You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

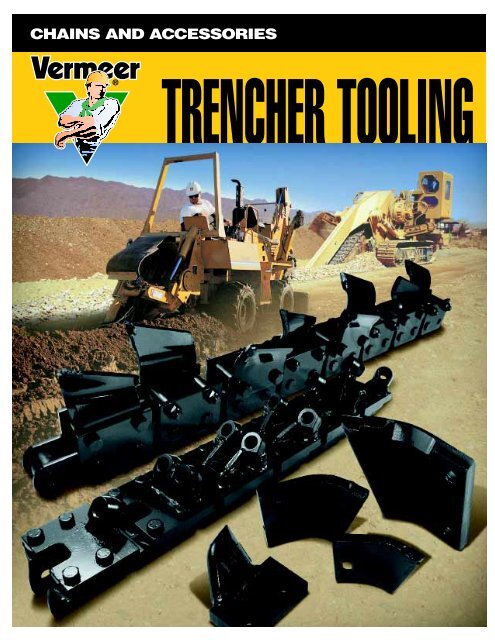

CHAINS AND ACCESSORIES®TRENCHER TOOLING

RIDE-ON/WALK-BEHIND TRENCHERCHAINSCutting-EdgeDesign WithEnduring Quality.As a world leader in trenching andunderground installation, Vermeerproudly offers the <strong>ind</strong>ustry’s latestdigging chain and cutting technology.Constructed from high-quality,heat-treated alloy steel, Vermeerchains per<strong>for</strong>m day after day in awide range of ground conditions.Five High-Per<strong>for</strong>mance<strong>Trencher</strong> Chain Styles.From hard clay to loam and sandyclay, from frost to light rock, Vermeeroffers a chain style to fit your needs.Precision machining and carefuldesign help to make Vermeer chainsamong the most productive you canuse <strong>for</strong> your trenching operations.Vermeer chains feature solid, precision-groundnickel/chrome alloy steel thimbles with exceptionalstrength and superior press fit control.Chain pins are carefully machinedto optimize the pin surface <strong>for</strong> bettercontrol of tolerance, surface hardnessand microstructure integrity.StandardThe standard chain offers a cost-efficient way to trenchin a variety of ground conditions. Loam, sandy clayand hard clay are just a few of the commonapplications that this S-style chain is designed <strong>for</strong>.Low-ProfileThe low-profile design delivers efficient cutting withminimal kickback — reducing side bar edge wearand extending cutter longevity. It features weldedconstruction to prevent pins and bars fromworking loose during demanding digging jobs.Flat BaseThis K-style chain delivers smooth per<strong>for</strong>mance.Cutting tools are bolted on its top (instead of side)<strong>for</strong> better per<strong>for</strong>mance in tough conditions.Optional bolt-on bases are available <strong>for</strong> frost,light rock and most soils.Long-term chain pitch and elongation overthe life of Vermeer chains is reduced via tighterclearances and optimal pin and bushing press fits.Double heat-treated pins with extra largepinheads offer superior wear resistance andless pinhead wear than other chains commonlyfound on the market.Anti-Back-Flex StandardThis chain helps reduce machine stress andfeatures a long life. Side bar edge wear is limitedby lessening the boom bounce and kickbackexperienced when attachment links back-flex.Anti-Back-Flex Super-DutyThis chain offers excellent attachment strength througha fixed-roller design that is equipped exclusivelywith heavier components and an ABF sidebar<strong>for</strong> reduced joint and side bar edge wear.NEW

TRACK TRENCHERCHAINSDesigned<strong>for</strong> MaximumPer<strong>for</strong>mance.Vermeer digging chains areuniquely designed to meetthe demanding conditions thattrenching projects impose.Each Vermeer chain designhas been field-tested under avariety of conditions to ensuregreater service and longevity.H-Series and AH-Series offerextra-tough per<strong>for</strong>mance <strong>for</strong>harsh conditions. Get thechain advantage that onlyVermeer can offer.STRONG STRONGER STRONGESTK-SeriesThe K-Series chain featuresthe original, proven Vermeerbent-bar chain design.Suitable <strong>for</strong> everyday use,the K chain is offeredstandard on some trenchermodels, and as an optionon others.H-SeriesThe H-Series chain is designedwithout rollers — no rollers towear out; larger pins reducefailures related to shock loading.Additionally, a greater contactarea on the side bar edgealso offers chain wear reduction.Standard on T755, T855 and T955.AH-SeriesFor trenching in the toughestconditions, AH-Series chainsoffer all the benefits ofH-Series chains, but featureadded chain and attachmentstrength.

TRACK TRENCHERCHAINSThe Added Value ofVermeer Track <strong>Trencher</strong>Chain Assemblies.Vermeer track chains are availablein K, H, and AH styles to meetyour job specifications — and yourbudget. Customize your chain bychoosing from a variety of cuts,configurations, tooling and material.Selected chains are now available inconvenient assemblies* — no morehandling of awkward cutter bases!Fit and life of the cutter baseis assured through the use of hightensile strength fasteners.Track chain bases are availablein several grades of steel to meetyour job specifications and budget.Stabilize and reduce excesswear on the digger chain,extend the life of the cutter base andmore effectively utilize cutting tools —bases are available with customanti-back-flex bars.*Single-style chains custom-ordered

TRENCHERACCESSORIESTackle Tough Jobs With Vermeer Cutters.• Quality-controlled by Vermeer• Designed to maximize Vermeer equipment per<strong>for</strong>mance• Components are precision-machined to integrate seamlesslywith all specified chains• Robotically applied welds and hardfacing improve cutter wearcharacteristics over hand-applied hardfacing methodsRobotically appliedhardfacing andcarbideCup CutterBoron alloy steelCup CutterThe cup cutter is constructedwith a large quantity of highqualitycarbide particles andincludes impact- and abrasionresistanthardened steel <strong>for</strong> longwear characteristics.Tiger ToothThe patented Tiger Tooth boastsa unique, productivity-enhancinggeometry that lifts spoil efficientlyfrom the trench.Shark ToothThe proven Shark Tooth features flexiblesetups <strong>for</strong> the operator who needs to changetrench widths; is compatible with the cupcutter <strong>for</strong> combination setups. A protectivebase plate saves on bolt head wear.Available <strong>for</strong> track and rubber tire digging chains.Rotary CutterAvailable in a variety of configurations,including bolt-on andwelded, rotary teeth are a goodchoice <strong>for</strong> moderate rock andfrost applications.Track Rotary CutterWith a width-adjustable chainsetup, track rotary cutters areexcellent <strong>for</strong> solid rock, rockysoils and frost.

RIDE-ON/WALK-BEHIND TRENCHERCHAIN ASSEMBLIESTough Chains Matched to Rugged Cutters.The Vermeer Cutting Edge Group produces a wide range ofstandard chain/cutter combinations <strong>for</strong> a variety of conditions.The Cutting Edge Group can also build custom chainsengineered to your unique soil or rock conditions — contactyour dealership <strong>for</strong> details.Full Cup ChainThis chain uses a series of cup cutterson each link; is designed to per<strong>for</strong>min moderate soil conditions.Available <strong>for</strong> all RT modelsPartial Cup ChainCup cutters are installed on everyother link; per<strong>for</strong>ms in moderatesoils with a high moisturecontent.Available <strong>for</strong> all RT modelsFull Tiger ChainDepending on the chain pattern,this chain can dig in medium- tohard-packed soil and frost.Available <strong>for</strong> all RT modelsTiger Combo ChainUtilizes the Tiger Tooth in conjunctionwith cup cutters to offer servicein compacted ground andsandy clay.Available <strong>for</strong> all RT modelsFull Shark ChainUses bolt-on rugged cutters and isdesigned <strong>for</strong> use in hard-packed soilsand frost. Allows the operator toadjust chain width.Available <strong>for</strong> all RT modelsShark Combo ChainOffers simultaneous trenching andcleaning in a variety of soilconditions, including loam,sandy clay and hard clay.Available <strong>for</strong> all RT modelsRotary ChainRotary chains per<strong>for</strong>m well incompacted ground, rocky conditionsand frost. Features carbide-tippedcutters <strong>for</strong> durability.Available <strong>for</strong> V4150, V5750,V5800, V8100, V8550A, V120,RT700/850Welded Rotary ChainIs a low-profile welded chain —per<strong>for</strong>ms with less kickback andhas no bolts to loosen with use.Features rotary cutters <strong>for</strong> usein tough conditions.Available <strong>for</strong> V3550, V4150,V5750, V5800, V8100, V8550A,V120, RT700/850Welded Shark ChainIs a low-profile welded chain —per<strong>for</strong>ms with less kickback and hasno bolts to loosen with use.Features the Shark Tooth <strong>for</strong>extended longevity.Available <strong>for</strong> all RT modelsAn example of a custom chain usedto pulverize Florida coral deposits.

ROTARYCUTTING TOOLS.74" (1.89 cm)Shank Series.86" (2.18 cm)Shank Series1" (2.54 cm)Shank SeriesStep Shank Series2892001289500110158100111119001 11118001 2117320014418001 86121001 8611900186127001 308000935 308000915567510012894001308000850238841001 238840001 30800088186122001 101580001 308000908308000916 308000917 308000918308000851 308000852 308000853308000882 308000883 30800088486123001 101579001 308000903308000919 308000920 308000921308000854 667410017580001 296264864308000891 308000893 308000894308000923 308000924 308000925CMM Series.76" (1.93 cm)Shank Series308000895 308000896 308000897308000926308000902308000928204936001 308000939 204938001308000871308000857308000858308000898 308000899 308000900308000929308000930308000931308000859 308000875308000901 308000902 308000913308000933308000934Installation andRemoval Tools28970011076400114116001 86129001296264847296264848308000949 296264853 308000950296264852296264878304569001296264861Ride-On/Walk-Beh<strong>ind</strong> <strong>Trencher</strong>s LM25 LM42 RT60 V1150 V1350 RT100 RT200 V3500A V4150A V5750CMM series • • • • • •.74" (1.89 cm) shank series • • •Ride-On <strong>Trencher</strong>s V5800 V6500 RT700 V8100 RT850 V8550A V120 CC145A OCC145.74" (1.89 cm) shank series • • • • • • •.76" (1.93 cm) shank series • • • • • •.86" (2.18 cm) shank series • • •Track <strong>Trencher</strong>s T455 T555 T558 T655 T755 T758 T855 T955 T1055 T1255.74" (1.89 cm) shank series • • •1" (2.54 cm) shank series • • • • • •Step shank series • • •

Worldwide coverage with a local touch.Your <strong>ind</strong>ependent, authorized Vermeer dealer knowsyour local conditions and is ready to provide expert sales,support, service and parts — wherever your job site.From small, walk-beh<strong>ind</strong> units to large rocktrenchers, from vibratory plows to special-applicationequipment, Vermeer has a long-standing reputation <strong>for</strong>production, innovation and dependability. With a full rangeof trencher support materials and systems, Vermeer is yourpartner at each and every job site.®Vermeer Manufacturing Company1210 Vermeer Road EastP.O. Box 200Pella, Iowa 50219 U.S.A.Phone: (641) 628-3141Fax: (641) 621-7734International fax: +1 (641) 621-7730www.vermeer.comCall toll-free 1-866-VERMEER1-866-837-6337 (U.S.A. only)Europe, Middle East and Africa:P.O. Box 3234460 AS GoesNetherlandsPhone: +31 113 272700Fax: +31 113 272727Vermeer Manufacturing Company reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation.VERMEER and VERMEER LOGO are registered trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. TIGER TOOTH is a trademark of Vermeer Manufacturing Company.SHARK TOOTH is a trademark of Consolidated Carbide, Inc.08/02.10k© 2002 Vermeer Manufacturing CompanyAll Rights ReservedPN 115153-219