Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

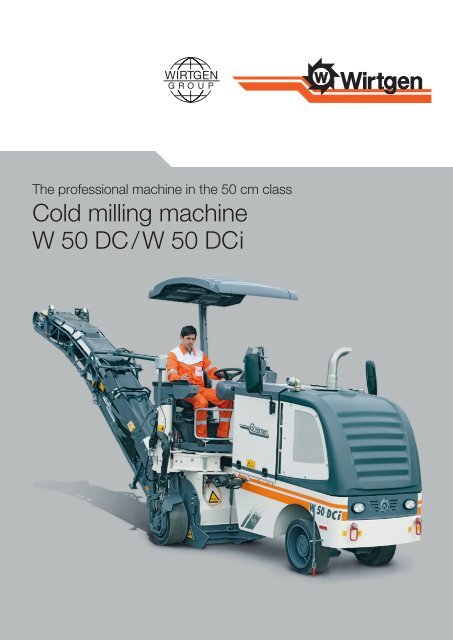

Maximum efficiencyon any job siteFully equipped – for even better performanceThe innovative, high-end W 50 DC / W 50 DC i machinesets the industry standard for any small andmedium-sized milling job. Milling in extremely tight spots,milling of special areas, cutting trenches and removingpavement strips at depths of up to 210 mm and widthsof up to 500 mm are just some fields of use in which thispowerful 50 cm cold milling machine achieves record-highoutputs. Its high engine performance, automatically operatedtravel drive, the complete FCS milling drum rangeand top-performance loading system make this compactall-rounder the perfect choice for demanding jobs of anytype.

The compact, powerfulW 50 DC / W 50 DC i is an outstandingperformer whatever the jobEconomical,powerful, versatileOperator and machine quicklybecome a strong teamGreater efficiencyTop-selling cold milling machine in the 500 mmrear-loader class thanks to unrivalled efficiency.State-of-the-art technologiesThe efficient WIDRIVE machine control and LEVELPRO levelling system minimize operating costs.Impressive manoeuvrability3-wheel or 4-wheel design for tremendousmanoeuvrability.Direct milling drum driveThe mechanical milling drum drive and electronic outputcontrol ensure maximum milling performance.Various discharge conveyorsShort and long discharge conveyors cater to a widerange of loading situations.2 // 3

Top performancein the 50 cm classEqually well-suited to high area performanceKey features of this machine are its high enginepower with ample reserve capacity and great millingdepth: the W 50 DC / W 50 DC i is the ultimate choiceto ensure top performance in the small milling machinesegment with working widths of up to 50 cm. <strong>Wirtgen</strong> isproud to provide far more than 50 different milling drumsto cater to the widest possible range of applications of thiscompact, powerful machine. This equipment enables theW 50 DC / W 50 DC i to achieve an incredibly high performance,particularly when milling off road pavements,removing pavement strips and cutting trenches.

Milling off large areas with therear-loading W 50 DC / W 50 DC iStrongperformanceAdvance rateAR (m/min)17,515,012,510,07,55,0High-performance removal of upto 210 mm deep pavements2,50,00 25 50 75 100 125 150 175 200 225Milling depth in mmAverage milling advancerate in metres per minuteThe modern engine and powerful mechanical millingdrum drive guarantee full performance up to a millingdepth of 210 mm.The powerful, flexible loading system ensures that thereis no drop in performance during the immenselyimportant process of loading the milled material.The intelligent, intuitive machine control system enablesthe operator to work effectively with the least possiblephysical stress.The W 50 DC / W 50 DC i has all it takes to achieve anenormously high area performance, particularly whenfine-milling road pavements.4 // 5

Ergonomics and ease of operationensure stress-free workA comfortable workplace quickly pays offSitting in a relaxed position with plenty of elbowspace, a perfect view and functionally arranged controls– these are the key features of a perfect ergonomicdesign. And they save a lot of money, for experience hasshown that an ergonomic workplace boosts performance.Here too, the W 50 DC / W 50 DCi is a true role model.The comfortable driver’s seat is a special highlight: it canbe adjusted in height and position to suit the operator’sneeds; it can swiftly be displaced beyond the right-handedge of the machine and ensures a clear overview. As amatter of course, the steering wheel and control panel canalso be adjusted together with the seat to ensure maximumcomfort.

Important functions are intuitivelyintegrated into the right-handarmrestFor safe andrelaxed operation,preventing fatigueNight design: illuminatedcontrol panel for workingin darknessPractical: multi-functionaldisplay with only a few switchesin the direct field of viewThe steering wheel can be pivoted; it is thus perfectlysuited to working in both upright and seated position.The spacious operator’s platform provides legroomand ample space even for tall operators.Lockable, rigid moulded covers protect the controls onthe panel and armrest against vandalism.The floor is vibration-damped and thus effectivelyabsorbs vibrations, protecting the operator’s health.6 // 7

Highly precise levellingwith LEVEL PROThe amazingly simple levelling systemThe W 50 DC / W 50 DC i can optionally be equippedwith the state-of-the-art LEVEL PRO system, a levellingsystem that will spark your enthusiasm immediately.An innovative and highly practical feature is that it permitsup to three sensor signals to be displayed simultaneously.Another highlight is the panel, which has been arrangedwithin optimum reach of the machine operator and enableseffortless operation. Redesigned graphical functionsymbols and large, clearly arranged switches complementthe compelling overall impression.

AutomaticsystemON / OFFExchangebuttonTarget valueSettingsTargetvalueRAISE /LOWERMaximum operatorconvenienceActual valueControlleroutputCalibrationCylinderRAISE /LOWERMemory 1Memory 2LEVEL PRO: always within view,clearly arranged functionsWire-rope sensor forprecise measurement ofthe milling depthSet values can be pre-programmed individually forboth sides of the machine, stored by pressing thememory button and then retrieved as and whenrequired.Different sensors, such as the wire-rope sensor orslope sensor, can be selected or de-selected duringthe milling operation as required.The levelling mode with related sensors can beaddressed at any time during the milling operation.The actual levelling controller is located separately inthe electrical cabinet, safely protected against anydamage.8 // 9

Highest milling outputat low diesel consumption ratesA powerful and intelligent engineIntelligent engine management is an important asset,all the more so as energy resources become scarcer.The modern, powerful diesel engine meets this requirement.Its high torque ramp-up makes the W 50 DC / W 50DCi the perfect choice for tough day-to-day operation onthe job site. The reliable engine control system ensuresthat the speed is adjusted accordingly both when drivingand when milling. The control system thus minimizes fuelconsumption and significantly reduces noise levels. Thecold milling machine also features effective sound insulationof the engine compartment and an elastically supported,low-vibration engine station.

P (kW)M [Nm] 12075011070010065060090M [Nm]750P (kW)12070011065010060090Lowemissions550 805007045060400350505508070500604505040040300 4035030250302002015010001100120013001400150016001700180019002000203001025002100 200[1/min]01000W 50 DC engine power1100 1200 1300W 50 DC torque14001500160017001800190020001502100 [1/min]M [Nm]P (kW)750120700110650100600905508050045040035070605040Noise insulation asa standard feature3003025020200101501000110012001300140015001600170018001900200002100 [1/min]W 50 DCi engine powerW 50 DCi torqueWide engine speed ranges ensureoptimum job performanceFor maximum milling output, the 50 DC / W 50 DC i canalso be operated at a reduced engine speed.The engine of the W 50 DC cold milling machinecomplies with the exhaust emission requirements ofEU Stage 3a / US Tier 3.The W 50 DC i features state-of-the-art engine technologyfor lowest environmental emission levels thatcomply with the stringent specifications of the ECStage 3b / US Tier 4i exhaust emission standards.The engine of the W 50 DC i is equipped with anoxidizing catalyst and a diesel particulate filter toensure effective exhaust cleaning.10 // 11

Always therewhen the going gets tightThe machine is fitted with3 or 4 wheels as requiredThe large steering angle of thefront wheels allows the machineto turn in extremely small circlesSmall milling circles are a speciality of the W 50 DC / W 50 DC iA compact, highly manoeuvrable small millingmachine is the perfect choice whenever the goinggets tight. The W 50 DC / W 50 DCi displays outstandingmanoeuvrability even in the smallest working space. Itsfinger-light, hydraulic steering permits extremely largesteering angles for correspondingly small turning circles.Regardless of whether the machine has three or fourwheels: accurate milling in narrow passageways or bendsis always a simple exercise for the W 50 DC / W 50 DCi. Itslarge ground clearance is another useful feature allowing itto pass over obstacles undamaged.

The steering angle is clearly indicatedby the pointer on the engine cowling(only for the 3-wheeled version)Optimummanoeuvrabilityin tight spotsA hydraulic cylinder letsthe rear right support wheelbe conveniently …… swivelled in and out withoutleaving the operator’s platformMilling round manhole covers, for example, is a simplematter thanks to the large steering angle.The rear right wheel can be swivelled inwards to cutalong obstacles, such as kerbstones, flush with theedge and with a perfect view.Four wheels instead of three increase the machine’straction and stability – an important factor whenworking on difficult ground.Permanent all-wheel drive with hydraulic tractioncontrol allows the machine to travel safely and reliablyon virtually any terrain.12 // 13

Change milling drumsin next to no timePerfect arrangement of cutting toolson the milling drumHydraulic tool extractorwithin easy reachQuick, simple, ergonomicFirst the W 50 DC / W 50 DC i works as a 50 cm widefine milling machine to restore the skid resistance ofa road pavement, then it needs to cut cut a 20 cm widetrench. These jobs would normally require two machines.The W 50 DC/W 50 DCi is different, though: all it takes tocomplete these jobs is to change its milling drum. Andthis is something that requires virtually no effort: openthe door of the drum compartment, loosen the bolts thatsecure the fine milling drum and pull the drum off its shaftso that the 20 cm wide milling drum can be fitted. Thenadjust the scraper blade to the new working width and theW 50 DC / W 50 DC i can resume its favourite task.

Open the door of the drumcompartment and loosenthe milling drumDifferent millingwidths in no timePull out the drum withoutundue effort and place it onan assembly trolleyThen simply fit the requiredFCS milling drum in the reverseorder of steps – finished!It’s so simple to change the milling drum that nospecial know-how is required.Thanks to its special bearing, the complete millingdrum is easily pulled out to the side.All the steps involved in changing milling drums can beperformed from the easily accessible right-hand sideof the machine.An ordinary assembly trolley or lift truck makes iteasier to remove and install the milling drum.14 // 15

An even widerrange of applications with FCSSimple cutting tool replacement –either conventionally or using thehydraulic tool extractorThe side milling wheelwith a milling width of 80 mmcan cut to a depth of 300 mmFor the widest possible rangeof applications – far more than50 milling drums are availablefor the W 50 DC / W 50 DCiFCS: The efficient success formula for utilizing your milling machine’s full capacityA lucrative job cannot be taken on because the rightmachine is not available? <strong>Wirtgen</strong>’s Flexible CutterSystem (FCS) offers an ingenious solution to that dilemma.FCS is a ground-breaking interpretation of machineutilization based on the specific job needs. This practicaloption enables virtually any milling width and tool spacingand a wide range of milling contours to make theW 50 DC / W 50 DC i exceedingly versatile. Fine millingdrums, for example, can be used to eliminate pavementirregularities or to improve the skid resistance of roadpavements. Enlarging the range of uses in this way notonly increases the small milling machine’s utilization butalso maximizes the benefits for the customer.

Rumble strip kitfor the W 50 DC / W 50 DC iSpecially arranged cutting toolscreate an oval milling contourWhen driven over, the rumblestrips generate vibrations andtyre noisesThe heavy-duty frame has beendesigned for tough milling jobsand extended operationThe rumble strip kit is the perfect choice for millingrumble strips into asphalt or concrete road pavementsin a highly efficient process.The profile wheel enables the milling drum to insert10 to 20 mm deep cuts into the pavement at specifiedintervals.This special equipment enables the milling oflong-lasting, extremely wear-resistant strips at highmilling speeds.Low operating costs ensure an economical productionprocess.16 // 17

Intelligently designedmilling drum assemblyThe side plate can be liftedover obstacles and pressed downonto the asphalt surface whennecessaryThe hydraulically adjustabledrum plate ensures neatcollection of the milled materialIn working position, the drumhousing is sealed by thehydraulically lifting side plateMature technology for optimum resultsOperators lay great store on “their” W 50 DC /W 50 DC i – and not without reason. This is not leastdue to the intelligent details of the milling drum assembly.Power belts ensure optimum power transmission; theirtension is kept at a constant level by an automatic belttensioner. The side plate and drum plate tightly close themilling chamber; the scraper blade always creates cleanmilled surfaces. An electric water spray system cools thepoint-attack tools, thus extending their service life. Oneuseful side effect of this system is that it largely reducesthe amount of dust produced during the milling operation.

Clean milled surfacesare crucialThe spray nozzlescan easily be removedindividually for cleaningThe scraper blade is adjustedto the required working widthThe water spray system isreadily accessible abovethe milling drumThe milling drum is located between the rear wheelsand rotates against the direction of travel.The vertically adjustable scraper blade determineswhether the milled material is loaded completely orpartially.Hydraulically raised side plates on both sides preventthe machine from digging into the ground on unpavedshoulders.18 // 19

A milling machine is only as good asits loading systemOptimum loading ensures swift job completionAs a matter of fact, a cold milling machine is only asgood as its loading system, for construction projectscan only be completed economically if the milled materialis removed efficiently and flexibly. The conveyor of thepowerful W 50 DC / W 50 DC i has been designed withprecisely this requirement in mind. The wide belt ensuresthat the milled material is taken up completely and loadedreliably without any backlogs. The loading system can beslewed to either side while a continuously adjustable, hydraulicallycontrolled drive motor ensures that the belt runsat optimum speed.

Rugged cleating ensures thatthe material is transported reliablyGetting rid of milledmaterial quicklyContinuously adjustablebelt speed and discharge rangeHigh belt speedLow belt speedThe continuously adjustable belt speed ensures thateven long trucks with trailers can be loaded completely.For complete loading, the scraper blade is set to“float” on the milled surface so that it seals the drumcompartment.For partial loading, the scraper blade is set to thecorresponding height so that part of the milled materialremains in the trench as a profiled surface.The wide loading conveyor with rugged cleatingensures that large volumes of material can beremoved.20 // 21

Swift job completionthanks to flexible loadingThe folding conveyordesign makes it easier totransport the machineShort conveyor for fillingthe shovel of a wheel loader orfor use in confined areasThree different conveyorversions are available aspart of the standard packageThe long conveyor foroptimum loading of large trucksThree different loading conveyors availableEvery contractor knows exactly which requirementstheir small milling machine must meet in practice. Forthis reason, <strong>Wirtgen</strong> also offers practical options for loadingthe reclaimed milled material. Whether with or withoutloading conveyor and the opportunity to choose the mostsuitable conveyor from among three efficient versions –our broad range allows contractors to put together theirown “personal” W 50 DC / W 50 DC i. The system has alsoproved its practicability on site, for the conveyor can beconnected and disconnected without wasting time. As aresult, the machine is rapidly available for many differentjobs, such as working in narrow passageways where theshort loading conveyor is ideal.

The loading conveyor is easilyremoved to make space for millingin tight spotsOnly one person isneeded to connect anddisconnect the conveyorThe loading conveyor canbe adjusted in height as wellas to the right or leftAn ingenious coupling device allows the loadingconveyor to be connected and disconnected quicklyand without difficulty by just one person.All conveyors are covered over their full length tominimize the nuisance due to dust (e.g. in windyconditions).The large, widely slewing conveyor is particularlyuseful for filling trucks completely.The exceedingly wide slewing range of 25° to the leftand 20° to the right ensures that trucks can be loadedeffectively even when positioned beside the machine.22 // 23

Sophisticated maintenanceis an assetDaily servicing, daily savingsEven heaviest-duty machines such as theW 50 DC / W 50 DC i need to be serviced at regularintervals. Smart <strong>Wirtgen</strong> engineers have done their utmostto make servicing as quick and easy as possible for theoperator. All service work is undertaken from one side.The small number of service and inspection points can bereached directly as soon as the service doors have beenopened. The tanks are similarly refilled in next to no timevia conveniently positioned diesel and water ports. Thewell-conceived maintenance concept greatly helps to minimizeservice intervals in favour of longer operating periods.

For a longservice lifeService doors open wide for easyaccess to filters, hydraulic systemand engineFilling ports for the tanksare easy to reachThe battery is easily reachedunder the access ladderLong duty periods without stopping for refilling thanksto large, easily refilled water and diesel tanks.Visual inspections are undertaken without leaving theground.All filters are within easy reach behind the servicedoors.Lubricating and service points are combined intoblocks to make maintenance even simpler.24 // 25

Many smart detailsenhance productivityThe electrohydraulically adjustablecanopy protects the operator fromboth rain and sun exposureSafe, comfortable access at therear of the milling machineComprehensive tool kitavailable whenever neededFor even more comfort and safetyOur compact powerhouse is equipped withnumerous extras to make day-to-day work bothmore more comfortable but also safer. For example, theW 50 DC / W 50 DC i is prepared to work under any weatherconditions. Whether rain or shine, the height-adjustablecanopy is a useful feature. At cold temperatures, the hotair supply is switched on. The lighting fixtures attached allaround the machine turn night into day. Bright headlampsensure safety all round. Spacious steps leading up to theoperator’s platform at the rear of the machine complementthis wide range of comfortable features.

Working safelyday and nightA shining exampleof night designWorking lamps illuminatethe track and milled edgewhen necessaryMirrors make it easierto manoeuvre the machineA readily accessible emergency stop switch ensuresthat the milling machine can be turned off in criticalsituations.An intelligent data converter can optionally be installedto read out defined data from the machine controlsystem, encoded according to the WIFMS standard.A loud reversing horn warns bystanders of theapproaching machine.26 // 27

Moving swiftly fromone job site to the nextThe quicker it travels, the greater its utilizationNot uncommonly, several jobs have to be completedon different sites in rapid succession within asingle day, which makes quick and easy transport of themachine an important factor. Our cold milling machineW 50 DC / W 50 DC i scores top marks in this regard, too,for its manoeuvrability and compact size allow it to betransported quickly on small, cost-efficient trailers.Fix the machine to the retaining lugs, retract the protectivecanopy electrohydraulically − and transport the cold millingmachine to its next job. For those who prefer to do withoutthe trailer, the machine can also drive to its next job directlywhen licensed to travel on public roads.

Several retaining lugson the machine allow forits secure transportCompact dimensionsfor convenienttransportThe canopy is lowered fortransport, saving spaceNo special permit is needed fortransport on a low-bed trailerQuick and easy transport to the next job site ensuresthat the machine is always fully utilized.Retaining lugs ensure that the machine is securelylashed on a trailer or for loading by crane.Equipped with the optional direction indicators andadditional lights, the W 50 DC / W 50 DC i is licensed totravel on public roads.Our large portfolio also includes several trailersperfectly suited to transporting the W 50 DC /W 50 DC i.28 // 29

Powerful small milling machinefor a wide variety of applicationsMilling of small areas in tight spotsAccurate milling arounda manhole cover, adheringto an exactly defined depthFinal cross-milling at theend of an existing cutThere’s more to this small machine than meets the eyeIn addition to rehabilitating large areas of motorwaysor airport facilities, cost-efficient maintenance ofthe traffic infrastructure is becoming increasingly important.The wide range of repairs required in this contextare the special domain of our robust all-rounder, theW 50 DC / W 50 DC i. Partial repairs, removal of asphaltstrips, precise milling around obstacles such as kerbstonesor manhole covers, cutting grooves and indooroperations are just a few of the W 50 DC / W 50 DC i’sspecialities: the machine has exactly what it takes andproduces top-class results.

The W 50 DC / W 50 DCi ismilling rumble strips into thehard shoulder at high speedAn impressiveall-rounderCutting a trench with the milledmaterial deposited at the sideto be backfilled laterWith the W 50 DC / W 50 DC i,even large areas can bemilled without difficultyState-of-the-art machine control, smart enginemanagement and a second-to-none levelling systemensure maximum milling performance of theW 50 DC / W 50 DC i.The machine’s unrestricted transportability makes itperfectly possible to complete several jobs on differentsites within a single day.Different conveyor and milling drum versions additionallyextend the range of applications and capacityutilization of the machine.Cutting-edge technical equipment enables this smallmilling machine to also tackle jobs that would normallyonly be possible with larger milling machines.30 // 31

Illustrations and texts are non-binding and may include customized fittings. Subject to technical changes.Performance data depend on operational conditions. No. 2176122 04-10 EN-04/13 © by <strong>Wirtgen</strong> <strong>GmbH</strong> 2013. Printed in Germany<strong>Wirtgen</strong> <strong>GmbH</strong>Reinhard-<strong>Wirtgen</strong>-Str. 2 · 53578 Windhagen · GermanyPhone: +49 (0) 26 45 / 131-0 · Fax: +49 (0) 26 45 / 131-242Internet: www.wirtgen.com · E-Mail: info@wirtgen.com