Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

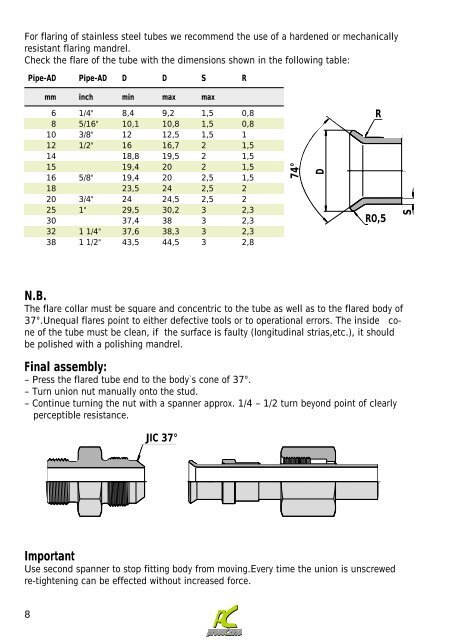

For flaring of stainless steel tubes we recommend the use of a hardened or mechanicallyresistant flaring mandrel.Check the flare of the tube with the dimensions shown in the following table:Pipe-AD Pipe-AD D D S Rmm inch min max max6 1/4" 8,4 9,2 1,5 0,88 5/16" 10,1 10,8 1,5 0,810 3/8" 12 12,5 1,5 112 1/2" 16 16,7 2 1,514 18,8 19,5 2 1,515 19,4 20 2 1,516 5/8" 19,4 20 2,5 1,518 23,5 24 2,5 220 3/4" 24 24,5 2,5 225 1" 29,5 30,2 3 2,330 37,4 38 3 2,332 1 1/4" 37,6 38,3 3 2,338 1 1/2" 43,5 44,5 3 2,874°DRRO,5SN.B.The flare collar must be square and concentric to the tube as well as to the flared body of37°.Unequal flares point to either defective tools or to operational errors. The inside coneof the tube must be clean, if the surface is faulty (longitudinal strias,etc.), it shouldbe polished with a polishing mandrel.Final assembly:– Press the flared tube end to the body`s cone of 37°.– Turn union nut manually onto the stud.– Continue turning the nut with a spanner approx. 1/4 – 1/2 turn beyond point of clearlyperceptible resistance.JIC 37°ImportantUse second spanner to stop fitting body from moving.Every time the union is unscrewedre-tightening can be effected without increased force.8