Control of membrane fouling by Hydrogen Sulfide (H2S) diffusion ...

Control of membrane fouling by Hydrogen Sulfide (H2S) diffusion ...

Control of membrane fouling by Hydrogen Sulfide (H2S) diffusion ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

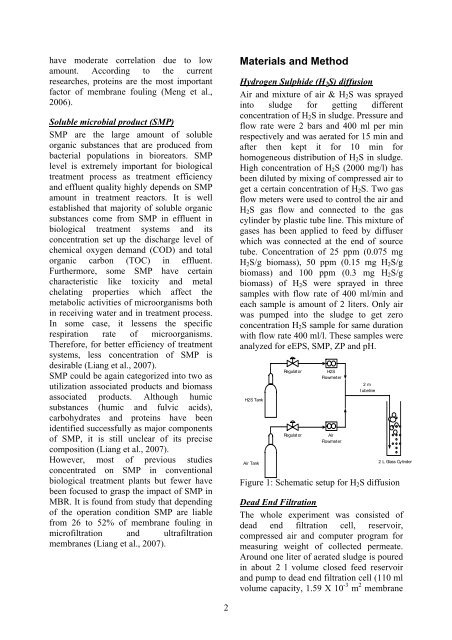

have moderate correlation due to lowamount. According to the currentresearches, proteins are the most importantfactor <strong>of</strong> <strong>membrane</strong> <strong>fouling</strong> (Meng et al.,2006).Soluble microbial product (SMP)SMP are the large amount <strong>of</strong> solubleorganic substances that are produced frombacterial populations in bioreators. SMPlevel is extremely important for biologicaltreatment process as treatment efficiencyand effluent quality highly depends on SMPamount in treatment reactors. It is wellestablished that majority <strong>of</strong> soluble organicsubstances come from SMP in effluent inbiological treatment systems and itsconcentration set up the discharge level <strong>of</strong>chemical oxygen demand (COD) and totalorganic carbon (TOC) in effluent.Furthermore, some SMP have certaincharacteristic like toxicity and metalchelating properties which affect themetabolic activities <strong>of</strong> microorganisms bothin receiving water and in treatment process.In some case, it lessens the specificrespiration rate <strong>of</strong> microorganisms.Therefore, for better efficiency <strong>of</strong> treatmentsystems, less concentration <strong>of</strong> SMP isdesirable (Liang et al., 2007).SMP could be again categorized into two asutilization associated products and biomassassociated products. Although humicsubstances (humic and fulvic acids),carbohydrates and proteins have beenidentified successfully as major components<strong>of</strong> SMP, it is still unclear <strong>of</strong> its precisecomposition (Liang et al., 2007).However, most <strong>of</strong> previous studiesconcentrated on SMP in conventionalbiological treatment plants but fewer havebeen focused to grasp the impact <strong>of</strong> SMP inMBR. It is found from study that depending<strong>of</strong> the operation condition SMP are liablefrom 26 to 52% <strong>of</strong> <strong>membrane</strong> <strong>fouling</strong> inmicr<strong>of</strong>iltration and ultrafiltration<strong>membrane</strong>s (Liang et al., 2007).Materials and Method<strong>Hydrogen</strong> Sulphide (H 2 S) <strong>diffusion</strong>Air and mixture <strong>of</strong> air & H 2 S was sprayedinto sludge for getting differentconcentration <strong>of</strong> H 2 S in sludge. Pressure andflow rate were 2 bars and 400 ml per minrespectively and was aerated for 15 min andafter then kept it for 10 min forhomogeneous distribution <strong>of</strong> H 2 S in sludge.High concentration <strong>of</strong> H 2 S (2000 mg/l) hasbeen diluted <strong>by</strong> mixing <strong>of</strong> compressed air toget a certain concentration <strong>of</strong> H 2 S. Two gasflow meters were used to control the air andH 2 S gas flow and connected to the gascylinder <strong>by</strong> plastic tube line. This mixture <strong>of</strong>gases has been applied to feed <strong>by</strong> diffuserwhich was connected at the end <strong>of</strong> sourcetube. Concentration <strong>of</strong> 25 ppm (0.075 mgH 2 S/g biomass), 50 ppm (0.15 mg H 2 S/gbiomass) and 100 ppm (0.3 mg H 2 S/gbiomass) <strong>of</strong> H 2 S were sprayed in threesamples with flow rate <strong>of</strong> 400 ml/min andeach sample is amount <strong>of</strong> 2 liters. Only airwas pumped into the sludge to get zeroconcentration H 2 S sample for same durationwith flow rate 400 ml/l. These samples wereanalyzed for eEPS, SMP, ZP and pH.<strong>H2S</strong> TankAir TankRegulatorRegulator<strong>H2S</strong>FlowmeterAirFlowmeter2 mtubeline2 L Glass CylinderFigure 1: Schematic setup for H 2 S <strong>diffusion</strong>Dead End FiltrationThe whole experiment was consisted <strong>of</strong>dead end filtration cell, reservoir,compressed air and computer program formeasuring weight <strong>of</strong> collected permeate.Around one liter <strong>of</strong> aerated sludge is pouredin about 2 l volume closed feed reservoirand pump to dead end filtration cell (110 mlvolume capacity, 1.59 X 10 -3 m 2 <strong>membrane</strong>2