MF WR Series Windrowers Brochure - Hesston.com

MF WR Series Windrowers Brochure - Hesston.com

MF WR Series Windrowers Brochure - Hesston.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

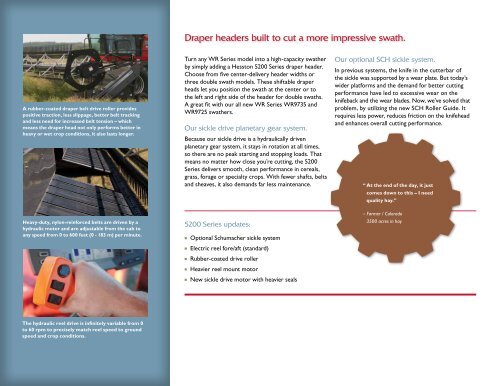

Draper headers built to cut a more impressive swath.A rubber-coated draper belt drive roller providespositive traction, less slippage, better belt trackingand less need for increased belt tension – whichmeans the draper head not only performs better inheavy or wet crop conditions, it also lasts longer.Turn any <strong>WR</strong> <strong>Series</strong> model into a high-capacity swatherby simply adding a <strong>Hesston</strong> 5200 <strong>Series</strong> draper header.Choose from five center-delivery header widths orthree double swath models. These shiftable draperheads let you position the swath at the center or tothe left and right side of the header for double swaths.A great fit with our all new <strong>WR</strong> <strong>Series</strong> <strong>WR</strong>9735 and<strong>WR</strong>9725 swathers.Our sickle drive planetary gear system.Because our sickle drive is a hydraulically drivenplanetary gear system, it stays in rotation at all times,so there are no peak starting and stopping loads. Thatmeans no matter how close you’re cutting, the 5200<strong>Series</strong> delivers smooth, clean performance in cereals,grass, forage or specialty crops. With fewer shafts, beltsand sheaves, it also demands far less maintenance.Our optional SCH sickle system.In previous systems, the knife in the cutterbar ofthe sickle was supported by a wear plate. But today’swider platforms and the demand for better cuttingperformance have led to excessive wear on theknifeback and the wear blades. Now, we’ve solved thatproblem, by utilizing the new SCH Roller Guide. Itrequires less power, reduces friction on the knifeheadand enhances overall cutting performance.“ At the end of the day, it just<strong>com</strong>es down to this – I needquality hay.”Heavy-duty, nylon-reinforced belts are driven by ahydraulic motor and are adjustable from the cab toany speed from 0 to 600 feet (0 - 183 m) per minute.5200 <strong>Series</strong> updates:n Optional Schumacher sickle systemn Electric reel fore/aft (standard)n Rubber-coated drive rollern Heavier reel mount motorn New sickle drive motor with heavier seals– Farmer / Colorado3500 acres in hayThe hydraulic reel drive is infinitely variable from 0to 60 rpm to precisely match reel speed to groundspeed and crop conditions.