Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

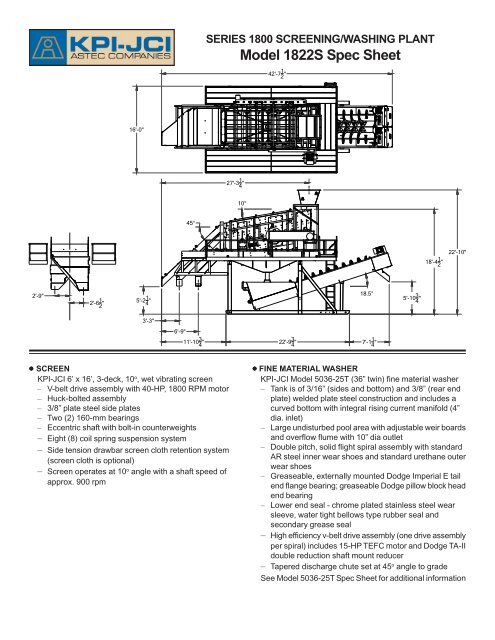

SERIES 1800 SCREENING/WASHING PLANT<strong>Model</strong> <strong>1822S</strong> <strong>Spec</strong> <strong>Sheet</strong>42'-7 1 2 "16'-0"27'-3 1 4 "10°45°18'-4 1 2 "22'-10"2'-9"2'-6 1 2 " 5'-2 1 4 "18.5°5'-10 3 4 "3'-3"6'-9"11'-10 3 4 " 22'-93 4 " 7'-11 4 "SCREEN<strong>KPI</strong>-<strong>JCI</strong> 6’ x 16’, 3-deck, 10 o , wet vibrating screen– V-belt drive assembly with 40-HP, 1800 RPM motor– Huck-bolted assembly– 3/8” plate steel side plates– Two (2) 160-mm bearings– Eccentric shaft with bolt-in counterweights– Eight (8) coil spring suspension system– Side tension drawbar screen cloth retention system(screen cloth is optional)– Screen operates at 10 o angle with a shaft speed ofapprox. 900 rpmFINE MATERIAL WASHER<strong>KPI</strong>-<strong>JCI</strong> <strong>Model</strong> 5036-25T (36” twin) fine material washer– Tank is of 3/16” (sides and bottom) and 3/8” (rear endplate) welded plate steel construction and includes acurved bottom with integral rising current manifold (4”dia. inlet)– Large undisturbed pool area with adjustable weir boardsand overflow flume with 10” dia outlet– Double pitch, solid flight spiral assembly with standardAR steel inner wear shoes and standard urethane outerwear shoes– Greaseable, externally mounted Dodge Imperial E tailend flange bearing; greaseable Dodge pillow block headend bearing– Lower end seal - chrome plated stainless steel wearsleeve, water tight bellows type rubber seal andsecondary grease seal– High efficiency v-belt drive assembly (one drive assemblyper spiral) includes 15-HP TEFC motor and Dodge TA-IIdouble reduction shaft mount reducer– Tapered discharge chute set at 45 o angle to gradeSee <strong>Model</strong> 5036-25T <strong>Spec</strong> <strong>Sheet</strong> for additional information

STRUCTURAL SUPPORT– Steel 8” wide-flange support columns and 8” wide-flangeskid runners on each side– Broken down for shipment and match-marked for easeof assembly in the fieldWATER SYSTEM– All fresh water plumbing to a single 8” inlet located nearthe tail end of the fine material washer– Fine material washer manifold includes a 4” butterflyvalve, 4” swing check valve and pressure gauge– 1” chase water plumbing with gate valves– Screen manifold with flow control valves for each spraybar– Eleven (11) spray bars with a total of ninty-nine (99) 7.0gpm (@ 40 psi) spray nozzles and fourty-two (42) 15.0gpm (@ 40 psi) spray nozzles– 3” connection on the screen manifold for the optionalfeed boxSCREEN CHUTES / FINES HOPPER– 3/16” A36 welded plate steel construction– Chutes allow for positioning of three (3) radial stackersunder the chutes– Fines hopper transitions to the feed box of the 36” twinfine material washerPHYSICAL / OPERATING CHARACTERISTICS– Feed Material Size - Typically 6” minus– Capacity - Approximately 400 TPH (dependent on feedgradation and desired products)– Water Requirements - Up to 1,200 gpm (dependent onfeed gradation and desired products)– Operating DimensionsLength 42’-8” overallWidth 16’-0”Height 18’-4-1/2” without feed box / 22’-10” withfeedbox– LoadsOverall 90,000 lbsNote individual plant weights will vary dependent onoptions includedOPTIONAL EQUIPMENT– AR or urethane chute and hopper wear liners– Fixed feed box with header pipes– Wire mesh or urethane screen media– Electrical package– Blending gates– Stair access vs ladder access– Roll-away top & middle deck overs chutesACCESS– 36” wide access platform with 1-1/2” OD handrails andtoeboards across the feed end and one side of the screen– 48” wide access platform with 1-1/2” OD handrails,and toeboards along drive side of the screen– Ladder access from grade which can be located on eitherside of the plantFOR MORE INFORMATION CALL 1-800-542-9311 AND ASK FOR A KOLBERG EQUIPMENT SPECIALISTNOTE: <strong>Spec</strong>ifications are subject to change without notice.Because <strong>KPI</strong>-<strong>JCI</strong> may use in its catalog & literature, field photographs of its products which may have been modified by the owners, products furnished by <strong>KPI</strong>-<strong>JCI</strong> may not necessarily be as illustrated therein. Also continuous design progress makes it necessary that specifications be subject tochange without notice. All sales of the products of <strong>KPI</strong>-<strong>JCI</strong> are subject to the provisions of its standard warranty. <strong>KPI</strong>-<strong>JCI</strong> does not warrant or represent that its products meet any federal, state, or local statutes, codes, ordinances, rules, standards or other regulations, including OSHA and MSHA,covering safety, pollution, electrical wiring, etc. Compliance with these statutes and regulations is the responsibility of the user and will be dependent upon the area and the use to which the product is put by the user. In some photographs, guards may have been removed for illustrative purposesonly. This equipment should not be operated without all guards attached in their normal position. Placement of guards and other safety equipment is often dependent upon the area and how the product is used. A safety study should be made by the user of the application, and, if required additionalguards, warning signs and other safety devices should be installed by the user, wherever appropriate before operating the products.700 W 21st. St., Yankton, SD 57078Email: mail@kpijci.com1-800-542-9311 Fax: 605-665-8858www.kpijci.comMdl <strong>1822S</strong> Rev. 2, 08/09