Specalog for 267B/277B/287B Multi Terrain Loaders ...

Specalog for 267B/277B/287B Multi Terrain Loaders ...

Specalog for 267B/277B/287B Multi Terrain Loaders ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

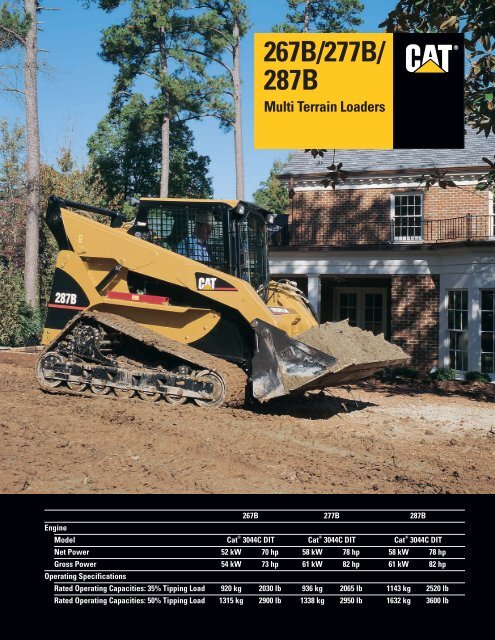

<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong><strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong>®<strong>267B</strong> <strong>277B</strong> <strong>287B</strong>EngineModel Cat ® 3044C DIT Cat ® 3044C DIT Cat ® 3044C DITNet Power 52 kW 70 hp 58 kW 78 hp 58 kW 78 hpGross Power 54 kW 73 hp 61 kW 82 hp 61 kW 82 hpOperating SpecificationsRated Operating Capacities: 35% Tipping Load 920 kg 2030 lb 936 kg 2065 lb 1143 kg 2520 lbRated Operating Capacities: 50% Tipping Load 1315 kg 2900 lb 1338 kg 2950 lb 1632 kg 3600 lb

<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong>Designed and built by Caterpillar to deliver exceptional per<strong>for</strong>mance and versatility,ease of operation, serviceability and customer support.Operator StationOperator com<strong>for</strong>t and ease of operationare designed into the operator’s stationfrom every aspect including ergonomicfeatures such as low-ef<strong>for</strong>t joystickcontrols and an adjustable contouredseat. pg. 4Rubber Track UndercarriageThe unique rubber track undercarriageand suspension provide exceptionalflotation, traction and stability withminimal pressure on the ground.pg. 6<strong>287B</strong> Vertical Lift LinkageThe vertical lift linkage is an efficientand lightweight design that provideshigh load carry capacity. pg. 7Quick Coupler and Cat Work ToolsThe universal work tool interface andquick coupler helps make the Cat <strong>Multi</strong><strong>Terrain</strong> Loader the most versatilemachines on the job site. Add the widerange of per<strong>for</strong>mance-matched CatWork Tools <strong>for</strong> maximum utility andproduction. pg. 11Customer SupportCaterpillar dealers offer unmatchedcustomer support, with excellentwarranty programs and fast partsavailability, resulting in maximumuptime and minimum repair costs.Equipment maintenance services helpoptimize machine per<strong>for</strong>mance andreliability. pg. 12The Caterpillar <strong>Multi</strong> <strong>Terrain</strong> Loader, withits many work tool options, is a highlyversatile, compact construction machine.It is designed to deliver traditional Catreliability and productivity in the toughestworking conditions.2

High Per<strong>for</strong>mance Power TrainThe Cat 3044C DIT engine provideshigh engine horsepower and torque,allowing part-throttle operation <strong>for</strong>lower sound levels and lower fuelconsumption. Anti-stall featuremaximizes power to the drive trainand work tools without stalling theengine. pg. 8Advanced Hydraulic SystemThe hydraulic system in the Cat <strong>Multi</strong><strong>Terrain</strong> Loader is designed <strong>for</strong> maximumpower and reliability. More hydraulicpower means better overall per<strong>for</strong>mance.Fewer components mean fewer hydraulicconnections and reduced chance of leaks.pg. 9ServiceabilityThe Cat <strong>Multi</strong> <strong>Terrain</strong> Loader offersquick and easy routine maintenance andservice. The rear door opens 90 degreesand the cooling package tilts up out ofthe way <strong>for</strong> the unparalleled access tothe engine compartment. The cab alsotilts up <strong>for</strong> easy access. pg. 103

Operator StationWorld-class operator station provides exceptional working com<strong>for</strong>t with excellent visibility,enhanced fingertip controls and optimum instrumentation.Operator StationLow Ef<strong>for</strong>t Machine Controls.Ergonomic, pilot hydraulic controlsgive operators precision control ofCat <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> with minimalef<strong>for</strong>t. The right joystick controls loaderup/down and tilt control and the leftjoystick controls <strong>for</strong>ward and reversetravel speed plus direction. Both joysticksuse an intuitive “S” control pattern.Optional deluxe joysticks now providemore auxiliary controls than be<strong>for</strong>e,using positive-action buttons to provideprecision fingertip control of manymachine functions, including:• Proportional work tool hydraulics• Work tool electricalBasic and Deluxe joystick functionsinclude:• One-touch continuous auxiliaryhydraulic flow• Momentary auxiliary hydraulic flowCab Conveniences. Long hours in theCat <strong>Multi</strong> <strong>Terrain</strong> Loader are madeeasier by many standard conveniencesthat include a new 12 volt DC powersocket. Side, sliding windows offerprotection from the elements and allowfresh air ventilation. Redesigned sidewindows are now removable <strong>for</strong> easycleaning. Cabs with the door optioninstalled feature a new, automaticlock-out switch that prevents accidentaldamage by disabling the loaderfunctions when the door is open.High-Efficiency Climate Controls.Operating in extreme temperatures canbe more com<strong>for</strong>table with the optionalcab air conditioner and heater installed.Airflow is increased up to 83 percent andis now directed through six adjustablevents. Twice as many vents makedefrosting the optional front door andside windows easier. The heater and airconditioner can be ordered separatelyor together.Instrumentation. Cat <strong>Multi</strong> <strong>Terrain</strong>Loader instrument panels and gaugesare simple, easy to use and reliable.Bright indicator lights and audiblewarnings signal any critical systemsituation. Positive feel switches, withstatus lights, control most on/offfunctions. An engine air cleanerrestriction indicator is now in thecab <strong>for</strong> easier monitoring.4

Visibility. Operating ease and productivityare enhanced on the Cat <strong>Multi</strong> <strong>Terrain</strong>Loader by excellent visibility. The widecab opening offers an exceptional viewof the work tool. The sloped angle ofthe engine compartment allows excellentvisibility to the rear of the machine.A new, standard convex rearview mirrorgives the operator a panoramic view ofthe machine’s rear and sides. For bettervisibility in low-light conditions,the standard <strong>for</strong>ward lights are nowadjustable 10 degrees in any direction.Access/Egress. The Cat <strong>Multi</strong> <strong>Terrain</strong>Loader cab is designed to make machineoperation simple, productive andcom<strong>for</strong>table. Getting in and out of thecab is easy through a wide opening withthree point grab irons and skid-resistantsteps. Tilt cylinders are neatly locatedunder the lift arms so not to interferewith operator access and egress. Plentyof uncluttered floor space makes steppinginto the cab even easier.Cab Packages. Several cab packagesand options are available. The standardcab offers features such as an adjustablecontoured seat, cushioned contouredarmbar, dual throttle controls, pilotoperated joysticks, 12 volt DC powersocket and optional cup holder.Excellent Visibility5

Rubber Track UndercarriageThe unique rubber track undercarriage provides low ground pressure, stability,high traction, fast travel and suspension.Rubber Track UndercarriageRubber Track Undercarriage withSuspension. The rubber trackundercarriage transfers machine weightto the ground through wheeled contactpoints. The machine weight is distributedevenly throughout the track.Large Contact Area. The large groundcontact area helps maximize tractionand minimize ground pressure.Positive Track Drive. The elevatedpositive track drive keeps drivecomponents away from ground debris.Durable Rubber Track. The rugged,durable rubber track is lightweight andpliable, yet rein<strong>for</strong>ced with high tensilestrength cords.Torsion Axles. The heavy dutytorsion axles suspend each side ofthe undercarriage from the machineframe to absorb most of the shock,especially over rough conditions,<strong>for</strong> smooth travel.<strong>Multi</strong>ple Suspension Levels.The <strong>267B</strong>/<strong>277B</strong> undercarriage offersmultiple levels of suspension throughtwo torsion axles and six articulatingwheel carriages.6

<strong>287B</strong> Vertical Lift LinkageDesigned and built <strong>for</strong> operation in the toughest working conditions requiringvertical lifting capabilities.Lift Arms. The loader lift arms arepurpose-designed to provide asubstantially straight load path into themachine and a good viewing area tothe work tool and side of the machine.The lift arms are also designed tohandle heavy loads without twistingand bending <strong>for</strong> exceptional reliability.Spherical Bearing. The sphericalbearing distributes the load from thelift arms into the frame by allowing thepin to rotate and pivot within the bore,reducing the chance of developingfatigue cracks in the arms.Vertical Lift PathRadial Lift PathVertical Lift7

High Per<strong>for</strong>mance Power TrainThe Caterpillar hystat power train delivers aggressive per<strong>for</strong>mance and easy operation.Anti-Stall Feature. The anti-stall systemon the Cat <strong>Multi</strong> <strong>Terrain</strong> Loader allowsmaximum power to the tracks whileminimizing engine stalling. The systemhelps maximize productivity <strong>for</strong>experienced operators and makes iteasier <strong>for</strong> novice operators to becomeproductive.Closed-Loop, High Output, HydrostaticSystem. The dual, closed-loop, axialpiston hydrostatic pumps are drivendirectly off the engine. The pumpsprovide pressure and flow to two fixeddisplacement motors that power thefinal drive motors, driving the tracks.No chains are used.Aggressive Per<strong>for</strong>manceCat Diesel Power. The heart of theCat <strong>Multi</strong> <strong>Terrain</strong> Loader power train isthe Caterpillar 3044C DIT diesel engine.This rugged, reliable, four cylinderengine offers aggressive per<strong>for</strong>manceand a fast torque curve <strong>for</strong> quickresponse. It is also a low emissionengine, fully U.S. EPA Tier 2 andEU Stage II compliant.Dual Engine Throttle Controls. The handand foot throttles allow the operator tomatch engine speed to the task. Thehand throttle is ideal <strong>for</strong> jobs requiringconsistent engine speed — such as coldplaning, trenching or snow blowing.The foot throttle lets the operator varyengine speed and minimizes fuelconsumption <strong>for</strong> other tasks such asload and carry, truck loading, gradingand dozing.8

Advanced Hydraulic SystemHydraulic system has built-in reliability and provides exceptional lift, breakout and auxiliarypower to work tools.Power and Reliability. Maximumpower and reliability are built into theCat <strong>Multi</strong> <strong>Terrain</strong> Loader hydraulicsystem. In addition to providing powerto drive the tracks, this system alsoprovides the loader lift and tilt functions,powers the auxiliary circuit to drivework tools and drives the enginecooling fan.Hydraulic Pumps. The hydraulic pumpsare driven directly off the engine <strong>for</strong>maximum hydraulic per<strong>for</strong>mance andreliability — no belts are used. Pumpsare fixed-displacement and provide81 L/min (22 gal/min) at high idle.Maximum system pressure <strong>for</strong> theloader and standard auxiliary circuitsis 23 000 kPa (3335 psi). High Flow XPSis an option <strong>for</strong> the <strong>287B</strong>. A load sensing,variable displacement piston pumpprovides flow and pressure <strong>for</strong> the<strong>287B</strong> loader and auxiliary circuit at125 L/min (33 gal/min) at high idle.Maximum system pressure <strong>for</strong> theHigh Flow auxiliary circuit is 28 000 kPa(4060 psi). Control of the loader liftand tilt functions is by hydraulicallyoperatedjoystick controls <strong>for</strong> low ef<strong>for</strong>tand precise operation.Auxiliary Hydraulics. Standard auxiliaryhydraulics to power work tools is availablethrough quick connect hydraulic couplingsthat are rigidly mounted to the loaderarm. The Caterpillar line of high pressureXT ES hoses and O-ring face sealshelp assure a leak-free system.Reliability and Cleanliness. Hydraulicsystem reliability and cleanliness areimproved by using single componentsin place of multiple components, suchas the monoblock hydraulic valve andmonoblock pumps. Fewer leak pointsimprove reliability and result in a cleanermachine. In addition, hydraulic oil flowsthrough a 5-micron spin-on filter. A filterrestriction indicator is located in theoperator station. A 74-micron screen inthe hydraulic tank prevents larger debrisfrom entering the system and causingdamage to the hydraulic components.Powerful and ReliableHydraulic Oil Cooler. A high-efficiency,hydraulic oil cooler lets the Cat <strong>Multi</strong><strong>Terrain</strong> Loader work longer and harderin higher ambient temperatures, evenwhen using continuous flow worktools. The high capacity, hydraulicoil reservoir also helps keep operatingtemperatures lower.<strong>287B</strong> High Flow XPS. Maximum pressurecan be maintained regardless of thework tool speed or conditions with thisload sensing, pressure compensatingsystem. Hydraulic power is maximized<strong>for</strong> any given load with a variabledisplacement, axial piston pump thatallows high pressure at any given speed<strong>for</strong> high hydraulic power at low orhigh idle.9

ServiceabilityQuick access and superior design make the Cat <strong>Multi</strong> <strong>Terrain</strong> Loader easy to serviceand maintain.Tilting CabService Access. The rear door opens90 degrees <strong>for</strong> easy access to bothsides of the in-line (lengthwise)mounted engine.Filters. All filters are easily accessible,which makes routine service quickerand virtually spill-free.Cooling System. The radiator, hydraulicoil cooler and grill tilt up to increaseaccess to the cooling system duringmaintenance and allow easier cleaningof debris from between the grill andcooling packages. The cooling fan ishydraulically-driven <strong>for</strong> quieter operationand to eliminate the service andmaintenance that comes with beltdriven fans.Easy Tilting Cab. The machine cab cannow be tilted rearward by an individualusing a single tool. The cab is held inplace by a self-latching mechanism.When the cab is tilted back, all hydraulicpumps, motor, valves, lines and fuel tankare accessible <strong>for</strong> quicker, easier service.Removable Belly Pan. A removablebelly pan section in the floor of themachine’s lower frame providesexcellent access <strong>for</strong> periodic cleaning.Electrical and Hydraulic Lines. Cleanerrouting of electrical and hydraulic linescompared to <strong>for</strong>mer models improvesreliability and simplifies service.Maintenance Points. Maintenancepoints are grouped in easily accessiblelocations.Caterpillar Scheduled Oil Sampling(S•O•S SM ). The scheduled oil samplingvalves are standard to allow regularmonitoring of the engine and hydraulicoil quality.Other Standard Service Features.The following help make servicingfast and easy:• Easy access to battery, air filter andsingle engine belt• Sight glasses on hydraulic tank andradiator allow quick, easy level checks• Air filter restriction indicator nowlocated inside the operator station• Ecology drains simplify changingengine and hydraulic oil• Grease fittings are countersunkto prevent damage• Extended life coolant and 500-hourengine oil change intervals10

Quick Coupler and Cat Work ToolsChoose from a wide variety of tools that are per<strong>for</strong>mance matched to theCat <strong>Multi</strong> <strong>Terrain</strong> Loader.Optional Quick CouplerQuick Coupler. Work tools can bechanged quickly and easily with theCat <strong>Multi</strong> <strong>Terrain</strong> Loader’s quickcoupler system. The universal couplerinterface features:• Low profile side plate designed <strong>for</strong>optimum match to work tools andminimal material packing• Opposing wedges ensure a tight toolfit, even after years of use• Rugged design and large contact areaabsorbs loads and minimizes stress• Vertical pins are chrome plated andlubricated <strong>for</strong> smooth engagementand prevention of corrosion• Coupler allows excellent visibilityto work tools and unobstructed entryand exit to the cabThe standard quick coupler featuresmanual engagement and disengagementof work tools using two high leveragehandles.An optional hydraulic quick coupler isalso available and allows engagementand disengagement of work tools withoutthe operator needing to exit the machine.Control of the coupler by use of a rockerswitch inside the cab makes work toolchanges quicker and easier.Cat SG16 Stump GrinderCat Work Tools. Cat Work Tools extendthe versatility of the Cat <strong>Multi</strong> <strong>Terrain</strong>Loader. Designed and built <strong>for</strong> optimumper<strong>for</strong>mance and durability, these toolsdeliver high productivity, long servicelife and excellent value:• Angle blades• Augers• Backhoes• Brooms• Brush cutters• Buckets- Dirt- General purpose- Light material- <strong>Multi</strong> purpose- Utility• Cold planers• Compactor, vibratory• Grapples• Hammers• Landscape rakes• Landscape tillers• Material handling arm• Mulchers (<strong>for</strong> HF XPS <strong>287B</strong> only)• Pallet <strong>for</strong>ks• Snowblower• Stump grinder• Trenchers• Utility <strong>for</strong>ks• Wheel saw11

Customer SupportCat dealer services help you operate longer with lower costs.Worldwide Parts AvailabilityMachine Selection. With five differentCat <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> to choosefrom, selecting the right machine iseasy when you consult your Caterpillardealer. Your dealer helps you makedetailed machine comparisons be<strong>for</strong>eyou purchase.You can also build the machine that isright <strong>for</strong> you. Go on-line anytime toreview the full range of features andoptions available using the Build andQuote application on your Cat dealer’swebsite or www.cat.com.Purchase Options. Purchase optionslet you look beyond the initial machineprice. With your Cat dealer, you canreview available financing optionsplus look at day-to-day operating costs.You can also look at dealer servicesthat can be included in the cost of themachine to yield lower equipmentowning and operating costs over thelife of the machine.Customer Support Agreements.Customer Support Agreementsoffer you a variety of service andmaintenance options that can becustomized to best fit your specificneeds. These can cover the entiremachine and included work toolsto help protect your investment.Machine Support. Machine support isone of your Cat dealer’s primary goals.Nearly all parts are available at yourCat dealer. If not, your dealer can usethe Caterpillar worldwide computernetwork to find the closest in-stockparts to minimize machine downtime.Your Cat dealer can also save you moneyby suggesting Cat Remanufactured partsthat carry the same warranty as new,but with savings of 40 to 70 percent.Service Plans. Maintenance ServicePlans help you manage machinemaintenance. Choose from a widerange of maintenance plans and servicesat the time you purchase a machine.Repair option plans guarantee thecost of repairs up front. Diagnosticsprograms such as Scheduled OilSampling, Coolant Sampling andTechnical Analysis help you avoiddowntime and unscheduled repairs.Training. Operator training by Catdealers can improve your operator’stechniques and help boost your profits.Your Cat dealer also has trainingvideo tapes, literature, applicationand equipment training courses, plusother ideas to help you maximize yourmachine investment.Security Systems. Cat machine securitysystems help you manage your Cat <strong>Multi</strong><strong>Terrain</strong> Loader. This dealer-installedoption provides control of machineaccess by untrained operators orunauthorized personnel. Use up to50 unique key ID’s to customize machineaccess to fit your needs. You can programthis system to allow access only duringcertain hours or days.Repair, Rebuild or Replace. The repair,rebuild or replace choices become evenmore evident when you consult yourCaterpillar dealer. Your Cat dealer canhelp evaluate the costs involved so youcan make the right decision every time.12

EngineModel- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> Cat 3044C DITGross Power SAE J1995- <strong>267B</strong> 54 kW 73 hp- <strong>277B</strong>/<strong>287B</strong> 61 kW 82 hpEngine Power ISO 14396- <strong>267B</strong> 53 kW 71 hp- <strong>277B</strong>/<strong>287B</strong> 60 kW 80 hpNet Power 80/1269/EEC- <strong>267B</strong> 53 kW 71 hp- <strong>277B</strong>/<strong>287B</strong> 59 kW 78 hpNet Power ISO 9249- <strong>267B</strong> 53 kW 71 hp- <strong>277B</strong>/<strong>287B</strong> 59 kW 78 hpNet Power SAE 1349- <strong>267B</strong> 52 kW 70 hp- <strong>277B</strong>/<strong>287B</strong> 58 kW 78 hpDisplacement- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 3.3 L 201 in 3Bore- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 94 mm 3.7 inStroke- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 120 mm 4.7 inWeightsOperating Weight- <strong>267B</strong> 4250 kg 9371 lb- <strong>277B</strong> 4269 kg 9411 lb- <strong>287B</strong> 4660 kg 10,275 lb- <strong>287B</strong> (HF XPS) 4721 kg 10,409 lbOperating SpecificationsRated Operating Capacities:35% Tipping Load- <strong>267B</strong> 920 kg 2030 lb- <strong>277B</strong> 936 kg 2065 lb- <strong>287B</strong> 1143 kg 2520 lbRated Operating Capacities:50% Tipping Load- <strong>267B</strong> 1315 kg 2900 lb- <strong>277B</strong> 1338 kg 2950 lb- <strong>287B</strong> 1632 kg 3600 lbGround contact area- <strong>267B</strong>/<strong>277B</strong> 1.87 m 2 2898 in 2- <strong>287B</strong> 1.68 m 2 2610 in 2Ground Pressure- <strong>267B</strong>/<strong>277B</strong> 21.7 kPa 3.1 psi- <strong>287B</strong> 26 kPa 3.8 psiTipping Load- <strong>267B</strong> 2630 kg 5800 lb- <strong>277B</strong> 2676 kg 5900 lb- <strong>287B</strong> 3265 kg 7200 lbBreakout Force, Tilt Cylinder- <strong>267B</strong>/<strong>277B</strong> 2487 kg 5484 lb- <strong>287B</strong> 2498 kg 5508 lbBreakout Force, Lift Cylinder- <strong>267B</strong>/<strong>277B</strong> 2112 kg 4657 lb- <strong>287B</strong> 2372 kg 5230 lbDimensions shown are based on standard machine equippedwith 1981 mm (78 in) GP Bucket on the <strong>267B</strong>/<strong>287B</strong> and1981 mm (78 in) GP Bucket with Bolt-on Teeth on the <strong>277B</strong>.The specifications <strong>for</strong> the Cat <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> are staticand con<strong>for</strong>m to SAE J732 JUN 92, SAE J818 MAY87 andISO 5998:1986.<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> specifications13

Hydraulic SystemHydraulic Flow- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> Standard- <strong>287B</strong>* High Flow XPSLoader Hydraulic Pressure- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 23 000 kPa 3335 psi- <strong>287B</strong>* 28 000 kPa 4060 psiLoader Hydraulic Flow- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 83 L/min 22 gal/min- <strong>287B</strong>* 125 L/min 33 gal/minHydraulic Power- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 31.9 kW 42.8 hp- <strong>287B</strong>* 58.3 kW 78.3 hp* Designates specs in the high flow circuit when equippedwith the optional High Flow XPS.CabROPS- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> SAE J1040 MAY94,ISO 3471:1994FOPS- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> SAEJ/ISO 3449 APR98Level I, ISO 3449:1992Level IFOPS Level II- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> SAEJ/ISO 3449 APR 98Level II, ISO 3449:1992Level II (optional)Power TrainTravel Speed — Forward- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 11.2 kph 7 mphTravel Speed — Reverse- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 11.2 kph 7 mphService Refill CapacitiesCooling System- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 10 L 2.6 galEngine Crankcase- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 10 L 2.6 galFuel Tank- <strong>267B</strong>/<strong>277B</strong> 95 L 25.1 gal- <strong>287B</strong> 110 L 29.1 galHydraulic System- <strong>267B</strong>/<strong>277B</strong> 52 L 13.7 gal- <strong>287B</strong> 51 L 13.5 galHydraulic Tank- <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> 35 L 9.2 gal14<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> specifications

DimensionsAll dimensions are approximate.199136151775181014121112341 Length of Track on ground- <strong>267B</strong>/<strong>277B</strong> 2045 mm 81 in- <strong>287B</strong> 1842 mm 73 in2 Overall Length of track- <strong>267B</strong>/<strong>277B</strong> 2494 mm 98 in- <strong>287B</strong> 2293 mm 90.3 in3 Length w/o Bucket- <strong>267B</strong>/<strong>277B</strong> 2923 mm 115 in- <strong>287B</strong> 2901 mm 114 in4 Length w/Bucket on ground- <strong>267B</strong>/<strong>277B</strong> 3684 mm 145 in- <strong>287B</strong> 3697 mm 146 in5 Height to Top of Cab- <strong>267B</strong>/<strong>277B</strong> 2074 mm 82 in- <strong>287B</strong> 2123 mm 84 in6 Max Overall Height- <strong>267B</strong>/<strong>277B</strong> 4025 mm 158 in- <strong>287B</strong> 4182 mm 165 in7 Hinge Pin Height at max lift- <strong>267B</strong>/<strong>277B</strong> 3091 mm 122 in- <strong>287B</strong> 3250 mm 128 in8 Hinge Pin Height at carry position- <strong>267B</strong>/<strong>277B</strong> 251 mm 10 in- <strong>287B</strong> 218 mm 8.6 in9 Reach at max lift and dump- <strong>267B</strong>/<strong>277B</strong> 676 mm 27 in- <strong>287B</strong> 837 mm 33 in10 Clearance at max lift and dump- <strong>267B</strong>/<strong>277B</strong> 2349 mm 93 in- <strong>287B</strong> 2386 mm 94 in811 Ground Clearance- <strong>267B</strong>/<strong>277B</strong> 353 mm 14 in- <strong>287B</strong> 283 mm 11 in12 Departure Angle- <strong>267B</strong>/<strong>277B</strong> 62º- <strong>287B</strong> 47º13 Maximum Dump Angle- <strong>267B</strong>/<strong>277B</strong> 40º- <strong>287B</strong> 51º14 Vehicle Width- <strong>267B</strong>/<strong>277B</strong> 1898 mm 75 in- <strong>287B</strong> 1962 mm 77 in15 Turning Radius from center — left- <strong>267B</strong>/<strong>277B</strong> 1545 mm 60.8 in- <strong>287B</strong> 1615 mm 63.6 in16 Turning Radius from center — right- <strong>267B</strong>/<strong>277B</strong> 1603 mm 63.1 in- <strong>287B</strong> 1514 mm 59.6 in17 Turning Radius from center — full- <strong>267B</strong>/<strong>277B</strong> 2512 mm 98.9 in- <strong>287B</strong> 2433 mm 95.8 in18 Max Reach w/Arms Parallel to ground- <strong>267B</strong>/<strong>277B</strong> 1455 mm 57.3 in- <strong>287B</strong> 1378 mm 54.3 in19 Rack Back Angle at max height- <strong>267B</strong>/<strong>277B</strong> 97.4º- <strong>287B</strong> 87°16<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> specifications15

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer <strong>for</strong> details.CONTROLSPilot Operated Implement Control, RHPilot Operated Hydrostatic Transmission Control, LHHand and Foot ThrottleELECTRICAL12 volt Electrical System90 ampere AlternatorIgnition Key Start/Stop SwitchLights:Gauge BacklightingTwo Rear Tail LightsTwo Adjustable Front Halogen LightsDome LightOPERATOR ENVIRONMENTGauges:Fuel LevelHour MeterOperator Warning System Indicators:Air Filter RestrictionAlternator OutputArmrest Raised/Operator Out of SeatEngine Coolant TemperatureEngine Oil PressureGlow Plug ActivationHydraulic Filter RestrictionHydraulic Oil TemperaturePark Brake EngagedAdjustable Vinyl SeatPull Down Ergonomic Contoured ArmrestControl Interlock System, when operator leaves seator armrest raised:Hydraulic System DisablesHydrostatic Transmission DisablesParking Brake EngagesROPS Cab, Open, Tilt UpFOPS, Level ITop and Rear WindowsInterior Rear View Mirror12 volt Electric SocketPOWER TRAINCaterpillar 3044C DIT Diesel EngineDrain, Engine Oil EcologyFuel Priming PumpGlow Plugs Starting AidLiquid Cooled, Direct InjectionAir Cleaner, Dual Element, Radial SealS•O•S SM Sampling Valves, Engine Oil and Hydraulic OilFilter, Spin-on, HydraulicFilters, Bayonet-Type, Fuel and Water SeparatorTilt Up Radiator/Hydraulic Oil CoolerMuffler, StandardSpring Applied, Hydraulically Released,Wet <strong>Multi</strong> Disc Parking BrakesHydrostatic TransmissionRubber Track Drive (457 mm [18 in] wide)OTHER STANDARD EQUIPMENTEngine Enclosure — LockableExtended Life Antifreeze –36° C (–33° F)Machine Tie Down Points (4)Coupler, MechanicalSupport, Lift ArmHydraulic Oil Level Sight GaugeRadiator Coolant Level Sight GaugeRadiator Expansion BottleXT HoseAuxiliary, Hydraulics, Continuous FlowHeavy Duty, Flat Faced Quick DisconnectsSplit D-Ring to route Work Tool hoses along sideleft lift armElectrical Outlet, BeaconBelly Pan Cleanout16 <strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> specifications

Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer <strong>for</strong> details.Alarm, BackupBattery, Heavy Duty, 880 CCABelt, Seat, 75 mm (3 in), <strong>for</strong> Static SeatBelt, Seat, 75 mm (3 in), <strong>for</strong> Suspension SeatControl GroupsHornWork Tool Electrical (C1/C2 Switch)ProportionalDebris BarrierDoor, Front, Safety Glass with Wiper-WasherDoor, Front, Polycarbonate with Wiper-Washer(<strong>for</strong> Demolition use)Floormat, DeluxeFOPS, Level II (Attaches to existing FOPS)HeadlinerHeater and DefrosterAir Conditioning, Heater, DefrostEngine, Coolant HeaterHydraulics, Auxiliary, Front, ProportionalHydraulics, Auxiliary, Proportional High FlowXPS Hydraulics with case drain (<strong>287B</strong> only)Hydraulics, Self-LevelingHydraulic Quick CouplerLifting Eye, Single PointLifting Eyes, Four PointLights, Warning Beacon (with Switch)Lights, Rear WorkingOil, Hydraulic, Cold ClimateSeat, SuspensionWindow, Side, Sliding<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> specifications17

Notes18<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> specifications

Notes<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong> specifications 19

<strong>267B</strong>/<strong>277B</strong>/<strong>287B</strong> <strong>Multi</strong> <strong>Terrain</strong> <strong>Loaders</strong>For more complete in<strong>for</strong>mation on Cat products, dealer services,and industry solutions, visit us on the web at www.cat.com© 2005 CaterpillarAll Rights ReservedPrinted in U.S.A.Materials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.See your Caterpillar dealer <strong>for</strong> available options.AEHQ5568-01 (8-05)Replaces AEHQ5568CAT, CATERPILLAR, their respective logos and “Caterpillar Yellow,”as well as corporate and product identity used herein, aretrademarks of Caterpillar and may not be used without permission.R