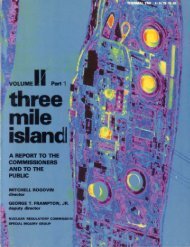

- Page 2: COVER:A heat-sensitive DOE photogra

- Page 5 and 6: 15. Public Announcements16. Board N

- Page 7 and 8: 4. Estimates of Doses and Potential

- Page 9 and 10: 7. Effects on Aquatic Biota and Fis

- Page 11 and 12: IV.Safety Management Factors German

- Page 13 and 14: A SEQUENCE OFPHYSICAL EVENTSThe fol

- Page 15 and 16: polisher system are discussed in Se

- Page 17 and 18: FIGURE 11-3. The Makeup and Letdown

- Page 19 and 20: pumps 6 into the RCS. At TMI-2, the

- Page 21 and 22: FIGURE II-5. The Once-Through Steam

- Page 23 and 24: March 28,1979-4:30 a.m.At approxima

- Page 25 and 26: still having trouble stabilizing th

- Page 27 and 28: [The low steam pressure in steam ge

- Page 29: [Leakage through the PORV had now b

- Page 33 and 34: Each of the two core flood tanks ho

- Page 35 and 36: March 28,1979-3:10 p.m.At 11 hours

- Page 37 and 38: FIGURE 11-8. Gas Venting SystemGase

- Page 39 and 40: perature in the loop A cold leg was

- Page 41 and 42: Up to this time, degassing of the R

- Page 43 and 44: oxygen in the presence of radiation

- Page 45 and 46: B RADIOLOGICALRELEASES AND THEIREFF

- Page 47 and 48: either trapped or chemically bound.

- Page 49 and 50: FIGURE 11-9. Ventilation and Waste

- Page 51 and 52: a representative sample of carbon r

- Page 53 and 54: FIGURE II-10. Liquid Radioactive Wa

- Page 55 and 56: cess radioactive material. The IWTS

- Page 57 and 58: FIGURE 11-12. Release PathwaysConti

- Page 59 and 60: tective efforts did not provide any

- Page 61 and 62: TABLE 11-3. 1-131 releases-Continue

- Page 63 and 64: TABLE 11-4. Calculated 1311 release

- Page 65 and 66: The cleanup components installed in

- Page 67 and 68: was made prior to the large influx

- Page 69 and 70: TABLE 11-7. Analysis of TMI-2 conta

- Page 71 and 72: TABLE 11-9. Inventories of radioact

- Page 73 and 74: a. Offsite Radiological Environment

- Page 75 and 76: COLOR PLATE I. LOCATION OF OOSIMETR

- Page 77 and 78: These samples were later counted wi

- Page 79 and 80: TABLE 11-12. NRC TLD locations-Cont

- Page 81 and 82:

TABLE II-13. Raw milk sample progra

- Page 83 and 84:

TABLE 11-14. Source locations for H

- Page 85 and 86:

TABLE 11-14. Source locations for H

- Page 87 and 88:

TABLE 11-14. Source locations for H

- Page 89 and 90:

TABLE 11-16. EPA milk sampling loca

- Page 91 and 92:

0331 3:28 a.m. GE-4; Fence, east Gr

- Page 93 and 94:

0331 9:03 p.m. '/4 east ofObservati

- Page 95 and 96:

April 6, 1979-By April 6, offsite e

- Page 97 and 98:

TABLE 11-20. Met Ed Teledyne and RM

- Page 99 and 100:

TABLE 11-21. Net exposures, attribu

- Page 101 and 102:

Table 11-22 contains daily data fro

- Page 103 and 104:

SW-1 0.9±0.1 0.8 1.2 ±0.3 1.1 ±0

- Page 105 and 106:

Other Collective Dose Estimate-Usin

- Page 107 and 108:

not have any discernible effect. Th

- Page 109 and 110:

em and dose rates on the order of r

- Page 111 and 112:

dose will, according to BEIR III es

- Page 113 and 114:

cancer, which corresponds to 175.8

- Page 115 and 116:

The technical specifications for TM

- Page 117 and 118:

that facility did not provide suffi

- Page 119 and 120:

FIGURE 11-17. Actual Organization o

- Page 121 and 122:

FIGURE II-18. "Normal" Emergency Or

- Page 123 and 124:

monitoring activities and Dubiel wo

- Page 125 and 126:

FIGURE 11-21. Emergency Radiation P

- Page 127 and 128:

clothing was exchanged for paper co

- Page 129 and 130:

As part of the training conducted b

- Page 131 and 132:

equipped with Geiger-Muller (G-M) t

- Page 133 and 134:

TABLE 11-37. Atmospheric monitoring

- Page 135 and 136:

SAM-2 in another kit was issued eve

- Page 137 and 138:

Preaccident Personnel Dosimetry-The

- Page 139 and 140:

ecommendations for correcting them.

- Page 141 and 142:

nel, reflect the continued inadequa

- Page 143 and 144:

that have evolved comprehensively a

- Page 145 and 146:

REFERENCES AND NOTES1 Met Ed, "Fina

- Page 147 and 148:

term Environmental Radiation Monito

- Page 149 and 150:

United Nations Scientific Committee

- Page 151 and 152:

302NRC, "Investigation into the Mar

- Page 153 and 154:

the emergency feedwater system, amo

- Page 155 and 156:

FIGURE 11-22. Pressurizer Surge Lin

- Page 157 and 158:

k)ss of heat removal from the prima

- Page 159 and 160:

main feedwater pumps and turbine ar

- Page 161 and 162:

Recommendations-The categorization

- Page 163 and 164:

through the break will not result i

- Page 165 and 166:

Findings-Under normal circumstances

- Page 167 and 168:

psig, 66although some reactor build

- Page 169 and 170:

A thorough evaluation should be per

- Page 171 and 172:

Shortly after their start the diese

- Page 173 and 174:

thereby providing high level coolin

- Page 175 and 176:

the service-instrument air cross-se

- Page 177 and 178:

Following recovery of hotwell level

- Page 179 and 180:

TABLE 11-44. Accident monitoring in

- Page 181 and 182:

TABLE 11-47. Information readouts a

- Page 183 and 184:

TABLE 11-47. Information readouts a

- Page 185 and 186:

2TABLE 11-47. Information readouts

- Page 187 and 188:

TABLE 11-49. Errors at most recent

- Page 189 and 190:

TABLE 11-51. Estimated data reliabi

- Page 191 and 192:

expected to survive environments mo

- Page 193 and 194:

TABLE 11-52. Sources of data about

- Page 195 and 196:

FIGURE 11-23. TMI-2 Isometric Schem

- Page 197 and 198:

FIGURE 11-25. The Pressurizer492

- Page 199 and 200:

COLOR PLATE IV. HOT AND COLD LEG TE

- Page 201 and 202:

egan to heat up. When the hottest p

- Page 203 and 204:

FIGURE 11-26. System Parameters for

- Page 205 and 206:

Steaming to Condenser.SRM-count rat

- Page 207 and 208:

emained open for more than 1 1 /2 h

- Page 209 and 210:

FIGURE II 2'1. Hydrogen Burn at 9.9

- Page 211 and 212:

PZR Vent and Spray Valves-closed.De

- Page 213 and 214:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

- Page 215 and 216:

of time, to determine a heat balanc

- Page 217 and 218:

locked to steam flow by hydrogen th

- Page 219 and 220:

two-phase mixture of water and stea

- Page 221 and 222:

e made for two reasons: (1) the act

- Page 223 and 224:

FIGURE 11-31. Fuel Temperature Hist

- Page 225 and 226:

Additionally, it is estimated that

- Page 227 and 228:

15 minutes (3 hours 21 minutes to 3

- Page 229 and 230:

system if all of the water removed

- Page 231 and 232:

FIGURE 11-32. Reactor Primary Syste

- Page 233 and 234:

eleased before melting. In general,

- Page 235 and 236:

the decay calculation. Table 11-57

- Page 237 and 238:

RadiolysisRadiation absorbed in wat

- Page 239 and 240:

principle-the compliance of a liqui

- Page 241 and 242:

Error AnalysisAn error analysis of

- Page 243 and 244:

Explosive Hazard in Reactor VesselA

- Page 245 and 246:

gression was such that a substantia

- Page 247 and 248:

TABLE 11-58. Timing of a meltdown a

- Page 249 and 250:

vessel steel are matters of conside

- Page 251 and 252:

Reactor Building Base Mat Penetrati

- Page 253 and 254:

1 Met Ed, "Final Safety Analysis Re

- Page 255 and 256:

Injection Signal Reset Following a

- Page 257 and 258:

175Id. at 18-21.176Electrical Power

- Page 259 and 260:

D ALTERNATIVEACCIDENT SEQUENCESIn t

- Page 261:

• failure of operators to recogni

- Page 264 and 265:

Two variations in the flow rates fr

- Page 266 and 267:

gression than alternative sequences

- Page 268 and 269:

TABLE 11-59. Description of alterna

- Page 270 and 271:

FIGURE II-39. Comparison of Base Ca

- Page 272 and 273:

lack of emergency feedwater after a

- Page 274 and 275:

FIGURE 11-42. Effect of Pump Trips

- Page 276 and 277:

egions occurring as the reactor coo

- Page 278 and 279:

TABLE 11-61. Typical containment de

- Page 280 and 281:

E HUMAN FACTORS1. INTRODUCTIONFrom

- Page 282 and 283:

FIGURE 11-44. PORV Indicator Light

- Page 284 and 285:

cable to this written procedure and

- Page 286 and 287:

FIGURE 11-46. EFW Control Station S

- Page 288 and 289:

accident; and (2) these errors resu

- Page 290:

guidance on the use of some very im

- Page 293 and 294:

TABLE 11-62. TMI-2 control room key

- Page 295 and 296:

FIGURE 11-49. Visual Scan Necessary

- Page 297 and 298:

FIGURE 11-51. Relationship of Makeu

- Page 299 and 300:

FIGURE 11-53. Typical TMI-2 Alarm P

- Page 301 and 302:

than the other two, having only one

- Page 303 and 304:

• too many exceptions to the go-n

- Page 305 and 306:

tion or production facility," which

- Page 307 and 308:

5. classroom training course on TMI

- Page 309 and 310:

applicants for CRO licenses for nuc

- Page 311 and 312:

6. It took an archaic approach to l

- Page 313 and 314:

may be compared to nuclear powerpla

- Page 315 and 316:

evaluating the need for operator tr

- Page 317 and 318:

• misleading labeling due to viol

- Page 319 and 320:

encourage an increased rate of inco

- Page 321 and 322:

REFERENCES AND NOTES1 NRC, Investig

- Page 323 and 324:

' * Letter from Miller, Met Ed, to

- Page 325 and 326:

F ENVIRONMENTAL ANDSOCIOECONOMICIMP

- Page 327 and 328:

FIGURE 11-55. Map of Area621

- Page 329 and 330:

FIGURE 11-58. Initial Sources of In

- Page 331 and 332:

FIGURE 11-59. Percent of Persons Sa

- Page 333 and 334:

FIGURE 11-62. Percent of Individual

- Page 335 and 336:

FIGURE 11-64. Respondents' Reasons

- Page 337 and 338:

FIGURE 11-66. Respondents' Evaluati

- Page 339 and 340:

considered changing jobs more frequ

- Page 341 and 342:

FIGURE 11-70. Respondent's Concern

- Page 343 and 344:

FIGURE II-71. Costs Per Evacuating

- Page 345 and 346:

three-tenths of 1% of annual person

- Page 347 and 348:

posed by the municipality and appro

- Page 349 and 350:

achieved with volunteer labor, addi

- Page 351 and 352:

eady done so. Within 15 miles, an e

- Page 353 and 354:

APPENDIX 11.1I NTRODUCTION TOSEQUEN

- Page 355 and 356:

EventNumberDateTimeafterinitiationE

- Page 357 and 358:

EventNumberDateTimeafterinitiationE

- Page 359 and 360:

EventNumberDateTimeafterinitiationE

- Page 361 and 362:

EventNumberDateTimeafterinitiationE

- Page 363 and 364:

EventNumberDateTimeafterinitiationE

- Page 365 and 366:

EventNumberDateTimeafterinitiationE

- Page 367 and 368:

EventNumberDateTimeafterinitiationE

- Page 369 and 370:

EventNumberDateTimeafterinitiationE

- Page 371 and 372:

EventNumberDateTimeafterinitiationE

- Page 373 and 374:

EventNumberDateTimeafterinitiationE

- Page 375 and 376:

EventNumberDateTimeafterinitiationE

- Page 377 and 378:

EventNumberDateTimeafterinitiationE

- Page 379 and 380:

EventNumberDateTimeafterinitiationI

- Page 381 and 382:

EventNumberDateTimeafterinitiationE

- Page 383 and 384:

EventNumberDateTimeafterinitiationE

- Page 385 and 386:

EventNumberDateTimeafterinitiationE

- Page 387 and 388:

EventNumberDateTimeafterinitiationE

- Page 389 and 390:

EventNumberDateTimeafterinitiationE

- Page 391 and 392:

EventNumberDateTimeafterinitiationE

- Page 393 and 394:

EventNumberDateTimeafterinitiationE

- Page 395 and 396:

EventNumberDateTimeafterinitiationE

- Page 397 and 398:

EventNumberDateTimeafterinitiationE

- Page 399 and 400:

EventNumberDateTimeafterinitiationE

- Page 401 and 402:

EventNumberDateTimeafterinitiationE

- Page 403 and 404:

EventNumberDateTimeafterinitiationI

- Page 405 and 406:

EventNumberDateTimeafterinitiationE

- Page 407 and 408:

EventNumberDateTimeafterinitiationE

- Page 409 and 410:

EventNumberDateTimeafterinitiationE

- Page 411 and 412:

APPENDIX 11.2CARBON PERFORMANCEWITH

- Page 413 and 414:

presented in App. Table 11-2. The g

- Page 415 and 416:

APP. TABLE 11-4. Physical propertie

- Page 417 and 418:

APPENDIX 11.3RADIOLOGICAL ENVIRONME

- Page 419 and 420:

Sampling locations are shown in Fig

- Page 421 and 422:

APPENDIX 11.4OFFSITE RADIOLOGICALMO

- Page 423 and 424:

APP. TABLE 11-7. Field Ge(Li) and H

- Page 425 and 426:

APP. FIGURE 11-2. EML Measurement S

- Page 427 and 428:

APPENDIX 11.5ATMOSPHERIC RELEASE AD

- Page 429 and 430:

they did not have enough familiarit

- Page 431 and 432:

APPENDIX 11.6RADIOLOGICAL CHRONOLOG

- Page 433 and 434:

ITEM DATE AND TIME EVENT DESCRIPTIO

- Page 435 and 436:

ITEM DATE AND TIME EVENT DESCRIPTIO

- Page 437 and 438:

ITEM DATE AND TIME EVENT DESCRIPTIO

- Page 439 and 440:

ITEM DATE AND TIME EVENT DESCRIPTIO

- Page 441 and 442:

REFERENCES AND NOTES1 NRC, "Investi

- Page 443 and 444:

The apparent surface area isFor Apr

- Page 445 and 446:

APPENDIX 11.8TMIBOIL CODE CALCULATI

- Page 447 and 448:

APP. TABLE 11-8.TMIBOIL calculation

- Page 449 and 450:

APP. FIGURE II-3. Fuel Temperature

- Page 451 and 452:

APP. FIGURE 11-7. Fuel Temperature

- Page 453 and 454:

APP. FIGURE II-11. Fuel Temperature

- Page 455 and 456:

APP. FIGURE 11-15. Fuel Temperature

- Page 457 and 458:

APP. FIGURE 11-19. Fuel Temperature

- Page 459 and 460:

Memorandum from G. P. Marino and J.

- Page 461 and 462:

This equation (which contains no ap

- Page 463 and 464:

We have not included the effects of

- Page 465 and 466:

APP. FIGURE 11-22. Bubble Volume at

- Page 467 and 468:

a) The fugacity coefficient of hydr

- Page 469 and 470:

TABLE 1. Hydrogen solubility dataTe

- Page 471 and 472:

APP. FIGURE 11-24. Hydrogen Solubil

- Page 473 and 474:

APP. FIGURE 11-26. B&W Test #5-Prop

- Page 475 and 476:

APP. FIGURE 11-28. B&W Test #7-Prop

- Page 477 and 478:

APP. FIGURE 11-30. Reactor Coolant

- Page 479 and 480:

2. EXCERPTS FROM TMI-2 SENSITIVITYS

- Page 481 and 482:

APP. FIGURE 11-32. Relative SRM Res

- Page 483 and 484:

tegration over time dependent varia

- Page 485 and 486:

A99 FIGURE D-33 Plots of Input Data

- Page 487 and 488:

APP. FIGURE 11-35. Postulated Core

- Page 489 and 490:

APP. FIGURE 11-37. Postulated Core

- Page 491 and 492:

APP. FIGURE 11-39.SRM Reading Versu

- Page 493 and 494:

4. ALTERNATE INTERPRETATION OFTHE A

- Page 495 and 496:

etween about 740 and 775 minutes (1

- Page 497 and 498:

APP. FIGURE II-43. Hydrogen Pressur

- Page 499 and 500:

APP. FIGURE 11-45. Hydrogen Pressur

- Page 501 and 502:

APP. FIGURE II-47. Water Flow Rates

- Page 503 and 504:

APP. FIGURE 11-49. Water Height in

- Page 505 and 506:

APP. FIGURE 11-51. Temperature Leve

- Page 507 and 508:

ing fuel (G. W. Parker et al. ORNL-