Breaking records in deepwater installations - Heerema Marine ...

Breaking records in deepwater installations - Heerema Marine ...

Breaking records in deepwater installations - Heerema Marine ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

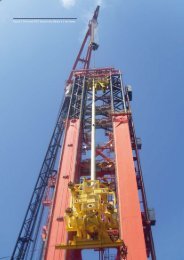

male connector. The components were<br />

assembled on board the Balder before<br />

be<strong>in</strong>g lifted and <strong>in</strong>stalled. The 27m long<br />

suction piles, weigh<strong>in</strong>g 180 t each, were<br />

<strong>in</strong>stalled at 2,442 m water depth, us<strong>in</strong>g<br />

Remotely Operated Vessels (ROVs) and<br />

transponders to verify orientation and<br />

position. All twelve piles were <strong>in</strong>stalled<br />

with<strong>in</strong> the required tolerances for<br />

position<strong>in</strong>g, orientation and <strong>in</strong>cl<strong>in</strong>ation.<br />

The first component of each moor<strong>in</strong>g<br />

l<strong>in</strong>e to be <strong>in</strong>stalled was the bottom cha<strong>in</strong><br />

with the subsea female connector. The<br />

Balder’s two cranes, capable of a tandem<br />

lift of 6,300 t, laid out the entire 244-mlong<br />

bottom cha<strong>in</strong> on deck to remove all<br />

twists and make the connection with the<br />

female connector.<br />

The cha<strong>in</strong> and connector were then<br />

lowered <strong>in</strong>to the water and the upper end<br />

was secured <strong>in</strong> a hang-off platform for<br />

the attachment to the polyester moor<strong>in</strong>g.<br />

The Balder’s Moor<strong>in</strong>g L<strong>in</strong>e<br />

Deployment W<strong>in</strong>ch (MLDW) was used<br />

to <strong>in</strong>stall the polyester moor<strong>in</strong>g l<strong>in</strong>e<br />

segments. They were connected to the<br />

bottom cha<strong>in</strong>, after which it was released<br />

from the hang-off platform. The female<br />

connector of the bottom cha<strong>in</strong> was<br />

IkkbIkYkkbUk IkzkS|ksfXkdh<br />

Pipel<strong>in</strong>e Technology<br />

The 12 moor<strong>in</strong>g assemblies each<br />

consisted of a suction pile, anchor<br />

cha<strong>in</strong>, connect<strong>in</strong>g shackles and a<br />

subsea male connector<br />

connected to the male connector on the<br />

moor<strong>in</strong>g pile.<br />

After the third segment was secured <strong>in</strong><br />

the hang-off table, the platform cha<strong>in</strong> was<br />

connected to the messenger cha<strong>in</strong> already<br />

<strong>in</strong>stalled at the hull. The platform cha<strong>in</strong><br />

was then lowered and the messenger<br />

cha<strong>in</strong> hauled <strong>in</strong> to transfer the moor<strong>in</strong>g<br />

l<strong>in</strong>e load to the semisubmersible. This