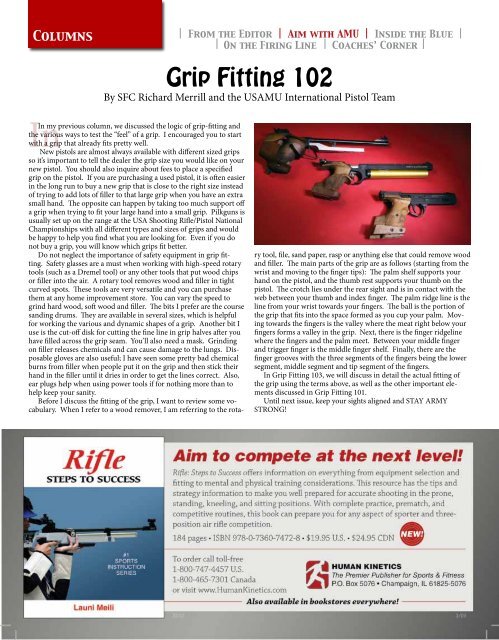

ColumnsFrom the Editor Aim with AMU Inside the BlueOn the Firing Line Coaches’ CornerGrip Fitting 102By SFC Richard Merrill and the <strong>USA</strong>MU International Pistol TeamIn with a grip that already fits pretty well.In my previous column, we discussed the logic of grip-fitting andthe various ways to test the “feel” of a grip. I encouraged you to startNew pistols are almost always available with different sized gripsso it’s important to tell the dealer the grip size you would like on yournew pistol. You should also inquire about fees to place a specifiedgrip on the pistol. If you are purchasing a used pistol, it is often easierin the long run to buy a new grip that is close to the right size insteadof trying to add lots of filler to that large grip when you have an extrasmall hand. The opposite can happen by taking too much support offa grip when trying to fit your large hand into a small grip. Pilkguns isusually set up on the range at the <strong>USA</strong> <strong>Shooting</strong> Rifle/Pistol NationalChampionships with all different types and sizes of grips and wouldbe happy to help you find what you are looking for. Even if you donot buy a grip, you will know which grips fit better.Do not neglect the importance of safety equipment in grip fitting.Safety glasses are a must when working with high-speed rotarytools (such as a Dremel tool) or any other tools that put wood chipsor filler into the air. A rotary tool removes wood and filler in tightcurved spots. These tools are very versatile and you can purchasethem at any home improvement store. You can vary the speed togrind hard wood, soft wood and filler. The bits I prefer are the coursesanding drums. They are available in several sizes, which is helpfulfor working the various and dynamic shapes of a grip. Another bit Iuse is the cut-off disk for cutting the fine line in grip halves after youhave filled across the grip seam. You’ll also need a mask. Grindingon filler releases chemicals and can cause damage to the lungs. Disposablegloves are also useful; I have seen some pretty bad chemicalburns from filler when people put it on the grip and then stick theirhand in the filler until it dries in order to get the lines correct. Also,ear plugs help when using power tools if for nothing more than tohelp keep your sanity.Before I discuss the fitting of the grip, I want to review some vocabulary.When I refer to a wood remover, I am referring to the rotarytool, file, sand paper, rasp or anything else that could remove woodand filler. The main parts of the grip are as follows (starting from thewrist and moving to the finger tips): The palm shelf supports yourhand on the pistol, and the thumb rest supports your thumb on thepistol. The crotch lies under the rear sight and is in contact with theweb between your thumb and index finger. The palm ridge line is theline from your wrist towards your fingers. The ball is the portion ofthe grip that fits into the space formed as you cup your palm. Movingtowards the fingers is the valley where the meat right below yourfingers forms a valley in the grip. Next, there is the finger ridgelinewhere the fingers and the palm meet. Between your middle fingerand trigger finger is the middle finger shelf. Finally, there are thefinger grooves with the three segments of the fingers being the lowersegment, middle segment and tip segment of the fingers.In Grip Fitting 103, we will discuss in detail the actual fitting ofthe grip using the terms above, as well as the other important elementsdiscussed in Grip Fitting 101.Until next issue, keep your sights aligned and STAY ARMYSTRONG!

Columns From the Editor Aim with AMU Inside the BlueOn the Firing Line Coaches’ CornerRules of EngagementBy: Master Sgt. Jeffrey J. Julig, Air Force <strong>Shooting</strong> TeamRulesadvance the common interests of society. InRules govern our actions in all aspects oflife and are necessary to preserve order andthe military, rules of engagement are the setof rules used to control the use of lethal forceagainst the enemy. Like many concepts, thephrase “rules of engagement” is often usedin a wider context to identify a collection ofrules that apply to a specific event or activity.While never a popular topic, rules in sportsare necessary to set the limits of fair and opencompetition and measure the skill of an individualor team under similar circumstances.Rules set boundaries but do not limit drive,determination, hard work, focus and intensity.An athlete’s knowledge of the rules allowshim or her to maximize effort and focus onspecific tasks within defined limits. In this article,we will explore how understanding the“rules of engagement” that govern our sportmay help improve performance.Student of the GameElite athletes are often referred to as “studentsof the game” for good reason. High performerspursue every possible edge over theircompetition and plan to overcome obstaclesthat may adversely impact their performance.As an athlete advances and becomes morecompetitive within his or her sport, the rulesbecome more restrictive and apply both onand off the firing line. Rules may govern areassuch as controlled substances, personal conduct,performance equipment and competition.Understanding the rules that apply toan athlete’s level of competition will improveperformance and may help place a marksmanon the medal stand.Presumed KnowledgeA well-established legal principle holdsthat a person is bound by the law even thoughhe or she is unaware of it. This principle,commonly known as “Ignorance of the Lawis No Excuse,” presumes that an individual isaware of laws within his or her jurisdiction.Athletes are judged by the same standard.When an athlete chooses to compete in amatch or accepts membership on a team, thatathlete is bound by the rules associated withthat group or event. The athlete must understandthe “rules of engagement” that governhis or her actions on and off the firing line.While it is not practicable for an athleteto memorize all of the rules and account foreach nuance that applies to his or her sport,it is important to understand the rules thatmay influence his or her performance. Whenseeking knowledge, an athlete should considerthe following areas:Know the competition rules and where tofind them. An athlete has a personal duty toread and comprehend the rules that apply tohis or her level of competition. It is unwiseto rely on the advice of “clubhouse lawyers”to know the rules or interpret them for you.Separate those who think they know fromthose who actually know the rules. Seek outthe rules and study them on your own. Notonce, but review them before each competitionas part of your training. The first timeyou read the rule book should not be whenyou are filing a protest.Ask for clarification before you act. If anathlete is unsure whether a rule or a policyapplies, he or she should seek guidance andclarification before his or her actions are challenged.Consult the competition manager, areferee, coach, physician or other subject matterexpert to avoid an unexpected outcome.An athlete’s personal knowledge of the rulesallows him or her to identify areas of concernprior to a competition or a drug test. Becomean informed athlete and do not be afraid toask for clarification when necessary.Understand your right to protest or appeal.Most rule sets and policies have provisionsto ensure due process. An informed athleteincreases his or her chance to successfully appealan errant ruling if he or she is fully awareof the process. Protests or appeals are usuallylimited in scope and must be filed withina specific timeframe. In addition, an appealor protest may take time to prepare and mayrequire the athlete to pay a fee. An athletewho understands the rules and policies is betterequipped to file a timely, well-supportedappeal. Hard lessons are often learned after aprotest is lost because action or inaction preventedsome form of relief.Uncommon SenseThe daily news reveals far too many examplesof self-destructive behavior that begsthe question, “What was he or she thinking?”Lapses in judgment, social influences andother factors may lead an otherwise disciplinedathlete off target away from his or hergoals. Following the rules outside of competitionappears to be common sense to many,but it is not as common as it should be.Athletes are required to adhere to rulesthat extend beyond the firing line. To protectthe identity of the group as a whole, organizationspublish rules to govern the conduct ofits members outside of competition. Marksman-athletesare no exception and remainsubject to the standards set forth by the sport’sgoverning bodies. While an athlete may notagree with a particular rule or policy, his orher membership in a group is contingent oncompliance with its standards. Failure tocomply with the rules may terminate the relationship.Listed below are several timeless pitfallsthat are worth revisiting:• Standards of Conduct. Athletes shouldreview the standards of conduct to learnthe limits of acceptable behavior on andoff the range. An athlete is accountablefor his or her actions and has a duty toseek out and comply with any applicablestandards of conduct. While standardsof conduct limit individual freedom, it isnecessary to create a minimum standardof behavior to advance the interests of thegroup.• Dress and Appearance Standards. Dressand appearance standards help cultivatean “athlete image” for an organizationand advance its brand. Market yourselfand your sport by knowing and followingthe dress and appearance standards.An athlete is judged using impressionsformed based on subtle characteristicsof personality, attitude and appearance.Whether you like it or not, dress is an importantelement.• Endorsements, Marketing and Sponsorship.Specific rules exist for amateurathletes in this area to protect the interestsof the athlete, cooperate and privatesponsors, and the sport. Understand thelimits of support and sponsorship andthat certain actions may have unintendedconsequences.• Group Mores and Etiquette. All rules arenot reduced to writing. Many groups establishpractices and adhere to unwrittenrules to influence individual behavior.These rules, as determined by the groupas a whole or members at a specific location,are also important. An athlete mustaccount for cultural and regional differencesboth in and outside the UnitedStates to avoid offensive behavior. Athletesshould recognize what is socially acceptablebefore they travel to ensure he orshe will leave a positive, lasting impression.• Perception is Reality. An athlete’s actions– especially non-verbal communication– shape the opinion of those he or sheencounters. Human nature and personalexperience encourage people to act uponstereotypes and prejudices; recognizehow others may perceive you. Athletesshould consider how their actions mayinfluence another’s perceptions and possiblyaffect their personal safety whentraveling abroad.• A Thought Left Unspoken. It is importantfor an athlete to exercise his or her abilitywww.usashooting.org 7