March 2003 - American Bonanza Society

March 2003 - American Bonanza Society

March 2003 - American Bonanza Society

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

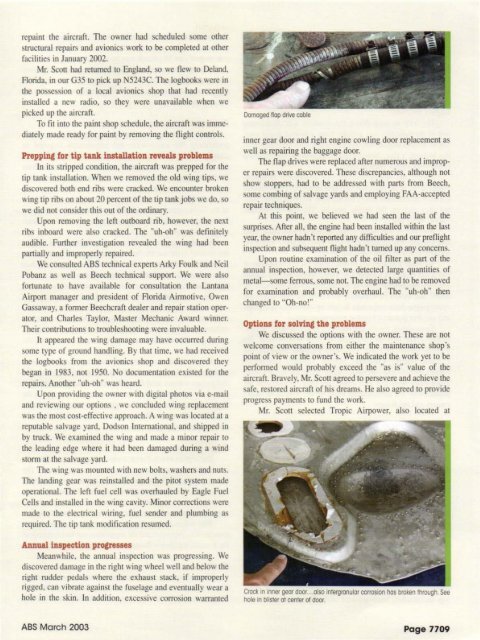

epaint the aircraft. The owner had scheduled some otherstructural repairs and avionics work to be completed at otherfacilities in January 2002.Mr. Scott had returned to England, so we new to Deland,Florida, in our G35 to pick up N5243C. The logbooks were inthe possession of a local avionics shop that had recentlymstalled a new radio, so they were unavailable when wepicked up the aircraft.To fit into the paint shop schedule, the aircraft was immediatelymade ready for paint by removing the flight controls.Prepping for tip tank installation reveals problemsIn its stripped condition , the aircraft was prepped for thetip tank installation. When we removed the old wing tips, wediscovered both end ribs were cracked. We encounter brokenwing tip ribs on about 20 percent of the tip tank jobs we do, sowe did not consider this out of the ordinary.Upon removing the left outboard rib, however, the nextribs inboard were also cracked. The "uh-oh" was definitelyaudible. Funher investigation revealed the wing had beenpanially and improperly repaired.We consulted ABS technical experts Arky Foulk and eilPobanz as well as Beech technical suppon. We were alsofonunate to have avai lable for consu ltation the LantanaAirport manager and president of Florida Airmotive, OwenGassaway, a fonner Beechcraft dealer and repair station operator,and Charles Taylor, Master Mechanic Award winner.Their contributions to troubleshooting were invaluable.It appeared the wing damage may have occurred duringsome type of ground handling. By that time, we had receivedthe logbooks from the avionics shop and discovered theybegan in 1983, not 1950. 0 documentation existed for therepairs. Another "uh-oh" was heard.Upon providing the owner with digital photos via e-mailand reviewing our options, we concluded wing replacementwas the most cost-effective approach. A wing was located at areputable salvage yard, Dodson International, and shipped inby truck. We examined the wing and made a minor repair tothe leading edge where it had been damaged during a windstorm at the salvage yard.The wing was mounted with new bolts, washers and nuts.The landing gear was reinsta lled and the pitot system madeoperational. The left fuel cell was overhauled by Eagle FuelCells and installed in the wing cavity. Minor corrections weremade to the electrical wiring, fuel sender and plumbing asrequired. The tip tank modification resumed.Annual inspection progresses. Meanwhile, the annual inspection was progressing. WedIscovered damage in the right wing wheel well and below theright rudder pedals where the exhaust stack, if improperlyrigged, can vibrate against the fuselage and eventually wear ahole m the skin. In addition, excessive corrosion warrantedDamaged flap drive cableinner gear door and right engine cowling door replacement aswell as repairing the baggage door.The flap drives were replaced after numerous and improperrepairs were discovered. These discrepancies, although notshow stoppers, had to be addressed with pans from Beech,some combing of salvage yards and employing FAA-acceptedrepair techniques.At this point, we believed we had seen the last of thesurprises. After all, the engine had been installed within the lastyear, the owner hadn't reponed any difficulties and our preflightinspection and subsequent flight hadn 't turned up any concerns.Upon routine examination of the oil filter as pan of theannual inspection, however, we detected large quantities ofmetal-some ferrous, some not. The engine had to be removedfor examination and probably overhaul. The "uh-oh" thenchanged to "Oh-no!"Options for solving the problemsWe discussed the options with the owner. These are notwelcome conversations from either the maintenance shop'spoint of view or the owner's. We indicated the work yet to beperformed would probably exceed the "as is" value of theaircraft. Bravely, Mr. Scott agreed to persevere and achieve thesafe, restored aircraft of his dreams. He also agreed to provideprogress payments to fund the work.Mr. Scott selected Tropic Airpower, also located atCroc~ in j~ner gear door .... oJso intergranular corrosion has broken through. Seehole In blister at center of door.ABS <strong>March</strong> <strong>2003</strong>Page 7709