Special Report - Finning Canada

Special Report - Finning Canada

Special Report - Finning Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

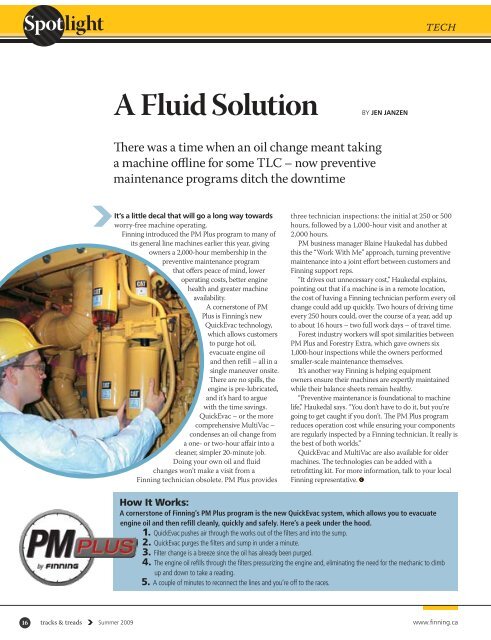

techA Fluid SolutionBy Jen JanzenThere was a time when an oil change meant takinga machine offline for some TLC – now preventivemaintenance programs ditch the downtimeIt’s a little decal that will go a long way towardsworry-free machine operating.<strong>Finning</strong> introduced the PM Plus program to many ofits general line machines earlier this year, givingowners a 2,000-hour membership in thepreventive maintenance programthat offers peace of mind, loweroperating costs, better enginehealth and greater machineavailability.A cornerstone of PMPlus is <strong>Finning</strong>’s newQuickEvac technology,which allows customersto purge hot oil,evacuate engine oiland then refill – all in asingle maneuver onsite.There are no spills, theengine is pre-lubricated,and it’s hard to arguewith the time savings.QuickEvac – or the morecomprehensive MultiVac –condenses an oil change froma one- or two-hour affair into acleaner, simpler 20-minute job.Doing your own oil and fluidchanges won’t make a visit from a<strong>Finning</strong> technician obsolete. PM Plus providesthree technician inspections: the initial at 250 or 500hours, followed by a 1,000-hour visit and another at2,000 hours.PM business manager Blaine Haukedal has dubbedthis the “Work With Me” approach, turning preventivemaintenance into a joint effort between customers and<strong>Finning</strong> support reps.“It drives out unnecessary cost,” Haukedal explains,pointing out that if a machine is in a remote location,the cost of having a <strong>Finning</strong> technician perform every oilchange could add up quickly. Two hours of driving timeevery 250 hours could, over the course of a year, add upto about 16 hours – two full work days – of travel time.Forest industry workers will spot similarities betweenPM Plus and Forestry Extra, which gave owners six1,000-hour inspections while the owners performedsmaller-scale maintenance themselves.It’s another way <strong>Finning</strong> is helping equipmentowners ensure their machines are expertly maintainedwhile their balance sheets remain healthy.“Preventive maintenance is foundational to machinelife,” Haukedal says. “You don’t have to do it, but you’regoing to get caught if you don’t. The PM Plus programreduces operation cost while ensuring your componentsare regularly inspected by a <strong>Finning</strong> technician. It really isthe best of both worlds.”QuickEvac and MultiVac are also available for oldermachines. The technologies can be added with aretrofitting kit. For more information, talk to your local<strong>Finning</strong> representative.How It Works:A cornerstone of <strong>Finning</strong>’s PM Plus program is the new QuickEvac system, which allows you to evacuateengine oil and then refill cleanly, quickly and safely. Here’s a peek under the hood.1. QuickEvac pushes air through the works out of the filters and into the sump.2. QuickEvac purges the filters and sump in under a minute.3. Filter change is a breeze since the oil has already been purged.4. The engine oil refills through the filters pressurizing the engine and, eliminating the need for the mechanic to climbup and down to take a reading.5. A couple of minutes to reconnect the lines and you’re off to the races.16 tracks & treads Summer 2009www.finning.ca