special issue

special issue

special issue

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

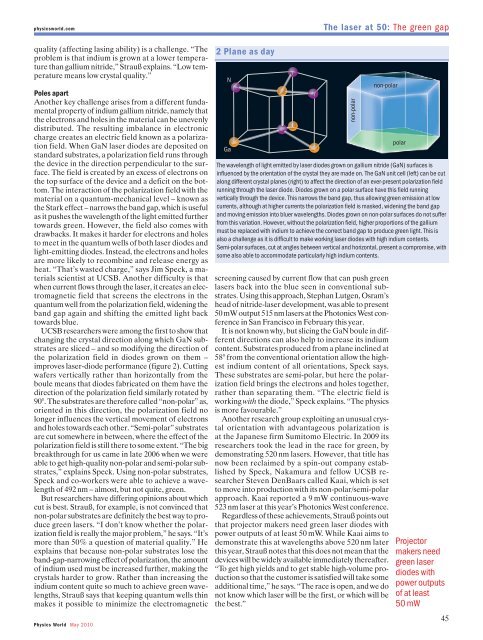

physicsworld.comThe laser at 50: The green gapquality (affecting lasing ability) is a challenge. “Theproblem is that indium is grown at a lower temperaturethan gallium nitride,” Strauß explains. “Low temperaturemeans low crystal quality.”Poles apartAnother key challenge arises from a different fundamentalproperty of indium gallium nitride, namely thatthe electrons and holes in the material can be unevenlydistributed. The resulting imbalance in electroniccharge creates an electric field known as a polariza -tion field. When GaN laser diodes are deposited onstandard substrates, a polarization field runs throughthe device in the direction perpendicular to the surface.The field is created by an excess of electrons onthe top surface of the device and a deficit on the bottom.The interaction of the polarization field with thematerial on a quantum-mechanical level – known asthe Stark effect – narrows the band gap, which is usefulas it pushes the wavelength of the light emitted furthertowards green. However, the field also comes withdrawbacks. It makes it harder for electrons and holesto meet in the quantum wells of both laser diodes andlight-emitting diodes. Instead, the electrons and holesare more likely to recombine and re lease energy asheat. “That’s wasted charge,” says Jim Speck, a ma -terials scientist at UCSB. Another difficulty is thatwhen current flows through the laser, it creates an electromagneticfield that screens the electrons in thequantum well from the polarization field, widening theband gap again and shifting the emitted light backtowards blue.UCSB researchers were among the first to show thatchanging the crystal direction along which GaN substratesare sliced – and so modifying the direction ofthe polarization field in diodes grown on them –improves laser-diode performance (figure 2). Cuttingwafers vertically rather than horizontally from theboule means that diodes fabricated on them have thedirection of the polarization field similarly rotated by90°. The substrates are therefore called “non-polar” as,oriented in this direction, the polarization field nolonger influences the vertical movement of electronsand holes towards each other. “Semi-polar” substratesare cut somewhere in between, where the effect of thepolarization field is still there to some extent. “The bigbreakthrough for us came in late 2006 when we wereable to get high-quality non-polar and semi-polar substrates,”explains Speck. Using non-polar substrates,Speck and co-workers were able to achieve a wavelengthof 492 nm – almost, but not quite, green.But researchers have differing opinions about whichcut is best. Strauß, for example, is not convinced thatnon-polar substrates are definitely the best way to producegreen lasers. “I don’t know whether the polar -ization field is really the major problem,” he says. “It’smore than 50% a question of material quality.” Heexplains that because non-polar substrates lose theband-gap-narrowing effect of polarization, the amountof indium used must be increased further, making thecrystals harder to grow. Rather than increasing theindium content quite so much to achieve green wavelengths,Strauß says that keeping quantum wells thinmakes it possible to minimize the electromagneticPhysics World May 20102 Plane as dayNGanon-polarThe wavelength of light emitted by laser diodes grown on gallium nitride (GaN) surfaces isinfluenced by the orientation of the crystal they are made on. The GaN unit cell (left) can be cutalong different crystal planes (right) to affect the direction of an ever-present polarization fieldrunning through the laser diode. Diodes grown on a polar surface have this field runningvertically through the device. This narrows the band gap, thus allowing green emission at lowcurrents, although at higher currents the polarization field is masked, widening the band gapand moving emission into bluer wavelengths. Diodes grown on non-polar surfaces do not sufferfrom this variation. However, without the polarization field, higher proportions of the galliummust be replaced with indium to achieve the correct band gap to produce green light. This isalso a challenge as it is difficult to make working laser diodes with high indium contents.Semi-polar surfaces, cut at angles between vertical and horizontal, present a compromise, withsome also able to accommodate particularly high indium contents.non-polarscreening caused by current flow that can push greenlasers back into the blue seen in conventional substrates.Using this ap proach, Stephan Lutgen, Osram’shead of nitride-laser development, was able to present50 mW output 515 nm lasers at the Photonics West conferencein San Fran cis co in February this year.It is not known why, but slicing the GaN boule in differentdirections can also help to increase its indiumcontent. Substrates produced from a plane inclined at58° from the conventional orientation allow the highestindium content of all orientations, Speck says.These substrates are semi-polar, but here the polar -iza tion field brings the electrons and holes together,rather than separating them. “The electric field isworking with the diode,” Speck explains. “The physicsis more favourable.”Another research group exploiting an unusual crystalorientation with advantageous polarization isat the Japanese firm Sumitomo Electric. In 2009 itsre search ers took the lead in the race for green, bydemonstrating 520 nm lasers. However, that title hasnow been reclaimed by a spin-out company establishedby Speck, Nakamura and fellow UCSB re -searcher Steven DenBaars called Kaai, which is setto move into production with its non-polar/semi-polarapproach. Kaai reported a 9 mW continuous-wave523 nm laser at this year’s Photonics West conference.Regardless of these achievements, Strauß points outthat projector makers need green laser diodes withpower outputs of at least 50 mW. While Kaai aims todemonstrate this at wavelengths above 520 nm laterthis year, Strauß notes that this does not mean that thedevices will be widely available immediately thereafter.“To get high yields and to get stable high-volume productionso that the customer is satisfied will take someadditional time,” he says. “The race is open, and we donot know which laser will be the first, or which will bethe best.”polarProjectormakers needgreen laserdiodes withpower outputsof at least50 mW45