Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Has quality changed?<br />

H<br />

News and events<br />

Nobody does it better as quality changed or has our perception<br />

of it changed?<br />

Cereals 9 – 10 June 2010<br />

WR200<br />

ohn Reynolds from Cromer wrote<br />

J to us after seeing the Maxtron<br />

Sugar Beet Harvester working –<br />

‘ Dear Sirs,<br />

Forty seven years ago the following article was published in a<br />

Farmers Weekly Potato Supplement. It would seem the pressure of<br />

gentle handling was very much in the forefront then as it is indeed<br />

now. The messages we receive from our customers is to provide<br />

equipment which will produce gentle but efficient potato harvesting<br />

and handling equipment. We should be proud that the message from<br />

Near Royston, Hertfordshire, Post code for park and ride system SG8 5LX<br />

Potatoes In Practice 12 August 2010<br />

Balruddery Farm, Invergowrie, By Dundee DD2 5LJ<br />

Two row windrower<br />

his semi-mounted windrower is<br />

T<br />

designed to work on the flat and on<br />

slopes and to operate with minimum<br />

Since leaving school I have seen and<br />

operated in 69 beet harvest and never did<br />

I imagine that a beet harvester could ever<br />

be invented to harvest beet better than by<br />

1963 is still basically the same. – we must be doing something right.<br />

Degrees of Damage<br />

Undamaged Scuffing – skin broken but no damage to underlying<br />

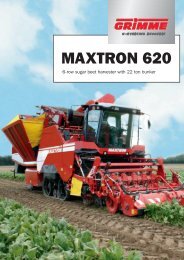

Rexor 620<br />

The efficient way to harvest sugar beet<br />

horsepower (70hp).<br />

hand work your machine which I have just<br />

seen operating locally does. Well done to<br />

the manufacturers and does a perfect job.<br />

tissue. No economic importance, but can lead to excessive water<br />

loss, shrivelling and rot infection<br />

Peeler Damage – acceptable to general trade as it can be<br />

utomotive steering, a turning circle of just 7.5m and 40kph<br />

A road speed make the new Rexor the most agile and fastest<br />

Yours truly, J Reynolds.’<br />

removed by domestic peeler, Not suitable for pre-pack trade.<br />

sugar beet harvester in the World.<br />

Severe Damage – should not be sold as ware according to the<br />

<strong>Grimme</strong> has increased cropflow by around 70% and with the high<br />

We replied<br />

proscriptive regulations of the PMB (the bushel weight of potatoes<br />

performance Defoliator FM 300 or the advanced inline FT 300 front<br />

Thank you very much for your kind letter<br />

about the <strong>Grimme</strong> Sugar Beet Harvester.<br />

It certainly has caused some comments<br />

within the <strong>Grimme</strong> organisation, not only<br />

about the machine but also about yourself<br />

varies between 52 and 60cu ft a ton for practical purposes 56cu ft<br />

is taken as standard).<br />

Eleven Points for Damage Protection<br />

•Drop 9’ maximum on to hard surface 18’ on another potato<br />

•Cover all sharp edges with rubber<br />

topper and up to 70% better crop-flow it’s also the most productive.<br />

A 22 tonne bunker with moving floor technology ensures fast gentle fill<br />

and discharge and there’s plenty of power from REXOR’s 490hp engine.<br />

Add to this its advanced drive, control and hydraulic systems and it’s the<br />

most economical too.<br />

A main web links to a variety of options<br />

including second web or separator, cross<br />

conveyor and/or fine haulm elevator. Crop can<br />

either be set to one side of the windrower or<br />

and the vast changes you will have<br />

•Adjust baffles and boards on machinery to do the least possible<br />

behind the machine.<br />

experienced over the 69 years.<br />

I do not know if you would agree to have<br />

your photograph in a magazine which<br />

<strong>Grimme</strong> publishes and direct mails to our<br />

<strong>UK</strong> customer base, perhaps with a short<br />

resume of your experiences. Perhaps I could<br />

ask Glyn Argent who lives in Norfolk to call<br />

and talk to you about this sometime in the<br />

near future? Glyn is our area sales manager<br />

for East Anglia.<br />

In the meantime thank you for your<br />

correspondence.<br />

damage<br />

•Slats on boxes can be as little as ¼’ apart<br />

•Where not used for storage, boxes could be made of plywood<br />

•When walking over a stored crop, wear rubber boots or use planks.<br />

•Use a pusher for levelling not a fork Potato forks can be lethal.<br />

•Keep them in trim, use with care Transport all loads carefully<br />

over rough ground<br />

•Use wicker, plastic or rubber baskets in preference to wire or<br />

galvanised buckets<br />

•Point out the cost of damage and train all staff to treat the crop<br />

like eggs than spuds.<br />

Extract from Farmers Weekly August 9th 1963 By kind<br />

Robust, low maintenance digging technology<br />

offers a cost-effective higher output two row<br />

harvesting system without the need for a<br />

bunker or trailers running alongside the<br />

harvester when opening up fields.<br />

Minimising drop heights and fewer working<br />

parts significantly reduce the chances of<br />

damaging the crop,<br />

Rear wheel steering improves manoeuvrability,<br />

while levelling rams on each side of the machine<br />

and the pivot point at the front follow the<br />

Sincerely, <strong>Grimme</strong> <strong>UK</strong><br />

permission of Museum of English Rural Life<br />

ground and keep the digging web level.<br />

NOBODY DOES IT BETTER HAS QUALITY CHANGED NEWS AND EVENTS NEW PRODUCTS