Reference system for Wire EDM machining. The standard range.

Reference system for Wire EDM machining. The standard range.

Reference system for Wire EDM machining. The standard range.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

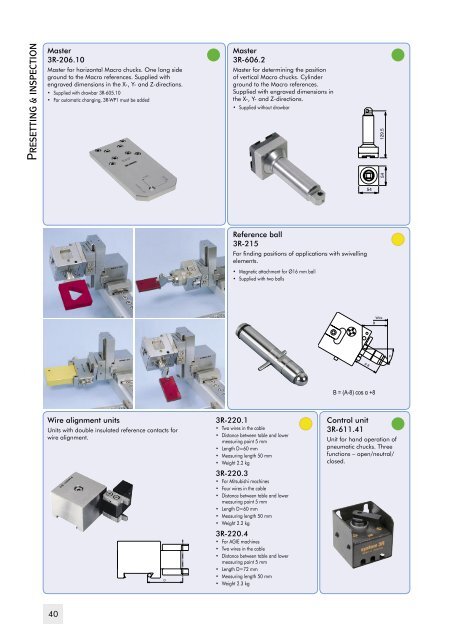

Presetting & inspectionMaster3R-206.10Master <strong>for</strong> horizontal Macro chucks. One long sideground to the Macro references. Supplied withengraved dimensions in the X-, Y- and Z-directions.• Supplied with drawbar 3R-605.10• For automatic changing, 3R-WP1 must be addedMaster3R-606.2Master <strong>for</strong> determining the positionof vertical Macro chucks. Cylinderground to the Macro references.Supplied with engraved dimensions inthe X-, Y- and Z-directions.• Supplied without drawbar<strong>Reference</strong> ball3R-215For finding positions of applications with swivellingelements.• Magnetic attachment <strong>for</strong> Ø16 mm ball• Supplied with two balls<strong>Wire</strong> alignment unitsUnits with double insulated reference contacts <strong>for</strong>wire alignment.3R-220.1• Two wires in the cable• Distance between table and lowermeasuring point 5 mm• Length D=60 mm• Measuring length 50 mm• Weight 2.2 kg3R-220.3• For Mitsubishi machines• Four wires in the cable• Distance between table and lowermeasuring point 5 mm• Length D=60 mm• Measuring length 50 mm• Weight 2.2 kg3R-220.4• For AGIE machines• Two wires in the cable• Distance between table and lowermeasuring point 5 mm• Length D=72 mm• Measuring length 50 mm• Weight 2.3 kgControl unit3R-611.41Unit <strong>for</strong> hand operation ofpneumatic chucks. Threefunctions – open/neutral/closed.40