Water: Logged Ply the River Company Secret - Finning Canada

Water: Logged Ply the River Company Secret - Finning Canada

Water: Logged Ply the River Company Secret - Finning Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

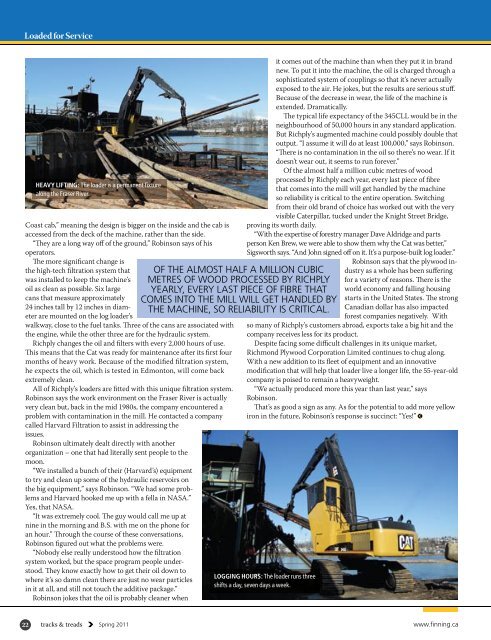

Loaded for ServiceHEAVY LIFTING: The loader is a permanent fixturealong <strong>the</strong> Fraser <strong>River</strong>.Coast cab,” meaning <strong>the</strong> design is bigger on <strong>the</strong> inside and <strong>the</strong> cab isaccessed from <strong>the</strong> deck of <strong>the</strong> machine, ra<strong>the</strong>r than <strong>the</strong> side.“They are a long way off of <strong>the</strong> ground,” Robinson says of hisoperators.The more significant change is<strong>the</strong> high-tech filtration system thatwas installed to keep <strong>the</strong> machine’soil as clean as possible. Six largecans that measure approximately24 inches tall by 12 inches in diameterare mounted on <strong>the</strong> log loader’swalkway, close to <strong>the</strong> fuel tanks. Three of <strong>the</strong> cans are associated with<strong>the</strong> engine, while <strong>the</strong> o<strong>the</strong>r three are for <strong>the</strong> hydraulic system.Richply changes <strong>the</strong> oil and filters with every 2,000 hours of use.This means that <strong>the</strong> Cat was ready for maintenance after its first fourmonths of heavy work. Because of <strong>the</strong> modified filtration system,he expects <strong>the</strong> oil, which is tested in Edmonton, will come backextremely clean.All of Richply’s loaders are fitted with this unique filtration system.Robinson says <strong>the</strong> work environment on <strong>the</strong> Fraser <strong>River</strong> is actuallyvery clean but, back in <strong>the</strong> mid 1980s, <strong>the</strong> company encountered aproblem with contamination in <strong>the</strong> mill. He contacted a companycalled Harvard Filtration to assist in addressing <strong>the</strong>issues.Robinson ultimately dealt directly with ano<strong>the</strong>rorganization – one that had literally sent people to <strong>the</strong>moon.“We installed a bunch of <strong>the</strong>ir (Harvard’s) equipmentto try and clean up some of <strong>the</strong> hydraulic reservoirs on<strong>the</strong> big equipment,” says Robinson. “We had some problemsand Harvard hooked me up with a fella in NASA.”Yes, that NASA.“It was extremely cool. The guy would call me up atnine in <strong>the</strong> morning and B.S. with me on <strong>the</strong> phone foran hour.” Through <strong>the</strong> course of <strong>the</strong>se conversations,Robinson figured out what <strong>the</strong> problems were.“Nobody else really understood how <strong>the</strong> filtrationsystem worked, but <strong>the</strong> space program people understood.They know exactly how to get <strong>the</strong>ir oil down towhere it’s so damn clean <strong>the</strong>re are just no wear particlesin it at all, and still not touch <strong>the</strong> additive package.”Robinson jokes that <strong>the</strong> oil is probably cleaner whenOF THE ALMOST HALF A MILLION CUBICMETRES OF WOOD PROCESSED BY RICHPLYYEARLY, EVERY LAST PIECE OF FIBRE THATCOMES INTO THE MILL WILL GET HANDLED BYTHE MACHINE, SO RELIABILITY IS CRITICAL.it comes out of <strong>the</strong> machine than when <strong>the</strong>y put it in brandnew. To put it into <strong>the</strong> machine, <strong>the</strong> oil is charged through asophisticated system of couplings so that it’s never actuallyexposed to <strong>the</strong> air. He jokes, but <strong>the</strong> results are serious stuff.Because of <strong>the</strong> decrease in wear, <strong>the</strong> life of <strong>the</strong> machine isextended. Dramatically.The typical life expectancy of <strong>the</strong> 345CLL would be in <strong>the</strong>neighbourhood of 50,000 hours in any standard application.But Richply’s augmented machine could possibly double thatoutput. “I assume it will do at least 100,000,” says Robinson.“There is no contamination in <strong>the</strong> oil so <strong>the</strong>re’s no wear. If itdoesn’t wear out, it seems to run forever.”Of <strong>the</strong> almost half a million cubic metres of woodprocessed by Richply each year, every last piece of fibrethat comes into <strong>the</strong> mill will get handled by <strong>the</strong> machineso reliability is critical to <strong>the</strong> entire operation. Switchingfrom <strong>the</strong>ir old brand of choice has worked out with <strong>the</strong> veryvisible Caterpillar, tucked under <strong>the</strong> Knight Street Bridge,proving its worth daily.“With <strong>the</strong> expertise of forestry manager Dave Aldridge and partsperson Ken Brew, we were able to show <strong>the</strong>m why <strong>the</strong> Cat was better,”Sigsworth says. “And John signed off on it. It’s a purpose-built log loader.”Robinson says that <strong>the</strong> plywood industryas a whole has been sufferingfor a variety of reasons. There is <strong>the</strong>world economy and falling housingstarts in <strong>the</strong> United States. The strongCanadian dollar has also impactedforest companies negatively. Withso many of Richply’s customers abroad, exports take a big hit and <strong>the</strong>company receives less for its product.Despite facing some difficult challenges in its unique market,Richmond <strong>Ply</strong>wood Corporation Limited continues to chug along.With a new addition to its fleet of equipment and an innovativemodification that will help that loader live a longer life, <strong>the</strong> 55-year-oldcompany is poised to remain a heavyweight.“We actually produced more this year than last year,” saysRobinson.That’s as good a sign as any. As for <strong>the</strong> potential to add more yellowiron in <strong>the</strong> future, Robinson’s response is succinct: “Yes!”LOGGING HOURS: The loader runs threeshifts a day, seven days a week.22tracks & treadsSpring 2011www.finning.ca