Appendix A Page 1 Commercial Bin Maintenance Checklist - GEAPS

Appendix A Page 1 Commercial Bin Maintenance Checklist - GEAPS

Appendix A Page 1 Commercial Bin Maintenance Checklist - GEAPS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

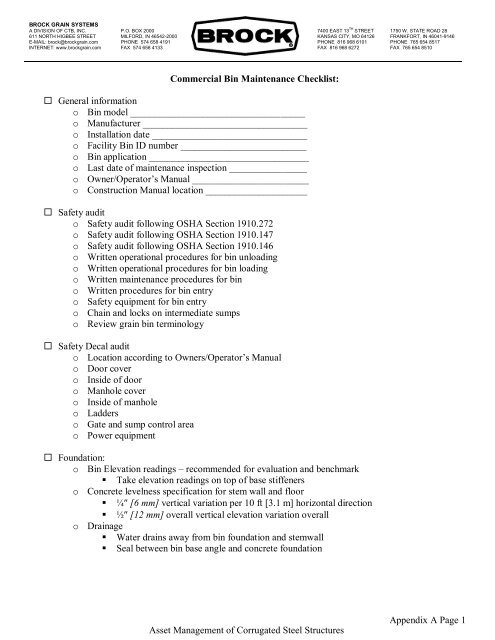

BROCK GRAIN SYSTEMSA DIVISION OF CTB, INC.611 NORTH HIGBEE STREETE-MAIL: brock@brockgrain.comINTERNET: www.brockgrain.comP.O. BOX 2000MILFORD, IN 46542-2000PHONE 574 658 4191FAX 574 658 41337400 EAST 13 TH STREETKANSAS CITY, MO 64126PHONE 816 968 6101FAX 816 968 62721750 W. STATE ROAD 28FRANKFORT, IN 46041-9146PHONE 765 654 8517FAX 765 654 8510<strong>Commercial</strong> <strong>Bin</strong> <strong>Maintenance</strong> <strong>Checklist</strong>:¨ General informationo <strong>Bin</strong> model ____________________________________o Manufacturer __________________________________o Installation date ________________________________o Facility <strong>Bin</strong> ID number __________________________o <strong>Bin</strong> application _________________________________o Last date of maintenance inspection ________________o Owner/Operator’s Manual ________________________o Construction Manual location _____________________¨ Safety audito Safety audit following OSHA Section 1910.272o Safety audit following OSHA Section 1910.147o Safety audit following OSHA Section 1910.146o Written operational procedures for bin unloadingo Written operational procedures for bin loadingo Written maintenance procedures for bino Written procedures for bin entryo Safety equipment for bin entryo Chain and locks on intermediate sumpso Review grain bin terminology¨ Safety Decal audito Location according to Owners/Operator’s Manualo Door covero Inside of dooro Manhole covero Inside of manholeo Ladderso Gate and sump control areao Power equipment¨ Foundation:o <strong>Bin</strong> Elevation readings – recommended for evaluation and benchmark• Take elevation readings on top of base stiffenerso Concrete levelness specification for stem wall and floor• ¼″ [6 mm] vertical variation per 10 ft [3.1 m] horizontal direction• ½″ [12 mm] overall vertical elevation variation overallo Drainage• Water drains away from bin foundation and stemwall• Seal between bin base angle and concrete foundation<strong>Appendix</strong> A <strong>Page</strong> 1

BROCK GRAIN SYSTEMSA DIVISION OF CTB, INC.611 NORTH HIGBEE STREETE-MAIL: brock@brockgrain.comINTERNET: www.brockgrain.comP.O. BOX 2000MILFORD, IN 46542-2000PHONE 574 658 4191FAX 574 658 41337400 EAST 13 TH STREETKANSAS CITY, MO 64126PHONE 816 968 6101FAX 816 968 62721750 W. STATE ROAD 28FRANKFORT, IN 46041-9146PHONE 765 654 8517FAX 765 654 8510o Concrete cracks greater than 1/32″ [1mm] wide• Note location(s) and length - document• Digital photos of area• Future measurement points identified for next inspection• 1-3 months before next inspectiono Areas of exposed rebar• Note locations if any _______________________________o Stiffener support over work tunnel & aeration tunnelo Fans supported according to bin manufacturer’s specificationso Good seal to foundation¨ Anchors:o None missing• Aeration inlets through stem wall• At equipment unload tunnelso Clean and free from rusto Proper washero Nuts tightened¨ Stiffenerso Aligned ends of stiffenerso Splice plate hardware tight and aligning connection• Properly shimmed at connectiono Missing or broken boltso Evaluate for bowing• Upper rings• Mid rings• Lower ringso Stiffener alignment to corrugated body sheet• Inspect for signs of rotationo Inspection at aeration tunnels• Proper support• Anchored to foundationo Inspection at equipment unload tunnels• Proper support• Anchored to foundationo Stiffener base plate• Not field modified or cut• Full contact and supported· On concrete foundation· Properly shimmed<strong>Appendix</strong> A <strong>Page</strong> 2

BROCK GRAIN SYSTEMSA DIVISION OF CTB, INC.611 NORTH HIGBEE STREETE-MAIL: brock@brockgrain.comINTERNET: www.brockgrain.comP.O. BOX 2000MILFORD, IN 46542-2000PHONE 574 658 4191FAX 574 658 41337400 EAST 13 TH STREETKANSAS CITY, MO 64126PHONE 816 968 6101FAX 816 968 62721750 W. STATE ROAD 28FRANKFORT, IN 46041-9146PHONE 765 654 8517FAX 765 654 8510¨ Sidewall:o Missing or broken boltso Rusted body sheets on exterior of bin• Document and record location(s)o Rusted body sheets on interior of bin• Document and record location(s)o Wind Ring(s) aligned• Connected• In proper position• Mounting brackets secureo Damaged or dented sheetso Observe for body sheet alterations• Approved by manufacturero Side Discharge Chutes (Side Draw System)• small end up and angles installed on both sides¨ Aeration flooro Supports properly locatedo Inspect for signs of sweep damageo Inspect for signs of overloading – floor permanently deformedo Clean under the floor and aeration trencheso Temperature Cables: weights removed and tie downo Support spacing and proper installation¨ Unload sumpso Alternate or emergency sump at ¼ Radius• Separate control mechanismo Free and clear of any material buildupo Center sump operation independent of intermediate sumpso All sump gates function properlyo Controls are labeledo Intermediate sumps gate mechanism lockedo Proper guardingo Visible and properly located decals for unloading instructions¨ Temperature cableso Properly located on roofo Vertical orientation between floor and roof – plumbo Inspect for damageo Tie down after sweepingo Observe for damage to cables• Replace if damaged<strong>Appendix</strong> A <strong>Page</strong> 3

BROCK GRAIN SYSTEMSA DIVISION OF CTB, INC.611 NORTH HIGBEE STREETE-MAIL: brock@brockgrain.comINTERNET: www.brockgrain.comP.O. BOX 2000MILFORD, IN 46542-2000PHONE 574 658 4191FAX 574 658 41337400 EAST 13 TH STREETKANSAS CITY, MO 64126PHONE 816 968 6101FAX 816 968 62721750 W. STATE ROAD 28FRANKFORT, IN 46041-9146PHONE 765 654 8517FAX 765 654 8510¨ Electrical checkso <strong>Bin</strong> ground wireso Qualified electrician that knows national, regional and local codes and requirements• Code conformance checks• Switches and electrical controls¨ Ladders (inside and outside) and platformso All hardware installed and tight• Attaching brackets• Ladder splices• Ladder cages• Ladder strapso Inspect for signs of deterioration (rust, cracks, etc.) ladder rung components.• Replace ladders, platforms, or any other weight-bearing parts. Do not paint over.¨ Roofo Hardware in place and tighto Roof panel secure and not looseo Gravity roof vents• Screens are clean• Clear any debris buildupo Power roof vents• Screens are clean• Braces for wind loading• Clear any debris buildupo Insure center fillingo Downspout, conveyor, handrails etc. painted¨ Dooro Door panels aligned on pinso Door latch bars adjustedo Door lapped outside at bottomo All bolts installedo Door sealed properly against leaking¨ <strong>Commercial</strong> Hopper <strong>Bin</strong> structureo Inspect for center loadingo Observe for center unloading• Clear any debris buildupo Bracing hardware tight – nothing missingo Paint any areas that may appear to be rustingo Check levelness of support structure legs• Check elevations with a transito Inspect hopper aeration attachments• Components securely fastened<strong>Appendix</strong> A <strong>Page</strong> 4

BROCK GRAIN SYSTEMSA DIVISION OF CTB, INC.611 NORTH HIGBEE STREETE-MAIL: brock@brockgrain.comINTERNET: www.brockgrain.comP.O. BOX 2000MILFORD, IN 46542-2000PHONE 574 658 4191FAX 574 658 41337400 EAST 13 TH STREETKANSAS CITY, MO 64126PHONE 816 968 6101FAX 816 968 62721750 W. STATE ROAD 28FRANKFORT, IN 46041-9146PHONE 765 654 8517FAX 765 654 8510¨ Site sketch or plan view drawing for documentationo Location• City, State, Zip Code• Facility name• Contact persono Site manager and contact informationo Date of reporto <strong>Bin</strong> modelo <strong>Bin</strong> manufacturero Year builto <strong>Bin</strong> ID numbero Surveyoro Date of surveyo Action takeno Date of actiono Ladder access locationo Sidedraw locations if applicableo Sump dimensional information• Distance(s) from center of bin to next nearest sumpo <strong>Bin</strong> elevation readings to correspond to sketcho Sweep information• Model• Manufacturer• Sweep capacity• Single or multiple passChecked by: ________________________Date: ______________________________Location: ___________________________(City, State, Zip Code)Facility name: _______________________Contact person: ______________________(Site Manager and contact information)<strong>Appendix</strong> A <strong>Page</strong> 5