Plate & Shell - Vahterus

Plate & Shell - Vahterus

Plate & Shell - Vahterus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

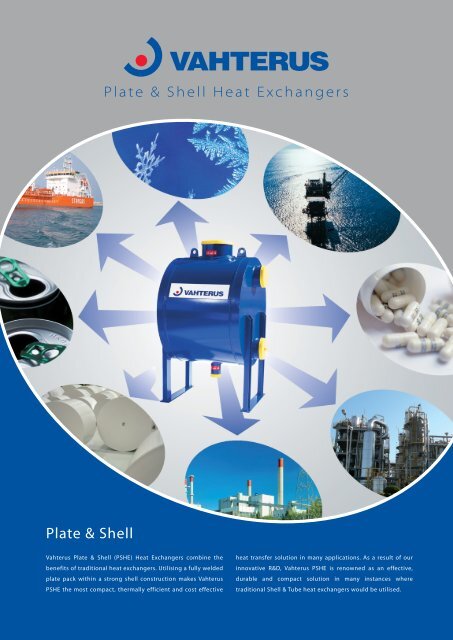

<strong>Plate</strong> & <strong>Shell</strong><strong>Vahterus</strong> <strong>Plate</strong> & <strong>Shell</strong> (PSHE) Heat Exchangers combine thebenefits of traditional heat exchangers. Utilising a fully weldedplate pack within a strong shell construction makes <strong>Vahterus</strong>PSHE the most compact, thermally efficient and cost effectiveheat transfer solution in many applications. As a result of ourinnovative R&D, <strong>Vahterus</strong> PSHE is renowned as an effective,durable and compact solution in many instances wheretraditional <strong>Shell</strong> & Tube heat exchangers would be utilised.

Fully Welded <strong>Plate</strong> & <strong>Shell</strong> TechnologyThe Per fect Solution<strong>Plate</strong> & <strong>Shell</strong>, Fully Welded <strong>Plate</strong> & <strong>Shell</strong>, Openable <strong>Plate</strong> & <strong>Shell</strong>, CompactThe Best of Both Worlds<strong>Plate</strong> & <strong>Shell</strong> Product Family:<strong>Vahterus</strong> PSHE combines the benefits of <strong>Plate</strong> & Frame and <strong>Shell</strong> & Tube heat exchangers.<strong>Plate</strong> & Frame:<strong>Shell</strong> & Tube:+ High Heat Transfer+ High Pressure+ Compact+ High Temperature+ Low Fouling+ No Gaskets+ Close Approach Temperatures+ Low Pressure Drop- Pressure Limitations- Low Heat Transfer- Temperature Limitations- Large Size and Heavy Weight- Gaskets- High Fouling• Universal Heat Exchanger• Wide Capacity Range• Design Pressures up to 200 bar• Large Heat Transfer Area: 1 – 2000 m2/exchanger• Applications:- Liquid/Liquid- Liquid/Gas- Gas/Gas- Condensers- Evaporators- Cascades- Multi-Phase / Multi-Component SystemsAs the inventors and market leaders of <strong>Plate</strong> & <strong>Shell</strong> Technology, <strong>Vahterus</strong> PSHE is now used in manyapplications, across almost all industrial sectors. Using the thermal capabilities of corrugated platetechnology, housed with a pressure vessel (shell), provides the user with a solution to many mechanicaland operational issues, such as space and weight constraints. The flexibility of <strong>Vahterus</strong> PSHE can bedemonstrated by the fact it can be operated in true counter-current flow (as shown above), co-currentflow, by reversing either flow stream, or cross-flow, by simply moving the shell side nozzles to the sideof the shell. The wide range of <strong>Vahterus</strong> PSHE plate sizes means that we can accommodate the needs ofproduction environments ranging in scale from laboratory, to pilot plant, to full-scale production.<strong>Plate</strong> & <strong>Shell</strong>, Fully Welded:<strong>Plate</strong> & <strong>Shell</strong>, Openable:<strong>Plate</strong> & <strong>Shell</strong>, Compact:• Fully welded shell construction• Easy to open and clean• All connections in the end plate• Available sizes: 2, 3, 4, 5, 6,• Available sizes: 2, 3, 4, 5,• Available sizes: 3, 4, 5 and 7<strong>Plate</strong> & <strong>Shell</strong>7, 9 and 146, 7, 9 and 14• Minimum space requirement+ High Heat Transfer+ Wide Pressure Range+ Wide Temperature Range+ No Gaskets+ Compact+ Low Fouling+ Close Approach Temperatures

<strong>Vahterus</strong> provides solutions for many heat transfer needs. We have considerable experiencewith heat transfer technology and continually invest in Research & Development.High quality, consistent and reliable products are a matter of principle to us.Compact & Effective<strong>Vahterus</strong> PSHE combines the benefits of <strong>Plate</strong> & Frame and <strong>Shell</strong> & Tube heat exchangers. PSHE caneither be described as a fully welded, high integrity plate heat exchanger, with no gaskets; or a genericalternative to <strong>Shell</strong> & Tube, approx. 25% of the footprint, displaying both space and weight benefits.<strong>Vahterus</strong> OyPruukintie 7FI-23600 KalantiFINLANDTel. +358 2 840 70Fax +358 2 840 7299sales@vahterus.com<strong>Vahterus</strong> Americas, LLCPO Box 77264CharlotteNC 28271USATel. +1 704 846 5050sales.americas@vahterus.com<strong>Vahterus</strong> Deutschland GmbHMagnolienweg 2663741 Aschaff enburgGERMANYTel. +49 6021 181 700webmaster@vahterus.de<strong>Vahterus</strong> Heat ExchangersShanghai Co., LtdRoom 816, Enterprise SquareMei Yuan Road 228,Zha Bei District200070 ShanghaiCHINATel. +86 21 638 00848 *113sales_china@vahterus.com<strong>Vahterus</strong> (UK) Ltd12-14 Derby Road, MelbourneDerbyshire DE73 8FEUKTel. +44 1332 863175vahterus.uk@vahterus.comwww.vahterus.comBenefits of PSHE• No Gaskets or Brazing• High Integrity / Total Containment• Strong and Safe Construction• Unique Protection and Resistanceto Thermal and Pressure Cycling• Thermally Efficient• Compact and Low Weight• Flexible Construction• Proven, Reliable Technology• Low Fouling• Minimal Maintenance Requirement• Close Approach TemperaturesTechnical SpecificationMaximum Heat Transfer Area• 2 000 m²/exchangerMechanical Design• Full vacuum to 150 bar possible• -164 to +899°CMain Data:Quality Systems:• ISO 9001:2000• EN ISO 3834-2• PED Module B+D• ASME U Stamp• OHSAS 18001• ISO 14001Approvals:• PED• R.I.N.A• ASME U Stamp & R Stamp • ABS Europe Ltd.• SELO, China• Bureau Veritas• AD-2000 HPO• DNV• Germanischer Lloyd• MKE South Korea• Lloyd´s RegisterMaterials:<strong>Shell</strong>:<strong>Plate</strong>s:• AISI 316• AISI 316L• St 35.8/1 / P235GH • Titanium, Grade 1• P265GH• C22• P355NL2• C276• EN 1.4547, SMO254 • Nickel 201• EN 1.4539. 904L • EN 1.4547, SMO254• EN 1.4539, 904L• EN 1.4462, Duplex• other materials on requestArea/plate, m² <strong>Plate</strong> side nozzles, DN <strong>Shell</strong> side nozzles, DNPSHE 2PSHE 3PSHE 4PSHE 5PSHE 6PSHE 7PSHE 9PSHE 14PRHE 120.0320.0760.150.260.350.460.801.551.0025508010012515020030020020-8025-25025-30025-35025-50025-50025-70025-100025-1000