UNM engineering - School of Engineering - University of New Mexico

UNM engineering - School of Engineering - University of New Mexico

UNM engineering - School of Engineering - University of New Mexico

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

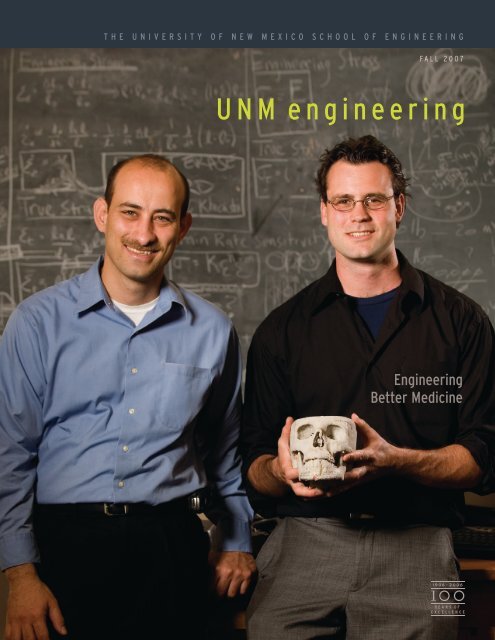

The <strong>University</strong> <strong>of</strong> <strong>New</strong> <strong>Mexico</strong> <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>fall 2007<strong>UNM</strong> <strong>engineering</strong><strong>Engineering</strong>Better Medicine

From the DeanCollaborations and InnovationsSolving today’s complex biomedical problems necessitates collaboration among<strong>engineering</strong>, computer science, and the life and health sciences. <strong>UNM</strong>’s top-rankedmedical school, distinguished biology department, innovative research centers, andour own <strong>School</strong> <strong>of</strong> <strong>Engineering</strong> provide a vibrant environment for teams to jointlyexplore and solve biomedical challenges.In this issue, you will read how <strong>UNM</strong> collaborators cross disciplines and campuses tomake significant contributions. A surgeon frustrated with jaw implants for correctivejaw surgery turns to mechanical engineers, who design tougher, more pliant plates.A researcher trained in <strong>engineering</strong> bridges helps doctors heal injured ligaments andbroken bones. Computer scientists work along with doctors and biologists, usingcomputational geometry and powerful algorithms to create s<strong>of</strong>tware that improvescancer treatment. At a neuroscience research center, teams are investigating how brainimaging can unlock clues to better diagnosis and treatment techniques for schizophrenia.These collaborations and the <strong>School</strong>’s increased research funding reflect the growingemphasis on biomedical <strong>engineering</strong> at <strong>UNM</strong>. Partnerships with industry andgovernment laboratories are ongoing and expanding. <strong>New</strong> educational and researchprograms have been developed. High school outreach programs, undergraduateresearch opportunities, internships, and graduate research assistantships areincreasing. Next year, a new state-<strong>of</strong> the-art facility, the Centennial <strong>Engineering</strong>Center, will accommodate the <strong>School</strong>’s expansion and serve as the home for theCenter for Biomedical <strong>Engineering</strong>, which has received $8 million in grants sinceits founding two years ago.Interdisciplinary collaborations represent an important dimension <strong>of</strong> diversity.Engineers, computer scientists, biologists, and medical researchers have differentacademic training, perspectives, vocabularies, and ways to solve problems. Thosedifferences are precisely the source <strong>of</strong> excitement, creativity, new insights, andinnovation that these alliances can produce. The challenge is having to deal withthe attendant complexity. There must be a shared commitment to the team’s workand project goals, as well as an openness to crossing the barriers <strong>of</strong> individualbackgrounds and beliefs. It is a process <strong>of</strong> bridging multiple cultures that involveslearning to speak other “technical languages,” and appreciating the differentmaterials and tools each individual brings.We were inspired by all those pr<strong>of</strong>iled in this issue. We hope you are, too.Joseph L. CecchiDean <strong>of</strong> <strong>Engineering</strong>

0206 1410Points <strong>of</strong> PrideStarting Fall 2007, the <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>,in partnership with the <strong>UNM</strong> Division <strong>of</strong> ContinuingEducation, introduced a series <strong>of</strong> short courses for<strong>engineering</strong> and technical pr<strong>of</strong>essionals. Ranging fromone to five days in length, the short courses are taughtby SOE pr<strong>of</strong>essors and other experts, who presentpractical theory and application.<strong>UNM</strong> Assistant Pr<strong>of</strong>essor <strong>of</strong> Chemical and Nuclear<strong>Engineering</strong> Dimiter N. Petsev was co-author <strong>of</strong> an articlepublished in Nature Materials (March, 2007) exploringvarious types <strong>of</strong> miniature semiconductor diodes floatingin water that act as self-propelling particles when poweredby an external alternating electric field.Pr<strong>of</strong>essor and Chairman <strong>of</strong> the Department <strong>of</strong> Civil<strong>Engineering</strong> Arup Maji has been appointed to chair theAerospace Division <strong>of</strong> the American Society <strong>of</strong> CivilEngineers. He will oversee the ASCE technical committeeson Advanced Materials and Structures, Aerodynamics,Dynamics and Controls, Space <strong>Engineering</strong>, andConstruction, and Field Sensing and Robotics.Computer Science graduate Dino Dai Zovi (BS, 2002)was featured recently on SearchSecurity.com as a securityresearcher worth watching. Dino discovered a Java-basedvulnerability in QuickTime to win a $10,000 prize in theCanSecWest MacBook Pro hacking contest. The vulnerabilitywas disclosed responsibly to Apple and has been patched.Electrical and Computer <strong>Engineering</strong> Pr<strong>of</strong>essor EdlSchamiloglu chaired the highly successful 2007 IEEEPulsed Power and Plasma Science Conference June 17–22at the Albuquerque Convention Center. 1,200 engineersand physicists from 34 countries attended, many seeing<strong>New</strong> <strong>Mexico</strong> for the first time, and about 130 registrantsattended the open house at ECE’s laboratory facilities.Mechanical <strong>Engineering</strong> Pr<strong>of</strong>essor Marc Ingber hasbeen appointed Program Director for Particulate andMultiphase Processes in the Division <strong>of</strong> Chemical,Bio<strong>engineering</strong>, Environmental, and Transport Processes<strong>of</strong> the National Science Foundation. The appointmentis expected to be for two years.Contents02 The Doctor – and Engineer –will See You NowEngineers and doctors collaborate to improvemedical techniques06 Centered on SuccessCBME fosters biomedical <strong>engineering</strong> research andeducation at <strong>UNM</strong>10 Head Detectives<strong>UNM</strong> engineers investigate the mysteries <strong>of</strong> the mind14 Turning 1s and 0s Into HopeInnovations in bioinformatics research16 <strong>Engineering</strong> Surgical InnovationsAlumni Pr<strong>of</strong>ile: Robert Solenberger17 <strong>New</strong> FacultyOn the CoverTariq Khraishi and Scott Lovald are developing plates designed to cutcorrective jaw surgery time and post-operative complications almost in half.<strong>UNM</strong> <strong>Engineering</strong>Fall 2007Volume 4, Number 2EditingTamara WilliamsWritingMegan Fleming Writing & Creative Services; Susan Georgia andTamara Williams, <strong>UNM</strong>DesignCisneros DesignPhotographyEric Swanson and Chris Corrie<strong>UNM</strong> <strong>Engineering</strong> is published biannually by the <strong>University</strong> <strong>of</strong> <strong>New</strong> <strong>Mexico</strong><strong>School</strong> <strong>of</strong> <strong>Engineering</strong>. Subscriptions are free; requests should be submittedto the address below. Material may not be reproduced without permission.<strong>School</strong> <strong>of</strong> <strong>Engineering</strong>, Farris <strong>Engineering</strong> Center, 107 , MSC01-11401 <strong>University</strong> <strong>of</strong> <strong>New</strong> <strong>Mexico</strong>, Albuquerque, NM 87131-0001505-277-5521www.soe.unm.edu<strong>UNM</strong> <strong>Engineering</strong> 01

The Doctorand EngineerWill See You NowEngineers and doctors collaborate to improve medical techniquesDr. Jon Wagner enters a brightly lit surgery suite and examineshis patient’s broken jawbone. Then Wagner selects a three-inchlong, thick titanium plate from an orthopedic implant kit andmeasures the plate against his patient’s jaw line. Too big. Heselects another plate. Still too big. And another. Too small. OnceWagner finds a plate that fits, he begins the painstaking process<strong>of</strong> bending and shaping the hard metal to match the contours<strong>of</strong> the patient’s face. Finally, he screws the plate into the brokenbones and finishes the surgery. The process, which can takewell over three hours, is difficult and expensive consideringoperating room costs exceed $2,000 an hour.Wagner has earned a M.D., a D.D.S. and is associate pr<strong>of</strong>essor inthe Division <strong>of</strong> Plastic Surgery at the <strong>UNM</strong> <strong>School</strong> <strong>of</strong> Medicine’sDepartment <strong>of</strong> Surgery. He knew there had to be a better way.02 <strong>UNM</strong> <strong>Engineering</strong>

Tariq Khraishi and Scott Lovald are developingplates designed to cut corrective jaw surgery timeand post-operative complications almost in half.The fun, but challengingpart <strong>of</strong> working withdoctors is that they havedifferent pr<strong>of</strong>icienciesthan engineers. We talkabout the same things,but we describe themin different terms.Tariq KhraishiHe hypothesized that the smaller, easier to attach plates heused to fix other facial fractures would work on the jaw. Butcould the plates withstand the powerful forces in the jaw?Wagner and his colleagues conducted their own tests to findout. “We were simulating a jaw using levers and beams andthen applying pressure until the plates broke. It was prettyrudimentary experimentation,” says Wagner.Searching for Sophisticated SolutionsWith no definitive answers from their tests, the doctors turnedtheir sights across campus to the Mechanical <strong>Engineering</strong>Department and Tariq Khraishi, associate pr<strong>of</strong>essor <strong>of</strong>mechanical <strong>engineering</strong> and expert in materials science andfracture mechanics. Khraishi and graduate student Scott Lovald,’06 Manufacturing <strong>Engineering</strong>, MBA, were the perfect partnersfor Wagner’s team. “Collaborating across campus has been sucha novel concept,” says Wagner. “I would still be doing archaicstudies, but with the engineers it quickly became a verysophisticated problem-solving pursuit.”Stryker Leibinger, a medical implant manufacturer, fundedthe multidisciplinary team’s research with a $150,000 fiveyearfellowship. It was the largest fellowship donated directlyto the Mechanical <strong>Engineering</strong> Department and the first tobe dedicated to biomechanics research. The first fellowshiprecipient was graduate student Victor Caraveo in 2006,followed by Julie Kimsal in 2007. Both have been studying theeffect <strong>of</strong> different bite forces and fracture locations, includingfracture surface friction, on fracture healing and fixation.Before Khraishi and Lovald could begin their research, thedoctors and engineers had to learn each other’s processes andjargon. “The fun, but challenging part <strong>of</strong> working with doctors isthat they have different pr<strong>of</strong>iciencies than engineers,” explainsKhraishi. “We talk about the same things, but we describe themin different terms.”From Medical to MechanicalAfter learning about the anatomy <strong>of</strong> the jaw and Wagner’shypothesis, the engineers created a three-dimensional digitalmodel <strong>of</strong> the jaw based on CT scans from an actual patient. Themodel replicated the jaw’s parabolic shape, the various forcesexerted upon the jaw, and the exact material qualities <strong>of</strong> thedifferent tissue and bone types in the jaw. The modeling processrequired two s<strong>of</strong>tware programs and months <strong>of</strong> meticulous work.Then the team used the model to analyze how well differenttypes <strong>of</strong> plates stabilized jaw fractures. The jaw’s complexmovement and materials required a robust analysis tool.Khraishi had just the thing: finite element analysis, a techniquethat solves <strong>engineering</strong> problems in complex structures.“Basically, you take one impossibly complicated problem andbreak it up into a number <strong>of</strong> reasonably complicated problems,”explains Khraishi. “By knowing how the part behaves, you canunderstand how the whole behaves.”Khraishi and Lovald used finite element analysis to quantifybite force, muscle movement, stress on the screws that hold theplates in place, and finally how different plate designs stabilized<strong>UNM</strong> <strong>Engineering</strong> 03

Orthopaedics and Rehabilitation (Dr. Robert Schenck,Dr. Thomas Decoster, and Dr. Deana Mercer) to improve theprocess <strong>of</strong> fixing bone fractures in the arm and leg.A Fuzzy Approach to HealingLike Khraishi, Mahmound Reda Taha, assistant pr<strong>of</strong>essor <strong>of</strong> civil<strong>engineering</strong>, is using his expertise to advance medicine. ButTaha is approaching the challenges from another perspectiveand applying the tools he uses for <strong>engineering</strong> bridges to helpdoctors heal injured ligaments and broken bones.Christina Salas (left) is working towards her M.Sc in biomechanics withMahmoud Taha, assistant pr<strong>of</strong>essor, Civil <strong>Engineering</strong> Department. Bothare collaborating with Thomas Decoster, MD, pr<strong>of</strong>essor, Department <strong>of</strong>Orthopaedics, <strong>UNM</strong> Hospital and Dr. Deana Mercer, MD, Resident PhysicianDepartment <strong>of</strong> Orthopaedics, <strong>UNM</strong> Hospital.fractured bones. Their results confirmed Wagner’s hunch: thesmaller plates were strong enough to stabilize most jawbonefractures. In addition, the team showed that the smaller plateswould cut surgery time and post-operative complicationsalmost in half.The team is now publishing papers on the research and Wagneris promoting the concept <strong>of</strong> using smaller plates to othermaxill<strong>of</strong>acial surgeons. Inspired by the findings, Lovald started acompany to market his new, smaller plate designs. (See sidebar.)“I may have stopped pursuing this idea without the engineers,”says Wagner. “The cross-campus collaboration has made all thedifference in the world.”Khraishi is also using finite element analysis to help othermedical teams. Using his expertise in fluid mechanics,Khraishi is helping doctors in the Department <strong>of</strong> Neurosurgery(Dr. Howard Yonas and Dr. Christopher Taylor) evaluateblockages in the carotid artery that runs from the heartinto the brain. He’s also working with the Department <strong>of</strong>In 2006, Taha completed a two-year research collaborationwith the <strong>UNM</strong> <strong>School</strong> <strong>of</strong> Medicine Department <strong>of</strong> Orthopaedicsand Rehabilitation, where he used fuzzy logic to modelknee ligaments. Fuzzy logic is a technology that applies amathematical framework to processes or situations—likebiology—that are inherently imprecise or ambiguous. “We usefuzzy logic because it helps us quantify things that aren’tcrisp,” says Taha. “The concept <strong>of</strong> healing is pretty difficult tocapture and quantify. We see a lot <strong>of</strong> value in using fuzzy logicin biomedical <strong>engineering</strong> because <strong>of</strong> the unclear boundariesand the difficulty <strong>of</strong> quantifying <strong>engineering</strong> values forbiomechanical problems,” he adds.Prior to Taha’s research, knee ligament models didn’t addressthe complexity <strong>of</strong> how the ligaments work. Using a fuzzy model,Taha and his students showed that tissues in the knee ligamentdon’t all stretch at once. Some tissues stretch to handle theinitial load and then, as the stress increases, additional fibers inthe ligament are called upon. That’s a critical–and fundamental–finding for researchers who want to engineer better artificialligaments. says Taha. “Knee ligaments have very specific/intelligent behaviors, and without studying those behaviors wecannot make effective artificial ligaments,” he says.Taha received the Oakridge Associated Universities RalphE. Powe Junior Faculty Enhancement Award for the workand he was the first to publish a paper on the use <strong>of</strong> fuzzyEngineer and EntrepreneurScott Lovald’s graduate research was more than a degreerequirement; it was his inspiration to become an entrepreneur.During his graduate fellowship study on the stability <strong>of</strong>orthopedic implants used to fix jawbone fractures, Lovald (’06Manufacturing <strong>Engineering</strong>, MBA) discovered that plate designsused in the jaw hadn’t changed in more than a century.That’s when research became opportunity. In spring 2006,Lovald and his business partner, Ryan Smith (’06 Management04 <strong>UNM</strong> <strong>Engineering</strong>

systems to model biological tissues in the Journal <strong>of</strong>Biomechanical <strong>Engineering</strong>.Fixing Bones with Bridge-Building ToolsRecently, Taha started another biomechanics researchcollaboration with the orthopedic surgeons at the <strong>School</strong> <strong>of</strong>Medicine. The team is studying femur fractures in patientswith osteoporosis and evaluating which methods <strong>of</strong> fixation,or stabilization <strong>of</strong> the fracture with a metal plate, can be moreeffective. “Femur fractures in patients with osteoporosis orpoor bone quality are challenging,” says Deana Mercer, residentphysician in the Department <strong>of</strong> Orthopaedics at the SOM. “Thecurrent technology does not work well in some situations due toproblems with capturing enough bone to stabilize the fracture.”Mercer says collaborating with Taha is strategic because hisexpertise in load transfer in structures is complementary to theorthopedic surgeons’ focus on human body biomechanics.Taha is using an innovative new <strong>engineering</strong> modelingtechnique to simulate osteoporosis in bones in finite elementmodels and then analyze fixation options. “Our research mightshow that <strong>of</strong> all the options, only one or two methods areappropriate for patients with osteoporosis,” says Taha. Withonly a small part <strong>of</strong> the research complete, Taha says he’salready seeing good initial results.Above: an image showing the finite-element mesh usedin the computer model <strong>of</strong> a dentate mandible. Each meshelement is shaped like a tetrahedron. Also shown are twoband plates bridging a symphyseal fracture.Below: A contour plot <strong>of</strong> the nodal displacements ormovement <strong>of</strong> the jaw under biting action showing thestrains that the bands experienceThe value <strong>of</strong> collaborating with the SOM is two-fold, saysTaha. “We get to address issues <strong>of</strong> clinical relevance withsolutions that have a direct impact on people’s lives—and that isextremely satisfactory for me,” he says. “And multidisciplinaryresearch brings people together that think differently andspeak different scientific languages. By doing so you can seethings other people can’t, and that is key to innovation.”Taha adds that this collaborative research lays the groundworkfor his ultimate goal: creating a large biomechanics program atthe SOE, which means even more talented engineers will usetheir knowledge and insight to solve medical problems. dTechnology), entered a <strong>UNM</strong> business plan competition withtheir idea for a company that would design and marketmore stable, less intrusive orthopedic implants. They wonthe competition and $28,000, which they used to start theircompany, Satyrne.The partners are now promoting the company full time andsearching for start-up funds. Ultimately, they’ll need $1 millionto $2 million to move into full production. Lovald is als<strong>of</strong>inalizing Satyrne’s nine new plate designs. “For the first time,plates have been designed from a mechanistic perspective toprovide more stability and less volume,” explains Lovald. Thetitanium plates, which feature cross bars for better load sharingbetween screws, are the smallest, most stable plates in theindustry, according to Lovald. Satyrne’s first plate design hasbeen patented and is now going through FDA approval.Ultimately, Lovald and Smith hope to enter a strategic partnershipwith a larger orthopedic implant manufacturer or have anothercompany acquire Satyrne. In the meantime, Lovald says,building the company is the chance <strong>of</strong> a lifetime. “It’s a greatfeeling knowing that our small project is coming to fruition andsustaining itself,” he says. “We’re passionate about this becausewe know we have a product that can do some real good.” d<strong>UNM</strong> <strong>Engineering</strong> 05

CenteredONSuccesSCBME fosters biomedical <strong>engineering</strong> research and education at <strong>UNM</strong>A test tube made <strong>of</strong> water. A “Post-It note” <strong>of</strong> cells. A diagnostic device smaller than a human cell.Sound futuristic? Actually, they’re in development now at the Center for Biomedical <strong>Engineering</strong>.Established at the <strong>School</strong> <strong>of</strong> <strong>Engineering</strong> in 2005, the CBME is an interdisciplinary center thatcoordinates research activities in biomedical <strong>engineering</strong> (BME) among engineers, clinicians, andbiologists. The CBME is also a strategic first step toward the ultimate goal <strong>of</strong> providing a full range<strong>of</strong> BME educational opportunities at <strong>UNM</strong>. The center has already fostered research amongdisciplines and with the high-tech industry, has hired faculty, and developed an outreach programfor K-12 students. Each <strong>of</strong> those efforts supports the CBME’s goal <strong>of</strong> improving <strong>New</strong> <strong>Mexico</strong>’seducational, research, and economic environment.06 <strong>UNM</strong> <strong>Engineering</strong>

Dimiter Petsev, assistant pr<strong>of</strong>essor <strong>of</strong> chemicaland nuclear <strong>engineering</strong>, and Jeremy Edwards,assistant pr<strong>of</strong>essor <strong>of</strong> molecular genetics andmicrobiology and assistant pr<strong>of</strong>essor <strong>of</strong> chemicaland nuclear <strong>engineering</strong>, have been collaboratingthrough the CBME for a year and a half.In just two years, the center has received $8 million in grants.“We’ve already produced a 17-to-1 return on the university’sinvestment,” says Gabriel Lopez, director <strong>of</strong> the CBME andpr<strong>of</strong>essor <strong>of</strong> chemical and nuclear <strong>engineering</strong> and chemistry.“We’re really proving that this kind <strong>of</strong> collaboration can beachieved here at <strong>UNM</strong>.”“test tubes” using a customized microscope, one <strong>of</strong> onlytwo in the world. The collaboration, which also involvesresearchers at Harvard <strong>University</strong>, is organized by the CBMEand is part <strong>of</strong> the National Science Foundation Partnershipfor Research and Education in Materials: <strong>UNM</strong>/HarvardPartnership for Leadership in Biomaterials.Here’s how some CBME researchers are <strong>engineering</strong>better medicine:Droplets <strong>of</strong> DNAImagine a billion glass test tubes lined up, row after row, ina gigantic laboratory. Now, shrink that picture. Way down.Dimiter Petsev, assistant pr<strong>of</strong>essor <strong>of</strong> chemical and nuclear<strong>engineering</strong> is using his expertise in micr<strong>of</strong>luidic devices t<strong>of</strong>abricate miniaturized test tubes made <strong>of</strong> water droplets.Jeremy Edwards, assistant pr<strong>of</strong>essor <strong>of</strong> molecular geneticsand microbiology and assistant pr<strong>of</strong>essor <strong>of</strong> chemical andnuclear <strong>engineering</strong>, plans to use billions <strong>of</strong> these tiny testtubes to develop a fast, inexpensive way to sequence theDNA <strong>of</strong> patients with different cancers or even an individual’sentire genome.Each tiny drop, about ten microns in diameter, is loaded witha small fragment <strong>of</strong> DNA and a bit <strong>of</strong> reactant. Then, thedroplets are suspended in an oil emulsion and used for tests.Once the droplets are floating in the emulsion, Edwards usesa chemical process to break the droplets open. He reads thebiochemical results emanating from streams <strong>of</strong> these brokenPetsev’s challenge is to fabricate these minute droplets in auniform size and shape. With input from Harvard researchers,Petsev has achieved very fast production <strong>of</strong> highly uniformdroplets using micr<strong>of</strong>luidic devices formed using a processcalled s<strong>of</strong>t lithography. Through this process, a network <strong>of</strong>channels 10-100 micrometers deep and wide can easily beformed in a silicone rubber material. Petsev then bonds theprinted polymer channels on a glass slide and uses pressureor electric fields to force oil and water through separatechannels. The droplets form where the channels intersect.Petsev’s next challenge is perfecting the process <strong>of</strong> loadingthe DNA fragments into the droplets.Petsev and Edwards have been collaborating through theCBME for a year and a half. Petsev says access to the CBMEfacilities has been critical, but the opportunity to collaborateis most important. “There’s an exchange <strong>of</strong> information andideas here which is very beneficial for our multidisciplinarywork.” Edwards agrees. “I have an <strong>engineering</strong> backgroundbut I don’t have the ability to make micr<strong>of</strong>luidic devices. Withengineers like Dimiter bringing their skills to the table, wecan achieve our goals.”<strong>UNM</strong> <strong>Engineering</strong> 07

Heather Canavan, assistant pr<strong>of</strong>essor <strong>of</strong> chemical andnuclear <strong>engineering</strong>, (left) and chemical <strong>engineering</strong>graduate student Jamie Reed (below left), collaboratewith Angela Wandinger-Ness, pr<strong>of</strong>essor <strong>of</strong> pathologyat the <strong>School</strong> <strong>of</strong> Medicine in developing smartsurfaces for cell analysis.Solution: Smart SurfacesAngela Wandinger-Ness, pr<strong>of</strong>essor <strong>of</strong> pathology at the<strong>School</strong> <strong>of</strong> Medicine, needed a better process for one facet<strong>of</strong> her research. Heather Canavan, assistant pr<strong>of</strong>essor<strong>of</strong> chemical and nuclear <strong>engineering</strong>, had the perfecttechnique. The CBME brought them together in a successfulresearch collaboration.Wandinger-Ness studies cells and how therapeutic drugsinteract with them. Her goal is to analyze single cellsand measure protein levels on their surface using a flowcytometer, a machine that measures particles in a streamingfluid. Currently, Wandinger-Ness uses enzymes to removecells from surfaces like Petri dishes, on which they aregrown. Then she places them into suspension, where theycan be analyzed by flow cytometry. Her concern is thatthe enzymatic process destroys some <strong>of</strong> the proteins shewants to study.Canavan’s new technique is a perfect fit. She studies “smartsurfaces,” thermoresponsive polymers with properties thatchange based on environmental cues like temperature orelectrical field. By growing cells on these smart, flexiblesurfaces, Canavan can create clumps <strong>of</strong> cells that peel <strong>of</strong>flike a Post-It note, or even isolate single cells that pop <strong>of</strong>f thepolymer without changing their structure.The researchers’ ultimate goal is to create an <strong>of</strong>f-the-shelfdevice that Wandinger-Ness could use to allow accuratecell analysis. Canavan says the research wouldn’t havebeen possible without the CBME. “Gabriel Lopez madethe initial connection between the two sides and theCBME provided financial support,” says Canavan. “Therewas both an intellectual and financial contribution thatwas very significant.”08 <strong>UNM</strong> <strong>Engineering</strong>

One Bead, Two InnovationsTwo sides <strong>of</strong> campus, two disciplines, two goals, one sharedinterest: microscopic beads. Gabriel Lopez and Larry Sklar,pr<strong>of</strong>essor <strong>of</strong> pathology at <strong>UNM</strong>’s <strong>School</strong> <strong>of</strong> Medicine, arecollaborating on fluorescent biosensors that use tiny, proteincoatedbeads the size <strong>of</strong> a human cell. While their researchgoals are different, it’s a strategic collaboration because theresearchers share an interest in the microbiosensors andin biochemistry. “It’s technically a natural fit and our workis nicely complementary,” says Lopez. The two researchers,along with Tione Buranda, research assistant pr<strong>of</strong>essor inthe Pathology Department, have shared a series <strong>of</strong> five-yeargrants during their twelve-year collaboration.Sklar uses the beads for drug discovery, coating them with aspecific protein and suspending them in a fluid that he wantsto test. By running the suspension through a flow cytometer,Sklar can evaluate the reaction <strong>of</strong> the proteins on the surface<strong>of</strong> the beads with those in the solution. Using this process,Sklar and Buranda can screen molecules involving more thana dozen molecular interactions that contribute to cancer,infectious diseases, and inflammatory diseases. Sklar sayscollaborating with engineers at the CBME moves the teamcloser to its goals. “An engineer’s skill set is complementaryto those <strong>of</strong> a biomedical scientist,” he explains. “One <strong>of</strong> thebiggest factors is the different types <strong>of</strong> materials that weuse for building sensors or instrumentation. <strong>Engineering</strong>students have different interests in technology thanbiologists, including materials, fluidics, automation,electronics, and computers.”Lopez and his team use the beads to create diagnosticassays. They make chip-based, micr<strong>of</strong>luidic devices bypacking thousands <strong>of</strong> the protein-coated beads into tiny glasscapillaries. Lopez injects a fluid, for example a blood sample,into the bead-packed channels. When he exposes the channelsto a laser, the beads that are attached to specific proteinsfluoresce, indicating the presence <strong>of</strong> a toxin or diseasemarker in the liquid. Lopez and his team are currently testingsuch devices, using samples from patients with respiratoryinfections. The devices have already successfully detectedseveral different viruses in one small sample. dTione Buranda, research assistant pr<strong>of</strong>essor in thePathology Department and Gabriel Lopez, director<strong>of</strong> the CBME and pr<strong>of</strong>essor <strong>of</strong> chemical and nuclear<strong>engineering</strong> and chemistry, have shared a series <strong>of</strong> fiveyeargrants during their twelve-year collaboration.Above: Confocal scanning laser fluorescencemicroscopy image <strong>of</strong> mesoporous silica particlesfilled with rhodamine dye (red) and encapsulatedby fluorescent lipid bilayer (green). Bottomimage shows one particle (arrow) which hasbeen partially bleached for measurements <strong>of</strong>diffusive fluorescence recovery.<strong>UNM</strong> <strong>Engineering</strong> 09

Vince Calhoun,Director <strong>of</strong> ImageAnalysis and MRIResearch at theMIND Institute10 <strong>UNM</strong> <strong>Engineering</strong>

headdetectivesunm engineers investigate the mysteries <strong>of</strong> the mindPhoto: John Yost, Marble Street StudioWith its high ceilings, displays <strong>of</strong>modern art, and expansive views,this gleaming building certainlydoesn’t look anything like yourtypical detective <strong>of</strong>fice. Thenagain, your typical gumshoesdon’t work here. These specialinvestigators aren’t searching forclues to a crime; they’re trying tocrack a much more difficult case:how the mind works.This modern HQ for these high-tech detectives is The MIND Institute, a non-pr<strong>of</strong>itneuroscience research center just north <strong>of</strong> <strong>UNM</strong>’s main campus. Multidisciplinaryteams at the institute collaborate with researchers around the country and usethe latest imaging technology to sleuth for new ways <strong>of</strong> understanding humanbehavior, especially mental illness.Collaborating to Find CluesOne <strong>of</strong> the head detectives is Vince Calhoun, director <strong>of</strong> image analysis and MRIresearch at The MIND Institute and associate pr<strong>of</strong>essor <strong>of</strong> electrical and computer<strong>engineering</strong> at the <strong>School</strong> <strong>of</strong> <strong>Engineering</strong>. With his background in biomedical<strong>engineering</strong> and years <strong>of</strong> experience working with psychiatrists at The JohnsHopkins <strong>University</strong> <strong>School</strong> <strong>of</strong> Medicine Department <strong>of</strong> Psychiatry as well as Yale<strong>UNM</strong> <strong>Engineering</strong> 11

<strong>University</strong>, Calhoun is uniquely qualified to apply <strong>engineering</strong> approaches to aninvestigation <strong>of</strong> how the brain works. The MIND Institute is a perfect match forhis special qualifications. “The MIND is one <strong>of</strong> the few centers <strong>of</strong> its kind in thecountry,” says Calhoun. “What’s unique is its focus on mental illness and thefact that it has all <strong>of</strong> this excellent technology in one place.”The MINDInstituteis one <strong>of</strong> the fewcenters <strong>of</strong> its kindin the country.What’s uniqueis its focus onmental illnessand the fact thatit has all <strong>of</strong>this excellenttechnology inone place.Vince CalhounCalhoun is also adept at creating successful collaborations between engineersand psychiatrists, who have distinct approaches to research. “I’ve seen goodideas from engineers go to the point <strong>of</strong> a paper and then stop because theengineer doesn’t know how to address questions <strong>of</strong> relevance in psychiatry.And psychiatrists don’t understand how to read an engineer’s paper,” explainsCalhoun. “So, I’ve learned how to work with psychiatrists, but think aboutthings from an <strong>engineering</strong> perspective.”Detecting DifferencesCalhoun leads a multidisciplinary team investigating how brain imaging canunlock clues to better diagnosis and treatment techniques for schizophrenia,which affects 3.2 million Americans. The team is using brain scans to look forindicators <strong>of</strong> the disease. They’re also creating powerful new tools to analyzethe data they collect.Using high tech imaging systems, including magnetic resonance imaging (MRI),functional magnetic resonance imaging (fMRI), and electroencephalography(EEG), the team is searching for biomarkers, or measurable changes in thebrain that indicate schizophrenia.Calhoun uses the imaging tools to collect brain scans while subjects performsimple memory or auditory tasks. Each image type yields different informationabout how the brain works. For instance, fMRI provides a dynamic view <strong>of</strong> bloodflow in the brain, while EEG picks up electrical fields created when neuronsfire in the brain. By comparing images from a control group with those froma group <strong>of</strong> patients with schizophrenia, the researchers can see differencesin how the brain works. Those differences could point to possible biomarkersfor the disease.Calhoun and his team are also developing better ways to analyze andsynthesize all <strong>of</strong> the data from hundreds <strong>of</strong> patients who have had multipleimages made during numerous tests. Calhoun already has an analysis toolboxonline. Now he and his team are developing more robust tools to first analyzeeach data type independently, and then to conduct “data fusion,” analysis <strong>of</strong>combinations <strong>of</strong> images, such as fMRI and MRI, or EEG, fMRI, and MRI. “Thegoal is to combine the information in a way that gives us a better ability to lookfor differences in the brain,” explains Calhoun. The National Institutes <strong>of</strong> Healthis funding his data fusion study with a $1.5 million grant. His approach, calledjoint independent component analysis, decomposes the high dimensional datainto a smaller set <strong>of</strong> independent parts. The different types <strong>of</strong> data are groupedtogether in the algorithm, and Calhoun then uses an approach based uponinformation theory to identify which parts <strong>of</strong> this massive decomposition arethe most informative about differences between patients and healthy controls.12 <strong>UNM</strong> <strong>Engineering</strong>

Cracking the CodeCalhoun is not alone in his investigation. Terran Lane, assistant pr<strong>of</strong>essor <strong>of</strong>computer science, is also on the case. Lane, too, is investigating data fusionand is just starting to develop a sophisticated joint probability model that cancombine the different types <strong>of</strong> data.Lane is collaborating with Vince Clark, associate pr<strong>of</strong>essor <strong>of</strong> psychologyand scientific director <strong>of</strong> The MIND Institute, to study networks in the brain.“We’re trying to understand how different regions <strong>of</strong> the brain influence eachother and send messages to each other,” says Lane. “The goal is to untanglethe story and pull out a network.” Lane receives data directly from MINDresearchers and loads it on to computers in the Computer Science Department.Then comes the real challenge: the brain’s complexity and the immenseamount <strong>of</strong> data involved make teasing out relevant networks very difficult.“It’s as if I gave you a list <strong>of</strong> how many telephone calls enter and leave everybuilding on the <strong>UNM</strong> campus without telling you who they came from or wentto. Then, I asked you to tell me who called who,” explains Lane.Lane is cracking the code using powerful machine learning and statisticaltechniques. While his tools are decidedly high-tech, he’s based his processon a probability theorem, developed in the 18th century, called Bayes’ Rule.Using only a small fraction <strong>of</strong> the available data, s<strong>of</strong>tware based on Bayesiannetworks can scan the brain images for possible networks, learn about the dataas it goes, and use that information to improve the ongoing analysis process.Lane and senior doctoral student John Burge have created an in-house version<strong>of</strong> Bayesian network s<strong>of</strong>tware that includes anatomical and hierarchicalinformation about the brain’s structure as it evaluates the structural andtemporal data collected by MIND researchers. Lane filters results from thes<strong>of</strong>tware to improve the statistical confidence, then shares his findings withneuroscientists at The MIND Institute, who provide input and context on theresults. “It’s a feedback loop. We give them results and they give us backnew data and new questions to ask. Hopefully, from this process we’ll gainneuroscience consequences and computational consequences,” says Lane.A joint analysis was performed toidentify a component showing linkedelectrical changes as measured byelectroencephalography (EEG) andblood oxygenation changes asmeasured by functional magneticresonance imaging (fMRI) duringthe presentation <strong>of</strong> infrequent sounds,called an auditory oddball task. Thepink curve (below) provides informationabout ‘when’ and the orange coloredregions (above) provide informationabout ‘where’ the brain activity isdifferent in patients versus controls.Lane’s research, funded by a three-year grant from the National Institutes<strong>of</strong> Health, is at its midpoint. The team is currently evaluating some new networksextracted by the s<strong>of</strong>tware. “In the 20 years that I’ve been studying thehuman brain, I have watched the tools for data acquisition become far moresophisticated, while our methods <strong>of</strong> analysis have remained very simplistic. Weonly understand about 10 percent <strong>of</strong> the data we collect; the rest is obscuredby its complexity,” says Clark. “One <strong>of</strong> my goals for The MIND Institute is tosupport the work <strong>of</strong> scientists like Vince Calhoun and Terran Lane, who candevelop more sophisticated methods for analyzing brain data. Their algorithmshave already produced a flood <strong>of</strong> new insights into the kind <strong>of</strong> data that hasbeen available to us for years, but couldn’t be analyzed using available methods.”MICROVOLTS-1.0-0.500.51.01.5N1N2CONTROLPATIENTCOMPONENTP30 200 400TIME (MS)With clues, collaboration, and cutting-edge technology, <strong>UNM</strong>’s head detectivesare piecing together answers that will not only unlock the mysteries <strong>of</strong> themind, but could also improve millions <strong>of</strong> lives. d<strong>UNM</strong> <strong>Engineering</strong> 13

Working alongside doctors andbiologists armed with laser beams andmicroscopes, <strong>UNM</strong> researchers ShuangLuan and Terran Lane wield complexcomputer codes <strong>of</strong> 1s and 0s to fightdisease. Luan and Lane, both assistantpr<strong>of</strong>essors <strong>of</strong> Computer Science, studybioinformatics, the use <strong>of</strong> computers,s<strong>of</strong>tware, and databases to solvebiological questions.010111001010101010100010011101110111Luan is interested in the interfacebetween computer science and radiationoncology. “You need committedcollaborators in medicine and thebackground in the theory <strong>of</strong> computerscience to design algorithms to solvethese problems,” explains Luan. “Wehave both here at <strong>UNM</strong>. And ourTurning 1s and 0s Into Hopedepartment makes interdisciplinaryresearch a priority.” Collaboratingwith researchers at <strong>UNM</strong> and acrossthe country, Luan is working on threecancer-related bioinformatics projects.Shuang (Sean) Luan, Assistant Pr<strong>of</strong>essor <strong>of</strong>Computer Science and Joint Assistant Pr<strong>of</strong>essor<strong>of</strong> Radiology, <strong>University</strong> <strong>of</strong> <strong>New</strong> <strong>Mexico</strong>.<strong>New</strong> Dimensions in Cancer TreatmentLuan helped develop two s<strong>of</strong>twareprograms to improve linear acceleratorbased(LINAC) cancer treatment. LINAC,the most common radiation device, usesa precisely positioned beam to irradiatecancerous tumors. Multileaf collimators,or moveable “leaves,” placed underthe beam, shield healthy bodyparts from the radiation. Accuratelypositioning the beam and the leaves ischallenging when the tumor is locatedin a moving body part like the lung.14 <strong>UNM</strong> <strong>Engineering</strong>

Luan collaborated with researchersat <strong>University</strong> <strong>of</strong> Maryland, <strong>University</strong><strong>of</strong> Notre Dame, and <strong>UNM</strong> Radiologyto develop new four-dimensionaltreatment techniques that optimize theleaves and synchronize the angle <strong>of</strong> thebeam with the body’s movement. Theteam used computational geometryand powerful algorithms to createthe program.Gamma knife treatment uses focused beams <strong>of</strong> radiation to treat brain tumors. The Automatic PatientPositioning System (APS) on the Elekta Leksell Gamma Knife ® 4C System makes dynamic Gamma Kniferadiosurgery possible. Photos courtesy <strong>of</strong> Elekta, Atlanta, GA, www.elekta.com.001001110111011101010111011010010“You need committed collaborators in medicine and a background in the theory <strong>of</strong>computer science to solve these problems. We have both here at <strong>UNM</strong>.” Shuang Luan010101110110100101010101110010001In a second LINAC project, Luanand researchers at the <strong>University</strong><strong>of</strong> Maryland and <strong>University</strong> <strong>of</strong> NotreDame pioneered another treatmentoptimization technique. Normally,LINAC machines use up to 13 individualbeams <strong>of</strong> radiation positioned atdifferent angles to treat a tumor.Using computational geometry, theteam developed Single ARC DosePainting Therapy, treatment plannings<strong>of</strong>tware that moves the beams aroundthe patient, continuously deliveringradiation from all possible directions.Luan says results are excellent.“Treatment time can be as much as80% shorter and we can deliver ahigher dose <strong>of</strong> radiation to the tumorand less to the surrounding structures.”The team has filed a provisional patentfor the technique.Gamma knife treatment uses focusedbeams <strong>of</strong> radiation to treat braintumors. Again, using powerfulalgorithms, Luan and his researchpartner at <strong>University</strong> <strong>of</strong> California atSan Francisco developed s<strong>of</strong>tware thatoptimizes the beams, turning theminto a relative brush that “paints” thecontours and volume <strong>of</strong> the tumorwith radiation. The dynamic processcovers the tumor faster and moreevenly. Ultimately, the s<strong>of</strong>tware could beincorporated into a treatment planningprogram. A provisional patent has alsobeen filed for the technique.Improving cancer treatment is a longway from the theoretical work Luan hadplanned to pursue. His goals changedthe day he saw how his work could heal.“I’ll never forget the first day they usedmy algorithm to treat patients,” saysLuan. “I was nervous, but it worked.That’s when I decided to make it thefocus <strong>of</strong> my career.”Probing RNAiLike Luan, Terran Lane is using hiscomputer science expertise to conductbioinformatic research. One focus <strong>of</strong>Lane’s work is ribonucleic acid (RNA),which is closely associated with DNA.While DNA contains the code for cellgrowth, RNA acts as the “middleman,” controlling the flow <strong>of</strong> geneticinformation between DNA and theproteins it ultimately produces. Manyresearchers believe understandingRNA will dramatically improve diseasetreatment and genomic research.Recently, biology researchersdiscovered a cellular process, nowcalled RNA interference (RNAi), thatcan be used to stop malfunctioninggenes from producing bad proteins.Lane is conducting RNAi researchwith immunologists in the <strong>UNM</strong>Biology Department and the Centerfor Evolutionary and TheoreticalImmunology. He uses algorithms tocreate models <strong>of</strong> chemical probesthat connect with RNA and stop theprocess <strong>of</strong> protein production. “We’redesigning these RNAi probes totarget specific RNA and disrupt them,while creating as few side effects aspossible,” explains Lane. The challengeis how to design the short interferingRNA probe (siRNA) so that the probetargets a specific malfunctioning geneor protein without disrupting beneficialones. The powerful algorithms help theresearchers evaluate all the possiblevariations in the structure <strong>of</strong> the probe.It’s early in the research, but Lane andhis team have made one important find.“Some <strong>of</strong> the early work in the areaassumed that everything was highlyspecific and you didn’t have to worryabout side effects,” explains Lane.“But we predicted computationallythat you’re likely to have side effectsunless you work to design probes thatare free <strong>of</strong> side effects.” The teamalready developed one algorithm thatother RNAi researchers can use todesign more effective drugs with fewerside effects. It’s clear that with theirbioinformatic research already yieldingresults, Lane and Luan are turningcomputer codes into hope. d<strong>UNM</strong> <strong>Engineering</strong> 15

Alumni Pr<strong>of</strong>ile: Robert I. Solenberger<strong>Engineering</strong>SurgicalInnovationsWhether you address him as “Dr. Robert Solenberger” or “Colonel RobertSolenberger,” you’ll be talking to an outstanding surgeon and highly decoratedmilitary <strong>of</strong>ficer who has helped heal thousands <strong>of</strong> lives with his own hands andthrough his medical innovations.Robert Solenberger, a native <strong>of</strong> Oakland, California,graduated from the <strong>University</strong> <strong>of</strong> <strong>New</strong> <strong>Mexico</strong> in 1965 witha degree in chemical <strong>engineering</strong> and had a successful<strong>engineering</strong> career. But things changed after he developedwalking pneumonia and a serious disability during OfficerCandidate <strong>School</strong>. Inspired by the doctors and nurses whonot only helped him but treated soldiers wounded in Vietnam,he soon had a different goal. He decided to pursue medicine.He received his M.D. in 1974 from the <strong>University</strong> <strong>of</strong> Maryland<strong>School</strong> <strong>of</strong> Medicine, completed his surgical residency, andwent on to fellowships in pediatric surgery at the JohnHopkins Hospital in Baltimore, Maryland and the <strong>University</strong> <strong>of</strong>Texas Medical Branch in Galveston. Solenberger’s long careerincluded appointments at several army medical centers, mostrecently as Chief <strong>of</strong> the Department <strong>of</strong> Surgery at Carl R.Darnall Army Medical Center at Fort Hood, Texas, the largestArmy base in the world.Solderberg’s training at <strong>UNM</strong> provided a valuable foundationfor his career as he used his <strong>engineering</strong> skills to developmany important medical innovations. “I learned aboutmethodologies, the systematic examination <strong>of</strong> subjects,separating facts from fiction, and how not to be afraid <strong>of</strong>thinking out <strong>of</strong> the box,” says Solenberger <strong>of</strong> his <strong>engineering</strong>experience at <strong>UNM</strong>. In 1982, he developed a three-prongedtreatment for ruptured appendicitis that is still consideredthe gold standard today. In 1995, Solenberger coordinatedthe delivery <strong>of</strong> twins who were born attached from thebreastbone down, sharing one pelvis and three legs. Hehelped lead the 70-member surgical team that transformedthe twins’ lives with five medical breakthroughs. Thesuccessful operations gave both girls the ability to walkand to bear children.Giving Back“My <strong>UNM</strong> pr<strong>of</strong>essors advised us to never forget thatlearning is followed by leading and teaching others andsharing, and your learning process has to go on forever,”says Solenberger. He stays busy following their advice.Solenberger continues to practice medicine as the onlypediatric surgeon at the Carl R. Darnall Army Medical Center.He is on the teaching faculty at two medical schools andruns an emergency room training program at Fort Hoodthat has produced residents with the highest ER boardcertification scores for the past six years.During his career, Solenberger has authored articles formedical journals and has been affiliated with numerouspr<strong>of</strong>essional organizations. He has also received severaldistinguished awards for his exemplary military serviceand exceptional dedication to his pr<strong>of</strong>ession. Solenbergerfrequently travels to combat zones around the globe topatch up Purple Heart recipients because, “as long as they’reout there doing what they’re doing, I should be there too.” d16 <strong>UNM</strong> <strong>Engineering</strong>

<strong>New</strong> FacultyChemical and Nuclear <strong>Engineering</strong>Cassiano de Oliveira Pr<strong>of</strong>essorThroughout his research career, de Oliveirahas specialized in unstructured finiteelement techniques, high-performancecomputing and advanced solution methodsapplied to radiation transport andradiative transfer and also to multiphaseflow, electro-seismics and global oceancirculation. Most recently he was apr<strong>of</strong>essor at the Nuclear and Radiological <strong>Engineering</strong> Programwithin the George Woodruff <strong>School</strong> <strong>of</strong> Mechanical <strong>Engineering</strong> <strong>of</strong>the Georgia Institute <strong>of</strong> Technology.Civil <strong>Engineering</strong>Rafiqul A. Tarefder Assistant Pr<strong>of</strong>essorTarefder’s research interests includecharacterization and modeling <strong>of</strong> pavementmaterials and system, mechanistic pavementdesign, geotechnical applicationsrelated to transportation systems, numericalmodeling at multiple length scales, neuralnetworks, and nanoscale measurements ingeo-paving materials. He received his Ph.D.from the <strong>University</strong> <strong>of</strong> Oklahoma.Giovanni C. Migliaccio Assistant Pr<strong>of</strong>essorJoining the CE department in Construction<strong>Engineering</strong> and Management, Migliaccio’sareas <strong>of</strong> expertise include innovativeprocurement, project management,sustainability and design-constructionintegration. He completed his Ph.D. at the<strong>University</strong> <strong>of</strong> Texas at Austin.Andrew J. Schuler Assistant Pr<strong>of</strong>essorA recipient <strong>of</strong> the NSF CAREER Award,Schuler brings his expertise in biologicalwastewater treatment, nutrient removal,agent-based modeling, sedimentation,and the application <strong>of</strong> molecular methodsto the expanding <strong>UNM</strong> Environmental<strong>Engineering</strong> faculty. He received hisPh.D. from the <strong>University</strong> <strong>of</strong> Californiaat Berkeley.Computer ScienceJoel Castellanos LecturerCastellanos’ background includesworking as a senior s<strong>of</strong>tware engineersubcontractor to Lockheed Martin andteaching college and high school math,science and computer science. He receivedhis MS in Computer Science from <strong>UNM</strong>.Joseph Kniss Assistant Pr<strong>of</strong>essorKniss is currently conducting research onhigh quality, interactive visualization <strong>of</strong>extremely large-scale 3D datasets fromscience and medicine. His work also focuseson the visualization <strong>of</strong> 3D image data forvisual representation <strong>of</strong> uncertainty anddecision-making using visualization tools.He looks forward to developing stronginterdisciplinary collaborations within science, medicine, and industry.He received his Ph.D. from the <strong>University</strong> <strong>of</strong> Utah.Jedidiah Crandall Assistant Pr<strong>of</strong>essorCrandall’s research interests includesystems, security, and malware. Hismain area <strong>of</strong> research is to understandInternet worms and the exploits thatthey use to propagate so that computerscientists can automatically captureand analyze them. He received his Ph.D.from <strong>University</strong> <strong>of</strong> California, Davis.Electrical and Computer <strong>Engineering</strong>Rafael Fierro Associate Pr<strong>of</strong>essorFierro’s interests include hybrid andembedded systems, coordination <strong>of</strong>multiagent systems, optimization-basedcooperative control <strong>of</strong> unmanned aerialand ground vehicles, mobile sensornetworks, and robotics. He receivedhis Ph.D. from the <strong>University</strong> <strong>of</strong> Texas-Arlington and was an assistantpr<strong>of</strong>essor at Oklahoma State.Nasir Ghani Associate Pr<strong>of</strong>essorGhani’s research interests includecyber-infrastructures, optical networks,protocols, traffic <strong>engineering</strong>, survivability,network virtualization and services,performance evaluation, simulation,and stochastic modeling. He received hisPh.D. from Ontario’s <strong>University</strong> <strong>of</strong> Waterlooand has held senior positions in industry.Jamesina J. Simpson Assistant Pr<strong>of</strong>essorSimpson is interested in computationalelectromagnetics theory and applications,especially finite-difference time-domain(FDTD) solutions <strong>of</strong> Maxwell’s equations.Her research topics range from near-DC to light, and include modeling theEarth-ionosphere waveguide and opticalinteractions with living tissues. Shereceived her Ph.D. from Northwestern.<strong>UNM</strong> <strong>Engineering</strong> 17

<strong>School</strong> <strong>of</strong> <strong>Engineering</strong>MSC01-11401 <strong>University</strong> <strong>of</strong> <strong>New</strong> <strong>Mexico</strong>Albuquerque, NM 87131-0001Non-pr<strong>of</strong>itOrganizationUS Postage PaidAlbuquerque, NMPermit No. 39