- Page 2:

The Electrical Engineering Handbook

- Page 8:

The Electrical Engineering Handbook

- Page 12:

Published in 2006 byCRC PressTaylor

- Page 16:

with the structure, organization, a

- Page 22:

Advisory BoardFrank BarnesUniversit

- Page 28:

E.J. KennedyUniversity of Tennessee

- Page 34:

ContentsSECTION IElectronics1 Semic

- Page 38:

18 Microwave Devices18.1 Passive Mi

- Page 44:

I -2Electronics, Power Electronics,

- Page 48:

1 -2 Electronics, Power Electronics

- Page 52:

1 -4 Electronics, Power Electronics

- Page 56:

1 -6 Electronics, Power Electronics

- Page 60:

1 -8 Electronics, Power Electronics

- Page 64:

1 -10 Electronics, Power Electronic

- Page 68:

1 -12 Electronics, Power Electronic

- Page 72: 1 -14 Electronics, Power Electronic

- Page 76: 1 -16 Electronics, Power Electronic

- Page 80: 1 -18 Electronics, Power Electronic

- Page 84: 1 -20 Electronics, Power Electronic

- Page 88: 1 -22 Electronics, Power Electronic

- Page 92: 1 -24 Electronics, Power Electronic

- Page 96: 1 -26 Electronics, Power Electronic

- Page 100: 1 -28 Electronics, Power Electronic

- Page 104: 1 -30 Electronics, Power Electronic

- Page 108: 1 -32 Electronics, Power Electronic

- Page 112: 1 -34 Electronics, Power Electronic

- Page 116: 1 -36 Electronics, Power Electronic

- Page 120: 1 -38 Electronics, Power Electronic

- Page 128: 2-2 Electronics, Power Electronics,

- Page 132: 2-4 Electronics, Power Electronics,

- Page 136: 2-6 Electronics, Power Electronics,

- Page 140: 2-8 Electronics, Power Electronics,

- Page 144: 2-10 Electronics, Power Electronics

- Page 148: 2-12 Electronics, Power Electronics

- Page 152: 2-14 Electronics, Power Electronics

- Page 156: 2-16 Electronics, Power Electronics

- Page 160: 2-18 Electronics, Power Electronics

- Page 164: 2-20 Electronics, Power Electronics

- Page 168: 2-22 Electronics, Power Electronics

- Page 172: 2-24 Electronics, Power Electronics

- Page 176:

2-26 Electronics, Power Electronics

- Page 180:

2-28 Electronics, Power Electronics

- Page 184:

2-30 Electronics, Power Electronics

- Page 188:

2-32 Electronics, Power Electronics

- Page 192:

2-34 Electronics, Power Electronics

- Page 196:

2-36 Electronics, Power Electronics

- Page 200:

2-38 Electronics, Power Electronics

- Page 204:

2-40 Electronics, Power Electronics

- Page 208:

2-42 Electronics, Power Electronics

- Page 212:

2-44 Electronics, Power Electronics

- Page 216:

2-46 Electronics, Power Electronics

- Page 220:

2-48 Electronics, Power Electronics

- Page 224:

2-50 Electronics, Power Electronics

- Page 230:

Semiconductor Manufacturing2-53FIGU

- Page 234:

Semiconductor Manufacturing2-55opti

- Page 238:

Semiconductor Manufacturing2-57Phot

- Page 242:

Semiconductor Manufacturing2-59wher

- Page 246:

Semiconductor Manufacturing2-61Star

- Page 250:

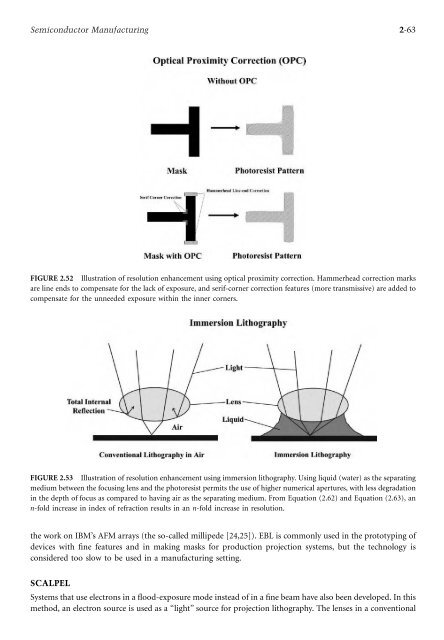

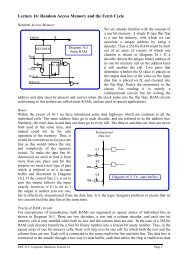

Semiconductor Manufacturing2-63FIGU

- Page 254:

Semiconductor Manufacturing2-65It i

- Page 258:

Semiconductor Manufacturing2-67FIGU

- Page 262:

Semiconductor Manufacturing2-6928.

- Page 268:

3 -2 Electronics, Power Electronics

- Page 272:

3 -4 Electronics, Power Electronics

- Page 276:

3 -6 Electronics, Power Electronics

- Page 280:

3 -8 Electronics, Power Electronics

- Page 284:

3 -10 Electronics, Power Electronic

- Page 288:

3 -12 Electronics, Power Electronic

- Page 292:

3 -14 Electronics, Power Electronic

- Page 296:

3 -16 Electronics, Power Electronic

- Page 300:

3 -18 Electronics, Power Electronic

- Page 304:

3 -20 Electronics, Power Electronic

- Page 308:

3 -22 Electronics, Power Electronic

- Page 312:

3 -24 Electronics, Power Electronic

- Page 316:

3 -26 Electronics, Power Electronic

- Page 320:

3 -28 Electronics, Power Electronic

- Page 324:

3 -30 Electronics, Power Electronic

- Page 328:

3 -32 Electronics, Power Electronic

- Page 332:

3 -34 Electronics, Power Electronic

- Page 336:

3 -36 Electronics, Power Electronic

- Page 340:

3 -38 Electronics, Power Electronic

- Page 344:

3 -40 Electronics, Power Electronic

- Page 348:

3 -42 Electronics, Power Electronic

- Page 352:

3 -44 Electronics, Power Electronic

- Page 356:

3 -46 Electronics, Power Electronic

- Page 360:

3 -48 Electronics, Power Electronic

- Page 364:

3 -50 Electronics, Power Electronic

- Page 368:

3 -52 Electronics, Power Electronic

- Page 372:

3 -54 Electronics, Power Electronic

- Page 376:

3 -56 Electronics, Power Electronic

- Page 380:

3 -58 Electronics, Power Electronic

- Page 384:

3 -60 Electronics, Power Electronic

- Page 388:

3 -62 Electronics, Power Electronic

- Page 392:

3 -64 Electronics, Power Electronic

- Page 396:

4 -2 Electronics, Power Electronics

- Page 400:

4 -4 Electronics, Power Electronics

- Page 404:

4 -6 Electronics, Power Electronics

- Page 408:

4 -8 Electronics, Power Electronics

- Page 412:

4 -10 Electronics, Power Electronic

- Page 416:

4 -12 Electronics, Power Electronic

- Page 420:

4 -14 Electronics, Power Electronic

- Page 424:

4 -16 Electronics, Power Electronic

- Page 428:

4 -18 Electronics, Power Electronic

- Page 432:

4 -20 Electronics, Power Electronic

- Page 436:

4 -22 Electronics, Power Electronic

- Page 440:

4 -24 Electronics, Power Electronic

- Page 444:

4 -26 Electronics, Power Electronic

- Page 448:

4 -28 Electronics, Power Electronic

- Page 452:

4 -30 Electronics, Power Electronic

- Page 456:

4 -32 Electronics, Power Electronic

- Page 460:

4 -34 Electronics, Power Electronic

- Page 464:

4 -36 Electronics, Power Electronic

- Page 468:

4 -38 Electronics, Power Electronic

- Page 472:

4 -40 Electronics, Power Electronic

- Page 476:

4 -42 Electronics, Power Electronic

- Page 480:

4 -44 Electronics, Power Electronic

- Page 484:

4 -46 Electronics, Power Electronic

- Page 488:

4 -48 Electronics, Power Electronic

- Page 492:

4 -50 Electronics, Power Electronic

- Page 496:

4 -52 Electronics, Power Electronic

- Page 500:

4 -54 Electronics, Power Electronic

- Page 504:

5 -2 Electronics, Power Electronics

- Page 508:

5 -4 Electronics, Power Electronics

- Page 512:

5 -6 Electronics, Power Electronics

- Page 516:

5 -8 Electronics, Power Electronics

- Page 520:

5 -10 Electronics, Power Electronic

- Page 524:

5 -12 Electronics, Power Electronic

- Page 528:

5 -14 Electronics, Power Electronic

- Page 532:

5 -16 Electronics, Power Electronic

- Page 536:

5 -18 Electronics, Power Electronic

- Page 540:

5 -20 Electronics, Power Electronic

- Page 544:

5 -22 Electronics, Power Electronic

- Page 548:

6 -2 Electronics, Power Electronics

- Page 552:

6 -4 Electronics, Power Electronics

- Page 556:

6 -6 Electronics, Power Electronics

- Page 560:

6 -8 Electronics, Power Electronics

- Page 566:

7AmplifiersGordon L. CarpenterCalif

- Page 570:

Amplifiers7 -3equations:V BB ¼ V T

- Page 574:

Amplifiers7 -5FIGURE 7.8 Complement

- Page 578:

Amplifiers7 -7ReferencesP.R. Gray a

- Page 582:

Amplifiers7 -9FIGURE 7.12 (a) Schem

- Page 586:

Amplifiers7 -11FIGURE 7.13The hybri

- Page 590:

Amplifiers7 -13andR CO ¼ R LTð 7

- Page 594:

Amplifiers7 -15appreciable load on

- Page 598:

Amplifiers7 -17whereR C p ¼R p jj

- Page 602:

Amplifiers7 -19With R o ignored:R C

- Page 606:

8Active FiltersJohn E. AyersUnivers

- Page 610:

Active Filters8 -3TABLE 8.1Butterwo

- Page 614:

Active Filters8 -5TABLE 8.2 Chebysh

- Page 618:

Active Filters8 -7TABLE 8.4Chebyshe

- Page 622:

Active Filters8 -9TABLE 8.6Bessel P

- Page 626:

Active Filters8 -11TABLE 8.8Ellipti

- Page 630:

Active Filters8 -13Fifth-Order Cheb

- Page 634:

Active Filters8 -15If the section o

- Page 638:

Active Filters8 -17Now that the pro

- Page 642:

Active Filters8 -198.2 RealizationJ

- Page 646:

Active Filters8 -21functions, ladde

- Page 650:

Active Filters8 -23As in the case o

- Page 654:

Active FiltersT ð s Þ¼H ð s 2

- Page 658:

9Power ElectronicsAndrew MarshallTe

- Page 662:

Power Electronics9 -3bypassing carr

- Page 666:

Power Electronics9 -5Some Darlingto

- Page 670:

Power Electronics9 -7The most commo

- Page 674:

Power Electronics9 -9T1Load Voltage

- Page 678:

Power Electronics9 -11Cycloconverte

- Page 682:

Power Electronics9 -13FIGURE 9.15Th

- Page 686:

Power Electronics9 -15FIGURE 9.18dc

- Page 690:

Power Electronics9 -17P.C. Sen, Thy

- Page 694:

Power Electronics9 -19FIGURE 9.20 P

- Page 698:

Power Electronics9 -21FIGURE 9.24(a

- Page 702:

Power Electronics9 -23FIGURE 9.28Fu

- Page 706:

Power Electronics9 -25FIGURE 9.32 (

- Page 710:

Power Electronics9 -27FIGURE 9.34 T

- Page 714:

Power Electronics9 -29FIGURE 9.36 (

- Page 718:

Power Electronics9 -31frequency cha

- Page 722:

Power Electronics9 -33with zero-cur

- Page 726:

Power Electronics9 -3515. G. Hua, C

- Page 730:

Power Electronics9 -37Q 4 —choppi

- Page 734:

Power Electronics9 -39FIGURE 9.47Fo

- Page 738:

Power Electronics9 -41FIGURE 9.50Sl

- Page 742:

Power Electronics9 -43Defining Term

- Page 746:

Power Electronics9 -45Current filam

- Page 750:

Power Electronics9 -47where t L is

- Page 754:

Power Electronics9 -49FIGURE 9.55 T

- Page 758:

Power Electronics9 -51primarily in

- Page 762:

Power Electronics9 -53FIGURE 9.60 (

- Page 766:

Power Electronics9 -55GateLight tri

- Page 770:

Power Electronics9 -57FIGURE 9.64An

- Page 774:

Power Electronics9 -5911. A. Rosen

- Page 778:

Power Electronics9 -61FIGURE 9.65Ap

- Page 782:

Power Electronics9 -63FIGURE 9.68Ga

- Page 786:

Power Electronics9 -65v ai loadv bv

- Page 790:

Power Electronics9 -67FIGURE 9.72 C

- Page 794:

Power Electronics9 -69FIGURE 9.74 S

- Page 798:

Power Electronics9 -7124. P. Mattav

- Page 802:

Power Electronics9 -73UPS systems a

- Page 806:

Power Electronics9 -75ACMainsStatic

- Page 810:

Power Electronics9 -77ACMainsACDCDC

- Page 814:

Power Electronics9 -79ACMainsStatic

- Page 818:

Power Electronics9 -81Static Switch

- Page 822:

Power Electronics9 -83in many circu

- Page 826:

Power Electronics9 -85V ref+−Erro

- Page 830:

10OptoelectronicsJeff HechtLaser Fo

- Page 834:

Optoelectronics10-3FIGURE 10.1 Simp

- Page 838:

Optoelectronics10-5despite their lo

- Page 842:

Optoelectronics10-7where e is the d

- Page 846:

Optoelectronics10-9FIGURE 10.4 (a)

- Page 850:

Optoelectronics10-11Twomethods are

- Page 854:

Optoelectronics10-13Higher luminanc

- Page 858:

Optoelectronics10-15where u is the

- Page 862:

Optoelectronics10-17The output curr

- Page 866:

Optoelectronics10-19FIGURE 10.13The

- Page 870:

Optoelectronics10-21Light falling o

- Page 874:

Optoelectronics10-23Defining TermsC

- Page 878:

Optoelectronics10-25integrated on t

- Page 882:

Optoelectronics10-27FIGURE 10.21Ele

- Page 886:

Optoelectronics10-29FIGURE 10.24Dir

- Page 890:

Optoelectronics10-31FIGURE 10.27Pro

- Page 894:

Optoelectronics10-33ApplicationsMan

- Page 898:

Optoelectronics10-35Further Informa

- Page 904:

11-2 Electronics, Power Electronics

- Page 908:

11-4 Electronics, Power Electronics

- Page 912:

11-6 Electronics, Power Electronics

- Page 916:

11-8 Electronics, Power Electronics

- Page 920:

11-10 Electronics, Power Electronic

- Page 924:

11-12 Electronics, Power Electronic

- Page 930:

12Digital and AnalogElectronic Desi

- Page 934:

Digital and Analog Electronic Desig

- Page 938:

Digital and Analog Electronic Desig

- Page 942:

Digital and Analog Electronic Desig

- Page 946:

Digital and Analog Electronic Desig

- Page 950:

Digital and Analog Electronic Desig

- Page 954:

Digital and Analog Electronic Desig

- Page 958:

Digital and Analog Electronic Desig

- Page 962:

Digital and Analog Electronic Desig

- Page 966:

Digital and Analog Electronic Desig

- Page 972:

13-2 Electronics, Power Electronics

- Page 976:

13-4 Electronics, Power Electronics

- Page 980:

13-6 Electronics, Power Electronics

- Page 984:

13-8 Electronics, Power Electronics

- Page 988:

13-10 Electronics, Power Electronic

- Page 992:

13-12 Electronics, Power Electronic

- Page 996:

13-14 Electronics, Power Electronic

- Page 1002:

14Electromagnetic FieldsBanmali S.R

- Page 1006:

Electromagnetic Fields14-3d E nd E

- Page 1010:

Electromagnetic Fields14-5The term

- Page 1014:

Electromagnetic Fields14-7For apoin

- Page 1018:

Electromagnetic Fields14-9Ampere’

- Page 1022:

Electromagnetic Fields14-11Magnetic

- Page 1026:

Electromagnetic Fields14-13If we co

- Page 1032:

15-2 Electronics, Power Electronics

- Page 1036:

15-4 Electronics, Power Electronics

- Page 1040:

15-6 Electronics, Power Electronics

- Page 1044:

15-8 Electronics, Power Electronics

- Page 1048:

15-10 Electronics, Power Electronic

- Page 1052:

15-12 Electronics, Power Electronic

- Page 1056:

15-14 Electronics, Power Electronic

- Page 1060:

15-16 Electronics, Power Electronic

- Page 1064:

15-18 Electronics, Power Electronic

- Page 1068:

15-20 Electronics, Power Electronic

- Page 1072:

15-22 Electronics, Power Electronic

- Page 1076:

15-24 Electronics, Power Electronic

- Page 1082:

16Wave PropagationMatthew N.O. Sadi

- Page 1086:

Wave Propagation16-3where g ¼ a þ

- Page 1090:

Wave Propagation16-5TABLE 16.1Atten

- Page 1094:

Wave Propagation16-7a correction fa

- Page 1098:

Wave Propagation16-9FIGURE 16.5Geom

- Page 1102:

Wave Propagation16-11FIGURE 16.6 Ro

- Page 1106:

Wave Propagation16-13The cumulative

- Page 1110:

Wave Propagation16-15TM modes:EH mo

- Page 1114:

Wave Propagation16-17surfaces form

- Page 1118:

Wave Propagation16-19FIGURE 16.11Ac

- Page 1122:

Wave Propagation16-21TABLE 16.5Stan

- Page 1126:

Wave Propagation16-23FIGURE 16.15 V

- Page 1130:

Wave Propagation16-25FIGURE 16.18 C

- Page 1136:

17-2 Electronics, Power Electronics

- Page 1140:

17-4 Electronics, Power Electronics

- Page 1144:

17-6 Electronics, Power Electronics

- Page 1148:

17-8 Electronics, Power Electronics

- Page 1152:

17-10 Electronics, Power Electronic

- Page 1156:

17-12 Electronics, Power Electronic

- Page 1160:

17-14 Electronics, Power Electronic

- Page 1164:

17-16 Electronics, Power Electronic

- Page 1168:

17-18 Electronics, Power Electronic

- Page 1172:

17-20 Electronics, Power Electronic

- Page 1176:

17-22 Electronics, Power Electronic

- Page 1180:

17-24 Electronics, Power Electronic

- Page 1186:

18Microwave DevicesMichael B.SteerN

- Page 1190:

Microwave Devices18-3Using travelin

- Page 1194:

Microwave Devices18-5Most passive d

- Page 1198:

Microwave Devices18-7FIGURE 18.5 Te

- Page 1202:

Microwave Devices18-9provide anumbe

- Page 1206:

Microwave Devices18-11transmission

- Page 1210:

Microwave Devices18-13FIGURE 18.11

- Page 1214:

Microwave Devices18-15maximum RF vo

- Page 1218:

Microwave Devices18-17FIGURE 18.13

- Page 1222:

Microwave Devices18-19FIGURE 18.14

- Page 1226:

Microwave Devices18-21Comparison of

- Page 1230:

19CompatibilityLeland H. HemmingMcD

- Page 1234:

Compatibility19-3Cable shield groun

- Page 1238:

Compatibility19-5TABLE 19.1 Absorpt

- Page 1242:

Compatibility19-7FIGURE 19.6Methods

- Page 1246:

Compatibility19-9Shield Seams. All

- Page 1250:

Compatibility19-11FIGURE 19.11chara

- Page 1254:

Compatibility19-13TEMPEST: Acode wo

- Page 1258:

Compatibility19-15Spectrum Specific

- Page 1262:

Compatibility19-17ySourcezElectricF

- Page 1266:

Compatibility19-19TABLE 19.4 Exampl

- Page 1270:

Compatibility19-21guidelines in con

- Page 1274:

Compatibility19-23the standards and

- Page 1278:

Compatibility19-25TABLE 19.13The CI

- Page 1282:

Compatibility19-27H. Eren, Electron

- Page 1286:

Compatibility19-29Commonly used rel

- Page 1290:

Compatibility19-31FIGURE 19.20 Meas

- Page 1294:

Compatibility19-33Modeling the Retu

- Page 1298:

Compatibility19-35corona envelope w

- Page 1302:

Compatibility19-37FIGURE 19.23 Exam

- Page 1306:

Compatibility19-39FIGURE 19.25 Meas

- Page 1310:

Compatibility19-41Y.T. Lin, M.A. Um

- Page 1314:

20RadarMelvin L. BelcherGeorgia Tec

- Page 1318:

Radar20-3techniques. As defined in

- Page 1322:

Radar20-5TABLE 20.2 Median Target R

- Page 1326:

Radar20-7pulse integration over agi

- Page 1330:

Radar20-9TABLE 20.4Typical Microwav

- Page 1334:

Radar20-11TABLE 20.6Selected Wavefo

- Page 1338:

Radar20-13textbook detection curves

- Page 1342:

Radar20-15Tracking Filter Performan

- Page 1346:

Radar20-17FIGURE 20.7 Waveforms for

- Page 1350:

Radar20-19mixer.After mixing with t

- Page 1354:

Radar20-21and for atriangle wave th

- Page 1358:

Radar20-23derivedfrom the returned

- Page 1362:

Radar20-25FIGURE 20.11 Honeywell 35

- Page 1366:

Radar20-27TABLE 20.13 PILOT Mk3 FMC

- Page 1370:

Radar20-29Collins (Rockwell Interna

- Page 1376:

21-2 Electronics, Power Electronics

- Page 1380:

21-4 Electronics, Power Electronics

- Page 1384:

21-6 Electronics, Power Electronics

- Page 1388:

21-8 Electronics, Power Electronics

- Page 1392:

21-10 Electronics, Power Electronic

- Page 1396:

21-12 Electronics, Power Electronic

- Page 1400:

21-14 Electronics, Power Electronic

- Page 1404:

21-16 Electronics, Power Electronic

- Page 1408:

21-18 Electronics, Power Electronic

- Page 1412:

21-20 Electronics, Power Electronic

- Page 1416:

21-22 Electronics, Power Electronic

- Page 1420:

21-24 Electronics, Power Electronic

- Page 1424:

21-26 Electronics, Power Electronic

- Page 1428:

21-28 Electronics, Power Electronic

- Page 1432:

22-2 Electronics, Power Electronics

- Page 1436:

22-4 Electronics, Power Electronics

- Page 1440:

22-6 Electronics, Power Electronics

- Page 1444:

22-8 Electronics, Power Electronics

- Page 1448:

22-10 Electronics, Power Electronic

- Page 1452:

22-12 Electronics, Power Electronic

- Page 1456:

22-14 Electronics, Power Electronic

- Page 1460:

22-16 Electronics, Power Electronic

- Page 1464:

22-18 Electronics, Power Electronic

- Page 1470:

23ComputationalElectromagneticsMatt

- Page 1474:

Computational Electromagnetics23-3X

- Page 1478:

Computational Electromagnetics23-5t

- Page 1482:

Computational Electromagnetics23-7F

- Page 1486:

Computational Electromagnetics23-9w

- Page 1490:

Computational Electromagnetics23-11

- Page 1494:

Computational Electromagnetics23-13

- Page 1498:

Computational Electromagnetics23-15

- Page 1502:

Computational Electromagnetics23-17

- Page 1506:

Computational Electromagnetics23-19

- Page 1510:

Computational Electromagnetics23-21

- Page 1514:

Computational Electromagnetics23-23

- Page 1518:

Computational Electromagnetics23-25

- Page 1522:

IIIElectrical Effectsand Devices24

- Page 1528:

24-2 Electronics, Power Electronics

- Page 1532:

24-4 Electronics, Power Electronics

- Page 1536:

24-6 Electronics, Power Electronics

- Page 1540:

24-8 Electronics, Power Electronics

- Page 1544:

25-2 Electronics, Power Electronics

- Page 1548:

25-4 Electronics, Power Electronics

- Page 1552:

25-6 Electronics, Power Electronics

- Page 1556:

25-8 Electronics, Power Electronics

- Page 1560:

25-10 Electronics, Power Electronic

- Page 1564:

25-12 Electronics, Power Electronic

- Page 1568:

25-14 Electronics, Power Electronic

- Page 1572:

26-2 Electronics, Power Electronics

- Page 1576:

26-4 Electronics, Power Electronics

- Page 1580:

26-6 Electronics, Power Electronics

- Page 1584:

26-8 Electronics, Power Electronics

- Page 1588:

27-2 Electronics, Power Electronics

- Page 1592:

27-4 Electronics, Power Electronics

- Page 1596:

27-6 Electronics, Power Electronics

- Page 1600:

28-2 Electronics, Power Electronics

- Page 1604:

28-4 Electronics, Power Electronics

- Page 1608:

28-6 Electronics, Power Electronics

- Page 1612:

28-8 Electronics, Power Electronics

- Page 1616:

28-10 Electronics, Power Electronic

- Page 1620:

29-2 Electronics, Power Electronics

- Page 1624:

29-4 Electronics, Power Electronics

- Page 1628:

29-6 Electronics, Power Electronics

- Page 1632:

29-8 Electronics, Power Electronics

- Page 1636:

29-10 Electronics, Power Electronic

- Page 1640:

29-12 Electronics, Power Electronic

- Page 1644:

29-14 Electronics, Power Electronic

- Page 1648:

TABLE 29.2MaterialElectrical and Ph

- Page 1652:

29-18 Electronics, Power Electronic

- Page 1656:

29-20 Electronics, Power Electronic

- Page 1660:

IV-2Mathematics, Symbols, and Physi

- Page 1664:

IV-4Mathematics, Symbols, and Physi

- Page 1668:

IV-6Mathematics, Symbols, and Physi

- Page 1672:

IV-8Mathematics, Symbols, and Physi

- Page 1676:

IV-10Mathematics, Symbols, and Phys

- Page 1680:

IV-12Mathematics, Symbols, and Phys

- Page 1684:

IV-14Mathematics, Symbols, and Phys

- Page 1688:

IV-16Mathematics, Symbols, and Phys

- Page 1692:

IV-18Mathematics, Symbols, and Phys

- Page 1696:

IV-20Mathematics, Symbols, and Phys

- Page 1702:

Author IndexAAgbo, Samuel O., Light

- Page 1706:

Author IndexA -3WWait, John V., Ide

- Page 1712:

S -2Electronics, Power Electronics,

- Page 1716:

S -4Electronics, Power Electronics,

- Page 1720:

S -6Electronics, Power Electronics,

- Page 1724:

S -8Electronics, Power Electronics,

- Page 1728:

S -10Electronics, Power Electronics

- Page 1732:

S -12Electronics, Power Electronics

- Page 1736:

S -14Electronics, Power Electronics

- Page 1740:

S -16Electronics, Power Electronics

- Page 1744:

S -18Electronics, Power Electronics

- Page 1748:

S -20Electronics, Power Electronics

- Page 1752:

S -22Electronics, Power Electronics

- Page 1756:

S -24Electronics, Power Electronics

- Page 1760:

S -26Electronics, Power Electronics

- Page 1764:

S -28Electronics, Power Electronics

- Page 1768:

S -30Electronics, Power Electronics

- Page 1772:

S -32Electronics, Power Electronics