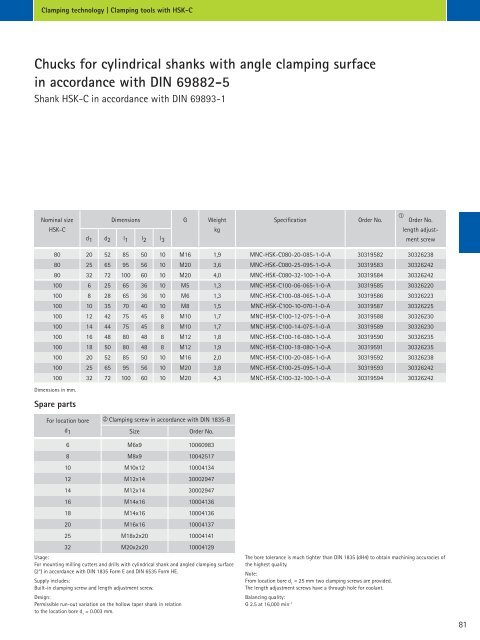

Clamping technology | Clamping tools with HSK-CChucks for cylindrical shanks with angle clamping surfacein accordance with DIN 69882-5Shank HSK-C in accordance with DIN 69893-1d 1d 2Gl 32°l 2l 1Nominal sizeHSK-CDimensions G WeightkgSpecification Order No.Order No.length adjustd1 d 2 l 1 l 2 l 3 ment screw32 6 25 60 36 10 M5 0,2 MNC-HSK-C032-06-060-1-0-A 30319548 3032622032 8 28 60 36 10 M6 0,3 MNC-HSK-C032-08-060-1-0-A 30319549 3032622332 10 35 65 40 10 M8 0,3 MNC-HSK-C032-10-065-1-0-A 30319550 3032622540 6 25 60 36 10 M5 0,3 MNC-HSK-C040-06-060-1-0-A 30319551 3032622040 8 28 60 36 10 M6 0,3 MNC-HSK-C040-08-060-1-0-A 30319552 3032622340 10 35 65 40 10 M8 0,5 MNC-HSK-C040-10-065-1-0-A 30319553 3032622540 12 42 70 45 8 M10 0,6 MNC-HSK-C040-12-070-1-0-A 30319554 3032623040 14 44 70 45 8 M10 0,7 MNC-HSK-C040-14-070-1-0-A 30319555 3032623040 16 48 75 48 8 M12 0,8 MNC-HSK-C040-16-075-1-0-A 30319556 3032623550 6 25 60 36 8 M5 0,5 MNC-HSK-C050-06-060-1-0-A 30319557 3032621950 8 28 60 36 8 M6 0,5 MNC-HSK-C050-08-060-1-0-A 30319558 3032622250 10 35 65 40 8 M8 0,6 MNC-HSK-C050-10-065-1-0-A 30319559 3032622550 12 42 75 45 10 M10 0,8 MNC-HSK-C050-12-075-1-0-A 30319560 3032623050 14 44 75 45 10 M10 0,9 MNC-HSK-C050-14-075-1-0-A 30319561 3032623050 16 48 80 48 10 M12 1,0 MNC-HSK-C050-16-080-1-0-A 30319562 3032623550 18 50 80 48 10 M12 1,0 MNC-HSK-C050-18-080-1-0-A 30319563 3032623550 20 52 80 50 8 M16 1,1 MNC-HSK-C050-20-080-1-0-A 30319564 3032623863 6 25 60 36 8 M5 0,7 MNC-HSK-C063-06-060-1-0-A 30319565 3032621963 8 28 60 36 8 M6 0,9 MNC-HSK-C063-08-060-1-0-A 30319566 3032622263 10 35 65 40 8 M8 1,0 MNC-HSK-C063-10-065-1-0-A 30319567 3032622563 12 42 75 45 10 M10 1,2 MNC-HSK-C063-12-075-1-0-A 30319568 3032623063 14 44 75 45 10 M10 1,2 MNC-HSK-C063-14-075-1-0-A 30319569 3032623063 16 48 80 48 10 M12 1,7 MNC-HSK-C063-16-080-1-0-A 30319570 3032623563 18 50 80 48 10 M12 1,8 MNC-HSK-C063-18-080-1-0-A 30319571 3032623563 20 52 80 50 8 M16 2,0 MNC-HSK-C063-20-080-1-0-A 30319572 3032623863 25 65 95 56 8 M20 2,4 MNC-HSK-C063-25-095-1-0-A 30319573 3032624263 32 72 100 60 8 M20 2,6 MNC-HSK-C063-32-100-1-0-A 30319574 3032624280 6 25 65 36 10 M5 1,2 MNC-HSK-C080-06-065-1-0-A 30319575 3032622080 8 28 65 36 10 M6 1,2 MNC-HSK-C080-08-065-1-0-A 30319576 3032622080 10 35 70 40 10 M8 1,4 MNC-HSK-C080-10-070-1-0-A 30319577 3032622580 12 42 75 45 8 M10 1,7 MNC-HSK-C080-12-075-1-0-A 30319578 3032623080 14 44 75 45 8 M10 1,7 MNC-HSK-C080-14-075-1-0-A 30319579 3032623080 16 48 80 48 10 M12 1,8 MNC-HSK-C080-16-080-1-0-A 30319580 3032623580 18 50 80 48 10 M12 1,8 MNC-HSK-C080-18-080-1-0-A 30319581 30326235Dimensions in mm.80

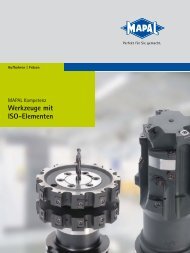

Clamping technology | Clamping tools with HSK-CChucks for cylindrical shanks with angle clamping surfacein accordance with DIN 69882-5Shank HSK-C in accordance with DIN 69893-1Nominal sizeHSK-CDimensions G WeightkgSpecification Order No.Order No.length adjustd1 d 2 l 1 l 2 l 3 ment screw80 20 52 85 50 10 M16 1,9 MNC-HSK-C080-20-085-1-0-A 30319582 3032623880 25 65 95 56 10 M20 3,6 MNC-HSK-C080-25-095-1-0-A 30319583 3032624280 32 72 100 60 10 M20 4,0 MNC-HSK-C080-32-100-1-0-A 30319584 30326242100 6 25 65 36 10 M5 1,3 MNC-HSK-C100-06-065-1-0-A 30319585 30326220100 8 28 65 36 10 M6 1,3 MNC-HSK-C100-08-065-1-0-A 30319586 30326223100 10 35 70 40 10 M8 1,5 MNC-HSK-C100-10-070-1-0-A 30319587 30326225100 12 42 75 45 8 M10 1,7 MNC-HSK-C100-12-075-1-0-A 30319588 30326230100 14 44 75 45 8 M10 1,7 MNC-HSK-C100-14-075-1-0-A 30319589 30326230100 16 48 80 48 8 M12 1,8 MNC-HSK-C100-16-080-1-0-A 30319590 30326235100 18 50 80 48 8 M12 1,9 MNC-HSK-C100-18-080-1-0-A 30319591 30326235100 20 52 85 50 10 M16 2,0 MNC-HSK-C100-20-085-1-0-A 30319592 30326238100 25 65 95 56 10 M20 3,8 MNC-HSK-C100-25-095-1-0-A 30319593 30326242100 32 72 100 60 10 M20 4,3 MNC-HSK-C100-32-100-1-0-A 30319594 30326242Dimensions in mm.Spare partsFor location bore Clamping screw in accordance with DIN 1835-Bd 1 SizeOrder No.6 M6x9 100609838 M8x9 1004251710 M10x12 1000413412 M12x14 3000294714 M12x14 3000294716 M14x16 1000413618 M14x16 1000413620 M16x16 1000413725 M18x2x20 1000414132 M20x2x20 10004129Usage:For mounting milling cutters and drills with cylindrical shank and angled clamping surface(2°) in accordance with DIN 1835 Form E and DIN 6535 Form HE.Supply includes:Built-in clamping screw and length adjustment screw.Design:Permissible run-out variation on the hollow taper shank in relationto the location bore d 1= 0.003 mm.The bore tolerance is much tighter than DIN 1835 (dH4) to obtain machining accuracies ofthe highest quality.Note:From location bore d 1= 25 mm two clamping screws are provided.The length adjustment screws have a through hole for coolant.Balancing quality:G 2.5 at 16,000 min -181