Frequency-Doubled Nd:YAG Lasers - Lee Laser, Inc.

Frequency-Doubled Nd:YAG Lasers - Lee Laser, Inc.

Frequency-Doubled Nd:YAG Lasers - Lee Laser, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

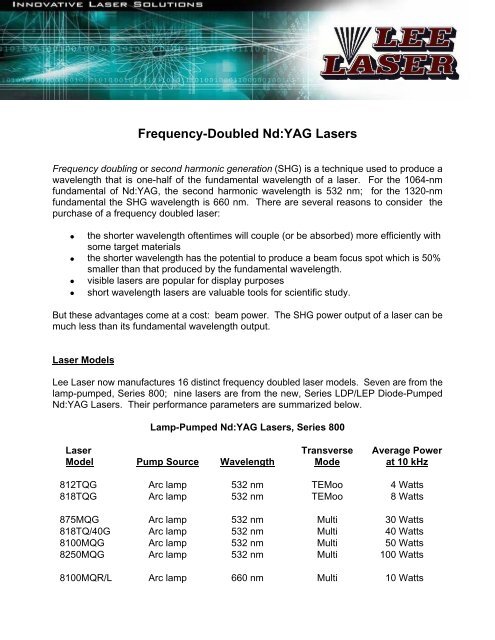

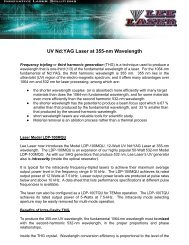

<strong>Frequency</strong>-<strong>Doubled</strong> <strong>Nd</strong>:<strong>YAG</strong> <strong><strong>Laser</strong>s</strong><strong>Frequency</strong> doubling or second harmonic generation (SHG) is a technique used to produce awavelength that is one-half of the fundamental wavelength of a laser. For the 1064-nmfundamental of <strong>Nd</strong>:<strong>YAG</strong>, the second harmonic wavelength is 532 nm; for the 1320-nmfundamental the SHG wavelength is 660 nm. There are several reasons to consider thepurchase of a frequency doubled laser:the shorter wavelength oftentimes will couple (or be absorbed) more efficiently withsome target materialsthe shorter wavelength has the potential to produce a beam focus spot which is 50%smaller than that produced by the fundamental wavelength.visible lasers are popular for display purposesshort wavelength lasers are valuable tools for scientific study.But these advantages come at a cost: beam power. The SHG power output of a laser can bemuch less than its fundamental wavelength output.<strong>Laser</strong> Models<strong>Lee</strong> <strong>Laser</strong> now manufactures 16 distinct frequency doubled laser models. Seven are from thelamp-pumped, Series 800; nine lasers are from the new, Series LDP/LEP Diode-Pumped<strong>Nd</strong>:<strong>YAG</strong> <strong><strong>Laser</strong>s</strong>. Their performance parameters are summarized below.Lamp-Pumped <strong>Nd</strong>:<strong>YAG</strong> <strong><strong>Laser</strong>s</strong>, Series 800<strong>Laser</strong>Model Pump Source WavelengthTransverseModeAverage Powerat 10 kHz812TQG Arc lamp 532 nm TEMoo 4 Watts818TQG Arc lamp 532 nm TEMoo 8 Watts875MQG Arc lamp 532 nm Multi 30 Watts818TQ/40G Arc lamp 532 nm Multi 40 Watts8100MQG Arc lamp 532 nm Multi 50 Watts8250MQG Arc lamp 532 nm Multi 100 Watts8100MQR/L Arc lamp 660 nm Multi 10 Watts

3Mechanisms are devised to raster scan the SHG crystal across the focused laser beam asmore impact locations become unusable. Eventually, the SHG crystal must be replaced. Ifeffect, the SHG crystal becomes a consumable component of the laser.<strong>Lee</strong> <strong>Laser</strong> avoids this problem by installing the SHG crystal inside the laser optical resonator.The high level of peak power density that is needed to achieve good wavelength conversion isprovided by the high circulating power of the 1064-nm beam inside the laser optical resonator.There is no need to focus the 1064-nm beam into the SHG crystal, thereby greatly extendingthe lifetime of the SHG crystal.This design provides a variety of useful benefits to the user:1. greater conversion efficiency from 1064 nm to 532 nm, up to 85 %2. superior Q-switched pulse stability; instability at 532 nm about 50 % of instability at 1064nm3. permissible operation at much higher Q-switch frequencies because of better pulsestability4. much longer SHG lifetime; no requirement to raster-scan 1064-nm beam across face ofSHG crystal (LBO) to maintain undamaged beam input site, as do competitorsNew Inline SHG ResonatorRecently <strong>Lee</strong> <strong>Laser</strong> developed a new, Inline Resonator design that achieves the same highefficiencyof second harmonic generation, but in a resonator that emits the 532-nmwavelength along the same axis as the 1064-nm emission. The inline SHG resonator alsobenefits from simpler optical alignment.LBO SHG Crystal<strong>Lee</strong> <strong>Laser</strong> now uses LBO (lithium triborate) as its choice of harmonic generator crystal. LBOis as much as seven (7) times more durable than KTP (potassium titanyl phosphate) againstinternal, bulk damage from laser beam propagation. However, because of LBO's inherentlyless efficient wavelength conversion from 1064 nm to 532 nm (and from 1320 nm to 660 nm),it is necessary to use a much longer crystal. <strong>Lee</strong> <strong>Laser</strong> uses LBO crystals that measure 18mm long. The crystal is housed inside a temperature controlled oven that maintains anelevated temperature within 0.1 o C. Precise temperature control of the LBO crystal isvital to maintain a stable level of output beam power. A 2-axis adjustable mount permitsangular tuning of the 532-nm or 660-nm wavelength beam output power.SHG Crystal Protection from <strong>Laser</strong> DamageIn a frequency-doubled optical resonator, the SHG crystal is the optical element that is mostsensitive to laser damage. This damage can be caused by airborne contamination that hasbeen allowed to settle on the optical surfaces (<strong>Lee</strong> <strong>Laser</strong> uses dust hoses to enclose thebeam path of the optical resonator). SHG damage may also be caused from operation of thelaser in a low-pulse-rate mode in which the high pulse energy and short pulse width combineto generate a high peak pulse power condition.

4To avoid SHG crystal and AR coating damage, <strong>Lee</strong> <strong>Laser</strong> recommends against operation atpulse rates (Q-switch frequencies) below 5 kHz, unless the laser has been specificallyconfigured by <strong>Lee</strong> <strong>Laser</strong> to do so.A special design feature of Series 800 Q-switched <strong>Nd</strong>:<strong>YAG</strong> lasers that helps to protect theSHG crystal from laser damage is Pulse Quench. Pulse Quench is a technique used by <strong>Lee</strong><strong>Laser</strong> to suppress the high pulse energy and peak pulse power that is characteristic of the firstpulse in a gated series of Q-switch pulses (ref. technical bulletin, Pulse Quench: <strong>Lee</strong> <strong>Laser</strong>First Pulse Suppression). For frequency-doubled lasers, the giant first pulse can causepremature damage to the SHG crystal. The suppression of this first pulse by Pulse Quenchgreatly extends the useful lifetime of the SHG crystal.Another possible source of SHG crystal damage can occur during initial installation orservicing of the harmonic generator. Because of the small crystal cross section (5 x 5 mm),there is little room for misalignment of the crystal with the <strong>YAG</strong> beam centerline. Should thecrystal be misaligned with the <strong>YAG</strong> beam, material from adjacent surfaces may cause ARcoating damage to the crystal. To help avoid this possibility, <strong>Lee</strong> <strong>Laser</strong> includes with the SHGpackage a 2-mW Helium-Neon Pointing <strong>Laser</strong> that is bore-sighted with the <strong>YAG</strong> beamcenterline. Then, by use of the HeNe laser, the user may verify the alignment of the SHGcrystal prior to ignition of the <strong>YAG</strong> beam.