Premier SD40-2 Diesel Engine - MTH Trains

Premier SD40-2 Diesel Engine - MTH Trains

Premier SD40-2 Diesel Engine - MTH Trains

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

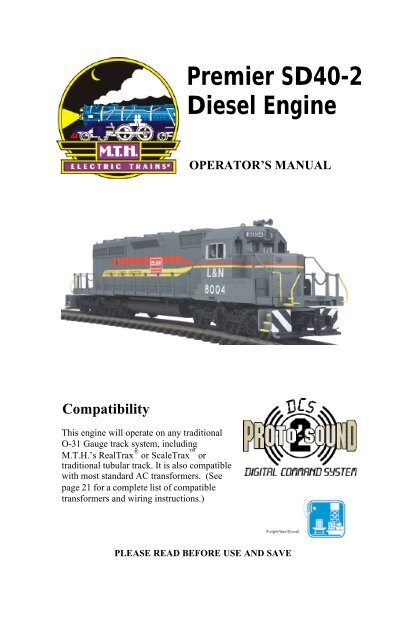

<strong>Premier</strong> <strong>SD40</strong>-2<strong>Diesel</strong> <strong>Engine</strong>OPERATOR’S MANUALCompatibilityThis engine will operate on any traditionalO-31 Gauge track system, includingM.T.H.’s RealTrax ® or ScaleTrax ortraditional tubular track. It is also compatiblewith most standard AC transformers. (Seepage 21 for a complete list of compatibletransformers and wiring instructions.)PLEASE READ BEFORE USE AND SAVE

Table of ContentsSet Up Checklis t...................................................................................................3Lubrication.............................................................................................3Priming The Smoke Unit....................................................................... 3Checking The Battery............................................................................ 4Basic Operation ....................................................................................................5Activating Features................................................................................5Proto-Sound 2.0 Operating Instructions........................................................... 7Activating Proto-Sound 2.0 Conventional Mode Features....................7Freight Yard Sounds (FYS)................................................................... 8Proto-Coupler® Operation.................................................................... 9Speed Control........................................................................................ 10Locking Locomotive Into A Direction.................................................. 11Reset To Factory Default.......................................................................11Automatic Sound Effects.......................................................................11Maintenance.........................................................................................................12Lubricating and Greasing Instructions...................................................12Cleaning The Wheels, Tires and Track..................................................13Traction Tire Replacement Instructions.................................................14Headlight Replacement Instructions......................................................15Self Charging Battery Back-Up.............................................................15ProtoSmoke® Unit Operation................................................................16Troubleshooting Proto-Sound® 2.0 Problems.......................................18Transformer Compatibility and Wiring Chart....................................... 21Additional Features Accessible Of DCS Remote Control System........22Service & Warranty Information........................................................... 23Limited One-Year Warranty..................................................................23CAUTION: ELECTRICALLY OPERATED PRODUCT:Not recommended for children under 10 years of age. M.T.H. recommends adult supervision with children ages 10 - 16.As with all electric products, precautions should be observed during handling and use to reduce the risk of electric shock.WARNING: When using electrical products, basic safety precautions should be observed, including the followi ng:Read this manual thoroughly before using this device.● M.T.H. recommends that all users and persons supervising use examine the hobby transformer and other electronic equipmentperiodically for conditions that may result in the risk of fire, electric shock, or injury to persons, such as damage to the primarycord, plug blades, housing, output jacks or other parts. In the event such conditions exist, the train set should not be used untilproperly repaired.● Do not operate your layout unattended. Obstructed accessories or stalled trains may overheat, resulting in damage to your layout.● This train set is intended for indoor use. Do not use if water is present. Serious injury or fatality may result.● Do not operate the hobby transformer with damaged cord, plug, switches, buttons or case.

Set Up Checklist• Lubricate the locomotive• Prime the smoke unit• Check to see whether the battery needs to be charged for full sound effects• Apply power to run as described in the Basic Operating Section of this manualLubricationYou should lubricate the engine to prevent it from squeaking. Uselight household oil and follow the lubrication points marked “L” inFig. 1. Do not over-oil. Use only a drop or two on each pivot point.DO NOTOVER OILLubricate Pick Up Rollers (L)Lubricate Wheel Axles (L)Figure 1. Lubrication Points on the LocomotivePriming The Smoke UnitWhen preparing to run this engine, add 15-20 drops of smoke fluid through thesmokestack (see Fig. 2). We recommend M.T.H. ProtoSmoke, Seuthe, LGB, or LVTSfluids. Do not overfill the unit or the fluid may leak out and coat the interior enginecomponents.If you choose not to add the fluid (or have already added the fluid but choose to runsmoke-free), turn off the smoke unit switch located under the engine (see Fig. 3).Failure either to add fluid to the unit or to turn it off may damage the smoke unitheating element and/or wicking material.<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 3

Running the engine without a primedsmoke unit may cause damageAdd Smoke FluidSmoke UnitON/OFF SwitchFigure 2: Adding Smoke FluidFigure 3: Smoke Unit Switch LocationChecking The BatteryYou may find, if your locomotive was built several months before you set it up, that therechargeable battery has run down and needs to be charged before operating. If younotice that the sounds are garbled, test and charge the engine as described in the"Self-Charging Battery Back-Up" on page 15.4 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

Basic OperationThe Throttle knob controls how fast your train will travel.Turn the throttle knob up ½-way, until the engine and caboose lights shine bright.Put the engine into motion by pressing the Direction button on your transformer once.(hold it for approximately 1 second)If the engine does not begin to move as soon as you firmly press the Direction button,you may not have sent enough voltage to the track to make the train move. Turn thethrottle up a bit higher until the train begins to move.Activating FeaturesThrottle To increase or decrease track voltage, and therefore train speed, turn thethrottle control knob. Turning clockwise will increase voltage and speed, while turningcounterclockwise will decrease voltage and speed. The engine will maintain the speedyou set after you release the throttle until you turn it again to change the voltage andspeed.Bell - To sound the bell, in an engine equipped with a bell firmly press and release theBell button. To turn the bell off, press and release the Bell button again. The bell willcontinue to ring from the time you turn it on until you press and release the button againto turn it off.Horn/Whistle - To sound the whistle, firmly press the Horn/Whistle button. The whistlewill sound for as long as you continue to depress the button. It will stop when yourelease the button.Direction Your train is programmed tostart in neutral. The train will alwayscycle neutral-forward-neutral-reverse witheach press and release of the directionbutton. The engine is programmed torestart in neutral each time the trackvoltage is turned off for 25 seconds ormore.Cycle PhasesNeutralReverseNeutralForward<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 5

Manual Volume ControlTo adjust the volume of all sounds made by this engine, turn the master volume controlknob located next to the fuel tank clockwise to increase the volume andcounter-clockwise to decrease the volume.Proto-Sound 2.0Volume Adjustment KnobFigure 4: Manual Volume Adjustment Knob6 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

Tips on Using FYS• You can terminate FYS at any time by turning off power to the track for 15seconds.• You do not have to be in Forward to use FYS. At the conclusion of the fullsequence, the train will pull away from the station in whatever direction youwere going when you activated the feature.• You can use FYS even if you are double-heading with another engine. If thesecond engine is not equipped with Proto-Sound 2.0, you must remembernot to leave the throttle at a high voltage level once you have stopped theengine to run the FYS. Otherwise, the engine without FYS will beginvibrating on the track as its motors strain to move the train, since theycannot be automatically disabled during the FYS cycle (or if an originalProto-Sound engine, FYS are triggered differently and that engine'smotor-disable feature will not be active when you run FYS in Proto-Sound2.0).• FYS can be triggered from Neutral. It will operate the same as if triggeredwhile in motion except that, at the conclusion of the FYS, the engine willdepart in the next direction of travel, as opposed to the direction it wastraveling before entering Neutral.Proto-Coupler® OperationThis locomotive is equipped with one or more coil-wound Proto-Couplers for remoteuncoupling action. Because Proto-Couplers are controlled through the Proto-Sound 2.0microprocessor, they do not require an uncoupling track section or modification to yourlayout to function. You can fire a coupler from neutral or while in motion. Use the codeshown below (and in the chart on p. 7) to fire the coupler(s).Rear Coupler:To fire the rear coupler, quickly tap the Bell button once followed by three quick taps ofthe Horn button, allowing approximately ½ second to lapse between each quick buttonpress. The sound of the liftbar and air line depletion will play, and the knuckle will bereleased.BellHornHornHornFireRear = Coupler<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 9

Front Coupler:To fire the front coupler (if your engine has one), quickly tap the Bell button oncefollowed by four quick taps of the Horn button, allowing approximately ½ second tolapse between each quick button press. The sound of the liftbar and air line depletionwill play, and the knuckle will be released.BellHornHornHornHornFireFront = CouplerSpeed ControlM.T.H. engines equipped with Proto-Sound 2.0 have speed control capabilities that allowthe engine to maintain a constant speed up and down grades and around curves, muchlike an automobile cruise control. You can add or drop cars on the run, and the enginewill maintain the speed you set.While the engine is programmed to start with the speed control feature activated, you canopt to turn it off. This means the engine's speed will fall as it labors up a hill and increaseas it travels downward. It is also affected by the addition or releasing of cars while on therun. Because the engine will run more slowly at a given throttle voltage when speedcontrol is on than when it is off, you should adjust the throttle to a lower power level foroperation with speed control off to avoid high-speed derailments. When speed control isoff, the volume will drop to allow for better low voltage operation.To turn speed control on and off, put the engine in neutral, then quickly tap thetransformer's Horn button one time then quickly tap the Bell button two times, allowingapproximately ½ second to lapse between each quick button press. Two horn blasts willindicate that the engine has made the change. Repeat the 1 horn, 2 bells code to return itto the other condition. You will want to do this during the initial neutral upon start-up ifyou ever couple this engine to another engine that is not equipped with speed control toavoid damaging the motors in either engine. Each time you shut down the enginecompletely, it will automatically turn speed control on.Place<strong>Engine</strong> intoNeutralHornBell Bell =Speed ControlTwo Horn Blasts(indicates change is made)Repeat to Returnto Normal Condition10 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

Locking Locomotive Into A DirectionYou can lock your engine into a direction (forward, neutral, or reverse) so that it will notchange directions. To do this, put the engine into the direction you want (or into neutralto lock it into neutral), run it at a very slow crawl (as slowly as it will move withouthalting), and quickly but firmly tap the Horn button once followed by three quick taps ofthe Bell button, allowing approximately ½ second to lapse between each quick buttonpress. Two horn blasts will indicate that the engine has made the change. The engine willnot change direction (including going into neutral) until you repeat the 1 horn, 3 bellscode to return the engine to its normal condition, even if the engine is kept without powerfor extended periods of time.Place<strong>Engine</strong> intoDesired HornDirectionHorn Bell Bell Bell =Direction LockTwo Horn Blasts(indicates change is made)Repeat to Returnto Normal ConditionReset To Factory DefaultTo override the settings you currently have assigned to the engine and reset it to itsfactory defaults, while in Neutral tap the Horn button quickly once, followed by fivequick taps of the Bell button, allowing approximately ½ second to lapse between eachquick button press. Two horn blasts will indicate that the engine has made the change.Place<strong>Engine</strong> inNeutralHornBellBellBellBellBell=ResetTwo Horn Blasts(indicates change is made)Repeat to Returnto Normal ConditionAutomatic Sound EffectsCertain Proto-Sound 2.0 sound effects automatically play in programmed conventionalmode conditions:• Squealing Brakes play any time the engine's speed decreases rapidly.• Cab Chatter plays at random intervals when the engine idles in neutral.• <strong>Engine</strong> Start-up and Shut-down sounds play when the engine is initially poweredon or is powered off for five seconds or more.<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 11

MaintenanceLubricating and Greasing InstructionsThe engine should be well oiled and greased in order to run properly.Regularly lubricate all axles and linkage components and pickup rollers to preventsqueaking. Use light household oil, such as that found in M.T.H.'smaintenance kit. Do not over oil. Use only a drop or two on eachpivot point.DO NOTOVER OILBody Mount ScrewsFigure 5: Body Removal Screw LocationsMotor Mounting ScrewThe locomotive’s internal gearing was greased at the factory and should not needadditional grease until after 50 hours of operation or one year, whichever comes first.Follow the greasing instructions below. Note that in some tightly packed engines youmay need to move internal components temporarily in order to access the gears.1. To access the gear box, remove the cab from the chassis by unscrewing the chassisscrews as seen in Figure 5 and lifting the cab from the chassis.2. Once the cab is removed, remove the trucks by unscrewing the black Phillips motormount screw located on the underside of the drive trucks (see Fig. 5).3. Once the motor mount screw has been removed, pull the motor away from the truckblock and lightly coat the motor worm gear and bronze drive gear (in the truck block)with grease.4. Reassemble the truck and motor, being careful not to pinch any wires between thetruck block and motor mount.12 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

5. After repeating the procedure for the other motor, reassmble the chassis and body,being careful that the wire harnesses are not caught between the chassis and body andreinstall the chassis screws.Lubricate the outside truck blockidler and drive gears with grease.Use the diagram shown in Figure 6below as a guide and add grease tothe points marked with a “G.”Grease Idler Gears (G)Figure 6: Greasing The Idler GearsCleaning The Wheels, Tires and TrackPeriodically check the locomotivewheels and pickups for dirt andbuildup, which can cause poorelectrical contact and traction andprematurely wear out the neoprenetraction tires. Wheels and tires can becleaned using denatured (not rubbing)alcohol applied with a cotton swab.To clean the track, use RailKing TrackCleaning Fluid and a clean rag ordenatured (not rubbing) alcohol.Unplug the transformer and wipe therails of the track, turning the ragfrequently to ensure that you are usingclean cloth on the rails. Thereafter,keep an eye on the track and clean itwhen it gets dirty to ensure good electrical contact and to lengthen the life of the tires.<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 13

Traction Tire Replacement InstructionsYour locomotive is equipped with two neoprene rubber traction tires on each poweredtruck block. While these tires are extremely durable, you may need to replace them atsome point.First, remove the trucks from the chassis by unscrewing the body mounting screws asnoted in Figure 5. Next, remove the trucks from the chassis by unscrewing the truckmounting screw also noted in Figure 5. Finally, turn the removed truck over and locateand remove the truckside screws to gain access to the drive wheel traction tires behindthe trucksides.Once the truck sides have been removed:1. Make sure the old tire has been completely removed from the groove in the drivewheel, using a razor blade or small flathead screwdriver to pry away any remains.2. Slip the new tire onto the wheel. You may find it useful to use two small flatheadscrewdrivers to stretch the tire over the wheel.3. If you twist the tire while stretching it over the wheel, you will need to remove andreinstall the tire. Otherwise your engine will wobble while operating.4. Make sure the tire is fully seated inside the groove. Use a razor blade to trim away anyexcess tire that will not seat inside the groove properly.5. Reassemble in the reverse order.One set of replacement tires is packaged with your model. Additional sets are availabledirectly from the M.T.H. Parts Department (order online: www.mth-railking.com,e-mail: parts@mth-railking.com; mail: 7020 Columbia Gateway Drive, Columbia MD21046-1532, FAX: 410-381-6122).14 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

Headlight Replacement InstructionsThe locomotive’s headlight is controlled by a constant voltage circuit in the engine. Theheadlight is easy to remove and replace when it burns out. The bulb has a quickdisconnect plug that attaches the bulb harness to a connector terminal inside the bodyshell. Replacement bulbs are available directly from the M.T.H. Parts Department.Follow the body removal instructions found in the Lubrication and Greasing Instructions.Replaceable LightsFigure 7: Removing The Replaceable LightsGently disconnect the bulb harness from the socket on the constant voltage circuit orconnector terminal and replace the bulb.Self Charging Battery Back-UpThe special NiCad 7-cell 8.4v self-charging battery recharges continuously during trainoperation and should last for up to five years. The battery is a dry battery that should notleak or cause any damage to your engine. Depending upon when your engine was built,it may need to be charged right out of the box. If engine sounds seem distorted orgarbled at low voltages or become silent when power from the transformer is turned off,test the battery to determine whether it should be recharged or replaced.Test: Put the engine in neutral and leave the track voltage at 10-12 volts (high enoughfor the lights to shine brightly and the engine to move steadily) for 15 minutes.<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 15

Recharge: If the sounds are improved at the end of the 15-minute test charge, the batterycharge has run down and can be recharged. There are a number of ways you can do this:• Leave the engine in neutral with track voltage at 10-12 volts for 6-7 hours so thebattery can fully recharge(if your engine has aBattery Charger Portsmoke unit, be sure it isturned off).• Use M.T.H.'s batteryrecharger (sold separately)that plugs into a wall outletand a special port under theengine to recharge thebattery overnight withoutleaving it on the track.Figure 8: Battery Charger PortReplace: If the sounds are notimproved at the end of the 15-minute test charge, it is time to replace the battery.Disconnect Battery,And Slide Out Battery In Direction Of ArrowFigure 9: Removing The BatteryProtoSmoke® Unit OperationThis <strong>Premier</strong> diesel locomotivecontains a Proto-Sound 2.0 controlledsmoke unit that outputs smokethrough the smokestack on the roofof the engine. The smoke unit isessentially a small heating elementand wick that soaks up and then heatsa mineral oil-based fluid that emits aFigure 10: Adding Smoke FluidAdd Smoke Fluid16 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

harmless smoke. The smoke is then forced out of the stack by a small electric fan.Smoke volume is controlled by the Proto-Sound 2.0 system.With a few easy maintenance steps, you should enjoy trouble-free smoke unit operationfor years.When preparing to run this engine, add 15-20 drops of smoke fluid through thesmokestack (see Fig. 10). We recommend M.T.H. ProtoSmoke, Seuthe, LGB, or LVTSfluids. Do not overfill the unit or the fluid may leak out and coat the interior enginecomponents.If you choose not to add the fluid (or have already added the fluid but choose to runsmoke-free), turn off the smoke unit switch located under the engine. Failure either toadd fluid to the unit or to turn it off may damage the smoke unit heating element and/orwicking material.When the smoke output while running the engine begins to diminish, add another 10-15drops of smoke fluid or turn the smoke unit off.When storing the unit for long periods of time, you may want to add about 15 drops offluid to prevent the wick from drying out.After removing the engine from storage, add another 25 drops of fluid, letting the wicksoak up the fluid for 15 minutes prior to operation.If you experience poor or no smokeoutput when the smoke unit is on andhas fluid, check the wick to see if it hasbecome hard, blackened, andunabsorbent around the heating element.After removing the locomotive bodyfrom its chassis (See Figure 5), removethe smoke unit inspection cover (seeFig. 11). After removing the inspectioncover screws, lift the inspection plateaway and inspect the wick. If it isdarkly discolored and hard, it should bereplaced.Figure 11 : Smoke Unit InspectionInspection CoverScrewsReplacement parts and wickreplacement instructions are available directly from the M.T.H. Parts Department (orderonline: www.mth-railking.com, e-mail: parts@mth-railking.com; mail: 7020 ColumbiaGateway Drive, Columbia MD 21046-1532, FAX: 410-381-6122).<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 17

Troubleshooting Proto-Sound® 2.0 ProblemsAlthough Proto-Sound 2.0 has been designed and engineered for ease of use, you mayhave some questions during initial operation. The following table should answer mostquestions. If your problem cannot be resolved with this table, contact M.T.H. forassistance (telephone: 410-381-2580; fax: 410-423-0009; service@mth-railking.com,7020 Columbia Gateway Drive, Columbia MD 21046-1532).Starting UpWhen I first turn the power on, theengine will not begin to run. I have toturn the throttle off and then on againto get the engine to operate.Whistle/HornWhen I press the whistle/horn button,the bell comes on instead.I can’t get the horn to blow when Ipress the whistle button.BellWhen I press the whistle button, thebell sounds.I can’t get the bell to ring when I pressthe bell button.The bell won’t work on a separate bellbutton.CouplerWhen I try to fire the coupler, FYSstarts.The Proto-Coupler won’t let the engineuncouple on the fly.The coupler does not fire or staycoupled.RemedyThis is normal behavior. To preventaccidental high-speed start-ups,Proto-Sound 2.0 is programmed tostart up in neutral anytime track powerhas been turned off for severalseconds. See the "Basic Operation"section for more details.RemedyReverse the transformer leads.You may be pressing the button tooRemedyquickly. Try pressing the whistle/hornbutton more slowly, taking approximatelyone full second to fully depress thebutton.RemedyReverse the transformer leads.You may be pressing the button tooquickly. Try pressing the bell buttonmore slowly, taking approximately onefull second to fully depress the button.Check the wiring of the separatebutton.RemedyYou are waiting too long betweenwhistle button presses.Try lubricating the coupler knucklewith a dry graphite lubricant. Do NOTuse oil.The coupler needs to be cleaned.Wipe with denatured alcohol (notrubbing alcohol) and let dry.18 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

Cab ChatterSometimes the Cab Chatter soundsdon’t play.Lock-outI can’t get the engine to run after Ipower up the transformer. It sits stillwith the engine sounds running.The engine won’t lock into forward,neutral, or reverse.VolumeThe sounds seem distorted, especiallywhen the whistle or bell is activated.RemedyCab Chatter plays only in neutral atrandom intervals.RemedyThe engine is locked into the neutralposition. Follow the procedure in the“Lock into a Direction” section.<strong>Engine</strong> speed must be below 10 scalemph (approx. 10 volts or less inconventional mode).RemedyProto-Sound 2.0 volume is set toohigh. Turn the volume control knob onthe bottom of the chassis counterclockwiseto reduce the volume.BatteryThe engine will not leave the initialneutral setting.I get no sounds when the engine shiftsbetween directions.RemedyCheck to be sure the battery isinstalled and fully charged. See the“Self-Charging Battery Back-Up”section.The battery may be dead or need tobe charged. See the “Self-ChargingBattery Back-Up” section.After I turn off my transformer, myengine continues to make soundsbefore quitting.FYSThe FYS sounds occasionally repeatthemselves.Proto-Sound 2.0 is designed tocontinue to sound for a few secondsafter power to the track has been shutoff.RemedyProto-Sound 2.0 has a built-in randomnumber generator that randomlyselects each sound clip to play.Because there are a limited number ofsound clips available in each FYSsequence, it is probable that some ofthese sound clips will be repeatedfrom time to time.<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 19

FYSOnce in FYS, the engine doesn’t gointo reverse.When the FYS enters its lastsequence the bell automaticallycomes on.When FYS is enabled, pressing thewhistle and bell buttons has no effect.RemedySo that FYS effects can be as realisticas possible, Proto-Sound 2.0disables the reversing unitwhenever FYS is enabled. Thisway the engine remains still at itsstop as the operator cyclesthrough the FYS sequences.FYS is programmed to startringing the bell at that point. Afterapproximately 12 rings of the bell,it will automatically turn off.Because FYS must control variouseffects in each sequence, Proto-Sound 2.0 takes control of thesesound effects until you exit FYS.I push the direction button but the nextsound clip in the sequence does notplay or the engine does not come outof FYS after fourth press of thedirection button.Each FYS clip must play for approx.30 seconds before FYS will advanceto the next step in the FYS cycle.Wait at least 30 seconds in each FYSsound clip before pressing thedirection button.20 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

Transformer Compatibility and Wiring ChartProto-Sound 2.0 is designed to work with most standard AC transformers. The chartbelow lists the many compatible transformers. Note that many of the operationalcommands described in these instructions require a bell button, so if your transformerdoes not have its own bell button, you should consider adding one to get the full benefitof the system. In addition, the chart details how the terminals on these transformersshould be attached to your layout.TransformerModelCenter RailOutside RailMin/Max.VoltagePowerRatingTransformerType<strong>MTH</strong> Z-500 Red Terminal Black Terminal 0-18v 50-Watt Electronic<strong>MTH</strong> Z-750 Red Terminal Black Terminal 0-21v 75-Watt Electronic<strong>MTH</strong> Z-4000 Red Terminal Black Terminal 0-22v 390-Watt ElectronicLionel 1032 U A 5-16v 90-Watt StandardLionel 1032M U A 5-16v 90-Watt StandardLionel 1033 U A 5-16v 90-Watt StandardLionel 1043 U A 5-16v 90-Watt StandardLionel 1043M U A 5-16v 90-Watt StandardLionel 1044 U A 5-16v 90-Watt StandardLionel 1053 U A 8-17v 60-Watt StandardLionel 1063 U A 8-17v 60-Watt StandardAll-Trol Left Terminal Right Terminal 0-24v 300-Watt ElectronicDallee Hostler Left Terminal Right Terminal ElectronicLionel LW A U 8-18v 75-Watt StandardLionel KW A or B U 6-20v 190-Watt StandardLionel MWOutside TrackTerminalInside TrackTerminal5-16v 50V.A. ElectronicLionel RS-1 Red Terminal Black Terminal 0-18v 50V.A. ElectronicLionel RW U A 9-19v 110-Watt StandardLionel SW U A Unknown 130-Watt StandardLionel TW U A 8-18v 175-Watt StandardLionel ZWA,B,C or DU8-20v275-WattStandardLionel Post-WarCelebrationSeries ZWA,B,C or DCommon0-20v135/190 WattElectronic* Conventional Mode Only<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 21

Additional Features Accessible With The DCSRemote Control System(Additional equipment required)While conventional mode operation of a Proto-Sound 2.0 engine yields wonderfullyrealistic sound and several train control features, command mode operation allows theuser to access a world of command functions never before accessible to O Gaugerailroaders. With the addition of the DCS Remote Control System (including a DCSremote handheld and Track Interface Unit) users gain many advanced features, including:• DCS Proto-Speed Control - Establishes desired locomotive speed in scale milesper hour increments via a thumbwheel control and allows operator to setmaximum speed and acceleration/deceleration rates• ProtoSmoke® Variable Output Control - Controls how much smoke each engineoutputs and matches smoke to locomotive speed• Locomotive Lighting Control - Controls locomotive headlights, marker andinterior lights, beacon lights, ditch lights, and MARS lights• Emergency Stop-Single button push stops all Proto-Sound 2.0 trains but does notturn off the power• One Touch Global Mute/UnMute-Single button mutes or unmutes allDCS-controlled locomotives' user-defined actions, including sound, lights, andsmoke• Proto-Dispatch Operation-Public Address-like feature allows users to speakthrough locomotive speaker during operation• Proto-Cast-Allows users to play audio recordings through locomotive speakerduring operation• Proto-Doppler Sound Effects Set Up-Users can configure locomotive forDoppler Operation, including setting distance points for Doppler start, repeat,and stop modes• Independent Volume Control of <strong>Engine</strong> Sounds, Bell, Horn & Whistle for eachLocomotive• Control up to 50 different DCS-Equipped Locomotives at one time with multipleTIUs• Proto-Effects Set Up-User can select individual Proto-Effects operations tobe active or inactive, including cab chatter, train wreck sounds, coupler sounds,and wheel clickety-clack sounds• Direction Control Set Up-User can set initial individual start-up direction (startin forward or reverse) for double-heading operations• Locomotive Consist Set-up-User can determine locomotive values for consistmake-ups, allowing multiple locomotives belonging to a consist to operatetogether22 <strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong>

Service & Warranty InformationHow to Get Service Under the Terms of the Limited One-Year WarrantyWhen you suspect an item is defective, please check the operator's manual for standardoperation and trouble-shooting techniques that may correct the problem. Additionalinformation may be found on the M.T.H. Website. Should you still require service, followthe instructions below to obtain warranty service.First, e-mail, write, call or fax a M.T.H. Authorized Service Center (ASC) in your area to obtain RepairAuthorization. You can find the list of ASCs on the M.T.H. Website, www.mth-railking.com. Authori zed ServiceCenters are required to make warranty repairs on items sold onlyfrom that store; all other repairs may-- or may notbe done at the store's own discretion. If you did not purchase the item directly from the ASC, you will need toselect a National Authorized Service Center (NASC). These centers are compensated by M.T.H. to performwarranty service for any customer whose repair qualifies for warranty service. A list of NASC retailers can belocated on the M.T.H. Website or by calling 1-888-640-3700. Should the warranty no longer apply, you maychoose either an ASC or NASC retailer to service your M.T.H. Product. A reasonable service fee will be charged.CAUTION: Make sure the product is packed in its original factory packaging including its foam and plasticwrapping material to prevent damage to the merchandise. There is no need to return the entire set if only one ofthe components is in need of repair unless otherwise instructed by the Service Center.The shipment must beprepaid and we recommend that it be insured. A cover letter including your name, address, daytime p honenumber, e-mail address (if available), Return Authorization number (if required by the service center, a copy ofyour sales receipt and a full description of the problem must be included to facilitate the repairs. Please includethe description regardless of whether you discussed the problem with a service technician when contacting theService Center for your Return Authorization.Please make sure you have followed the instructions carefully before returning any merchandise for service.Authorized M.T.H. Service Centers are independently owned and operated and are not agents or representatives ofM.T.H. Electric <strong>Trains</strong>. M.T.H. assumes no responsibility, financial or otherwise, for material left in theirpossession, or work done, by privately owned M.T.H. Authorized Service Centers.If you need assistance at any time email <strong>MTH</strong> Service at service@mth-railking.com, or call 410 381-2580.Limited One-Year WarrantyAll M.T.H. products purchased from an Authorized M.T.H. Train Merchant are covered by this warranty.See our website at www.mth-railking.com or call 1-888-640-3700 to identify an Authorized M.T.H. Train Merchant near you.M.T.H. products are warrantied for one year from the date of purchase against defects in material or workmanship, excluding wearitems such as light bulbs, pick-up rollers, batteries, smoke unit wicks, and traction tires. We will repair or replace (at our option)the defective part without charge for the parts or labor, if the item is returned to an M.T.H. Authorized Service Center (ASC) orM.T.H. National Authorized Service Center (NASC) within one year of the original date of purchase. This warranty does not coverdamages caused by improper care, handling, or use. Transportation costs incurred by the customer are not covered under thiswarranty.Items sent for repair must be accompanied by a return authorization number, a description of the problem, and a copy of theoriginal sales receipt from an Authorized M.T.H. Train Merchant, which gives the date of purchase. If you are sending thisproduct to an Authorized Service Center, contact that Center for their return authorization.This warranty gives you specific legal rights, and you may have other rights that vary from state to state. Specific questionsregarding the warranty may be forwarded to M.T.H. directly.Service DepartmentM.T.H. Electric <strong>Trains</strong>7020 Columbia Gateway Drive.Columbia MD 21046-1532<strong>Premier</strong> <strong>SD40</strong>-2 <strong>Diesel</strong> <strong>Engine</strong> 23

AUTHORIZED SERVICE CENTER7020 Columbia Gateway Dr. - Columbia, MD 21046Information: 410-381-2580 Fax: 410-381-6122www.mth-railking.comCANADATOY TRAIN WORKSHOPCUMBERLAND613-833-8331THE TRAIN ROOMFERGUS519-787-3280CALIFORNIATIN PLATE JUNCTIONOAKLAND510-444-4780COLORADOMIZELL TRAINS INCWESTMINSTER303-429-4811CONNECTICUTNEW ENGLAND HOBBYSUPPLYMANCHESTER860-646-0610FLORIDAROUNDHOUSE SOUTHPORT ORANGE386-304-7002MARYLANDPLAZA HOBBYCUMBERLAND301-729-6424ENGINE HOUSE HOBBIESGAITHERSBURG301-590-0816PARTICIPATING N.A.S.C.RETAILER LISTCATOCTIN MOUNTAIN TRAINS& HOBBIESTHURMONT301-694-8331MICHIGANMICHIGAN MODEL TRAINCENTERPINCKNEY734-426-1651BRASSEUR ELECTRIC TRAINSINC.SAGINAW989-793-4753NEW HAMPSHIRETREASURED TOYSSALEM603-898-7224NEW YORKAURORA RAILS & HOBBIESEAST AURORA716-652-5718OHIODAVIS ELECTRONICSMILFORD513-831-6425RICK'S TOY TRAINSTOLEDO419-478-0171PENNSYLVANIABUSSINGER TRAINSAMBLER215-628-2366FAIRCHANCE PHARMACYFAIRCHANCE724-564-7817TOBY TYLER'S HOBBYCENTERPITTSBURGH412-653-5030VIRGINIALOCUST GROVE TRAINSLOCUST GROVE540-854-8955DAVIS HOBBY SUPPLIESPORTSMOUTH757-397-1983T S G HOBBIESWARRENTON540-347-9212WISCONSINSOMMERFELD'S TRAINSBUTLER262-783-7797GRAMPA'S TRAIN SHOPRICE LAKE715-234-2996

AUTHORIZED SERVICE CENTER7020 Columbia Gateway Dr. - Columbia, MD 21046Information: 410-381-2580 Fax: 410-381-6122www.mth-railking.comCANADATOY TRAIN WORKSHOPCUMBERLAND613-833-8331THE TRAIN ROOMERGUS519-787-3280CREDIT VALLEY RAILWAYCOMPANYSTREETSVILLE905-826-1306B H TRAINSTERREBONNE450-492-0317ALABAMASOUTHERLAND STATIONHUNTSVILLE256-533-4720LIL' BOBBY'S HOBBIESMONTGOMERY334-277-1715ARIZONAARIZONA TRAIN DEPOTMESA480-833-9486CALIFORNIACENTRAL COAST TRAINSATASCEDERO805-466-1391TRAIN SHACKBURBANK818-842-3330ROUNDHOUSENORTH HOLLYWOOD818-769-0403PARTICIPATING A.S.C.RETAILER LISTDOLLHOUSES TRAINS & MORENOVATO415-883-0388TIN PLATE JUNCTIONOAKLAND510-444-4780RON'S WORLDSAN CLEMENTE949-361-5596TRUCKS & TRAINS HOBBIESSANTA ROSA707-537-6586COLORADOCUSTOM RAILWAY SUPPLYCOLORADO SPRINGS719-634-4616CABOOSE HOBBIESDENVER303-777-6766MIZELL TRAINSWESTMINSTER303-429-4811CONNECTICUTNEW ENGLAND HOBBYSUPPLYMANCHESTER860-646-0610FLORIDAHOLLYWOOD STATIONHOLLYWOOD954-921-2700DEPOT HOBBY SHOPLAKE WORTH561-585-1982READY TO ROLLMIAMI305-688-8868FRANK'S TRAINS & HOBBIESOLDSMAR813-855-1041COLONIAL PHOTO & HOBBYORLANDO407-841-1485WARRICK CUSTOM HOBBIESPLANTATION954-370-0708ROUNDHOUSE SOUTHPORT ORANGE386-304-7002ILLINOISBIKE & CHOO CHOOCONNECTIONSCHAUMBURG847-882-7728INDIANAY. O. R. K. TRAINSMUNSTER219-838-9999SAMUELSON'S TRAIN SHOPVALPARAISO219-462-2708IOWACABOOSE STOP HOBBIESCEDAR FALLS800-642-7012KENTUCKYL&N TRAINS & THINGSLOUISVILLE502-897-9005LOUISIANAAMERICA'S TRAIN YARDBATON ROUGE225-926-5592

MAINEWHEELS, WINGS & THINGSLUDLOW207-532-6277MARYLANDPLAZA HOBBYCUMBERLAND301-729-6424HOBBYTOWN U S AFREDERICK301-694-7395ENGINE HOUSE HOBBIESGAITHERSBURG301-590-0816J & B TRAINSHAGERSTOWN240-420-4930THE TRAIN ROOMHAGERSTOWN301-745-6681PURKEY'S TOY TRAINSSYKESVILLE410-549-6061CATOCTIN MOUNTAIN TRAINS& HOBBIESTHURMONT301-694-8331MASSACHUSETTSNORTHEAST TRAINSPEABODY978-532-1615EAST BAY HOBBIESSEEKONK508-336-5573MICHIGANMICHIGAN MODEL TRAINCENTERPINCKNEY734-426-1651BRASSEUR ELECTRIC TRAINSINC.SAGINAW989-793-4753MISSOURISWITCH STANDSAINT LOUIS314-781-4458MARK TWAIN HOBBY CENTERST. LOUIS636-946-2816NEVADARENO RAILSRENO775-337-6669NEW HAMPSHIRERAILROAD SPECIALTIESNASHUA603-801-0801TREASURED TOYSSALEM603-898-7224NEW JERSEYCOUNTRY AND STUFFANDOVER973-786-7086COLUMBUS TRAIN STATIONCOLUMBUS609-518-1800ATLANTIC RAILSHAMMONTON609-567-8490GRAND CENTRAL STATIONKEARNY201-955-6200J & B TRAINS, INC.MAPLE SHADE856-414-0092HOBBY SHOPMATAWAN732-583-0505HOBBYMASTERS, INCRED BANK732-842-6020RIDGEFIELD HOBBYRIDGEFIELD201-943-2636TOM’S MODEL TRAINSSCOTCH PLAINS908-322-6122TRAINS & THINGSTRENTON609-883-8790COAST TRAINS ANDCOLLECTIBLESWALL732-556-9005HOLLY BEACH TRAIN DEPOTWILDWOOD609-522-2379NEW YORKAURORA RAILS & HOBBIESEAST AURORA716-652-5718NASSAU HOBBY CENTER, INC.FREEPORT516-378-9594HOBBY WORLDMONTICELLO845-794-8770CITY DEPOT, INC.NEW HAMPTON845-374-3010SCAG’S ELECTRIC TRAINSSTATEN ISLAND718-727-7373AMERICANA STORETIVOLI845-757-4246KROSS HARDWAREWEST BABYLON631-669-3069NORTH CAROLINATHE ROUNDHOUSE &BACKSHOPCARY919-465-0810TRAINS LTD.CHARLOTTE704-566-9070DRY BRIDGE STATIONMOUNT AIRY336-786-9811THE FREIGHT YARDSMITHFIELD919-934-6229TRAIN LOFTWINSTON-SALEM336-760-9817OHIOGLEN'S TRAIN SHOPAKRON330-253-6527E & S TRAINSAKRON330-745-0785T & K HOBBY SHOPBRIDGEPORT740-633-6607PARMA HOBBYCLEVELAND216-741-6440SANDY'S HOBBY'S &COLLECTIBLESELYRIA440-365-9999HUDSON TOY, TRAIN &HOBBYHUDSON330-653-2997CLEARVIEW TRAIN & HOBBYLORAIN440-277-4488DIXIE UNION STATIONMASON513-459-0460DAVIS ELECTRONICSMILFORD513-831-6425

TRAINS-N- THINGSNORTH CANTON330-499-1666GRAND PACIFIC JUNCTIONOLMSTEAD FALLS440-235-4777RICK'S TOY TRAINSTOLEDO419-478-0171ERIE RAILWAY DEPOTTROY937-440-9972PENNSYLVANIAAMERICAN HOBBY CENTERALIQUIPPA724-378-3930ALLENTOWN TOY TRAINSERVICEALLENTOWN610-821-0740ON THE RIGHT TRACKALTOONA814-942-4345BUSSINGER TRAINSAMBLER215-628-2366JIM’S HOBBY SERVICEBERWICK570-759-2695YE OLDE TRAIN & CHRISTMASSHOPPEBOYERTOWN610-369-0755NICHOLAS SMITHBROOMALL610-353-8585CHARLEROI SWEEPERCENTERCHARLEROI724-483-3397CRANBERRY HOBBY DEPOTCRANBERRY TWP724-776-3640FAIRCHANCE PHARMACYFAIRCHANCE724-564-7817TOY TRAIN STATIONFEASTERVILLE TREV215-322-5182THE CABOOSELEHIGHTON570-386-5352HOBBY CITYMC MURRAY724-942-2557THE STATIONNEW CUMBERLAND717-774-7096FRYER'S STOREORWIGSBURG570-366-2258CHESTNUT TOYBOXPHILADELPHIA215-545-0455TOBY TYLER'S HOBBYCENTERPITTSBURGH412-653-5030WILCOX GREENHOUSE &NURSERYTITUSVILLE814-827-3823EASTERN DEPOTTROY570-297-1975J&J RAILROAD CROSSINGTURTLE CREEK412-824-6009TRAINS R FUNFRAZER610-644-4585SOUTH CAROLINAEMERALD TRAIN & HOBBYGREENWOOD864-223-2247TENNESSEEMODEL RAILROAD & HOBBYSHOPMEMPHIS901-384-6500TEXASHOBBY TIMEAMARILLO806.352.9660RIVERVIEW TRAINSANGLETON979-848-3895GREAT TRAINS & HOBBIESLONGVIEW903-757-2720VIRGINIALEESBURG HOBBIESLEESBURG703-779-8600LOCUST GROVE TRAINSLOCUST GROVE540-854-8955TRAIN DEPOTMANASSAS703-335-2216CHESTERFIELD HOBBIESMIDLOTHIAN804-379-9091DAVIS HOBBY SUPPLIESPORTSMOUTH757-397-1983TOY TRAIN CENTERRICHMOND804-288-4475NUTBUSH EXPRESSVICTORIA434-696-1902T S G HOBBIESWARRENTON540-347-9212NORGE STAT IONWILLIAMSBURG757-564-7623WASHINGTONEASTSIDE TRAINSKIRKLAND425-828-4098WEST VIRGINIAPATRICK'S TRAINSWHEELING304-232-0714WISCONSINWOODCRAFTERS SHOPBURLINGTON262-763-5239SOMMERFELD'S TRAINSBUTLER262-783-7797HOBBY OUTLETFOND DU LAC920-924-3770G B T V & TRAINSGREEN BAY920-496-9697GRAMPA'S TRAIN SHOPRICE LAKE715-234-2996THE TRAIN STOREWAUKESHA262-650-6675