Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

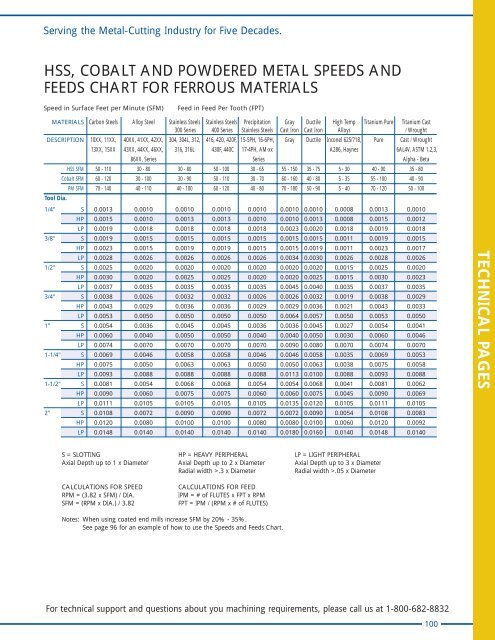

Serving the Metal-Cutting Industry for Five Decades.HSS, COBALT AND POWDERED METAL SPEEDS ANDFEEDS CHART FOR FERROUS MATERIALSSpeed in Surface Feet per Minute (SFM)Feed in Feed Per Tooth (FPT)MATERIALS Carbon Steels Alloy Steel Stainless Steels Stainless Steels Precipitation Gray Ductile High Temp Titanium Pure Titanium Cast300 Series 400 Series Stainless Steels Cast Iron Cast Iron Alloys / WroughtDESCRIPTION 10XX, 11XX, 40XX, 41XX, 42XX, 304, 304L, 312, 416, 420, 420F, 15-5PH, 16-6PH, Gray Ductile Inconel 625/718, Pure Cast / Wrought13XX, 15XX 43XX, 44XX, 46XX, 316, 316L 430F, 440C 17-4PH, AM-xx A286, Haynes 6AL4V, ASTM 1,2,3,86XX, Series Series Alpha - BetaHSS SFM 50 - 110 30 - 80 30 - 80 50 - 100 30 - 65 55 - 150 35 - 75 5 - 30 40 - 90 35 - 80Cobalt SFM 60 - 120 30 - 100 30 - 90 50 - 110 30 - 70 60 - 160 40 - 80 5 - 35 55 - 100 40 - 90PM SFM 70 - 140 40 - 110 40 - 100 60 - 120 40 - 80 70 - 180 50 - 90 5 - 40 70 - 120 50 - 100<strong>Tool</strong> Dia.1/4" S 0.0013 0.0010 0.0010 0.0010 0.0010 0.0010 0.0010 0.0008 0.0013 0.0010HP 0.0015 0.0010 0.0013 0.0013 0.0010 0.0010 0.0013 0.0008 0.0015 0.0012LP 0.0019 0.0018 0.0018 0.0018 0.0018 0.0023 0.0020 0.0018 0.0019 0.00183/8" S 0.0019 0.0015 0.0015 0.0015 0.0015 0.0015 0.0015 0.0011 0.0019 0.0015HP 0.0023 0.0015 0.0019 0.0019 0.0015 0.0015 0.0019 0.0011 0.0023 0.0017LP 0.0028 0.0026 0.0026 0.0026 0.0026 0.0034 0.0030 0.0026 0.0028 0.00261/2" S 0.0025 0.0020 0.0020 0.0020 0.0020 0.0020 0.0020 0.0015 0.0025 0.0020HP 0.0030 0.0020 0.0025 0.0025 0.0020 0.0020 0.0025 0.0015 0.0030 0.0023LP 0.0037 0.0035 0.0035 0.0035 0.0035 0.0045 0.0040 0.0035 0.0037 0.00353/4" S 0.0038 0.0026 0.0032 0.0032 0.0026 0.0026 0.0032 0.0019 0.0038 0.0029HP 0.0043 0.0029 0.0036 0.0036 0.0029 0.0029 0.0036 0.0021 0.0043 0.0033LP 0.0053 0.0050 0.0050 0.0050 0.0050 0.0064 0.0057 0.0050 0.0053 0.00501" S 0.0054 0.0036 0.0045 0.0045 0.0036 0.0036 0.0045 0.0027 0.0054 0.0041HP 0.0060 0.0040 0.0050 0.0050 0.0040 0.0040 0.0050 0.0030 0.0060 0.0046LP 0.0074 0.0070 0.0070 0.0070 0.0070 0.0090 0.0080 0.0070 0.0074 0.00701-1/4" S 0.0069 0.0046 0.0058 0.0058 0.0046 0.0046 0.0058 0.0035 0.0069 0.0053HP 0.0075 0.0050 0.0063 0.0063 0.0050 0.0050 0.0063 0.0038 0.0075 0.0058LP 0.0093 0.0088 0.0088 0.0088 0.0088 0.0113 0.0100 0.0088 0.0093 0.00881-1/2" S 0.0081 0.0054 0.0068 0.0068 0.0054 0.0054 0.0068 0.0041 0.0081 0.0062HP 0.0090 0.0060 0.0075 0.0075 0.0060 0.0060 0.0075 0.0045 0.0090 0.0069LP 0.0111 0.0105 0.0105 0.0105 0.0105 0.0135 0.0120 0.0105 0.0111 0.01052" S 0.0108 0.0072 0.0090 0.0090 0.0072 0.0072 0.0090 0.0054 0.0108 0.0083HP 0.0120 0.0080 0.0100 0.0100 0.0080 0.0080 0.0100 0.0060 0.0120 0.0092LP 0.0148 0.0140 0.0140 0.0140 0.0140 0.0180 0.0160 0.0140 0.0148 0.0140TECHNICAL PAGESS = SLOTTING HP = HEAVY PERIPHERAL LP = LIGHT PERIPHERALAxial Depth up to 1 x Diameter Axial Depth up to 2 x Diameter Axial Depth up to 3 x DiameterRadial width >.3 x DiameterRadial width >.05 x DiameterCALCULATIONS FOR SPEEDRPM = (3.82 x SFM) / DIA.SFM = (RPM x DIA.) / 3.82CALCULATIONS FOR FEEDIPM = # of FLUTES x FPT x RPMFPT = IPM / (RPM x # of FLUTES)Notes: When using coated end mills increase SFM by 20% - 35%.See page 96 for an example of how to use the Speeds and Feeds Chart.For technical support and questions about you machining requirements, please call us at 1-800-682-8832100