ape equipment catalog ape equipment catalog - American ...

ape equipment catalog ape equipment catalog - American ...

ape equipment catalog ape equipment catalog - American ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AMERICAN PILEDRIVING EQUIPMENTAPE EQUIPMENTCATALOGDEEP FOUNDATIONSOLUTIONS800-248-8498www.<strong>ape</strong>vibro.com

Wood and Concrete Pile ClampsCaisson Beam With Two ClampsAPE single-arm wood and concreteclamps incorporate patented featuresnot found on any other type of clamps.These features provide the contractorwith an edge over his competition. APEdeveloped the first wood and concretepile clamps with a pivoting jaw and anopen window that allows a pile crew toactually see the clamping jaws. APEclamps feature a topside anvil so pilescan be driven without impacting themounting bolts. The T-Bar mountingdesign eliminates the need to ever crawlinside the clamp jaws for attachmentinstallation. The jaws are removable,making it easy to change from wood toconcrete or pipe piles.Cage ClampUnited States PatentB1 5,609,380Sep 12, 2000APE caisson beams are the highest quality available on the market. They feature a T-Bar configuration with a double row of mountingbolts. This design allows APE caisson beams to use short, stretch-resistant bolts without sacrificing beam strength. The centered, singlerow design favored by our competitors results in the clamps blocking access to the bolts. On the APE T-bar design, all bolts are easy toaccess and can handle piles from 16” (406 mm) to 20’ (6.09 m) piles. Moreover, APE has engineered every clamp attachment to takethe same exact length of bolt. One size and length fits all, making for easy maintenance and repair.The APE Cage Clamp System streamlines the handling and placement of full length CFA cages into the pre-drilled pile. TheCage Clamp System can be used with any diameter and cage design. Consult the factory for further details.Quad Clamp SystemCaissons and large diameter piles become impossible to drive due to a phenomenon called deflection which causes diaphraming.To solve this problem, APE engineers developed a four way beam and clamp system. The clamps grip the pile every 90 degreesfor balanced energy transfer. Side-by-side tests show that using four clamps mounted 90 degrees greatly reduces deflection andincreases net amplitude to the pile tip while allowing for cost saving on casing wall thickness. The APE quad clamp system isvastly superior to the old style X beam which can cause deflection. The quad beam can be divided into two single beam systemsfor maximum versatility.United States Patent August 5, 19974www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 20135

Hydraulic Impact Hammer TechnologyIn response to the great demand for low headroomhammers, needed on both seismic retrofit jobs andoverhead obstructions such as power lines and indoorfoundations, APE developed its own line of low headroomhydraulic impact hammers. APE hydraulic impacthammers feature a patented (US-006557649) double walledlifting cylinder that raises the ram from the bottom.Round concrete pile follower.Box lead fixed pile gate.Floating pile gate on front riding leader.This technology greatly reduces the overall height, makingthe APE hydraulic hammer the shortest impact hammer onthe market today. The short design reduces pile splicinglabor and allows the driving of longer piles within thelimited overhead space. In addition, the large ram andslower energy transfer speed makes this hammer line idealfor sheet pile finishing in hard soil conditions. Less pilestress means less pile damage during driving.The Big HammerAPE manufactures the largest hydraulic impact hammermanufactured in the United States. These hammers aredesigned to operate on our larger standard driver/extractorpower units. The hammers incorporate technologies thateliminate the need for bulky container-size power unitsand control rooms and still deliver consistent stroke andunmatched efficiency. Stroke protections include optionalblow count and energy delivery monitoring and pile runshut off.Patented two piece box helmet.Concrete box insert.DB32 with 24” Square box insert.The APE Diesel RevolutionIn May of 1997, APE introduced German authorized anddesigned diesel hammers manufactured in Shanghai, China.These time-proven, single-acting, impact atomized dieselhammers are the highest quality diesel hammers availablein the world.All APE diesel hammers feature fast-remove trip systems,bolt on catch rings, in-line fuel filters, optional directdriveanvils, as well as optional bottom lift hydraulic tripassemblies and infinitely variable hydraulically controlledfuel pumps. They are equipped to operate with biodieselfuel which helps them run cleaner and start faster than anyother diesel hammer on the market. Each hammer comeswith a warranty package that is more than twice as longas any other in the industry. In addition, APE is the onlymanufacturer to demand that every drive cap and insertbe fully machined on top and bottom for perfect anvilalignment ensuring maximum energy transfer to the pile.Constant developments by our engineering team continueto keep APE a step ahead of the competition. APE dieselhammers remain the best value on the market by anystandard.Round concrete insert for concrete piles.Forklift mounted 7.5 Hydraulic Impact Hammer.6www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 20137

Direct Fluid To Torque Top Drive AugersAPE introduced cam-track technology to the augured-cast-in-place piling industry in 1993 when it converted a state-of-the-artPoclain hydraulic radial piston motor into a drilling tool. The compact motor, with its revolutionary cam-track roller pistons,needed only a hollow shaft and stronger bearings in order to revolutionize the top drive auger industry. No drill on the markettoday has the crowd force capacity of the APE drill. The cam-track technology converts hydraulic fluid directly to torque withoutthe aid of gears or planetary drives. No bull gears can be found on the APE system, thereby avoiding the efficiency losses thatplague gear reduction systems. The APE drill is rugged, self lubricating, and requires no maintenance. It can handle the abusecaused by down-the-hole hammers and it can even withstand the impact of telescoping kelly-bar applications.APE Model 20 DrillAPE Model 50 DrillCam Track LayoutExcavator mountedA Model 20 drill in a swinging leader.A Model 20 drill and an Adcock down-the-hole percussion drill.APE is the Largest User of Vegetable Hydraulic OilIn 1990, APE was the first to introduce pile driving and deep foundation <strong>equipment</strong> equipped with vegetable hydraulic oil. Weare now the largest user of vegetable hydraulic oil in the USA. Our power units are designed with built-in spare oil tanks toreplenish the main tank should a spill occur. APE has determined that its vegetable hydraulic oil provides even better qualityand performance than the most expensive petrochemical hydraulic oils. Our entire rental fleet operates on vegetable oil. Ofcourse, APE <strong>equipment</strong> owners may use whatever oil they desire. They overwhelmingly choose 100% biodegradable oilbecause they know that spills of any other type of oil are extremely costly. We choose to use vegetable oil because it makes senseenvironmentally and economically.Petrochemicals harm wildlife andpollute our water supply. APE and our<strong>equipment</strong> owners have taken a leadingrole by setting an example of how toprotect our rivers and streams using100% readily biodegradable vegetablehydraulic oil.Model 20 drill mounted on the APE rack and pinion leader with 15,000pounds of crowd capacity.An APE 75 Drill in a pre-drill format on the side of a fixed leaderwith a King Kong in San Francisco, CA owned by Kiewit.8www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 20139

Patents Define Our KnowledgePatent 5,263,544 - Shock absorbingapparatusThe two-stage rubber suppressor takes thevibration out during start and stop while increasingline pull ability. It also provides crane operatorvisual indicator that measures the line pull.Patent 5,355,964 - Pile driving and/or pile pulling vibratory assembly withcounterweightsEccentric cast in one piece with helical gear toeliminate bolts and pins that fail inside vibratorypile driver/extractors. Eccentric is filled withheavy metal lead or tungsten, thus providing moreeccentric moment with less parts. Eliminates allfasteners inside the vibratory gearbox.Concrete Driving andExtracting AttachmentPatent 5,544,979 - Clamp assemblies fordriving caissonsTwo vibros mount side by side with an opening inthe middle for the pile to pass through. Clampsgrip outside diameter of pile allowing full lengthpiles to be driven in low headroom areas like underbridges or inside buildings. This allows contractorto reduce number of pile splices.Patent 5,609,380 - Clamp assemblies fordriving piles into the earthClamp has ability to drive wood piles or concretepiles. Incorporates a pivoting jaw for proper gripof pile, plus a built-in anvil system to allow thepile to be driven without damage to the mountingbolts or to the vibratory machine. A view slotallows the crane operator and crew to see thepile. The housing completely captures the pile,which allows safe extraction or driving of batteredpilings.One PieceEccentric/GearTandem Vibro with Hole in MiddlePatent 5,653,556 - Clamping apparatus andmethods for driving caissonsThe APE quad clamp system attaches directly tothe bottom of the vibratory pile driver/extractorwithout using heavy mounting plates. Thesystem positions four clamps exactly 90 degreesfor balanced gripping and to reduce or preventdeflection or diaphraming of the pile. Systemenables contractor to drive light weight casingsand provides more vibratory amplitude to betransferred into the pile and soil.Clamp that Opens to Allow Loading ofPile from the SideArticulating JawTwo Stage SuppressorQuad Clamp10www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201311

Patent 5,794,716 - Vibratory systems for drivingelongated members into the earth in inaccessibleareasA template that is mounted to a hydraulic power unit thatincludes hydraulic leveling and pile positioning. Systemis commonly used in wet land areas where access is onlypossible via helicopter. Unit operates on vegetable hydraulicoil to prevent poisoning of wild life and vegetation should ahydraulic leak occur.Patent 6,039,508 - Wick drain installation deviceA system to drive wick drain mandrels into the soil using acombination of static force and dynamic force. Consists ofa vibratory pile driver with a hole or passage way directlyin the middle of the gearbox. The wick mandrel passesthrough the vibrator. A special sprocket drive is mounted ontop or on the bottom of the vibrator to provide static force.The entire system mounts on the bottom of a set of leads.Invention puts most weight near the ground, provides abilityto install super long wick drains, and reduces wear itemswhile improving safety.Helicopter TemplatePatent 6,427,402 B1 - Pile systems and methodsInterlocking pipe piles that can be made of plastic or othertypes of material. The interlocks allow concrete or grout toflow into one another. The interlock passageways also allowsteel reinforcing between piles. Piles can be driven on topor with a mandrel and a sacrificial tip. This solves manyinstallation and engineering problems associated with plasticsheet piles. Can be spliced quickly, driven in extremelydifficult soils, and provides easy ability to provide cantileverstrength without use of tie backs.Bottom Drive Wick MachinePatent 6,447,036 B1 - Pile clamp and systems andmethodsA clamping device that attaches to the bottom of a vibratorypile driver/extractor for the purpose of driving or extractingpipe piles, wood piles, and/or concrete piles of various sizesand diameters while maintaining perfect center alignment.Device has removable jaws to fit various sizes and sh<strong>ape</strong>sof piles. Timing gears keep both jaws perfectly centered onpile axis.The APE product line is protected by, but not limited to the followingpatent numbers: 5088565A, 5117925A, 5263544A, 5529132A, 5544979A,5609380A, 5653556A, 5794716A, 6039508A, 6386295B1, 6427402B1,6431795B2, 6447036B1, 6543966B2, 6648556B1,6672805B1, 6732483B1,6736218B1, 6896448B1, 6908262B1, 6942430B1, 6988564B2, 7168890B1,7392855B1, 7694747B1, 7708499B1, 7824132B1, 7854871B1, 7913771B2,7950876B2, 7950877B2, 8070391B2, 8181713B2, 8186452B1, 8434969B2,8496072B2, 20090200055A1. For a more detailed information and a morecomprehensive list of APE patents please visit the website at www.<strong>ape</strong>vibro.com/ver2/APEPatents.asp.12www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201313

Pile Driving SchoolFor the past 15 years APE, in conjunction with local unionsthroughout the United States and Canada, has been hostinga pile driving school free of charge for pile bucks around thecountry. The success of the school stems from the massiveamount of knowledge that is presented by the APE staffthrough hands on experience at our locations or in the field.At APE’s facilities, students see actual hammer manufacturingin process, including welding and machining of vibratory piledriver/extractors, drills, pile leads and other related <strong>equipment</strong>.Students participate with APE employees as they prepare pilehammers for shipment to actual job sites around the country.Contact APE at (800) 248-8498 regarding admission to the schooland for the scheduling of future classes, or for more up to dateinformation go to: http://www.<strong>ape</strong>vibro.com/ver2/pileschool.asp14www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201315

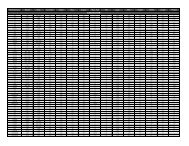

Vibratory Driver/ExtractorsAPE Vibratory Driver/Extractors Features and Benefits:• One-piece gear/eccentric eliminates fasteners inside the gearbox.• Heavy-Metal technology raises energy for more amplitude.• Multistage suppressor doubles the line pull at 1/3 of the hammer weight.• Bolt-on suppressors adjust the height and weight to job site needs.• Helical-cut gears add precision to the gear strength and eccentric speed.• Spherical bearings allow the vibro to handle side loads on batter piles.• Vibro can be used horizontally for stuck horizontal casing.• Field-designed assembly makes maintaining APE products simple and easy.• Gun-drilled top plate and manifolds eliminate unnecessary hydraulic hoses.• O-ring sealed gearbox makes transition to underwater operations easy.• Vegetable hydraulic oil reduces environmental impact and fines if a spill occurs.• Long-term warranty protection provides security on the investment.VIBRATORY DRIVER/EXTRACTOR SPECIFICATIONSModel 3 6 15 20 50 100 150 150T 200 200T 200-6 200-6T 200-6T2 200-6T3 400 600 600BEccentric Moment30 in-lb0.35 kgm60 in-lb0.69 kgm600 in-lb6.9 kgm900 in-lb10.4 kgm1,300 in-lb15 kgm2,200 in-lb25 kgm2,200 in-lb25 kgm2,600 in-lb30 kgm4,400 in-lb50 kgm5,200 in-lb60 kgm6,600 in-lb76 kgm7,000 in-lb80.6 kgm7,400 in-lb85.3 kgm7,800 in-lb90 kgm11,500 in-lb132.5 kgm17,200 in-lb198.2 kgm17,200 in-lb198.2 kgmDrive Force at Rated Frequency2 tons18 kN4 tons37 kN25 tons219 kN37 tons329 kN53 tons475 kN90 tons803 kN90 tons803 kN107 tons949 kN181 tons1,606 kN213 tons1,898 kN271 tons2,410 kN287 tons2,556 kN304 tons2,702 kN320 tons2,848 kN320 tons2,847 kN479 tons4,259 kN479 tons4,259 kNRated Frequency (vpm) 0 - 2,200 0 - 2,200 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,400 0 - 1,400 0 - 1,400Max Line Pull6 tons53 kN6 tons53 kN28 tons249 kN28 tons249 kN56 tons498 kN93 tons827 kN108 tons961 kN108 tons961 kN133 tons1,183 kN133 tons1,183 kN185 tons1,646 kN185 tons1,646 kN185 tons1,646 kN185 tons1,646 kN234 tons2,082 kN351 tons3,123 kN451 tons4,012 kNMax Bare Hammer Weight450 lbs204 kg720 lbs327 kg1,580 lbs717 kg2,510 lbs1,139 kg4,550 lbs2,064 kg5,900 lbs2,676 kg8,330 lbs3,778 kg8,500 lbs3,856 kg12,760 lbs5,788. kg12,960 lbs5,879 kg18,900 lbs8,573 kg19,100 lbs8,664 kg19,300 lbs8,754 kg19,500 lbs8,845 kg31,570 lbs14,319 kg48,500 lbs22,000 kg54,500 lbs24,721 kgThroat Width6 in15.24 cm6 in15.24 cm9 in22.86 cm12 in30.48 cm14.625 in37.15 cm14.5 in36.83 cm14.5 in36.83 cm14.5 in36.2 cm14.75 in37.47 cm14.75 in37.47 cm14.75 in37.47 cm14.75 in37.47 cm14.75 in37.47 cm14.75 in37.47 cm33 in83.82 cm37 in93.98 cm37 in93.98 cmLength27.63 in70.17 cm36.25 in92.08 cm36.5 in92.71 cm36.5 in92.71 cm57.25 in145.42 cm61.875 in157.16 cm88.75 in225.43 cm88.75 in225.43 cm104 in264.16 cm104 in264.16 cm140 in355.6 cm140 in355.6 cm140 in355.6 cm140 in355.6 cm141 in358.14 cm180 in457.2 cm180 in457.2 cmHeight w/o Clamp(Model 3 & 6 Include Clamp)38 in96.52 cm38 in96.52 cm45 in114.3 cm45 in114.3 cm53.5 in135.89 cm54.125 in137.48 cm72.375 in183.83 cm72.375 in183.83 cm65.5 in166.37 cm65.5 in166.37 cm75 in190.5 cm75 in190.5 cm75 in190.5 cm75 in190.5 cm88.5 in224.79 cm104.5 in265.43 cm123.5 in314 cmVIBRATORY EQUATIONSAmplitudeDrive Force In U.S. TonsAmplitude & DriveForce Variablesem * 2vmem * f 2 * 0.01421,000,000em = Eccentric Momentf = Frequencyvm = Vibrating Mass (lb)Pile Weight per Foot (od - wt) * wt * 10.69Pile Weight Variablesod = Pile Diameter (in)wt = Pile Wall Thickness (in)Vibrating Mass equals the total of the vibratory gearbox, inner suppressor,pile and a minimum of 4% for soil bond to pile.16www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201317

Variable Moment Vibratory Driver/ExtractorsExcavator Mounted Vibratory Driver/ExtractorsAPE Variable Moment Technology lets our driver/extractors shine in jobs with vibration sensitive requirements. APE VariableMoment Technology is teamed with all the special features available with the full line of APE Vibratory Driver/Extractors.• Gun drilled top plate and manifolds eliminate unnecessary hydraulic hoses.• O-ring sealed gearbox makes transition to underwater operations easy.• Vegetable hydraulic oil reduces environmental impact and fines if a spill occurs.• Long term warranty protection provides security on the investment.VARIABLE MOMENT SPECIFICATIONSEccentric MomentModel 120VM 170VM 250VMDrive Force1,600 in-lb18.4 kgm95 tons849 kN2,250 in-lb25.9 kgm134 tons1,195 kN4,500 in lb51.9 kgm269 tons2,389 kNFrequency (vpm) Maximum 0 - 2,050 0 - 2,050 0 - 2,050The APE Excavator Mounted Vibratory Driver/Extractors offer advanced, profit generating features that are aheadof the competition.• Designed for mounting and operation off backhoes for situations where crane use is not preferable.• Center safety pin shows pile crew and crane operator how much line pull is on pile and crane.• One piece helical gear/eccentric eliminates keyways, pins, splines, and bolts inside the gearbox.• Heavy-metal enhanced eccentric design reduces internal parts by up to 75% while increasing dynamicforce.• Giant spherical bearings allow for batter operations without damage and reduce heat for extremely long life.• Computer-designed gearbox is perfectly balanced with lowest center of gravity on the market.• Power unit comes standard with tool kit and dual controls on pendant and control panel.• Very simple open-loop hydraulic system with highest quality valves with lighted indicators.• Variable flow in both directions for use on drills, winches, hydraulic hammers and other attachments.• Oversized radiator and hydraulic oil cooler with proven performance in the heat of Saudi Arabia.• Four eccentric moment sizes allow APE to fine tune your vibro to fit your excavator’s engine power.• By changing only the eccentric moment, one vibro can adjust to four different power ranges.• All vibro eccentric sizes have the same clamp, bearings, suppressor housing and related parts.• APE excavator mounted vibros enjoy parts compatibility with all other APE vibros - including jaws!Max Line PullMax Bare Hammer WeightThroat WidthLengthHeight w/o Clamp81 tons721 kN7,500 lb3,402 kg14 in35.5 cm69 in175.3 cm77 in196 cm81 tons721 kN8,900 lb4,037 kg14 in35.5 cm69 in175.3 cm77 in196 cm99 tons881 kN15,400 lb6,985 kg14 in35.5 cm69 in175.3 cm102 in259 cmEccentric MomentEXCAVATOR MOUNTED SPECIFICATIONSE-SERIESX-SERIESModel 15E 20E 50E 100E 33X 64XDrive Force600 in-lb6.9 kgm25 tons219 kN900 in-lb10.4 kgm37 tons329 kN1,300 in-lb15 kgm53 tons475 kN2,200 in-lb25.4 kgm90 tons803 kN450 in-lb5.2 kgm18 tons164 kN781 in-lb9 kgm32 tons285 kNMax Frequency (vpm) 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700Max Line Pull9 tons80 kN18 tons160 kN18 tons160 kN44 tons391 kN10 tons89 kN32 tons285 kNMax Bare Hammer Weight1,690 lbs767 kg2,540 lbs1,152 kg3,940 lbs1,787 kg4,840 lbs2,195 kg1,900 lbs862 kg4,650 lb2,109 kgThroat Width9.625 in24.45 cm12.375 in31.43 cm14 in35.56 cm14.5 in36.83 cm12 in30.5 cm13.75 in34.92 cmLength36.5 in92.71 cm36.5 in92.71 cm57.25 in145.42 cm57 in144.78 cm40 in102 cm70 in177.8 cmHeight w/o Clamp40.125 in101.98 cm47.875 in121.6 cm49.125 in124.78 cm56.5 in143.51 cm32 in81 cm42.5 in107.95 cm18www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201319

Low Headroom Vibratory Driver/ExtractorsTandem Vibratory Driver/ExtractorsLow Headroom Driver/ExtractorsAPE Low headroom vibratory pile driver/extractors are designed to allow the contractor to drive full-length piles under bridgesor inside buildings. This system was created to solve low headroom issues for seismic retrofit applications. Specifications for thedimensions and max line pull are custom for the job the vibratory hammer will be used on. The suppressor setup will be modifiedby APE to work with specified height restrictions on the job site. Please consult an APE representative to discuss your particularapplication by calling (800) 248-8498.LOW HEADROOM SPECIFICATIONSModel 150 200 200-6Eccentric Moment2,200 in-lb25.4 kgm4,400 in-lb50.7 kgm6,600 in-lb76 kgmDrive Force90 tons803 kN181 tons1,606 kN271 tons2,410 kNMax Frequency (vpm) 0 - 1,700 0 - 1,700 0 - 1,700Max Line PullMax Bare Hammer WeightThroat WidthLengthHeight w/o ClampConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryConsultFactoryTandem Driver/ExtractorsTandem Vibratory driver/extractors allow for the installation of high mass casings.APE’s constant innovation has developed a method for joining multiple hammerstogether to match the casing and soil conditions for any job. From the World’s largestvibratory driver/extractor to the original low headroom setup, APE will alwaysbe your source for the solutions that work. Tandem vibrators can be mounted on acommon steel plate with a passage in the center to allow the pile to pass through.This type of setup allows massive jaw pivots to open like a gate, allowing the pilecrew to come in from the side to attach the machine to the pile.TANDEM DRIVER/EXTRACTOR SPECIFICATIONSModel50 TandemLow Headroom100 TandemLow Headroom150 TandemLow Headroom200 TandemLow Headroom400 Tandem11’ Quad Clamp600 Tandem15’ Quad ClampEccentric Moment2,600 in-lbs30 kgm4,400 in-lbs50.7 kgm4,400 in-lbs50.7 kgm8,800 in-lbs101.4kgm23,000 in-lbs264.99 kgm34,400 in-lbs396.3 kgmDrive Force107 tons949 kN181 tons1,606 kN181 tons1,606 kN361 tons3,213 kN640 tons5,695 kN957 tons8,518 NMax Frequency (vpm) 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,700 0 - 1,400 0 - 1,400Pile Clamping Force Consult Factory Consult Factory Consult Factory Consult Factory Consult Factory Consult FactoryMax Line Pull112 tons996 kN186 tons1,655 kN216 tons1,922 kN266 tons2,366 kN468 tons4,164 kN702 tons6,245 kNTotal Setup Weight Consult Factory Consult Factory Consult Factory Consult Factory Consult Factory Consult FactoryMax Pressure5,000 psi345 bar5,000 psi345 bar5,000 psi345 bar5,000 psi345 bar5,000 psi345 bar5,000 psi345 barLength Consult Factory Consult Factory Consult Factory Consult Factory Consult Factory Consult FactoryWidth Consult Factory Consult Factory Consult Factory Consult Factory Consult Factory Consult FactoryHeight with Clamp Consult Factory Consult Factory Consult Factory Consult Factory Consult Factory Consult Factory20www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201321

Wick Drain MachinesAPE Wick Drain:The APE wick installer allows the mandrel to pass directly through the center of the vibrator, while a sprocket drive provides staticforce. The sprocket drive delivers equal force on both sides of the mandrel for perfect axial loading with “On The Fly” vibrationwhen needed with all the crowd right at the point of entry into the ground stabilizing mandrel flexion.The APE wick installer was made for super-long wick drain installation. The lightweight machine mounts at the bottom of theleads rather than at the top. Leads can be longer because they only need to support the weight of the mandrel. The entire machinecan be fitted to an excavator without any added power units or valves. Capable excavator models may vary for unassistederection. Fixed and variable systems available. High speed/low torque and low torque/high speed and optional shift on the fly.BOTTOMDRIVE TM WICK DRAIN SPECIFICATIONSBottomdrive TM Model 2 (Two Motor) 4 (Four Motor)Static (Crowd) Force (USt/kN)Dynamic Force @ 1800 vpm (USt/kN)Combined Dynamic Force (USt/kN)151334035655489302664035670623Operating Frequency Max. (vpm) 0 -2,100 0 -2,100Suspended Weight (lb/kg)Maximum Pressure (psi/bar)Maximum Flow (gpm/lpm)Maximum Mandrel SpeedLength (in/cm)Width (in/cm)Height (in/cm)8,5003,8555,00034412045Up to 330Up to 100741883073.296243.810,7804,8895,000344230943Up to 330Up to 100741883073.296243.822www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201323

Attachments Vibratory Drivers/ExtractorsAttachments adapt a driver/extractor to fit a particular pile type, such as an H-beam, steel sheet pile, or pipe pile. Most vibratorypile driver/extractors come equipped with the APE standard universal clamp that has the ability to fit double sheet piles andH-beams. The universal clamp can be quickly adapted to fit flat plates or small diameter pipe piles including train rail. APE canalso manufacture adapters to mount competitor attachments on APE hammers and APE attachments on competitor <strong>equipment</strong>.APE manufactures attachments for every type of pile, yet all APE attachments use the same mounting bolts, so contractorsdon’t experience delays in the field due to improper bolt sizes. APE clamp cylinders are machined from solid blocks of steel formaximum strength and durability. Safety check valves keep the jaws closed even in the event of a hose failure and every seal inthe clamp is listed on the cylinder.The APE Standard Universal Clamp AttachmentASTM 148 heat treated cast steel.Raised letter instructions on how to install the attachmentand what bolt size to use are cast into the housing to helpguide the pile crew.Lifting eye balanced for attaching clampto hammer gearbox.Built in safety check valve including CAThigh pressure seal and wear bands.Fixed jaw and moveable jaw are clearly labeled.Many jaw types for custom fit to a particular piletype or size are quickly adaptable in the field.Bore, stroke and all internal seals sizes aremachined into the back of the cylinder foreasy service.Model 50E with a standard 50Clamp and single/double jawsModel 20 Vibro with a Model 20clamp.Model 150T Vibro with a Model150 Clamp.Model 200 vibro with a Model200 sheet clamp equipped withdouble sheet jaws.24www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201325

Driving InnovationEstimated Project Cost: 10.7 Billion US DollarsEstimated Project Completion Date: 2016Bridge Length: 23.9 MilesPile Weight: 604 Metric TonsNumber of Piles to be Driven: 127Wall Thickness of Pile: 1 inch or 25 mmDiameter of Pile: 72 feet or 22 metersPile Length Average: 136 ft or 41.5 metersThe Hong Kong-Zhuhai-Macau Bridge Construction ProjectWill Be The Worlds Longest Bridge At CompletionTo Drive The Piles APE Introduces The OctaKongThe World’s Largest Vibratory Driver ExtractorEccentric Moment: 8 x 20,000 in lbs or 230.42 kgmDeepest Embedment: 72 feet or 22 metersTotal OctaKong Weight: 427.2 metric tonsTotal HP: 8 x 1050 Horse PowerVibros: 8 X 45,309 lbs or 20,552 kgWheel Beam: 8 x 6,671 lbs or 3,026 kgVibro Beam: 8 x 48,841 lbs or 22,154 kgLifting Structure: 135,233 lbs or 61,341 kg

Model 20, 50, 150 and 200 Universal ClampsStandard Caisson BeamsModelWeightPistonDia.PistonStrokeCyl.ForceClampForceA B C D E F G H I J K L M N PModel Weight A B C D E F G H I J K L M N P R5 ft1,000 lbs454 kg60 in1.52 m84 in2.13 m8 in203 mm5.9 in150 mm13.75 in349 mm12 in305 mm5.9 in150 mm3 in76 mm4.94 in125 mm3.31 in84 mm2.75 in70 mm5.5 in140 mm6.5 in165 mm6 in152 mm8 in203 mm-2050790 lbs358 kg1350 lbs612 kg5 in127 mm8 in203 mm2.25 in57 mm2.25 in57 mm88 kips 177 kips 29.63 in391 kN 787 kN 752 mm226 kips 452 kips1005 kN 2010 kN44 in1117 mm10 in254 mm12 in304 mm28.63 in727 mm35 in889 mm11.75 in298 mm8.56 in217 mm12.25 in311 mm 260 10.25mm4.62 in117 mm7.19 in182 mm2.31 in38 mm1.44 in38 mm6 in152 mm14 in356 mm13.5 in343 mm22.38 in568 mm4.62 in117 mm5 in127 mm2.75 in70 mm11in279 mm8.25 in209 mm8.25 in209 mm4 in101 mm4 in101 mm7 in178 mm15.17 in385 mm5 in127 mm5 in127 mm8 ft11 ft13 ft1,500 lbs680 kg3,030 lbs1,374 kg3,593 lbs1,630 kg98 in2.48 m132.5 in3.35 m156 in3.96 m84 in2.13 m120 in3.04 m156 in3.96 m8 in203 mm8 in203 mm8 in203 mm5.9 in150 mm5.9 in150 mm5.9 in150 mm13.75 in349 mm13.41 in340 mm18 in457 mm12 in305 mm12 in305 mm13.5 in343 mm5.9 in150 mm5.9 in150 mm5.9 in150 mm3 in76 mm3 in76 mm3 in76 mm4.94 in125 mm4.94 in125 mm5 in127 mm3.31 in84 mm3.31 in84 mm3.31 in84 mm2.75 in70 mm2.75 in70 mm2.75 in70 mm5.5 in140 mm5.5 in140 mm5.5 in140 mm6.5 in165 mm6.5 in165 mm6.5 in165 mm6 in152 mm6 in152 mm6 in152 mm8 in203 mm8 in203 mm8 in203 mm-9 in229 mm9 in229 mm1501540 lbs698 kg8 in203 mm2.25 in57 mm226 kips 452 kips1005 kN 2010 kN44 in1117 mmModel 2012 in304 mm35 in889 mm12.88 in327 mm 260 10.25mm7 in178 mm1.44 in41 mm14 in356 mmModel 5027.75 in705 mm5 in127 mm11 in279 mm8.25 in209 mm4 in101 mm15 in383 mmModel 1505 in127 mm5ft & 8ft Beam11ft Beam13ft BeamModel 100 and 200 Caisson ClampsModelWeightPistonDia.PistonStrokeCyl.ForceClampForceA B C D E F G H J K L1001,100 lbs498 kg8 in203 mm2.25 in57 mm226 kips1,005 kN452 kips2,010 kN25.63 in651 mm11 in279 mm18.63 in473 mm6 in152 mm6.63 in168 mm6.25 in159 mm1.5 in38 mm14 in355 mm10.63 in270 mm11 in279 mm23.38 in594 mm20 Bolt Pattern50/150 Bolt Pattern2001,775 lbs804 kg8 in203 mm2.25 in57 mm226 kips1,005 kN452 kips2,010 kN28.56 in725 kN11 in279 mm22.56 in573 mm10.81 in274 mm6.63 in168 mm7.25 in184 mm1.5 in38 mm14 in355 mm11 in270 mm11279 mm23.25 in590 mmModelWeightPistonDia.PistonStrokeCyl.ForceClampForceA B C D E F G H I J K L M N P2002200 lbs998 kg8 in203 mm2.25 in57 mm226 kips 452 kips1005 kN 2010 kN50 in270 mm11.75 in298 mm41 in 18.25 in1041 mm 463 mm9 in228 mm7 in178 mm1.69 in44 mm15 in381 mm29.88 in759 mm5.75 in146 mm8.25 in209 mm-4 in102 mm21 in533 mm5 in127 mmModel 200Quad BeamModel 50 and 150 Dunce ClampsModel Weight A B C D E F HModelWeightPistonDia.PistonStrokeCyl.ForceClampForceA B C D E F G H I J K L M N P Q11 ft15 ft9,500 lbs4,309 kg13,000 lbs5896 kg134 in340 cm180 in457.2 cm136 in345 cm184 in467.3 cm53 in134.6 cm75 in190.5 mm31 in78.7 cm31 in78.7 cm21 in53.3 cm30 in76.2 cm30 in76.2 cm41 in104 cm6 in152 mm6 in152 mm501,350 lbs612 kg8 in20.3 cm2.25 in5.7 cm226 kips 452 kips1,005 kN 2,010 kN44 in111.7cm12 in30.4 cm35 in 12.25 in88.9 cm 31.1 cm 26.0 10.25cm 17.8 7 incm1.75 in44.5 cm14 in 22.75 in356 cm 57.7 cm 12.7 5 incm11 in27.9 cm8.25 in20.9 cm 10.1 4 incm15 in38.3 cm 12.7 5 incm11.5 in29.2 cm17 ft15,000 lbs6803 kg206 in523.2 cm208 in528.3 cm89 in226 cm31 in78.7 cm40 in101.6 cm41104 cm6 in152 mm1501,540 lbs698 kg8 in20.3 cm2.25 in5.7 cm226 kips 452 kips1,005 kN 2,010 kN44 in111.7cm12 in30.4 cm35 in 12.88 in88.9 cm 32.7 cm 26.0 10.25cm 17.8 7 incm1.75 in44.5 cm14 in 27.75 in35.6 cm 70.5 cm 12.7 5 incm11 in27.9 cm8.25 in20.9 cm 10.1 4 incm15 in38.3 cm 12.7 5 incm11.5 in29.2 cmCLAMP EQUATIONSModel 150 DunceClamp Cylinder Forcedm 2 * 0.7854 * p2,000Clamp Gripping Force Clamp Cylinder Force * 2Clamp and GrippingForce Variablesdm = Diameterp = Pressure28www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201329

Wood/Concrete ClampsAttachment AccessoriesModelWeight PistonDia.Cyl.ForceClampForceA B C D E F G H I J K L MDRIVER/EXTRACTOR ACCESSORIES204,500 lbs2,041 kg7 in178 mm135 kips600 kN270 kips1200 kN44 in117 cm42 in106.7 cm44 in117.8 cm-20.5 in52 cm72 in182.9 cm58 in147.3 cm6.0 in15.2 cm31.91 in81.05 cm14 in35.6 cm4 in10.2 cm8.25 in21 cm4 in10.2 cmSpecification Weight A B C D E F G H25306,200 lbs2,811 kg7,000 lbs3,175 kg7 in178 mm7 in178 mm135 kips600 kN135 kips600 kN270 kips1200 kN270 kips1200 kN52.25 in13.2 cm60 in15.2 cm47 in119.4 cm52 in132 cm44 in117.8 cm44 in117.8 cm6 in12.7 cm10 in25.4 cm25.5 in64.8 cm30.5 in76.2 mm77 in195.683 in21.1 cm68 in172.7 cm68 in172.7 cm6.0 in15.2 cm6.0 in15.2 cm34.94 in88.75 cm44.38 in112.73 cm14 in35.6 cm14 in35.6 cm10 in25.4 cm14 in35.6 cm8.25 in21 cm8.25 in21 cm4 in10.2 cm4 in10.2 cm90 Degree Turn Plate4’ extension600 lb272 kg2,500 lb1134 kg12 in30.48 cm37 in94 cm8 in20.3 cm11 in28 cm8.25 in21 cm8.25 in21 cm11 in28 cm5 in12.7 cm16.5 in42 cm48 in122 cm37 in94 cm12 in30.5 cm12 in30.4 cm8 in20.3 cm16 in40.6 cm8’ extension4,000 lb1,814 kg37 in94 cm11 in28 cm8.25 in21 cm37 in94 cm96 in243.8 cm12 in30.5 cm8 in20.3 cmModel 20/25/30Caisson Beam toAttachment Adapter1,200 lb680 kgCaisson to sheet adapter with a 90degree turn plate.11 in28 cm8.25 in21 cm5 in12.7 cm37 in94 cmHybrid extension called the CaliforniaStinger for tight working dimensions.8 in20.3 cm4 in10.1 cm11.5 in29.21 cmAttachment adapters used to allow theextraction of a casining with an extendedrebar cage.Internal Pipe ClampWeight A B C D E F3,360 lbs1524 kg25 in63.5 cm41 in104.14 cm14 in35.56 cm11.5 in29.21 cm74.6 in189.48 cm21.7 in55.12 cmThe Internal Pipe Clamp canbe custom built for any pilediameter.90 Degree Turn Plate. 4’&8’ Extension.Caisson beam to attachment adapter.30www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201331

Top Drive AugersHydraulic Impact Hammers (HIH)APE manufactures an improved version of the Poclain cam track hydraulic motor. We’ve added stronger bearings and a hollowshaft to create a powerful light weight drill motor. A 200 ton dynamic force lock nut retains the shaft between the upper and lowerbearings, a 5 inch 300 pound flange easily accepts any type of connection. This APE motor withstands more dynamic axial loadingthan any other top drive drill on the market. The two-speed, direct fluid-to-torque motor needs no gearbox or troublesome planetarygear reductions. It is self-lubricating, light, compact.APE and King Oil tools joined forces to develop a grout swivel that can handle 2,500 psi and last up to 3000 holes without service.The APE/King Oil swivel is the only one on the market designed to carry high-pressure grout. The swivel incorporates a removableinner wear tube and replacement seals for fast and inexpensive repair. The initial cost of the APE swivel is more, but with highreliability and less down time the contractor is going to be more cost effective going APE!APE designed and built the first real low headroom hydraulic impact hammer in response to California’s1989 earthquake. The proceeding seismic retrofit repairs meant that thousands of piles, some over 100 feetlong, had to be driven underneath existing bridges, demanding <strong>equipment</strong> that could drive the piles andminimize splicing. The job called for very short hammers. APE designed an impact hammer that features aPatented, US-006557649, hydraulic cylinder that connects through the center of the ram above the impactpoint. This technique greatly reduces the overall height of any comparable hammer by more than half.APE’s low headroom technology has revolutionized pile driving, as contractors have discovered they candrive longer piles without splicing and welding. Since then, the APE hydraulic impact hammers haveevolved into a full line of tools including the largest hydraulic impact hammer made in North America.TOP DRIVE AUGER SPECIFICATIONSType 20 50 50BB 75 75BBTorque (ft-lbs/kgm)3,041 per1,000 psi420 per 69bar6,929 per1,000 psi958 @ 69 bar8,719 per1,000 psi1,205 per 69bar10,668 per1,000 psi1,475 per 69bar11,253 per1,000 psi1,556 per69 barCam track motor has highest volumetricand mechanical efficiencies with itsoutside rotary cam design. Oversizedshaft bearings and locknut retentionoffers the highest vertical and radialloads in the industry.LowSpeedHighTorqueMax Pressure(psi/bar)Rotation Speed(rpm)Max Flow (gpm/lpm)4,5003104,5003105,3503694,6403205,80040050 38 44 30 3655 @ 1.11 gal/ rev208 @ 4.20lit / rev100 @ 2.64gal / rev379 @ 9.99 lit/ rev147 @ 3.33gal / rev556 @ 12.6lit / rev120 @ 3.96gal / rev454 @ 14.99lit / rev150 @ 4.17gal / rev568 @ 15.8lit / revThe APE 7.5a witha direct drive boot.Max HorsePower (hp/kW)Torque (ft-lbspsi/kgm bar)1441071,546 per1,000 psi214 per 69bar2631963,363 per1,000 psi465 per 69 bar4593424,232 per1,000 psi585 per 69bar3252425,940 per1,000psi821 per 69bar5083795,498 per1,000 psi760 per 69barHYDRAULIC IMPACT HAMMER (HIH) SPECIFICATIONSType Low Headroom StandardHighSpeedLowTorqueMax Pressure(psi/bar)Rotation Speed(rpm)Max Flow (gpm/lpm)Max HorsePower (hp/kW)Crowd Force (lbs/kg)Suspendid Weight (lbs/kg)Length (in/cm)Width of Lead Section(in/cm)Shipping Width Overall(in/cm)Height (in/cm)3,0002074,002762,7001863,0002072,70018699 58 88 61 7255 @ 0.55gal / rev208 @ 2.61lit / rev967270,00034,9272,8101,2752563526660.4481,219.261.51,562.177 @ 1.32 gal/ rev291 @ 5 lit/ rev180134150,00068,0392,9701,3472563526660.4481,219.261.51,562.1147 @ 1.66gal / rev556 @ 6.28lit / rev2321733,0301,3742563526660.4481,219.261.51,562.1120 @ 1.98gal / rev454 @ 7.5 lit/ rev210157150,00068,0393,1301,4202563526660.4481,219.261.51,562.1150 @ 2.09gal / rev568 @ 7.91lit / rev2361763,1301,4202563526660.4481,219.261.51,562.1Ram Weight (lb/kg)Rated Energy (ft-lb/kNm)Stroke atRated Energy (in/cm)Blows Per Minute(Min-Max)Weight w/oInsert (lb/kg)Height (in/cm)Model 4-2 5-2 6-2 7-3 8-3 6-4 8-4 10-4 15-4 30-4 60-48,0003,62915,20020.6246110,0004,53620,00027.1246412,0005,44324,00032.5246114,0006,35044,24060.0389716,0007,25750,56068.6389712,0005,44348,00065.14812216,0007,25764,00086.84812220,0009,07180,000108.54812230,00013,607120,000162.74812260,00027,215240,000325.448122120,00054,431480,000650.845-75 45-75 45-75 30-65 30-65 30-65 30-80 30-65 30-65 30-65 30-6513,7006,21410526715,2006,89410526718,2308,26910526719,0008,618126320Standard U Lead Size 8”x26” 8”x26” 8”x26” 8”x26” 8”x26” 8”x26” 8”x26” 8”x32” 8”x32” Offshore Offshore21,7509,86512632019,5008,84514436625,00011,34014436630,00013,60816040642,00019,050175444varies39099048122varies4721,19932www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201333

X-Series Hydraulic Impact HammersA. Optional top sheave for two-parting craneline.B. Single eye pick point.C. Vertically mounted, proven parkeraccumulators.D. Protective enclosure for accumulators.E. Proven J&M hydraulic control head.F. Guiding for standard 26” leads.G. Patented APE Low-Headroom hydrauliccylinder.H. Rugged 5000 psi hydraulic hoses.J. Visible sled system for stroke control.K. Cable extension for longer ram.L. Bolted modular steel cages.M. SEMW (delmag) style proven alloy ramwith rings.N. Compression chamber for pre-load. Highcompression zone.P. High Compression Zone.Q. SEMW (Delmag) style proven alloy anvilwith rings.R. Proven D62 bottom end ring & bearings.S. Powered by APE 275 Power Unit.T. Optional PDI energy reporting system.The X-Series Hydraulic Impact Hammers offer many advantages over APE’sstandard Hydraulic Hammers. The lower end pre-compression for pile pre-load,while also having pre-load in excess of diesel hammers. Proven diesel hammerbottom end technology teamed with proven <strong>ape</strong> low-headroom cylinder technology.Reliable APE sled & trip valve system with industry-leading J&M all-hydrauliccontrol head. X-Series Hammers also offer no electrical control wires at all.X-SERIES HIH SPECIFICATIONSModel X8 X10 X13 X16 X18 X20 X22Ram Weight (lb/kg)8,0003,62810,0004,53513,0005,89616,0007,25718,0008,16420,0009,07122,0009,979Max Rated Energy (ft-lb/kNm)32,00043.440,00054.252,00070.564,00086.872,00097.680,000108.588,000119.3Stroke atRated Energy (in/cm)48121481214812148121481214812148121Max Obtainable EnergyRestrike Only (ft-lb/kNm)40,00054.250,00067.865,00088.180,000108.590,000122.0100,000135.6110,000149.1Max Stroke for Re-strikeOnly (in/cm)60152601526015260152601526015260152Blows Per Minute(max Stroke-min Stroke)38-75 38-75 38-75 38-75 38-75 38-75 38-75Operating Weight withLarge Pipe Insert (lb/kg)23,00010,40025,60011,60030,00013,60033,30015,10036,30016,50038,90017,60041,60018,900Height with Large PipeInsert (in/cm)296752317317327830371942402102142310744451130Standard U Lead Size 26” 26” 26” 26” 26” 26” 26”34www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201335

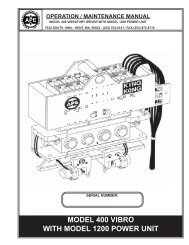

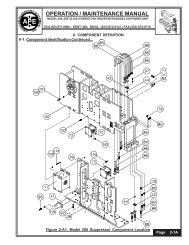

Power UnitsAPE power units provide the contractor with the most advanced, tier 3 rated electronic engines with the highest possiblehorsepower. The hydraulic systems are simple and the valves are easy to access and understand. The hydraulic tanks are filledwith vegetable hydraulic oil and each power unit comes with a built-in spare tank so that if a spill occurs, the crew can keep the jobgoing by turning a 1/4 turn ball valve filling the main tank to a safe operating level.APE power units have built in ladders to allow the pile crew to rig the unit safely. The muffler system is “hospital rated” for quietoperation. The control panel is made from stainless steel to prevent corrosion. All functions are located on the remote controlpendant as well as on the main control panel for emergency back up with optional radio remote systems available.All units come with “forward” and “reverse” flow capability, allowing the contractor to use his machine to operate vibratory piledriver/extractors, auger drills, hydraulic impact hammers, winches, spotters, and other related foundation <strong>equipment</strong> includingoscillators and dredging <strong>equipment</strong>.Engine TypePOWER UNIT SPECIFICATIONSModel 10 127 275 375 475 595 765 1200YanmarCaterpillarC4.4 Tier IVCaterpillarC7 Tier IIICaterpillarC9 Tier IIICaterpillarC13 Tier IIICaterpillarC15 Tier IIICaterpillarC18 Tier IICaterpillarC32 Tier IIAn APE D160 drives 30” square concrete pile in Ocean City, NJ.D46 driving dolphin piles at the Bainbridge Island ferry terminal.Rated Horse Power10 HP7 kW127 HP95 kW275 HP205 kW375 HP276 kW475 HP354 kW595 HP444 kW765 HP570 kW1,200 HP895 kWRated Drive Pressure3,500 psi238 bar2,500 psi172 bar4,800 psi331 bar4,800 psi331 bar4,800 psi331 bar4,800 psi331 bar4,800 psi331 bar4,800 psi331 barDrive Flow5.8 gpm22 lpm60 gpm227 lpm85 gpm322 lpm120 gpm454 lpm147 gpm556 lpm188 gpm712 lpm220 gpm833 lpm294 gpm1,113 lpmWeight275 lbs125 Kg4,750 lbs2,155 kg11,000 lbs4,990 kg12,600 lbs5,715 kg13,800 lbs6,260 kg19,000 lbs8,618 kg19,000 lbs8,618 kg23,000 lbs10,206 kgLength24 in61 cm99 in251 cm116.5 in296 cm126.5 in321 cm127.5 in324 cm151.75 in385 cm151.75 in385 cm169 in428 cmWidth31.5 in80 cm45 in114 cm58.75 in149 cm68.5 in174 cm73.5 in187 cm82 in208 cm82 in208 cm87 in221 cmHeight42 in107 cm66 in168 cm83.5 in212 cm82 in208 cm92.25 in234 cm94 in239 cm94 in239 cm103 in262 cmA D19-42 drives H-beam in North Carolina.APE D80-42 Working for the Army in Washington.Kidney loop filtration andhydraulic coolingCustom ball valvesfor serviceComplete tool set mountedin door panelAircraft quality wiring withsealed quick disconnectsTank transfer valve forreplenishing hydraulic fluidRemote controlpendant unit sealedfor protection againstweatherSwivel lifting eye rated for15,000 lbs for Models 275to 475 and 24,000 for Models575 to 1050Weather sealed stainlesssteel hydraulic gauges andcontrol panelReserve hydraulic fluidtank for replenishing maintank on demandTier 3 CAT enginesLift off hinges forSolid weldedtubular frameeasy door removal inthe fieldA D62 drives test piles at Terminal 18 in Seattle, WA.The D180-42, largest APE diesel hammer in North America drives 42” pipepile in Coquitlam, BC.36www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201337

Diesel HammersAPE maintains the largest fleet of single acting diesel hammers in the United States. We stock spare parts for all our Models fromthe D1 all the way to the D300. In addition, we stock replacement parts for Delmag diesel hammers for nearly every series. All ourhammers and parts come with the longest warranty in the business.SINGLE ACTING DIESEL HAMMER SPECIFICATIONSMaximum Energy Minimum Energy Ram Weight Hammer Weightft-lbs kNm ft-lbs kNm lbs tonnes lbs kgD8-52 19,845 26.79 9,724 13.13 1,764 0.8 4,540 2,059D12-52 29,768 40.19 14,884 20.09 2,646 1.2 6,890 3,125D16-52 39,690 53.58 19,845 26.79 3,528 1.6 8,000 3,629Drive Bases, Inserts and HelmetsAPE Drive Caps, Inserts, Helmets, Followers and Pile Gates forImpact Hammers.APE manufactures a full line of drive caps and inserts for any type of piling. APEdrive caps and inserts are fully machined on all striking surfaces. This providessuperior energy transfer to the pile and prevents premature wear of the hammerand decreases possible damage to the pile. APE drive caps accept inserts fromall major manufacturers. However, for precision alignment we recommend usingonly APE made components. APE also offers machining services to upgrade yourexisting drive caps, inserts helmets and followers.APE manufactures specialty items such as precision followers and pile gatesdesign and engineered for specific driving needs. Anything that can be driven,APE can design an adapter to drive it. Precision alignment is one of the keys to apiles drivability and productivity. With our in house engineering, machining andfabrication capabilities you can get the production edge you need for your nextjob in less time.Drive bases and insertsInsertsD19-52 47,132 63.63 23,566 31.81 4,190 1.9 8,400 3,810D25-52 62,016 83.72 31,008 41.86 5,513 2.5 12,569 5,701D30-52 74,419 100.47 37,209 50.23 6,615 3 13,571 6,156D36-26/52 89,303 120.56 43,758 59.07 7,938 3.6 14,894 10,421D36-52 89,303 120.56 44,651 60.28 7,938 3.6 22,975 6,756Striker PlatesAPE striker plates are made twice as thick as our competition to prevent bendingor cracks promoting consistent energy transfer. Each striker plate is fullymachined on all surfaces and comes complete with drilled and tapped holes onboth sides for easy loading and shipment.Cushion MaterialAPE offers industry standard cushion material such as conbest, aluminum, andhigh density nylon cushion material. Pile cushion specifications available uponrequest.ConbestStriker plateMC 904AluminumD46-52 114,109 154.05 55,913 75.48 10,143 4.6 25,000 11,340D50-52 124,031 167.44 60,775 82.05 11,025 5 25,882 11,740D62-52 153,799 207.63 76,899 103.81 13,671 6.2 29,100 13,200D70-52 173,644 234.42 86,822 117.21 15,435 7 30,864 14,000D80-42 198,450 267.91 127,008 171.46 17,640 8 38,434 17,433Drive Cap Layout(Diesel Hammer)D100-42 248,063 334.88 158,760 214.33 22,050 10 47,000 21,319Diesel HammerD125-42 310,078 418.61 198,450 267.91 27,563 12.5 62,000 28,123D128-42 317,520 428.65 203,213 274.34 28,224 12.8 68,000 30,844Rubber Rebound RingD138-42 342,326 462.14 219,089 295.77 30,429 13.8 70,295 31,885D160-42 396,900 535.82 242,109 326.85 35,280 16 85,000 38,555AnvilD180-42 446,513 602.79 272,373 367.70 39,690 18 92,000 41,730Striker PlateD220-42 545,738 736.75 332,900 449.41 48,510 22 102,820 46,638D225-42 558,141 753.49 340,466 459.63 49,613 22.5 112,820 51,174Dive Cap BaseD250-42 620,156 837.21 378,295 510.70 55,125 25 113,340 51,410D260-42 644,963 870.70 393,427 531.13 57,330 26 118,830 53,900Rigging of Drive Cap Baseto Bottom of Hammer38www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201339

SHEET PILE INSERTSlbs / kg & in / mm Wt# A B C D E F G H I J K L M N O PH-BEAM INSERTSlbs / kg & in / mm Wt# A B C D E F G H I J K LDCS-1DCS-5DCS-71,7007713,0801,3974,0501,8371640618457184571743219.7550220.255146152620382035127512751273.75953.5893.58931.5800421,06748122025.564832813328138.52198.52168.521616.541916.742516.74252255925.564833.58501025412.2531212.3531441022.9766.81727.7519737.595237.595212” (305 mm) Round14” (356 mm) Round12” & 14” (305 & 356 mm) Waffle16” & 18” (406 & 457 mm) Waffle1,0604811,2205538503862,140971174322563517432174322050820508112791743251275127512751273763763766152123051230537661521743221533205082666017.744921.65550153811948226.567526.6676205082666012.65321194823.75952.5646.75171133301.25322.564H-BEAM INSERT - WAFFLEH-BEAM INSERT - ROUNDBOX INSERTSSHEET PILE INSERT DCS-1SHEET PILE INSERT DCS-5SHEET PILE INSERT DCS-7lbs / kg & in / mm Wt# A B C D E F G HPIPE INSERTSlbs / kg & in / mm Wt# A B C D E F G H16”(406 mm)24”(610 mm)30”(762 mm)7303311,7708022,3401,06117432174311743117.14342050718.54703163162.5647.8720015381112799.85250174311845711.930218.754762563513.8535222.557731.98132666010”(254 mm)12”(305 mm)14”(356 mm)16”(406 mm)18”(457 mm)20”(508 mm)1,4806711,6107301,5607081,8108212,3601,0702,8401,2882050820508205082235924610266601743217432174321743 21743224610276852768527686276862973617432615261526152615282038.521616406164061640616406164062973611.529313.5343153811743219482820314.536916.54192050820508225591640621.5546STRIKER PLATESlbs / kg & in / mm Wt# A B C16” PIPE INSERT24” PIPE INSERT17.75”(450 mm)22.5”(572 mm)25”(635 mm)30”(762 mm)4401996502951,0364701,400635615261528203123051435618457194852973717.7545122.557225.063530762STRIKER PLATE10”- 18” BOX INSERT20” BOX INSERT30” PIPE INSERT40www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201341

DRIVE CAP BASESlbs / kg & in / mm Wt# A B C D E F G H20” - 4”(508 - 102 mm)7503408.52162050818.2546411.5292410241022050817.544526” - 6”(660 - 152 mm)1,2705768.5216266602358414.53674.511441012153317.544526” - 9”(660 - 229 mm)1,3506128.5216266602358417.54434.511441012153317.544532” - 6”(813 - 152 mm)2,2701,0308.52163281325.564816.54194.511461532461217.544532” - 9”(813 - 229 mm)2,4201,0978.52163281325.564819.54954.511461532461217.544537” - 6”(940 - 152 mm)3,0201,3708.52163794025.564818.54704.511482032461217.544520” DRIVE CAP BASE37” - 9”(940 - 229 mm)43” - 6”(1,092 - 152 mm)2,7901,2663,4001,5428.52168.52163794043109225.564825.564819.549518.54704.51144.511461538203246122461217.544517.544526” DRIVE CAP BASE43” - 9”(1,092 - 229 mm)4,0701,8468.521643109230.577521.55454.511482032461217.5445TWO PIECE BOX HELMETS32” 37” & 43” DRIVE CAP BASElbs / kg & in / mm Wt# A B C D E F G H I J K L M24”(610 mm)30”(762 mm)36”(914 mm)6,3502,8808,3803,80112,3295,592379404310925413723281342.5108043109225.564830.577530.57758.52168.52168.521625125125123584235842358492299229922982038203820324.7562930.7578136.7593332813379404310923794043109254137225.564831.580037.5953246102461024610ONE PIECE BOX HELMETSWOOD INSERTSlbs / kg & in / mm Wt# A B C D E17”(432 mm)19”(483 mm)8934461,17553320508194845127512711.252861845715.5394164061743219482 WOOD INSERTlbs / kg & in / mm Wt# A B C D E F G H I24”(610 mm)5,8182,63932813379408.52163281325.564835889123051948325.564530”(762 mm)6,1952,810379404310928.52163691425.5648421,067123052461031.5800ONE PIECE BOX HELMETTWO PIECE BOX HELMETPIPE HELMETSPIPE HELMETS Wt# A B C D E F G H I J K L M N O32/37” - 25.5”(813/940 - 648 mm)37/43” - 25.5”(940/1092 - 648 mm)3,4001,5426,6603,02117432431,09237940379408.52168.521625.564825.56482461028.572312.531816.5419615261523163162.9733162.9733162.757031617.544518.7547619.64992255926.166327.56993281333.585137/43” - 30.5”(940/1092 - 775 mm)6,5602,976431,092379408.521630.577528.572416.5419615231631631631618.754762255927.569933.585154” - 25.5”(1,372 - 648 mm)8,9104,041541,3728.521625.5648256351640682033763763762255831788401,01654” - 30.5”(1,372 - 775 mm)8,8103,996541,3718.521630.5775256351640682033763763762255831788401,01654” PIPE HELMET 37” TO 43” PIPE HELMET32” TO 37”PIPE HELMET42www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201343

Leads SetupsAPE manufactures U-type (Box) and Front-Riding (European) style leads. APE leads are pin connected, eliminating the need fornuts and bolts that can come loose or require changing after each set up. All fixed lead systems are analyzed for stresses by APEengineers. Many applications are available including fixed extended, telescoping, fixed under hung and swinging applications.FRONT RIDING LEAD SPECIFICATIONSDIMENSIONS ST-70 ST-75 ST-100 ST-150 ST-190Ain/cm28.5 in72.4 cm28.5 in72.4 cm28.5 in72.4 cm28.5 in72.4 cm37 in91.4 cmBOX LEAD DIMENSIONSBin/cm3 in7.62 cm3 in7.62 cm3 in7.62 cm5 in12.7 cm5 in12.7 cmKey 8 x 21 8 x 26 8 x 32 8 x 37 8 x 43 10 x 54Cin/cm36 in91.44 cm36 in91.44 cm36 in91.44 cm36 in91.44 cm45 in114.4 cmA 21.50 in 26.50 in 32.50 in 37.50 in 43.50 in 54.50 inAverage Weightlb/kg70 lb34.75 kg75 lb34.01 kg100 lbs45.35 kg150 lb68.02 kg190 lb86.16 kgB 8.00 in 8.00 in 8.00 in 8.00 in 8.00 in 10.00 inC 27.50 in 32.50 in 38.50 in 43.50 in 49.50 in 62.50 inD 30.00 in 30.00 in 34.00 in 42.00 in 46.00 in 48.00 inE 15.29 in 15.29 in 16.94 in 20.22 in 21.87 in 28.00 inE* 22.10 in 22.10 in 24.50 in 29.29 in 31.69 in N/AHeadblock2 or 3 lineF 34.00 in 34.00 in 38.00 in 46.00 in 50.00 in 54.00 inF* 39.25 in 39.25 in 43.25 in 51.25 in 55.25 in N/AG 27.50 in 32.50 in 38.50 in 43.50 in 49.50 in N/AW 33.50 in 38.50 in 44.50 in 49.50 in 55.50 in 74.50 inWL 38.50 in 43.50 in 49.50 in 54.50 in 60.50 in 79.50 inWeight 130 lb/ft 135 lb/ft 141 lb/ft 146 lb/tf 152 lb/ft 280 lb/ft*Dimension with pin-up railM - Average weight per foot for 100’ packageHeadblockStabberFootYokeOFFSHORE LEADSLead Size Min pile size Max pile size Overall length Overall width43”54”78”16 in40.6 cm18 in45.7 cm32 in81.3 cm38 in96.5 cm48 in122 cm94 in240 cm39 ft11.8 m39 ft11.8 m39 ft11.8 mOffshore leaders for up to 12 ft (3.65 m) piles are available61 in155 cm72 in183 cm90 in228.6 cmAPE Boom Point Connector SledAPE offshore leaders are designed to give the operator the best available control during thedriving of both vertical and batter (raked) piles. Pin-on offshore bells allow the greatestversatility for a standard lead section, Drive helmets and pin on drive bells are available forboth pipe and concrete piles.Boom Point ConnectorTelescoping Lead System44www.<strong>ape</strong>vibro.com(800) 248-8498Note: All technical specifications are subject to change without notice.<strong>American</strong> Piledriving Equipment, Inc. © October 201345

BRANCHLOCATIONSAPE Canada9004 Yellowhead Trail NWEdmonton, Alberta T5B 1G2Ph: (780) 474-9888(855) 328-9888APE BrazilRodovia Raposo Tavares Km, 22Sala 517- Bloco EGranja Vianna-Cotia-SPPh: 55 11 97238 9308(863) 660-8716APE MexicoAvenida Periferico Sur 7800,Sta. Ma TequetexpanTlaquepaque, Guadalajara Jalisco,Mexico C.P. 45601Ph: (786) 991-6875Fx: (253) 872-8710APE HollandPh: +31 (0) 593 54 08 91Fx: +31 (0) 593 27 84IMECO AustriaPh: (43) 1328-9980Fx: (43) 1328-9944FAE SingaporePh: (65) 6863-1633Fx: (65) 6863-1455APE RussiaPh: 7-495-603-5345Fx: 7-495-603-5345APE ChinaPh: 011-86-21-5677-1221Fx: 011-86-21-3604-0553APE Corporate7032 South 196th StreetKent, WA 98032Ph: (253) 872-0141Fx: (253) 872-8710(800) 248-8498APE West Coast2985 Loomis RoadStockton, CA 95205Ph: (209) 942-2166Fx: (209) 942-2455(888) 245-4401APE Mid-West50 Gerber Industrial DrSt. Peters, MO 63379Ph: (636) 397-8400Fx: (636) 278-4278(877) 296-8044APE Northeast401 Hartle StreetSayreville, NJ 08872Ph: (732) 432-6604Fx: (732) 432-6608(888) 217-7524APE Mid-Atlantic500 Newtown Road, #200Virginia Beach, VA 23462Ph: (757) 518-9740Fx: (757) 518-9741(866) 399-7500APE Southeast1345 Industrial Park Rd.Mulberry, FL 33860Ph: (863) 324-0378Fx: (863) 318-9409(800) 570-3844APE Gulf3975 FM Hwy 1485Conroe, TX 7730639266 Doyle DriveGonzales, Louisiana 70737Ph: (936) 271-1044Fx: (936) 271-1046(800) 596-2877The APE product line is protected by, but not limited to the following patent numbers:5088565A, 5117925A, 5263544A, 5529132A, 5544979A, 5609380A, 5653556A,5794716A, 6039508A, 6386295B1, 6427402B1, 6431795B2, 6447036B1, 6543966B2,6648556B1,6672805B1, 6732483B1, 6736218B1, 6896448B1, 6908262B1, 6942430B1,6988564B2, 7168890B1, 7392855B1, 7694747B1, 7708499B1, 7824132B1, 7854871B1,7913771B2, 7950876B2, 7950877B2, 8070391B2, 8181713B2, 8186452B1, 8434969B2,8496072B2, 20090200055A1. For a more detailed information and a more comprehensivelist of APE patents please visit the website at www.<strong>ape</strong>vibro.com/ver2/APEPatents.asp.800-248-8498www.<strong>ape</strong>vibro.comAMERICAN PILEDRIVING EQUIPMENT