Biomethane News - CNG Services

Biomethane News - CNG Services

Biomethane News - CNG Services

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

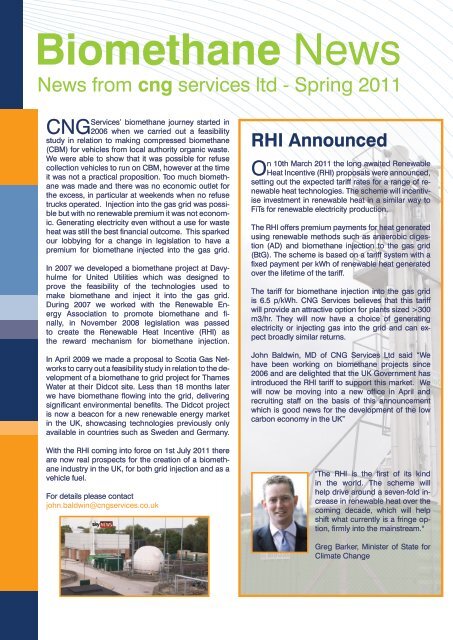

<strong>Biomethane</strong> <strong>News</strong><strong>News</strong> from cng services ltd - Spring 2011<strong>Services</strong>’ biomethane journey started in<strong>CNG</strong> 2006 when we carried out a feasibilitystudy in relation to making compressed biomethane(CBM) for vehicles from local authority organic waste.We were able to show that it was possible for refusecollection vehicles to run on CBM, however at the timeit was not a practical proposition. Too much biomethanewas made and there was no economic outlet forthe excess, in particular at weekends when no refusetrucks operated. Injection into the gas grid was possiblebut with no renewable premium it was not economic.Generating electricity even without a use for wasteheat was still the best financial outcome. This sparkedour lobbying for a change in legislation to have apremium for biomethane injected into the gas grid.In 2007 we developed a biomethane project at Davyhulmefor United Utilities which was designed toprove the feasibility of the technologies used tomake biomethane and inject it into the gas grid.During 2007 we worked with the Renewable EnergyAssociation to promote biomethane and finally,in November 2008 legislation was passedto create the Renewable Heat Incentive (RHI) asthe reward mechanism for biomethane injection.In April 2009 we made a proposal to Scotia Gas Networksto carry out a feasibility study in relation to the developmentof a biomethane to grid project for ThamesWater at their Didcot site. Less than 18 months laterwe have biomethane flowing into the grid, deliveringsignificant environmental benefits. The Didcot projectis now a beacon for a new renewable energy marketin the UK, showcasing technologies previously onlyavailable in countries such as Sweden and Germany.With the RHI coming into force on 1st July 2011 thereare now real prospects for the creation of a biomethaneindustry in the UK, for both grid injection and as avehicle fuel.For details please contactjohn.baldwin@cngservices.co.ukRHI AnnouncedOn 10th March 2011 the long awaited RenewableHeat Incentive (RHI) proposals were announced,setting out the expected tariff rates for a range of renewableheat technologies. The scheme will incentiviseinvestment in renewable heat in a similar way toFiTs for renewable electricity production.The RHI offers premium payments for heat generatedusing renewable methods such as anaerobic digestion(AD) and biomethane injection to the gas grid(BtG). The scheme is based on a tariff system with afixed payment per kWh of renewable heat generatedover the lifetime of the tariff.The tariff for biomethane injection into the gas gridis 6.5 p/kWh. <strong>CNG</strong> <strong>Services</strong> believes that this tariffwill provide an attractive option for plants sized >300m3/hr. They will now have a choice of generatingelectricity or injecting gas into the grid and can expectbroadly similar returns.John Baldwin, MD of <strong>CNG</strong> <strong>Services</strong> Ltd said “Wehave been working on biomethane projects since2006 and are delighted that the UK Government hasintroduced the RHI tariff to support this market. Wewill now be moving into a new office in April andrecruiting staff on the basis of this announcementwhich is good news for the development of the lowcarbon economy in the UK”"The RHI is the first of its kindin the world. The scheme willhelp drive around a seven-fold increasein renewable heat over thecoming decade, which will helpshift what currently is a fringe option,firmly into the mainstream."Greg Barker, Minister of State forClimate Change

Didcot - UK's firstBtG ProjectThe first biomethane to grid project completed in theUK was created by <strong>CNG</strong> <strong>Services</strong>. At the ThamesWater Didcot sewage works site, anaerobic digestersare used as part of the sewage treatment process.Most of the biogas produced through this process wasflared as it had previously been uneconomic to usethis resource due to the high cost of connection to theelectricity grid.The Didcot project, sponsored by SGN, establishedthat BtG is possible and identified opportunities toreduce the capital and operating costs of the plantto make it easier for future biomethane injection projectsto go ahead. SGN provided ‘Innovation Funds’,designed to facilitate research and development inthe UK gas industry which enabled the project to goahead without the RHI premium.<strong>Biomethane</strong> <strong>News</strong>Before - Gas being flaredBiogas produced at the site undergoes a clean-upand upgrading process using a water wash technologyprovided by Chesterfield Biogas. This removesmoisture, CO 2and H 2S to produce a clean, dry gascomposed of around 97% biomethane. Before the biomethanecan be injected into the grid, propane mustbe added so the calorific value of the biomethanematches that of the gas in the local SGN grid.The official launch event on October 5th marked thesuccessful completion of the project and showcasedthe first biomethane injected into the grid in the UK,with the gas purchased by British Gas.During construction“The Didcot project represents an important milestonefor the UK and the start of a new energymarket. SGN, Thames Water and Centrica deservecongratulations for the project and <strong>CNG</strong><strong>Services</strong> looks forward to many similar projects inthe years to come.”John Baldwin, MD of <strong>CNG</strong> <strong>Services</strong>For technical details on the Didcot project pleasecontact the project manager:iain.ward@cngservices.co.ukWhere is the gas grid?As part of our support to potential biomethaneprojects we have now obtained access to all gasGrid Network Maps owned by National Grid, Wales& West Utilities, Northern Gas Networks and ScotiaGas Networks (including Southern Gas Networks).With access to these maps we are now offering aservice to determine if there are any gas pipelinesin the areas for potential AD sites to enable gas injectioninto the grid. We will provide Satellite viewmaps, supported with the same image on a GasComplete - Gas being put to good useGrid Map, showing the closest connections andtype of pressure Gas Mains in the area of interest.Once connection points have been identified, we canprogress the query directly with the Grid owners forconfirmation of pipeline capacity to ensure your projecthas the opportunity to go down the biomethane route.For details please contact:angela.bagshaw@cngservices.co.uk

The Carbon Trustproject commissioned by The Carbon Trust andA aided by <strong>CNG</strong> <strong>Services</strong> compared the differentuses of biogas from AD in terms of carbon savingsand economics. It established that by 2020 the highestcarbon saving would result from biomethane asa transport fuel, closely followed by a biomethane togrid (BtG) scenario. The generation of electricity orCHP was found to result in much lower carbon savings.For biomethane to be used as a transport fuelor injected into the gas grid it is important for the gasto be cleaned and upgraded. This involves removingmoisture and impurities such as H 2S and NO Xfromthe biogas to produce clean, dry biomethane. <strong>CNG</strong><strong>Services</strong> completed a technology and cost review forThe Carbon Trust in relation to biogas cleanup andupgrading<strong>Biomethane</strong> <strong>News</strong>Adnams BreweryOne of the projects in which <strong>CNG</strong> <strong>Services</strong>has provided design and other consultancyrelates to the injection of gas into the service gridat the Adnams brewery, Southwold. Adnams BioEnergy, owned by Bio Group, alongside BritishGas and National Grid have delivered the UK’sfirst biomethane produced from brewery and foodwaste, to the gas grid.The project will generate up to 4.8 million kWhpa which would heat up to 235 homes for a yearor power a family sized car for 4 million miles. Inthe future it is hoped that enough gas will be producedto power both the Adnams brewery and itsfleet of lorries as well as injecting the remaining60% into the grid. The project uses an innovativecryogenic C0 2removal plant with the C0 2beingused to grow algae to make more biogas.In addition to reducing waste from the brewery itself,Adnams also provides an outlet for local foodwaste from both Waitrose and John Lewis, significantlyreducing waste sent to landfill. On top ofthis, other sources of renewable energy such asphotovoltaic cells and solar thermal panels havebeen incorporated into the site to further increasesustainability. Bio Group are now developingother similar projects across the UK.For details please contact:iain.ward@cngservices.co.ukTechnology VisitsIn the last 18 months <strong>CNG</strong> <strong>Services</strong> staff have completedtechnology reviews for a number of clientsincluding visits to operational biogas clean-up andupgrading plants across the EU, as follows:Sweden - Water Wash, Chemical wash, PSAAustria - MembraneSwitzerland - PSAGermany - Chemical Wash, Water Wash, PSAFrance - Water WashNetherlands - Chemical Wash, CryogenicIn each case we also visited the AD plants, includingone in Germany which was harvesting 'whole crop'silage (left) in July, ready to plant another crop the dayafter.If you are interested in the technical reports from thesevisits and our cost data base (which has capex andopex for different sized plants using the main clean upand upgrading technologies) then please contact:jen.clayton@cngservices.co.uk

Regulatory Round-UpManaging Director of <strong>CNG</strong> <strong>Services</strong>, John Baldwin isChairman of the Renewable Energy Association'sBiogas Group. The following sets out key developmentsin the last few months:• JB attended a Ministerial Round table meeting inJuly hosted by Ministers Greg Barker (DECC) andLord Henley (DEFRA). It was agreed to develop anAD Action Plan which would remove the remainingbarriers to the development of a thriving anaerobicdigester market in the UK. Subsequently Johnwas appointed at Chairman of the ‘Smarter WorkingModels” workstreams that are developing the ADStrategy. This is expected to be published by DECC/DEFRA in May 2011 and will set out how the industryis to move forward.<strong>Biomethane</strong> <strong>News</strong><strong>Services</strong> is the only UK member in<strong>CNG</strong> the German Energy Agency (DENA)“Biogaspartnership” project. The project aims toform a leading platform for the injection of biogasinto the gas grid. Although Dena’s role is of a neutralfacilitator for the acquisition and preparationof information and its distribution, Germany setsa prime example of the potential of BtG, as shownby the growth of the country’s biomethane market(see graph).• On behalf of the REA, JB has attended a numberof meetings of the Uniform Network Code ReviewGroup 251 to discuss the issues associated withenrichment of biomethane. There is consensusamongst this group (which includes all main gastransporters and gas suppliers) that it is appropriateto add propane, the costs associated with thisshould be taken into account by DECC when thelevel of RHI is set.• Following on from the success of the Didcot andAdnams projects, a 'Green Gas Certificate' schemehas been introduced which will allow the biomethaneenergy that enters the grid to be tracked andallocated properly to any consumers. This will allow,for example, supermarkets to have their food wastemade into biomethane and injected into the grid withan equivalent amount of natural gas taken out ofthe gas grid at a distribution depot and used to deliverfood to stores by fuelling dual fuel <strong>CNG</strong>/Dieseltrucks. For more information see page 7.• The REA Biogas Group has a Compressed <strong>Biomethane</strong>(CBM) sub-group and this has made a numberof proposals to DfT (Department for Transport) inorder to promote CBM as a vehicle fuel. Proposalsinclude making CBM duty free, offering 2 RenewableTransport Fuel Certificates and allow a higher GVWfor 3.5te vans that have CBM storage tanks to preventloss of payload (as is approved in the Frenchmarket) without affecting their vehicle categorisation.ReaseheathFarm slurry is a significant contributor to UK methaneemissions. As such, having AD plants on farms isseen as a highly attractive option to prevent methaneemissions and also create renewable energy. However,small individual farm AD plants are often noteconomic.<strong>CNG</strong> <strong>Services</strong> have completed a Feasibility Study forReaseheath College as part of a Rural DevelopmentProgramme for England funded project that analysesthe potential of joining farms together into a biogassystem, with a larger plant allowing BtG.The model presented is based on the formation of'clusters' of farms across the Cheshire area. The farmsin each cluster would first transport slurry to a centralAD plant to produce biogas; this would then be pipedto a single clean-up and upgrading facility at a gridinjection point. Not only would harnessing the biogasproduce a clean, renewable source of energy but puttingthe digestate by-product back onto the farmlandwould reduce the need for expensive and environmentallydamaging mineral fertilisers.For details please contact:terry.williamson@cngservices.co.uk

<strong>Biomethane</strong> for TransportIn the search for alternatives to petrol and diesel forfuelling vehicles, biomethane is making a strongchallenge with an ever increasing range of vans andtrucks. The first natural gas vehicles developed in theUK in the 1990s were petrol vehicles converted to runon natural gas. However, as the gas was 'wet'; this ledto problems both with the vehicles and filling stations.Additionally in the past the <strong>CNG</strong> storage cylindersmeant that storage space was reduced.In 2010, following from the example set by mainlandEurope, the UK is restarting the <strong>CNG</strong> industry. Naturalgas has claims to be a safer fuel than diesel or petrolas it is non-toxic and lighter than air so will rise anddisperse if a leak occurs. A gas-fuelled vehicle canreduce carbon monoxide (CO) emissions by 97%,hydrocarbons by 81%, nitrous oxides (NO X) by 86%and particulate matter by 94%. By designing thevehicles from first principles to run <strong>CNG</strong>, the storagecylinders arehidden underthe floor, withno loss of luggagespace.The UK producesthelargest volumeof renewablemethane (biomethane)in Europe due to the high level of wastesent to landfill sites. The other major source of biogasproduction is at sewage works, such as the YorkshireWater site in Sheffield.<strong>Biomethane</strong> <strong>News</strong>Sheffield City Council and the council’s main recyclingand waste management contractor, Veolia Environmental<strong>Services</strong>, have launched the country’s largestfleet of gas powered vehicles. This follows the council’ssuccessful six month trial of biomethane fuelledcaddy vans, part of a new initiative to promote ‘green’fuels. The fleet, purchased by Veolia, consists of 10Mercedes-Benz Econic lorries which will be used forrefuse collection across the city. The Econic runs oncompressed natural gas (<strong>CNG</strong>) which will produceless CO 2than a vehicle that uses fossil based fuels ona 'well to wheel' basis as well as very low emissions ofN0x and particulates.<strong>CNG</strong> <strong>Services</strong> supported Sheffield City Council in itssuccessful application to have a grant for a new <strong>CNG</strong>filling station which is expected to be in operation bySummer 2011.MB Sprinter <strong>CNG</strong>The Mercedes Benz Sprinter van runs on <strong>CNG</strong> butalso has aback-up petrolcapacity givinga total rangeof 1100km. Ithas a 1.8 litreturbochargedengine and fuelconsumptionof 13km per kgof fuel.VW Caddy EcofuelThis car runs primarily on <strong>CNG</strong> but has a back-uppetrol capability similar to the Sprinter. It has a 2.0 litreengine and a range of 550km. CO 2emissions per kmare around 20% less for the Ecofuel Caddy than forthe gasoline Caddy. Fuel consumption is around 18kmper kg of fuel.Passat EcofuelDuring September 2010, Volkswagen’s Passat Ecofuelmade its debut in the UK to showcase the drive forbiogas as a renewable vehicle fuel. The car proved popularat the recent Low Carbon Vehicle event at MillbrookProving Ground and made itsfirst TV appearance on BBCLook North and ITV Yorkshireat the launch of the biogasto Compressed <strong>Biomethane</strong>(CBM) plant in Sheffield. Suchapproval, however, comes asno surprise given the car’scredentials. It is exceptionallyenvironmentally friendly andproduces very little waste.On fossil Compressed Natural Gas (<strong>CNG</strong>), the vehicleemits 119 g CO 2per km, around 20% less than theequivalent performance diesel. On CBM, it produces just20g of CO 2emissions per km on a Well to Wheel basis.Cars powered by biomethane are indistinguishable intheir performance from fossil fuel powered cars.After 5 years of development(2004 – 2009), the CBM-fuelledPassat is now one of Sweden'stop selling low carbon vehicles.With a 1.4 litre engine, twinsuperchargerand turbochargerthe Passat offers high performanceof 0 - 60 mph in 9.5seconds and a range of 400 kmon CBM and a further 400 kmon petrol, so easily matches itsdiesel competitors.

Bio-SNG<strong>Biomethane</strong> can be produced during the conversionof a thermally-derived synthetic gas into methane.This is known as Bio-SNG (synthetic natural gas). TheRegional Bio-SNG Project funded by Nepic, NationalGrid and Centrica aims to provide an evaluation of theviability of Bio-SNG as a technology option in the UK. Afeasibility study was carried out by <strong>CNG</strong> <strong>Services</strong> andProgressive Energy which provided proposals for a leadproject in the North East.<strong>Biomethane</strong> <strong>News</strong>Kazakhstanjoint venture by KazTransGas and BG Kazakhstanhas resulted in Kazakhstan’s first <strong>CNG</strong> fillingAstation. The station in Almaty City has a capacity of2000m3 which will fuel 240 buses, 200 of which havealready been purchased by Akimat of Almaty. Thismarks the beginning of KazTransGas’ “Concept onExpansion of <strong>CNG</strong> as a motor fuel for 2010-2015” withinvestment funds totalling KZT 600 million.The concept aims to convert around 50,000 vehiclesin Kazakhstan to run on <strong>CNG</strong> fuelled by a network ofover 100 filling stations, at a cost of around KZT 20billion. It is hoped that by promoting <strong>CNG</strong> as a vehiclefuel it will push Kazakhstan towards a cleaner, moresustainable future.<strong>CNG</strong> <strong>Services</strong> provided design and project managementsupport to BG on this project. For details pleasecontact: nick.harbord@cngservices.co.ukTwo feedstock types are being trialled; the first is ‘indigenouswaste’ and the second is woody biomass. Theformer targets a moderate scale capacity potentiallysupplying 15,000 homes, whilst the latter targets a largerscale that could supply up to 100,000 homes.The long term vision is to use the existing gas grid totransport Bio-SNG to customers.For details of the Bio-SNG project please contact:john.baldwin@cngservices.co.uk<strong>CNG</strong> EconomicsWith the availability of new <strong>CNG</strong> vehicles made bythe likes of Mercedes Benz, <strong>CNG</strong> <strong>Services</strong> is workingon a number of <strong>CNG</strong> filling station feasibility studies.Whilst the 20% CO 2saving of diesel-<strong>CNG</strong> dual fuel isimportant, the economics of <strong>CNG</strong> are the key. The priceof <strong>CNG</strong> is made up of various elements as follows :1) The price of gas from the grid which is currentlyaround 50 p/therm if bought on a 'flat profile' (i.e. sameamount all year, no seasonality). 1 therm is 2 kg, so assume25 p/kg for gas.2) The fuel duty on <strong>CNG</strong> which is 25.05 p/kg3) Compression charges, fixed maintenance and capacityrelated gas transportation and electricity supplytariffs which can be calculated in p/kg - can be anythingfrom 20 p/kg to 40 p/kg depending on the size, throughputand also required reliability (i.e. if the vehicle onlyruns on <strong>CNG</strong> like an Econic Refuse truck you need morefilling station assets than if it was dual fuel diesel-<strong>CNG</strong>tractor or a bi-fuel Sprinter). Assume around 30 p/kg4) Variable costs such as variable maintenance (runninghours related) and variable gas transportationand electricity supply costs. Assume around 10 p/kgSo total would be around 90 p/kg for <strong>CNG</strong> of which30 p/kg is fixed and 60 p/kg is variable.This means that once a customer has covered thefixed cost in any year then any additional <strong>CNG</strong> reducesin cost to 60 p/kg. The best way to see what itcosts on <strong>CNG</strong> is to take a km/kg figure. So, a SprinterNGT will do around 12 km per kg. At 90 p/kg thatmeans it costs around 8.5 p/km. If you are above theminimum in a year (i.e. fixed costs covered) it falls to60 p/kg so that is 5 p/km. This is simplest way to workout the economics. It's all about throughput. It alsomakes it easy to compare with diesel.For information on our <strong>CNG</strong> Feasibility Studyplease contact: jen.clayton@cngservices.co.uk

<strong>Biomethane</strong> <strong>News</strong>Introducing the Green Gas Certificate SchemeThe Green Gas Certification Scheme (GGCS) enablesbiomethane (‘green gas’) to be trackedthrough the supply chain, ensuring certainty for thosethat buy it.<strong>CNG</strong> <strong>Services</strong> along with six other companies includingNational Grid, Eon, Centrica and Bio Groupfounded the scheme, which will be run by a subsidiaryof the Renewable Energy Association (REA), theRenewable Energy Assurance Ltd.The scheme works on the basis that each unit ofgreen gas injected into the grid displaces a unit of fossil-derivednatural gas. The GGCS tracks each unit ofgreen gas from its injection into the gas grid throughany number of trades to its sale to a consumer. Itmonitors the contractual rather than physical flowsto ensure there is no double-counting of the gas.Each kWh of green gas is electronically labelled witha unique identifier, the Renewable Gas Guarantee ofOrigin (RGGO), that contains information relating towhere, when and how the gas was produced. Thisacts as an assurance that the green gas traded orbought is authentic and has not been sold to anotherparty.There are a number of possibilities being considered.One tonne of food waste from a supermarket wouldmake around 80 m3 of methane which is around 60kgof <strong>CNG</strong> or 80 litres of diesel. This would fuel a Sprinterfor around 500km. The Green Gas Certificates couldtrack this gas and show that the Sprinters were actuallyfuelled by gas made from the food waste.Another option is to use Green Gas Certificates tosupply gas fired CHP plants for new housing with districtheating to provide a means to provide low carbonenergy to new housingThe following schematic shows how the GGCS systemwill work:For details please contact:john.baldwin@cngservices.co.uk

<strong>Biomethane</strong> <strong>News</strong>Biogas to <strong>Biomethane</strong> PlantThroughout Autumn 2010 <strong>CNG</strong> <strong>Services</strong> has beentrialling a portable gas clean up and upgradingplant at various sites throughout the UK. The unittakes Biogas produced from a waste source e.g.Sewage Works or Food waste treatment plants, cleansit, (H 2S and Siloxane removal), upgrades it (C0 2removal)and then compresses it to 250bar. The resultingcompressed biomethane can then be used as fuelfor vehicles. The trial successfully took place in threelocations:Biogen Greenfinch, BedfordThe plant was installed at a food waste processingplant with the gas being used to fuel Mercedez BenzSprinters provided by Bedfordshire County Council.Kelda Water <strong>Services</strong>, SheffieldIn partnership with Yorkshire Water and Sheffield CityCouncil the plant was installed at the Woodhouse MillSewage Treatment works. The gas was used to fuelSheffield City Council Caddy vans and the PassatEcofuel.Scottish Water Horizons, CumbernauldScottish Water Horizons have just opened a new Biogasproduction plant at the Deerdykes Food WasteTreatment Facility. As part of the opening event attendedby Scottish Environment Secretary, RichardLochhead, Scottish Water Horizons started their trial ofthe portable clean up plant in order to review the useof the CBM as a vehicle fuel for their fleet.The plant has successfully demonstrated that <strong>Biomethane</strong>is a sustainable alternative vehicle fuel thatcan be used in cases where there is surplus biogas orbiogas is used to generate electricity.Design, Consultancy,Project Management<strong>CNG</strong> <strong>Services</strong> Ltd is the UK's leading independent<strong>Biomethane</strong> Consultancy that provides support frominitial feasibility, design, costing, procurement, projectmanagement and gas contracts through to commissioning.We are independent of equipment suppliers.Contact:tel: 0121 707 3369mob: 07831 241217web:www.cngservices.co.ukBiogen Greenfinch, BedfordWoodhouse Mill, SheffieldDeerdykes CumbernauldNew Recruits<strong>CNG</strong> <strong>Services</strong> is expanding as the biomethanemarket develops. We are pleased to welcomeGreg Lee and Jen Clayton to our team.Jen has recently graduated from TheUniversity of Manchester after havingstudied Environmental and ResourceGeology. She joins the team as ProcessAnalyst and Support Officer.Greg has 10 years experience in the Gasand Oil Industry specialising in plant designand joins us a Mechanical Designer.<strong>CNG</strong> <strong>Services</strong> Ltd is a member of a number of trade associations that are supporting the development of <strong>Biomethane</strong> in the UK:<strong>CNG</strong> <strong>Services</strong> Ltd is registered in england. No. 4683805Reg. Office 37 St. Bernards Road, Olton, Solihull B92 7AX