong> has a role to play.ARCTIC AREASTo meet the world’s increasing energy demand, oiland gas must be produced in new geographical areas.The industry is now heading into the Arctic. There theoil companies will produce oil and gas under demandingconditions, and they must do so safely.How can the industry manage the risks involved inthis? What is necessary to succeed in these new areas?<strong>DNV</strong> has long experience of technology qualification,verification and certification related to the offshoresector. Many of our offshore standards have becomereference standards for international engineering andoil companies. Russian energy major Gazprom, in fact,adopted our offshore standard as its corporate standard.The offshore standard has also been used, forinstance, for the Kizomba field off Angola and forfields off the coast of Brazil.We will continue developing existing and newstandards to be at the forefront when it comes totechnology for ensuring safe operations.AGING INSTALLATIONSWhile the oil companies are investing in new geographicalareas, they also have to pay attention totheir existing installations. Many installations aroundthe world have exceeded their initially defined lifetimes.Not all of these have been particularly well maintainedover the years. Efforts are necessary to makeaging installations safe and as efficient as possible.The technical standard of old facilities is becominga key issue for the industry. We are cooperating withenergy companies to raise the standard of their aginginstallations, offering assistance ranging from assetintegrity management and support to due diligenceservices.The combination of our extensive technological knowhowand risk-based principles is helping the industryto develop sound risk-management strategies andappropriate measures to mitigate risk and ensure thequality, safety and environmental performance of theiroperations.MIKLOS KONKOLY-THEGEPresident and Chief Executive Officer<strong>DNV</strong> Forum 02 20051

<strong>Energy</strong><strong>deep</strong> <strong>thinker</strong>World Petroleum Council President Eivald M.Q. Røren is a firm believer that oil and gaswill play a central role in our energy future. TEXT > HARALD BRÅTHEN PHOTO > NINA EIRIN RANGØY“The world needs more and more energy –and we will produce it,” is the optimisticmessage from Eivald M.Q. Røren. Hardlyanyone has a better overview of the energysituation and energy developments in theworld today than the resigning presidentof the World Petroleum Council and formerSenior Executive Vice President of<strong>DNV</strong>.“We are facing major challenges andthreats which must be dealt with. Four billionpeople currently survive on less thanUSD 2 per day. In addition, the world populationwill probably increase from around6.5 billion today to just over 8 billion in2030, i.e. by around 1 percent per year –in OECD countries by around 0.4 percentper year and in developing countries byaround 1.2 percent.Based on this scenario, the developedcountries must considerably enhance theirenergy efficiency. With the global economygrowing at the rate of just over 3 percentper year, we can assume that the world’sprimary energy needs will rise fromaround 11 000 million ton oil equivalents(Mtoe) today to just over 16 000 Mtoe in2030, representing a growth rate of 1.7percent per year. This is greater than theincrease in population, but less than therate of growth in the economy. However,it is a total growth of 45 percent, and oiland gas will be central for many years,”says Røren.THE IMPOSSIBLE WILL BECOME POSSIBLE“The world has sufficient fossil resourcesto manage this,” he claims. These developmentswill require an oil production ofaround 120 million barrels of oil a day in2030, compared to 84 million barrels a dayat present. Environment-related issues mayalter these developments in the directionof much greater transport efficiency, notleast in the USA, and the widespread introductionof new fuels, such as hydrogen,which must also to a large extent comefrom natural gas.”Røren is in no doubt that technologywill play a central role in our energyfuture. The impossible will become possible,it only takes time.“Just over USD 200 billion will be investedeach year in the oil and gas industry until2030. Around 70 percent of this will bespent on exploration and development,while at least 5 percent will be spent onpipelines and ships. LNG transport willincrease tremendously.”INCREASED UTILISATION LEVEL The oil andgas industry has supplied energy and productsto help society develop for many years.Technological developments will be crucialto finding new reserves and utilising thesein an increasingly better way. Not only mustthe production volume increase. The volumesproduced by existing fields, equivalentto that produced in the North Seaeach year, must be replaced.“Will the global society manage this?”“The impossible will continue to be madepossible, both in upstream and downstreamoperations,” says Røren.“Upstream, this will take place by increasingthe recovery rate, thus improving theuse made of resources originally in place.2 <strong>DNV</strong> Forum 02 2005

“We need energy – and we will find it”,says WPC president Eivald M.Q. Røren.

“In the future it is not unrealisticto count on the recovery rate in oilproduction being increased from30 percent to 60 percent.”Eivald M.Q. Rørenaccess to reserves. They may have to makean increased commitment to alternativeenergy forms, as several majors have done.This is a question of time anyway.Two-thirds of the world’s oil resourcesare located in OPEC countries, especiallyaround the Persian Gulf. For gas, the pictureis rather different, with Russia havingthe largest reserves, followed by Iran.Russia is an important oil producer, producingaround 8 million barrels of oil aday (the second-largest net exporter in theworld). This production volume can probablybe increased to 11 million barrels aday in a few years’ time. However, Russiais even more important as a gas producer.It has around 32 percent of the world’sproven reserves, while the Middle East has40 percent. Russia mainly exports gas toEurope, the USA, China, Japan and Korea.This will increase considerably in thefuture.Nuclear power poses a special challenge.A few countries are continuing toexpand their nuclear power operations,such as France, Finland, Russia, Japan andChina, while many others are reducingtheirs. In time, fusion energy may make animpression, but that is a long way into thefuture. However, I believe that nuclearpower may experience a renaissance once<strong>DNV</strong> Forum 02 2005it is recognised that other environmentalissues are more of a problem.”THE OIL PRICE – AN INCENTIVE FORINVESTMENTS When we ask Røren to predicthow the oil price will develop, he isnot as certain as he is about productiondevelopments.“Most people’s predictions about theoil price will be wrong,” he says. “I thinkit’s important to note that the sparecapacity in OPEC’s production has shrunkconsiderably over the past few years. It’sprobably only Saudi Arabia that has anysignificant amount, around 1.5 millionbarrels a day, which can probably beincreased to 2.0 million barrels a day bythe end of 2005. However, we mustremember that the increase in annualconsumption is almost 2 million barrels aday. Any failure in production somewherein the world immediately results in a verydifficult situation. Uncertainty regardingreserves results in higher prices, as doespolitical unrest – as we have seen in Iraq.The global balance is tight, and is reflectedin price.“A common code for classifying reservesis necessary (United Nations FrameworkClassification of Petroleum Resources), asis transparent and consistent reporting.The Norwegian reporting model is a goodexample of this,” says Røren.“Most of the oil that is to be producedover the next 20 years will come from non-OPEC countries. This oil must be foundand produced in increasingly difficultareas. That costs money, which is why theoil price must also provide incentives forinvestments in exploration and developmentand in extra capacity. I believe thatOPEC has demonstrated responsibility andcarried out a good job of balancing thesupply and demand situation. Nonetheless,all the indications are that we will have torelate to continued high oil and energyprices.”Eivald Røren is about to resign as the11th President of the WPC. Now this 70-year-old bundle of energy who loves skiingand being outdoors is looking forward tospending his days with his family andfriends. He is retiring after many yearsof having the energy world at his feet.5

6 <strong>DNV</strong> Forum 02 2005

Buildinga strongerSingaporeSingapore is already a force to be reckoned with in themaritime industry. The next step is to make Singaporean International Maritime Centre. “To get there we needmore education, cooperation with the government, anda set of support services,” says Teo Siong Seng, betterknown as SS Teo, President of the Singapore ShippingAssociation. TEXT > ANDERS ØVREBERG PHOTO > NINA EIRIN RANGØY><strong>DNV</strong> Forum 02 20057

A man of many roles, SS Teo is Presidentof the SSA, chairman of SingaporeMaritime Foundation (SMF), as well asmanaging director of the second largestSingaporean shipping line, Pacific InternationalLines. The three roles are related,and he smilingly says, “I always have tomake sure I know which one I'm doing.”DEVELOPING SINGAPORE Singapore isalready well established as a maritimecentre, but it wants to grow even furtherto create an International Maritime Centre;a hub for international shipping with largepool of foreign shipowners.“When people think of Singapore, theyoften associate it with the ships, shipyardsand ports, but they don't think much onthe supporting services to the maritimeindustry. I see Singapore developing intoan International Maritime Centre with acomplete set of supporting services, so thatSingapore becomes a ‘one stop shop’ forinternational shipping; with lawyers, classsocieties, ship finance, arbitrations andmany other areas of expertise creatinga maritime cluster,” says SS Teo.The effort to create such a cluster, orInternational Maritime Centre, waslaunched two years ago. It was initiated bythe government, and is carried out by theMaritime Port Authorities in co-operationwith the SMF.MORE OPPORTUNITIES Asia shipping is setto become even more international in theyears to come.“The market will definitely grow. Of thetop ten container ports in the world, sevenare located in Asia. Of the top 20 containerowners in the world, I believe 12 areAsians. As Asia develops, more owners andmaritime related companies will set upbase here. At the same time we do seeemerging Asian players coming up to takeadvantage of opportunities, from China,India and South East Asia,” says SS Teo.According to him, local operators welcomethe competition.“Most people appreciate that you needa critical mass, a cluster, so that you cancreate more opportunities. It brings morebusiness, and different disciplines andexpertise that complement what we have.”And an International Maritime Centre issomething that will last, he claims.“You can move a factory overnight toVietnam or to Indonesia, but once youestablish a centre, the experience andknowledge that’s being build up cannoteasily be replaced or moved. London isa good example. Even though they havelimited number of ship owners now, theyare still recognised as a maritime centrebecause of the expertise they have availableand have gathered over the years.”A LARGE INDUSTRY The maritime industryin Singapore employs close to 100.000 peopleand contributes to about eight percentof the GDP (Gross Domestic Product).“I don’t think people realise how importantthis industry is to Singapore, and itwill only continue to grow. A recent forecastsuggests that in less than ten yearstime the industry would count 200.000people, and account for 12 percent of theGDP,” says SS Teo.He believes that the industry is robustand can withstand hardships. “Over thelast few years we went through Asian eco-8 <strong>DNV</strong> Forum 02 2005

“ I look upon it as a mission to grow Singaporeas an International Maritime Centre. We can achieve it, andthen we would have created more opportunites, not only forour own people, but also for the surrounding countries.I believe in that.”Teo Siong Sengnomic crisis, the 2001 terrorist attacks, andSARS, but in spite of all that the maritimeindustry continued to grow. I think there isa lot of room for growth, and that is a messageto the young people who are thinkingabout their careers,” says SS Teo.THE BEAUTY OF SINGAPORE Explainingthe competition, SS Teo lines up the centresin Asia that Singapore has to competewith. Hong Kong, a well establishedcentre, has a large and respectable poolof local and international ship owners,and takes full advantage of the proximityto China. Shanghai, up and coming, isthe maritime centre of the fastest growingeconomy in the world. He remainsundaunted.“What Singapore has to offer is an overallproposition; we have our stable governmentand is a transparent society. And thebeauty of Singapore is that it’s neutralground. We represent a good balancebetween the east and the west. There isalso ease of communication here; not justflight connections, but also IT. Singaporeis competitive,” says SS Teo.<strong>DNV</strong> Forum 02 2005He himself is an example of his east-meetswestargument, having studied in Scotland.In fact, one of the areas where Singaporeis making a push is within education, havingset up last year the first degree coursein maritime studies in Singapore. Soon adegree in marineengineering will also be available.SAFETY AND THE ENVIRONMENT Within theshipping industry, concerns for safety andthe environment are global. In Europeand America, however, there has beenmore pressure from the authoritiestowards the industry due to some highlypublicised cases of marine disasters.“In Europe and the US the governmentshave insisted on certain rulings.I am not sure if those rulings have comeabout with ample consultations, or if theyjust come as a reaction. Whether it isAsia, the EU or the US, we all believe thatwe must protect the environment, but inAsia I think there is more consultationbetween the industry and the authoritiesbefore new regulations are implemented,”says SS Teo.Regardless, Singapore supports andcomplies with the regulations from theInternational Maritime Organisation(IMO), and is serious in working for a safeand environmentally sustainable industry.“I don’t think anyone in the shippingindustry today, whether in Europe, Asia orin America, can sacrifice the environmentfor commerce,” says SS Teo.TEO SIONG SENGTEO SIONG SENG, better knownas SS Teo, President of the SingaporeShipping Association.9

System certification:“Nothing more than intel

ligent staff management”“Ultimately, process-oriented certification is nothing morethan intelligent staff management. In the course of ourpartnership with <strong>DNV</strong>, we have been able to successivelyincrease the individual responsibilities of our employees,”says chief executive of BMW M GmbH, Ulrich Bruhnke.TEXT: ISABEL RADWAN PHOTO: BMWWhen Ulrich Bruhnke starts talking abouthis company’s hand-made M engines, itbecomes immediately apparent that this isa man who has found his vocation. In theeyes of many a BMW enthusiast, professorUlrich Bruhnke, chief executive of BMWM GmbH, has the most coveted job in theworld. This is the man who presides overthe fortunes of BMW’s sports cars. Thenippy, top-end BMW M line, that hasachieved cult status among its fans, isdesigned, developed and manufactured,in part manually, here at the Munichheadquarters.“We’re the inspiration team within theBMW group,” explains Bruhnke, not withoutpride. “Our development departmentis a think-tank in which the whiz kids witha real driving passion can let their hairdown.”QUALITY NEEDS TO BE MANAGED Althoughan enviable job in one of the most vibrantsectors in the world, creativity anddynamism must be balanced by disciplineand quality controls. “Speed in our marketoften goes hand in hand with quality deficiencies,”Bruhnke continues. “BMW MGmbH stands for the best sports enginesaround the globe and for unconventional,custom-made products. We are goldsmithsand high-performance sportsmen in one.”Not an easy task in a market as mercilessand unforgiving of quality defects as theautomotive sector. For this reason, theindustry is turning increasingly to theobjective assessment and monitoring of itsperformance by impartial experts such as<strong>DNV</strong>.In 2002, BMW M GmbH hired <strong>DNV</strong> forthe first time to assess the company’s performanceaccording to the EN ISO9001:2000 quality management system.“We are grateful for the methodical supportand far-sightedness of <strong>DNV</strong>’s qualityauditors,” says Bruhnke. “The auditorsboost staff awareness of their workprocesses.”BMW M GmbH has the motto “Creativityby design”, a goal which is supported by<strong>DNV</strong>’s auditors who analyse the workprocesses jointly with the staff, identifyingresponsibilities and highlighting potentialbottlenecks.THE LEARNING COMPANY “Companies thatdon’t learn sufficiently quickly will be chastisedby the market. It couldn’t be simpler,”says Bruhnke. “We regard our collaborationwith <strong>DNV</strong> as a form of joint,>11

escorted learning. Ultimately, it is ourcustomers who benefit at the end of thisvalue-added chain. They are individualswho invest not only in the ultimate drivingexperience but also in their confidence ina world-class technology.”This can only be assured in the longterm by a management that takes a committedapproach to anticipating risks andbottlenecks. Risk management is thereforecommonplace at BMW M GmbH, with<strong>DNV</strong>’s auditors acting as a mirror thatregularly reflects the staff potential forimprovement. “If you’re going to spearheadthe market, you must also set thebenchmarks,” Bruhnke continues. “Forour staff, this collaborative venture is asportsmanlike assessment of their abilitiesand potential.”BMW M GmbH can look back on manyyears of measurable benefits for its stafffrom the collaboration with <strong>DNV</strong>. This isthe best incentive to continue ferventlyalong this path. Ultimately, a motivatedworkforce offers the best guarantee forquality. No one knows that better thanUlrich Bruhnke.<strong>DNV</strong> Forum 02 2005

BMW M – CREATIVITY BY DESIGNBMW M GmbH is synonymous with world-class sports engines and tailor-madeproduction for aficionados. At BMW, M stands for exceptionally powerful engines.Vehicles of the legendary BMW M line started being manufactured in 1972.ULRICH BRUHNKEProfessor ULRICH BRUHNKE became BMW M GmbH chief executive in December2003. Under his management, the company launched the new BMW M5 and BMWM6 cars. The professor of vehicle technology is commonly regarded as one of thetop managers in the automotive sector and is also an enthusiastic car fan in hisspare time.<strong>DNV</strong> Forum 02 200513

Using production equipmentlocated in water depths of 1,000 meters,the gas will be raised and transportedfrom Nyhamna all the way to the UK.Break

ing new groundHydro’s giant Ormen Lange project is currently Europe’sbiggest gas development. Due on stream in 2007, the fieldwill be linked to the UK via the world’s longest subsea gaspipeline, and will supply the UK with up to 20 percent ofits total gas requirement.TEXT: STUART BREWER ILLUSTRATION AND PHOTO: HYDROIn October 2007, gas will begin to flowthrough the process plant at Nyhamna onthe Møre coast of Norway, marking thestart of operations in Europe’s largest currentgas development. The project standsout for its plethora of first-time achievements,not least in bringing gas directly toshore in multi-phase flow pipelines fromsubsea wells in waters up to 1,000 m <strong>deep</strong>– Norway’s <strong>deep</strong>est offshore field to date.“This is one of the world’s most challengingoffshore developments,” says EinarKilde, Hydro’s vice president and offshoreproject manager for Ormen Lange. “Usingproduction equipment located in waterdepths of 1,000 metres, we will raise thegas and transport it from Nyhamna all theway to the UK through the world’s longestsubsea pipeline, the Langeled.”Some 21 billion m 3 a year of natural gaswill be produced at peak from the field’s24 wells, boosting Norway’s gas exportcapacity by 25 percent. Most of this gas willbe transported through the new Langeledpipeline (1,200 km) to Easington in theUK. “In Ormen Lange, we have a veryrobust project based on large gas reserves– around 400 billion m 3 . When the gasarrives onshore, it must be treated, turnedaround and redirected to the UK throughthe Langeled pipeline, and that is wherethe Nyhamna processing plant will act asthe hub for the field development,” saysKilde.SUBSEA-TO-LAND CONCEPT In selectingthe offshore field development solution,Hydro opted for a novel subsea-to-landconcept. Explains Kilde, “DevelopingOrmen Lange represents a major challengewith the combination of <strong>deep</strong>waters, extremely rough seabed conditions,long tie-back distance and demandingweather conditions. Consequently, weevaluated a range of solutions – rangingfrom a relatively novel subsea-to-land concept(subsea wells tied back to the onshoreterminal) to more traditional <strong>deep</strong>water15>

EINAR KILDEEINAR KILDE, Hydro’s vice presidentand offshore project manager forOrmen Lange.REMI ERIKSENREMI ERIKSEN,<strong>DNV</strong> Consulting director for Oil andGas.concepts involving an offshore processingfacility with wet and dry wells like a SPAR,tension leg platform or semi-submersiblerig. After reviewing all the technical andcommercial aspects, we opted for the subsea-to-landsolution.”Commenting on <strong>DNV</strong>’s role in the project,<strong>DNV</strong> Consulting director Remi Eriksensays that <strong>DNV</strong> assisted in selecting the offshorefield development solution throughcombining <strong>DNV</strong>’s risk management toolswith technology qualification services andother relevant specialist services.RISK-BASED APPROACH Says Eriksen, “Theapproach used included a risk-based gasdeliverability model, which was developedduring the concept evaluation phase andFEED (Front-End Engineering Design)phase to assist in concept selection andconcept optimisation. The model estimatedthe gas volumes that would be deliveredfrom Nyhamna on a yearly basis and themaintenance and intervention costs associatedwith producing these volumes. Allfailures and incidents which would resultin loss of production relative to specifiedmarket demand were included. Also, astrategy on how to manage the IMR(Inspection, Maintenance and Repair)activities was developed.”According to Eriksen, the economicsof <strong>deep</strong>water developments are differentfrom those of shelf developments – boththe stakes and risks are higher. Untilrecently, it was common to evaluate <strong>deep</strong>waterventures based on projections ofCapital Expenditures (CAPEX) andOperational Expenditures (OPEX), withouta proportional amount of effort toassess the magnitude of the cost associatedwith system failures and unplanned events– Risk Expenditures (RISKEX).“The project demonstrated how modernrisk techniques can facilitate the decision-makingprocess in <strong>deep</strong>water developments,”says Eriksen and adds “The valueof including RISKEX in the decision-makingprocess in <strong>deep</strong>water developments isapparent as larger amounts of money areinvested, which rely on future high revenuestreams. Furthermore, <strong>deep</strong>waterdevelopments rely on new technologywhich has yet to be field proven. Risk techniquesallow the implications of system failuresand unplanned events to be incorporatedinto business evaluations to arrive atthe best alternative.”16 <strong>DNV</strong> Forum 02 2005

newsPivotal to the Ormen Lange project is the gas processing plant at Nyhamna whichis designed to export 70 million m 3 /d of processed gas. The site stretches for almost1,500m along the coastline and goes back into the island almost 2,000m.Safe software in space<strong>DNV</strong> will carry out independent softwareverification and validation of the Aeolussatellite.“Ormen Lange is one of the world’smost challengingoffshore developments.”COST SAVINGS One of the project’s mainresults showed the potential cost savingsrelated to focusing attention on criticalareas and improving solutions and conceptswhere the potential value-yield ishighest. A second advantage of the risktechniques used is that enhancementopportunities are discovered during theconceptual design phase rather than laterin the development when the cost ofchanges is much higher.“It is generally acknowledged that operationalexperience provided by respectedspecialists within a team has larger impacton a decision process than a study done byan external party,” says Kilde. “With this inmind, Hydro decided to have <strong>DNV</strong> specialistsintegrated in the project team toinvolve multidisciplinary expertise and tobuild confidence in the results generated.This approach turned out to be a success,allowing the gas deliverability analysis tobecome a ‘real-time’ decision basis.”The Ormen Lange project is currentlyin the detail engineering and executionphase. The Nyhamna site has now beenprepared and work on pipes, undergroundpipelines and the casting of foundationsfor the process plant is well under way.<strong>DNV</strong> Forum 02 2005Einar KildeWork started on laying the pipelines fromNyhamna a few months ago. Subsea installationswere lowered onto the field seabedthis summer while the work of preparingthe seabed continues.ON SCHEDULE In June and July, the first33 km of the 130-km-long, 30” diametergas pipelines that are to bring the gas fromthe Ormen Lange field into the processplant at Nyhamna were laid, along with thefirst 33 km of the 42” diameter Langeledpipe, which will finally bring the treatedgas to cookers and power stations in theUK. Control cables and pipes for transportinganti-freeze to the subsea facilitywill be entrenched in the seabed next year.“The schedule for the Ormen Langeproject is tight in all phases, but we areconfident that we have the right peopleand the right tools to carry out this jobsuccessfully,” says Kilde. “We will be readyin 2007.”Independent software verification and validationis an engineering practice intended toimprove the quality and reduce costs of a softwareproduct. It is most successful if it savesthe mission by finding a fault not discoveredthrough the developer’s own quality systems.<strong>DNV</strong> is currently leading a project onbehalf of the European Space Agency (ESA),developing a guide for independent verificationand validation of software. This work ledto the recent contract where software verificationand validation is performed for theAeolus satellite, which is being built for ESAby Astrium Ltd. The satellite will provide globalobservations of wind profiles to improvethe quality of weather forecasts, and advanceour understanding of atmospheric dynamicsand climate change processes.The ESA, America’s NASA and Japan’sJaxa/Jamss routinely require independent verificationand validation for critical software.<strong>DNV</strong> has been asked by ESA to consolidate amethodology that represents the best industrypractice across industries. The main resultfrom the project will be an independent softwareverification and validation guide that issufficiently generic to be useful in all industries.The project is being carried out in cooperationwith Denmark’s Terma, the UK’s SciSysand Portugal’s Critical Software, and it will becompleted this autumn.“We’re developing expertise in Norwayto carry out this kind of service worldwide– and not just in the field of space,”says Narve Mjøs, who is in charge of<strong>DNV</strong>’s space activity.17Photo: Eva Halvorsen

Rio de Janeiro is one of Subsea 7´s main hubs in providing pipeline installations.Right the first time“You won’t get a second chance, so when constructing and installing pipelinesin <strong>deep</strong> waters, you have to do it right the very first time,” says Subsea 7´s Iain Adam.TEXT: PER WIGGO RICHARDSEN PHOTO: SUBSEA 7

“ Pipelines reduce the risk of spillsand will in the long termhave a positive economic effect.”Iain AdamSubsea 7’s vessel will soon leave Rio to start installing pipelines in <strong>deep</strong> waters off the coast of Brazil.New plans for developing oil and gasresources off the coast of Brazil haverecently been approved. All those involvedin these new projects have to overcomewater depth of 1,400 metres and a steeplysloping seabed.Petrobras, the Brazilian oil and gasmajor, is to install new pipelines for oil aswell as gas within the Campos basin andthe Espiríto Santo basin. Subsea 7 hasbeen awarded the engineering, procurement,installation and construction contractfor these jobs.Iain Adam is Subsea 7’s project managerand thus responsible for doing thewhole job right the first time. He says:“We need the skills and experience of allinvolved in these challenging projects.Pipelines have been installed in <strong>deep</strong>waters before, but you can never rely onold experience. I believe we have got offto a good start and have the pleasure ofcollaborating with capable professionalcompanies and professional people. Asyou meet tough challenges, you have tobe 100 percent focused at all times.”SUBSEA 7’S BIGGEST CONTRACTS The firstpipeline to be installed is a 67-kilometregas export line. This is part of an overallplan for the Golfinho field in the EspirítoSanto basin. The first gas is scheduled fordelivery by April 2006.As part of the overall plan for theCampos basin, three oil-export and twogas-export pipelines will then be completed.The total length of these pipelineswill be almost 130 kilometres and the firstpetroleum will flow through these pipesat the end of 2006.“This is among Subsea 7’s biggest contractsever, worldwide. Although the installationprocess will not start for almost a year, theengineering process has been on-going fora while,” says Adam.“This is a technically difficult project.The seabed the pipeline has to cross on itsway from the Golfinho field to shore risesfrom water depths of 1,200 metres to 70metres in less than four kilometres. Thepipeline may also cross 105 free spans –a number that we really want to reduce.”THE DEMAND WILL INCREASE Iain Adamexpects more pipelines to be laid in thesepetroleum-rich provinces off the Braziliancoast.“The plan for further developingGolfinho 2 is a hot topic right now. Thedemand for gas in Brazil is increasing. Thedemand for oil is high and will rise. Thereare currently some unsolved political questionsrelated to tax systems depending onwhere the oil is landed. If these are solved,my guess is that new pipeline projects willbe started in the years to come.”He wants to mention the environmentalaspect too: “Pipelines reduce the riskof spills. And pipeline will in the longterm have a positive economic effect too.”ADOPTED <strong>DNV</strong> PIPELINE STANDARD ForSubsea 7, as for all contractors operatingin Brazil, Petrobras is its most importantpartner. In 2000, Petrobras decided toadopt the <strong>DNV</strong> pipeline standard OS-F101as the company standard for the design ofall its subsea pipelines.Iain Adam completely understands whyPetrobras made this decision. “It’s a goodstandard. It addresses all parts of a pipelineproject, and the result is a high-qualityend product.”! facts:SUBSEA 7A major international subsea engineering contractor.The company’s offshore operations aresupported out of the Asia Pacific region,PETROBRASBrazil’s largest energy company, with some50,000 employees and a huge portfolio ofninety-three production platforms, ten refiner-Photo: Per Wiggo RichardsenIAIN ADAMBrazil, the Gulf of Mexico, Norway, the UKand West Africa. It has 3,000 employees.Subsea 7 has more than 100 remotely operatedvehicles, four pipeline construction yardsand a fleet of modern ships.ies, almost sixteen thousand kilometres ofpipeline, and seven thousand service stations.Petrobras, founded in 1953, is headquarteredin Rio de Janeiro and has offices and administrationmanagers in other major Brazilian cities.IAIN ADAM is project manager andresponsible for the pipeline that willstart in very <strong>deep</strong> waters offshoreBrazil, but will rise from water depthsof 1,200 metres to 70 metres in lessthan four kilometres.<strong>DNV</strong> Forum 02 200519

NYK (Nippon Yusen Kaisha) Line provides logistics services via sea, land, and air, buttheir activities are centered on marine transportation. They have more than 660 vesselsin their fleet, counting both chartered and owned. In 2005 the company celebrates its120th year, and does so focusing more on the environment and safety than ever before.Consideringenvironmentequal to safetyJapanese NYK Line is one of the worlds leading shipping companies, with more than 660vessels, both chartered and owned, in its fleet. Impressive environmental efforts broughtthe company the prestigious 2005 Heyerdahl award for environmental excellence. “Weconsider the environment equal to safety,” says Captain Hiroshi Sekine, General Managerof Safety and Environmental Management Group for NYK Line.TEXT: ANDERS ØVERBERG PHOTO: NYK LINE20 <strong>DNV</strong> Forum 02 2005

“Our focus in NYK Line when it comes toenvironmental safety is 99 percent onreducing the risks for accidents, whichcan cause devastating pollution.Protecting the environment is very importantfor us as a shipping company, and wehave made strict requirements to ensuresafe and reliable operations that all shipswe operate must follow,” says Sekine.COMPLIANCE NYK Line's quality assuranceactivities are based on a proprietary standarddesigned to achieve safe operationsabove a defined level. The standard iscalled ‘NAV9000’.“We request all ship owners and shipmanagement services companies to applythese standards to their own managementsystem. At present about 80 companiesthat charter ships to NYK have signed anagreement to follow these requirements,”says Sekine.NAV9000 has been designed in away that if they follow it, then automaticallyoperations are compliant withthe ISM code. “If everyone followed thecode, I believe there would be no incidents.However, some still don't comply,”he says.><strong>DNV</strong> Forum 02 200521

“We will continue our work andput our new environmental managementvision into practice.”Hiroshi SekinePhoto: Anders ØvrebergCAPTAINHIROSHI SEKINECaptain HIROSHI SEKINE, GeneralManager of Safety and EnvironmentalManagement Group for NYK Line,says that it is the role of a shippingcompany to carry out safe and environmentallysound operations, andcontribute to a sustainable economy.NEAR MISS BOX An important part ofNAV9000 involves the crews of every ship.“We encourage every member of thecrew on all our ships to become aware ofall incidents that did not lead to accidentsand to make a report, no matter how small,and drop it into a box called the ‘NearMiss Box’. The reports can be anonymous.Last year, we had more than 6,000 suchreports of Near miss and Unsafe Act/conditionrelated to safe operations and environmentalprotection, which I think issome kind of record,” says Sekine.Most of the reports are concerninghuman error, and they are used toimprove safety onboard even further.ENVIRONMENTAL EFFORTS In 2004, NYKLine published a Social & Environmentalreport detailing their efforts to ensuresafe and responsible operations.“In addition to safety considerations,we have taken a number of concreteactions to limit the adverse effects onthe environment from operations. Ballastwater exchange has been introduced, andballast water treatment system is underinvestigation and development as a partof a countermeasure. We have also introducedwaste management, and have overthe last 10 years worked hard on creatingthe NYK bilge water treatment system,which our government is taking to the IMO(International Maritime Organisation),”says Sekine.They are also in compliance withregards to the IMO regulations demandinglow sulphur fuels, and are switching tolow sulphur fuel on ships staying in Port ofLos Angeles.“New and advanced engines that areelectronically controlled and burn cleaner,therefore emitting less nitrogen oxide(NOx), have been introduced on someof the new NYK ships. For six years fromfiscal 2005 to 2010, the NYK Group willinvest 1.38 trillion yen (equivalent toUS$13.8 billion) to conduct fleet expansionto 880 ships, from the current 660ships. We believe that the electronicallycontrolled engine technology will be a keyfactor for these newbuildings. And overtime, NYK Line is looking to improve theengine on all current vessels,” says Sekine.HARD TO INNOVATE HARDWARE Such hardwareinnovations take time and effort.Shipping companies are typically morefocused on process improvements andstrict routines as tools in promoting safeoperations.“We would like to see an increased drivefor hardware innovations, such asimproved wind generators, solar powerand others, to make an impact on the shippingindustry. It is very difficult for a shippingcompany such as ours to be innovativein this regard. It takes a very long timeand it's costly. Classification societies aremuch better positioned, with plenty ofdata available. They should take the leadas innovators for the shipping industry,”says Sekine.A NEW VISION FOR THE FUTURE Accordingto Sekine, there is little environmentalconcern among the population in Japan.Unlike in the west, there isn't much pressurefrom environmental groups towardsthe industry to improve. But this does notreduce the environmental focus for NYKLine.“We will continue our work and put ournew environmental management visioninto practice. The vision focuses on contributingto a sustainable society, whileaiming to manage environmental risks.It fits together with our motto “Sail onSafety”, which underlines our mission tocontinue safe operations,” says Sekine.22 <strong>DNV</strong> Forum 02 2005

Accident triggered NYK´s environmental attention“We had an accident in Tokyo Bay abouteight years ago, which caused muchinconvenience and damage,” says TakaoKusakari, chairman of NYK Line. “Inhindsight it was this event that triggeredus to become serious when it comes toenvironmental issues.”The accident Kusakari refers to happenedin July 1997, when the NYK’s VLCC(very large crude carrier) DiamondGrace had an oil spill accident in TokyoBay.“Over the last eight years we have workedextensively and hard to improve. We haveaccomplished perhaps 50 to 60 percentof what we would like to achieve. I wouldlike to see us as the number one shippingcompany in the world with regards to safetyand the environment,” says Kusakari.HEYERDAHL AWARDKusakari accepted the prestigiousHeyerdahl award this year on behalf ofNYK Line at an award ceremony inrecognition of the company's impressiveefforts and commitment to improvetheir environmental performance.“Even though ships are environmentallymuch better than trucks and cars asmeans for transportation, we in the shippingindustry are still consuming hugequantities of fuel. We have to reducethat consumption. And most important,following up our motto “Sail on Safety”,we will try to realise one full year ofoperations without an accident,” saidKusakari at the award ceremony inTokyo.The Norwegian Minister of Trade andIndustry, Børge Brende, presented theThor Heyerdahl award to the Chairmanof NYK Line, Takao Kusakari. In his acceptancespeech Kusakari stated his ambitionto see NYK Line “as the number one shippingcompany in the world with regardsto safety and the environment.”Photo: Anders Øvreberg<strong>DNV</strong> Forum 02 200523

“This production methodmay mean a quantum leapfor shipbuilding.”Ole-Jacob Libæk

Perfect timing forconcrete sandwichThe timing is now perfect for <strong>DNV</strong>’s concept of building ships and floating offshorestructures using a sandwich design with steel surface plates and a lightweight concretecore, according to Ole-Jacob Libæk, the chairman of Libaek & Associates AS.TEXT: HARALD BRÅTHEN PHOTO: NINA EIRIN RANGØYLibæk has plenty of experience in launchingnew concepts. Many people have madelosses by introducing new concepts tooearly. However, when it comes to this project,developed by <strong>DNV</strong>’s Pål G. Berganand his team, the experienced shipbrokeris in no doubt: “The timing is perfect.”“There is now a huge demand in themarket for FSO (Floating Storage and Offloading)and FPSO (Floating Production,Storage and Offshore Loading) vessels. AnFSO or FPSO is exposed to different forcesthan an ordinary ship, which has to moveforwards in all kinds of weather and waves.We’ve seen that this is a logical place forthe concept to begin.”It is most interesting to see how this projecthas developed over the last three years;starting with concept benchmarking againstpanamax bulkcarriers to the present identificationof a whole range of exciting applicationareas. “The concept is no doubtcommercially viable,” says Libæk. Over thepast 18–24 months we have seen sharp risesin newbuilding prices and in the value ofsecond-hand ships. These are now in shortsupply. This is at the same time ideal forthe sandwich project.”FASTER, CHEAPER AND STRONGERIn Libæk’s opinion, two factors in particularmake the sandwich concept commerciallyviable: its price and delivery time.“The first sandwich FSO may well beready for delivery at the end of 2007. Withmaterial costs reduced by around 30 percentand a lifetime of 30–40 years for eachunit, the concept is clearly competitive. Ican see that this technology has an immediatepotential for FSOs and FPSOs, andsoon also for LNG gasification and regasificationfacilities.These ships, which will have a light concretecore, are also very simple and quickto build, and do not necessarily have to bebuilt at traditional shipyards. They do notrequire propulsion machinery and the topsideis containerised and uncomplicated toput in place. Cargo handling and ballasthandling are bought in ready-made packages.Existing newbuilding yards that build200,000-500,000 dwt ships and offshoreFSOs are fully booked and can only delivertowards the end of 2008 and beginning of2009. However, in for example the BarentsSea there are oil fields that will requirestorage in 2007. Libæk reports a firm interestfrom field developers, shipowners andbuilders.“They can’t wait until 2009,” says Libæk.Dr. Pål G. Bergan’s ideaThe concrete sandwich idea was conceived by Dr. Pål G. Bergan in <strong>DNV</strong> Research about five years ago. The concept hasbeen further developed during the past three years in a strategic research project together with Aker Yards ASA where<strong>DNV</strong> has focused on technology development and Aker Yards has studied the potential for efficient fabrication andimplementation in different types of ships. Recently a series of laboratory tests of component fatigue and strengthwere completed. The tests showed that the composite materials are superior to today’s welded steel structures. Thetests showed remarkable performance of sandwich components both with respect to strength and fatigue behaviour.A more comprehensive, formal technology qualification project will be finished by the end of this year.Photo: Eva Halvorsen<strong>DNV</strong> Forum 02 200525

The world’s largest underwater pipeline system:Providing risk statusGassco operates one of the world’s largest integrated gastransport systems. 7,000 kilometres of pipeline connectthe oil and gas fields in the North Sea to the refineries onland and the end-users in the UK and on the continent.TEXT > HARALD BRÅTHEN ILLUSTRATIONS > GASSCOFrom Gassco’s control centre at Karmøy inNorway, the company manages the transportof energy corresponding to 13 percentof the total European gas consumption in2004. <strong>DNV</strong> helps Gassco to monitor therisk status of the pipelines’ technicalintegrity.As the operator, Gassco is responsiblefor monitoring the technical conditionof the pipelines. <strong>DNV</strong> has installed a softwarepackage in each of the TechnicalService Providers (TSPs), which areresponsible for carrying out the work ofsecuring the pipelines’ integrity. This softwarepackage gathers informationand sends it to Gassco, which thus meetsboth its own and the authorities’ controlrequirements.SIMPLE AND INTUITIVE <strong>DNV</strong> has a longhistory of successful collaboration withGassco and has also arranged regularforums for the TSPs. It was through thiswork that the need for simplified, commonreporting was identified. Gassco nowachieves this by using <strong>DNV</strong>’s new integritymanagement portal, which is a modulewithin <strong>DNV</strong> Software’s Field Life CycleManager. Gassco is the first user of thepipeline portal.The web application presents the informationin a simple, intuitive manner.“With the integrity management portal,my work is simplified, both when reportingand when working on common tasks withthe TSPs,” says Benedicte Madsen, a seniorengineer and the person responsible forfollowing up the technical integrity andcondition of the pipelines at Gassco.The information shows the pipelines’technical integrity by stating the risk status,current activities around the pipelines,inspection plans and documents.EASY UPDATING “Each TSP sends regularupdates, which are stored so that a completehistory of the pipeline is available,”says Madsen.26 <strong>DNV</strong> Forum 02 2005

NorneGassco operates a pipeline system that is longer thanthe distance from Oslo to Chicago.St FergusEasingtonVesterledLangeledZeepipe ISleipnerFranpipeStatfjordGullfaksHeimdalUlaGydaEkofiskValhallSnorreHuldraTuneOsebergHodOGTGraneVisundKvitebjørnVeslefrikkBrageStatpipeJotunZeepipe II AZeepipe II BStatpipeDraupner S/EB11TrollNorpipeEuropipe IH7Europipe IIÅsgard TransportOrmen LangeFlorøStureKårstøBygnesKollsnesBergenStavangerNyhamnaKristinMongstadNORWAYDENMARKNGTSÅsgardDraugenHaltenpipeTjeldbergoddenHeidrunTrondheimThe reporting to Gassco is achieved simplyby entering the data manually in order toupdate the portal. The updates, which aresent via a web service, are received by theintegrity management portal and directlyupdated in Gassco’s database.The TSPs which use the software systemORBIT Pipeline for pipeline integrity management,updates the portal by simplypushing a button in ORBIT Pipeline.EFFICIENT, SECURE OPERATIONS Gas is oneof Norway’s most important export productsand, unlike other Norwegian exports, it hasits own transport network on the seabed.“Our most important task is to ensurethe efficient, secure operation of the pipelines,processing plants and platforms thatform part of the gas transport system,” saysMadsen. Gassco also coordinates theefforts to expand the gas transport capacity,including those relating to the planningand further development of new infrastructure.“This helps to ensure better control,both for our customers and for the authorities.In this way, we also contribute new,future-oriented solutions as well as monitoringwhat we already have in place,” saysMadsen.EmdenDornumUNITED KINGDOMGERMANYTHE NETHERLANDSDunkerqueFRANCEZeebruggeBELGIUMExisting pipelinesPlanned pipelinesPhoto: Harald BråthenBENEDIKTE MADSEN! facts about Gassco:> Owned by the Norwegian state. Operator for Gassled.> Responsible for safe, reliable gas transport.> Transports gas worth more than USD 10 billion each year.BENEDICTE MADSEN is senior engineerand responsible for following upthe technical integrity and conditionof the pipelines at Gassco. “With theintegrity management portal, my workis simplified, both when reportingand when working on common taskswith the Technical Service Providers.”<strong>DNV</strong> Forum 02 200527

Bottlingthe flavourof ArgentinaIn the 1950s Don Alberto Zuccardi set up his own irrigationsystem and transformed parts of a dessert into flourishingvineyards. Today, the Zuccardi family is one of Argentina’smost respected wine producers.TEXT: PER WIGGO RICHARDSEN PHOTO: WWW.FAMILIAZUCCARDI.COM“When we say we are bottling passion, wereally mean it. Passion is the pay for us.We believe that good wines are created bygood people in healthy vineyards.” This isJosé Alberto Zuccardi’s quote. Since 1985Familia Zuccardi has been managed byhim, the son of Don Alberto.INNOVATION – A MOTIVATING FACTORIn the 1950s Don Alberto Zuccardi wasa young, innovative man who started hisown irrigation company. His companyspecialised in irrigation techniques forthe grape and soft fruit industries in theregion of Mendoza, close to the AndesMountains of Argentina.Some years later – in 1963 – as a way ofdemonstrating the effectiveness of his prefabricatedconcrete and irrigation system,the founder of the Familia Zuccardi purchaseda part of the dessert himself. Herehe demonstrated the system to growers.Innovation has ever since been an importantmotivation for the Zuccardi family.They have their own research area and allin all 32 different types of grapes are grown28 <strong>DNV</strong> Forum 02 2005

<strong>DNV</strong> Forum 02 200529

“Good winesare createdby good peopleinhealthyvineyards.”José Alberto Zuccardiin their yards. All grape picking and pruningis carried out by hand. Almost nochemicals are used, and 60 percent of thegrapes are grown organically.Since the computer was introduced twodecades ago, every aspects of production isrecorded in minute detail on the winery’sdatabase. All this to ensure the best qualityof every bottle produced. But even moreimportant, “We are always looking forsomething better,” states José AlbertoZuccardi as another example of the family’sinnovative spirit.FORTH LARGEST EXPORTER Familia Zuccardiis not among the largest wineries inArgentina. In terms of production, theyare medium size, but in terms of exportthey are the fourth largest. 65 percent ofZuccardi’s wines are distributed to some35 different countries. Only 35 percentof their production is sold in theArgentinean market. The average forthe 1200 wine producers of Argentinais 10 to 90–10 percent export and 90percent to the domestic market.“During our first 10 years, we producedwine only for our domestic market. Theexport started in 1983, and has beenthrough a healthy growth since. Today,every day is a step into a more globalisingworld and our challenge is to always beperceived as a respectable provider. Bydifferentiation, not by copying, we believeFamilia Zuccardi will strengthen its position,but the ambitions will never be tobecome huge,” states José Asensio, theexport manager of Familia Zuccardi.Q FOR QUALITY He continues: “Right nowthere is an oversupply in the global winemarket. There are many vineyards thathave more focus at their financial situationand price of the wine, rather than thequality of the wine. But the customers willbe looking for alternatives to volume suppliers;in the long term they will pronouncetheir judgement of poor quality.”Mr. Zuccardi explains: “We have no ambitionsof being a volume producer. Our goalis to focus on quality. It might be though ina short run, but it will be good in the longrun. We will stay consistent on quality.”Zuccardi has a brand that emphasis this– it is represented by the letter Q –Q for quality. Zuccardi Q is the Zuccardi’spremium quality range. It is made fromgrapes aspecially selected and hand-picketfrom the winery’s top vineyard, andmatured in oak barrels for one year priorto release to the market.LOOKING FOR SOMETHING BETTER Theyalso use another letter in the alphabet tobrand their wine – Z as in Zuccardi. Sincethey always are searching for something totop what has already been achieved, a newbrand will soon be released: Zuccardi Zeta.“This is why bottling passion is a factualstatement, not only a profiling statement forour family,” says José Alberto Zuccardi.“Some grapes are good, but certainly someare superior. Some lots in the yard are betterthan others, but we the people workingat all parts of the process can do a betterjob at all single parts. As a result of all these,we can stretch for the next, higher level.”It is not that many wineries that are certifiedto meet international requirementsof management systems and food safety.Zuccardi has.Zuccardi says: “Certification fits into ourphilosophy – to be better today than yesterday.For us, the certification process is30 <strong>DNV</strong> Forum 02 2005

Don Alberto Zuccardi with his sonJosé Alberto Zuccardi, who has managedFamilia Zuccardi since 1985.an important tool in developing the wineryand in the end, the wine.”SEARCHING FOR THE RIGHT PERSONALITYBut wine is not only about innovation, itis also about passion, about tradition andabout roots. Ema, the 75 year old wife ofDon Alberto and the mother of JoséAlberto is still taking care of one of themost important functions at the winery.When the Zuccardi family are searchingfor new employees, no one is employedwithout Ema’s acceptance. All first interviewsare carried out by her – not onlysearching for the right skills, but for theright personality.“The next generation will follow theoriginal values, trust me,” says JoséAsensio, the export manager, beforehe corrects himself. “Trust Ema!”“Certification fits intoour philosophy– to be better todaythan yesterday.”José Alberto Zuccardi<strong>DNV</strong> Forum 02 200531

newsWind-turbine blade test centre openedin DenmarkPowerful hydrogen partnershipA partnership including the Norwegian majors Statkraft, Statoiland <strong>DNV</strong> are to establish a hydrogen research and demonstrationcentre in Trondheim, Norway.<strong>DNV</strong> Global Wind <strong>Energy</strong> has invested in a new test centrecalled the Blade Test Centre.Co-owned by the Danish companies Risø, Force Technology as wellas <strong>DNV</strong>, the Blade Test Centre is equipped with state-of-the-art bladetest facilities. While the old laboratory could test wind-turbine bladeswith a length of up to 50 metres, the Blade Test Centre is able totest blades with a length of up to 75 metres.<strong>DNV</strong> Global Wind <strong>Energy</strong> has been a key player since the first offshorewind farms were developed. In Denmark, wind energy todaygenerates 20 percent of all electricity.“Wind-generated energy is a mature technology that is expectedto take a significant share of the energy market,” says Henrik O.Madsen, chairman of the board of the Blade Test Centre and COOof <strong>DNV</strong> Certification.Port State Control ranking atteststo <strong>DNV</strong>’s quality standardsThe performance of <strong>DNV</strong>-classed vessels in Port State Control continuesto be one of the world’s best. In the recently published ParisMemorandum of Understanding (MoU) 2004 annual report,Germanischer Lloyd, <strong>DNV</strong> and Registro Italiano Navale are singledout as among the best performing classification societies.Based upon accumulated figures for the 3-year rolling period of2002-2004 from the four major port state regimes in the world(namely, the Paris MoU, Tokyo MoU, Indian Ocean MoU and UnitedStates Coast Guard), <strong>DNV</strong>’s detention rate as a percentage of vesselsinspected was 2.73 percent, compared to the average of 6.23 percent(all Class Societies) and 4.22 percent (IACS members).Photo: Horns RevThe research centre will develop environmentally friendly, profitableand safe ways of producing hydrogen. It will be an important contributionto the national efforts to prepare for a future hydrogen marketand will be operative by early 2007. <strong>DNV</strong> will develop and qualifysafe and reliable technology within consulting, qualification and certificationbased on activities at the hydrogen centre.Photo: Nina Eirin Rangøy“Hydrogen is expected to play an importantrole as an energy carrier in the future,” says<strong>DNV</strong>’s Ståle Selmer-Olsen.<strong>DNV</strong> secures more LNG ship orders<strong>DNV</strong> has won the lion’s share of Qatar’s second batch of LNGship orders. Seven of twelve megacarriers ordered for the RasGas III project will be built in Korea to <strong>DNV</strong> class.Qatar has prompted huge newbuilding orders in the LNG (LiquefiedNatural Gas) trade to cope with its forthcoming production volumes.Eight megacarriers (over 200,000 m 3 ) were ordered last year, four ofwhich are to <strong>DNV</strong> class. Another order for twelve ships has now beenplaced and seven of these will be classed by <strong>DNV</strong>.<strong>DNV</strong>’s business director for tankers, Jan Koren, comments, “Allseven vessels will be built in Korea. NYK in Japan ordered three 216000 m 3 ships from Hyundai (HHI) for delivery starting in April 2008.Also, Teekay has ordered four 217 000 m 3 ships from Samsung fordelivery during the periodApril-June 2008. These are thelargest LNG carriers on orderto date.”The vessels now ordered arepart of Qatar’s planned LNGshipbuilding program whichultimately could compriseover 60 LNG carriers.32<strong>DNV</strong> Forum 02 2005

<strong>DNV</strong> ringside when Olympic Games wereawarded to London<strong>DNV</strong> carried out the quality control of the voting system andprocedures when IOC elected London as host for the summerOlympic Games 2012.Appointed by IOC, a <strong>DNV</strong> team was present on the main floor duringthe exciting process in Singapore. In the days leading up to theannouncement, the technical system and procedures used by IOCwere tested by <strong>DNV</strong>’s team.Quantification of worldwide emissionsClimate impact of global and European transport systems onland based, shipping and aviation activities is to be quantified.<strong>DNV</strong> has joined the EU funded project QUANTIFY on global changeand ecosystems, and is responsible for two activities on modelling ofemissions to air from maritime operations in the past (from 1900),present and the future (year 2100).The understanding of short-term and long-term changes such asfleet, fuels and propulsion is important for <strong>DNV</strong>’s task. The projectwill provide provision of forecasts and policy-relevant advice, whichwill be supplied to governments and to international assessments ofclimate change and ozone depletion, such as the Kyoto Protocol.Photo: Eva Halvorsen“<strong>DNV</strong> was invited to participate inthe project due to our long-termresearch experience on modelingof emissions to air from maritimeoperations,” says Øyvind Endresenand Hanna Lee Behrens.Photo: SvanpixCompletes global research network<strong>DNV</strong> Petroleum Services completes worldwide R&D networkwith new research unit in Fujairah.World’s biggest semi-submersible rig<strong>DNV</strong> has been contracted to class the new 6th generationsemi-submersible drilling rig. When complete in 2007, EasternDrilling 1 will be the largest of its kind ever built.<strong>DNV</strong> has been contracted toclass the Eastern Drilling 1 semisubmersibledrilling rig at theSamsung Heavy Industry (SHI)yard in Korea. <strong>DNV</strong> will beresponsible for the total contractand the site supervision, as wellas for the approval and projectmanagement in the first phaseof the project.The rig is designed with dualderrick and an advanced dynamic positioning system. The operator,Smedvig, will employ the rig in harsh-environment areas. It will becapable of drilling to 3.000 meters. Construction work at Samsungis scheduled to start in March 2006.<strong>DNV</strong> Petroleum Services now has a global research network with theaddition of a research and development (R&D) unit in the company’sFujairah fuel testing facility. The new setup complements <strong>DNV</strong>PS’existing research units in Singapore, Oslo, Rotterdam and the USA.Equipped with a complete range of advanced analytical equipment,including Fuel Ignition Analyser and Gas Chromatography-Mass Spectrometry instruments, the R&D centre in Fujairah willstrengthen <strong>DNV</strong>PS’ capability in identifying fuel contaminants andtheir impact on ship operation and safety.Photo: Nina E. RangøyFuel testing in a <strong>DNV</strong> Petroleum Services lab.<strong>DNV</strong> Forum 02 2005 33

news<strong>DNV</strong> 25 years in ArgentinaUnique FPSO design<strong>DNV</strong> is providing risk management services to Sevan Marineduring the design and construction of a unique FPSO.<strong>DNV</strong> has commemorated its 25th anniversary in Argentina. Duringthese 25 years <strong>DNV</strong> has issued more than 1,000 certificates and istoday the market leader in the country.In 1990, <strong>DNV</strong> Argentina was the first certification body in thecountry to issue an ISO 9001 certificate. Today 70 highly skilled andexperienced employees work for <strong>DNV</strong> in Argentina.<strong>DNV</strong> operates in a large number of industries in both theArgentinean and international markets. These include the maritimeindustry, the automotive industry, the oil and gas industry and themetallurgical industry. Over the past few years, <strong>DNV</strong> Argentina hasalso developed services for the food and beverage sector.Enterprise risk management contractwith PDVSAVenezuelan oil major PDVSA has signed a contract with <strong>DNV</strong>in Houston to provide Enterprise Risk Management training.The Sevan Stabilized Platform, or SSP, is the innovative, round floatingproduction, storage and offloading (FPSO) unit currently underdevelopment. The first unit is scheduled to commence service off thecoast of Brazil for Petrobras in mid-2006 with a second unit destinedto enter service in the North Sea in 2007.Compared with traditional ship-shaped FPSO facilities, SevanMarine ASA, who are developing the concept, claim many advantages,most notably that it will deliver comparable production performancefor significantly lower cost.<strong>DNV</strong> is working closely with Sevan Marine to ensure that the SSPwill be designed, built and maintained to meet internationally recognisedsafety and quality standards. Additionally, <strong>DNV</strong> is assistingSevan Marine implement a world-class hazard management processby which safety, environmental impact and other business risks willbe effectively controlled.The SSP concept combines innovation, simplicity and re-use ofexisting technologies. It has many features and attributes found onexisting oil and gas production facilities, both fixed and floating. Itsintended marketplace is worldwide, in all water depths. Being scalableit will have storage capacities and deck size to suit a wide rangeof production profiles.<strong>DNV</strong> is bringing its international experience-base to support SevanMarine understand worldwide requirements. The goal is to internationalisethe concept design and risk management processes therebyminimising rework and maximising knowledge sharing from one unitto the next.The contract covers training for 25 PDVSA business managers fora five month period.Last year PDVSA executive management set out its vision for establishinga new risk management culture across the entire company.Corporate wide training in state of the art risk management tools,techniques and methodologies is key to realizing this vision.The training programme will cover nearly every aspect of modernrisk management, from qualitative and quantitative risk assessments,failure modes and effects analysis, financial risk management, projectrisk management and political risk assessments.“We are delighted to be presented with this opportunity to workwith the management team of one of the world’s largest energy companiesand important OPEC member,” says Iain Light, COO of <strong>DNV</strong>Consulting.Sevan Marine’s unique FPSO (Floating Production, Storageand Offshore Loading) design.34 <strong>DNV</strong> Forum 02 2005

New <strong>DNV</strong> office in ParisClass notations reduce accidentsAs Paris is an important hubfor the oil and gas industry,mainly for Europe and WestAfrica, the new <strong>DNV</strong> office inthe city is an important vehiclefor establishing closerrelationships with the majorFrench players.“We see Paris becoming anincreasingly important centre foroffshore-related business, withthe major companies – Total,Technip, Saipem, Stolt Offshore,Doris and Gaz de France – alllocated there,” said COOElisabeth Harstad, at the openingceremony in the ArevaTower, centrally located in La Défense, Paris, with Total and Technipas its closest neighbours.Over the past couple of years, <strong>DNV</strong> has developed business operationswith French offshore companies, and is currently involved inseveral of the <strong>deep</strong>water development projects in West Africa.A study of all <strong>DNV</strong>-classed vessels of 6,000 grt and aboveclearly shows the safety value of additional Class notations.The accident rate – collisions, groundings and contact damage –for vessels holding the “nautical” class notations NAUT-AW andNAUT-OC built since 1990 has been half that of ships without them.This statistical difference confirms the value of operational aspectsbeing covered by additional class notations. The main focus here ison the “total bridge system”, taking into account bridge procedures,the human operator, the technical system and the man/machineinterface: all these play a major role in ensuring the safety of avessel at sea.Solstad Offshore’s NormandSkipper is one of the world’sbiggest and most effectiveoffshore service vessels, builtaccording to <strong>DNV</strong>’s NAUT-OSV guidelines.Sonatrach awards <strong>DNV</strong> contract<strong>DNV</strong> has signed a contract with Algerian oil national Sonatrach forthe development and implementation of an emergency and crisismanagement system for the organisation’s 127 sites in Algeria.European markets, and one of the world’s leading exportersof liquefied petroleum gas.<strong>DNV</strong> will be responsible for the development and implementation ofthe emergency systems, which is the first phase in the development ofan overall risk management programme. The work will involve a seriesof assessments and gap analyses focussing on the hazards and risksinherent in major hydrocarbon activities in a desert location.The work commences immediately and is planned for the forthcoming18 months. “We will place teams in Algeria to conduct the work,drawing resources from our offices in the UK, Benelux and Norway,”says COO of <strong>DNV</strong> Consulting Iain Light.Sonatrach, the 11th biggest oil and gas producer in the world,employs 120,000 people and has been operating in Algeria forover 40 years. It is one of the major suppliers of gas to the centralFrom left: Iain Light, COO of <strong>DNV</strong> Consulting, MohamedMeziane, President Director General, Sonatrach, and Madjid AitAllak, HSE Director, Sonatrach.<strong>DNV</strong> Forum 02 2005 35

!last wordShipping has a great story to tellWithout us, the world would come to a grinding halt, unfed, unfuelled and unlubricated. Therewould be precious little manufacturing, with no access to either raw materials or markets, allthat “out of season” produce would rot in the fields and starvation would spread, grimly andinexorably, across the planet. Fanciful?MICHAEL GREY,maritime consultantThis frightful prospect would be a worldwithout merchant ships; those wonderful,yet invisible conveyors of everything weneed for modern 21st century life. Theyare as essential as electricity and potablewater, yet just like the utilities we dependupon, we take merchant ships completelyfor granted. We fill our supermarket trolliesand petrol tanks with abandon, withoutconsidering for a second how thegoods and fuel are made so accessible.Only when a ship sinks, leaving oil in thewater are folk reminded of our maritimedependence. Then people just tend to getangry.It’s a fact of life, and human nature, butwe in the shipping industry ought to beconcerned about the widespread publicignorance of what it is we do and the widegulf that exists between our small maritimepopulation and everyone else. We needsome bridges to be built.delivery system that criss-crosses the oceans.We need to get in first and fast, as early aspossible, so that children at primary schoolslearn about the amazing job done by modernshipping, before environmental interestgroups present them with negative messages.We then have to keep up the pressurethrough the generations, as thesechildren mature.IS IT SO DIFFICULT? It depends how we goabout the task. For a start we have to buildour visibility. We are probably never goingto get prime time television on networkchannels or positive front page stories onnational newspapers, where there is a distinctlack of interest in “good news”, butthere are plenty of alternatives for interestingarticles and features about ships andshipping people.You can list some of the essential elementsthat the industry needs, if it is topromote awareness among the public.We could do with a better political constituencyand a higher profile, positive rolemodels among both our industry leadersand senior officers.We need to be more open and less secretiveabout our industry, boasting moreabout our many achievements. There istoo much false modesty about. We shouldbe cultivating the local media, making surethere is somebody who knows our managementsand something about our business.We need to be more active in challengingthe frequently wrong assertions that aremade about ships and shipping by illinformedjournalists, but we should alsobe asking why it is that they are so ignorant,and what we can do to make thembetter informed!Above all we need leadership, along witha few heroic souls who are prepared to puttheir heads above the parapet and supportshipping and its institutions, telling thegreat story we have to recount.BUT IT IS ONLY THE INDUSTRY THAT CANBRIDGE THE GAP? We, who understand themagic and mystery of ships, have to takemore seriously the responsibility of tellingthe general public why they are so important,and why shipping is so fascinating anindustry.We have to recognise that our communicationhas not been effective, and that wehave been too defensive and reactive inour approach. We should not wait until atanker spills her cargo, before we tell thepublic something about the amazing energyAnother tanker on its way to help fill our petrol tanks.36 <strong>DNV</strong> Forum 02 2005

contactCORPORATE HEADQUARTERSHøvik (Oslo)NO-1322 HøvikNorwayTel: +47 67 57 99 00ABERDEENCromarty House67-72 Regent QuayAberdeen AB115ARUnited KingdomTel: +44 (0) 1224 335000COPENHAGENTuborg Parkvej 8,3rd FloorDK-2900 HellerupDenmarkTel: +45 39 45 48 00DUBAIPO Box 11539, JumeirahDubaiUnited Arab EmiratesTel: +971 4 3526626ESSENBusinesspark Essen - NordSchnieringshof 1445329 EssenGermanyTel: +49 201 7296 0GOTHENBURGNeongatan 4B43153 MölndalGothenburgSwedenTel: +46 31 727 6400HELSINKINahkahousuntie 3(Skinnbyxvägen 3)00210 HelsinkiFinlandTel: +358 9 681 691HOUSTON16340 Park Ten PlaceSuite 100Houston, TX 77084United StatesTel: +1 281 721 6600KOBEKobe Port PO Box 77Kobe 6510191JapanTel: +81 78 291 1302KUALA LUMPUR24th Floor, Menara WeldJalan Raja Chulan50200 Kuala LumpurMalaysiaTel: +603 2050 2888LONDONPalace House,3 Cathedral StreetLondon SE1 9DEUnited KingdomTel: +44 (0) 20 7357 6080MADRIDC/Almansa105- 1ª Pta.- Ofic. 228040 MadridSpainTel: +34 91 4561600MILANCentro Direzionale ColleoniPalazzo Sirio 2,Viale Colleoni 920041 Agrate Brianza (MI)Tel: +39 039 6899 905MUMBAIEmgeen Chambers, 10, C.S.T.Road,Vidyanagari, KalinaSantacruz EastMumbai 400098IndiaTel: +91 22 26650909 / 26654606NEW YORKCrossroads Corporate CenterSuite 1200One International BoulevardMahwah, New Jersey 07495USATel: +1 201 512-8900OSLON-1322 HøvikNorwayTel: +47 67 57 99 00PIRAEUS26-28 Akti KondyliPiraeus 18545GreeceTel: +30 210 41 00 200RIO DE JANEIRORua Sete de Setembro,111/12th Floor20050 006 Rio de Janeiro,BrazilTel: +55 21 2517 7250ROTTERDAMBox 95993007 AN RotterdamNetherlandsTel: +31 (0) 10 2922600SEOULRoom 2110, Kyobo Bldg.,Jongro 1, 1-KA, Jongro-KuSeoul 110714Republic of KoreaTel: +82 2 734 7326/7SHANGHAIHouse No. 9,1591 Hong Qiao RoadShanghai 200336ChinaTel: +86 21 6278 8076SINGAPORE<strong>DNV</strong> Technology Centre10 Science Park DriveSingapore 118224SingaporeTel: +65 6779 1266STOCKHOLMBox 3023410425 StockholmSwedenTel: +46 8 587 940 00SYDNEYLevel 19, Northpoint100 Miller StreetNorth Sydney, NSW 2060AustraliaTel: +61 2 9922 1966<strong>DNV</strong> PETROLEUM SERVICESPTE LTD27 Changi South Street 1Singapore 486071Tel: +65 6779 2475www.dnv.com

<strong>DNV</strong> Forumcorporate magazinePUBLISHED BYCorporate CommunicationsN-1322 Høvik, NorwayTel: +47 67 57 99 00Fax: +47 67 57 91 60EDITOREva HalvorsenTel: +47 67 57 97 19Mobile: +47 906 80 956eva.halvorsen@dnv.comDESIGN<strong>DNV</strong> Graphic CommunicationPRINTGAN Grafisk, OsloCOVER PHOTONina Eirin Rangøy© Det Norske Veritas 2005<strong>DNV</strong> is a global provider ofservices for managing risk.Established in 1864, <strong>DNV</strong> is anindependent foundation withthe objective of safeguardinglife, property and the environment.<strong>DNV</strong> comprises 300 officesin 100 countries, with 6,400employees.WWW.<strong>DNV</strong>.COM